Dyeing method of bio-based nylon 56 fabric disperse dye

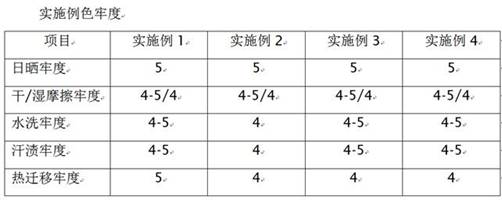

A bio-based nylon and disperse dye technology, which is applied in the field of textile printing and dyeing, can solve the problems of less research on disperse dye dyeing of bio-based nylon fabrics, no way to mass-produce, and high cost of acid dyes, so as to promote the reduction cleaning process and prevent discoloration. Flowers, high color fastness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Bio-based nylon 56 fabric disperse dyeing method, comprises the following steps:

[0048] 1) The bio-based nylon 56 fabric is treated with a stabilizer in the pre-treatment whitening process, which protects the nylon material during the heat-fixing process, making the nylon material not easily oxidized, resulting in dyeing quality problems;

[0049] 2) High-temperature and high-pressure dyeing of disperse dyes: including dyeing process and reduction cleaning process. The dyeing process can not only make the polyester component obtain deeper dyeing, but also reduce the dyeing of the spandex component by the dye; the reduction cleaning process is effective Clean floating color, and avoid the use of traditional hydrosulfite and caustic soda, thereby reducing the steps of acid neutralization.

[0050] Dyeing: Immerse the bio-based nylon 56 fabric to be dyed in the dyeing solution, the dyeing bath ratio is 1:3, heat up to 115°C at a speed of 2~3°C / min, and keep it warm for 60 ...

Embodiment 2

[0053] Bio-based nylon 56 fabric disperse dyeing method, comprises the following steps:

[0054] 1) The bio-based nylon 56 fabric is treated with a stabilizer in the pre-treatment whitening process, which protects the nylon material during the heat-fixing process, making the nylon material not easily oxidized, resulting in dyeing quality problems;

[0055] 2) Hot-melt dyeing with disperse dyes: including three steps of dyeing, pre-baking and hot-melt color fixing:

[0056] Ⅰ) Dyeing: Dyeing: disperse dyes are evenly dyed on the bio-based nylon white cloth through a hot-melt dyeing machine: uniform padding, the weight of the fabric is 150 grams per square meter, and the excess dyeing rate is 65 %; Pad dyeing is carried out at room temperature, in the dyeing liquor: disperse dye 20% owf; dispersant 1.5g / L; adjust the pH to 5~7 with acetic acid, then add a pH stabilizer, the dosage is 1g / L; Agent (sodium alginate) 3%; dyeing speed 50m / min.

[0057] Ⅱ) Pre-baking: focus on anti-...

Embodiment 4

[0067] Bio-based nylon 56 fabric disperse dyeing method, comprises the following steps:

[0068] 1) The fabric made of high stability bio-based nylon fiber has good thermal oxidation resistance, and no stabilizer is used in the whitening process;

[0069] 2) Hot-melt dyeing with disperse dyes: including three steps of dyeing, pre-baking and hot-melt color fixing:

[0070] Ⅰ) Dyeing: the disperse dyes are evenly dyed on the bio-based nylon white cloth by the disperse dyeing machine. Disperse dyes are applied to bio-based nylon fabrics. Dyeing is carried out at room temperature. In the dyeing solution: disperse dye 30% owf; dispersant 1.5g / L; use acetic acid to adjust the pH to 5~7, then add a pH stabilizer, the dosage is 1g / L; anti-swimming agent ( Sodium alginate) 3%; dyeing speed 60m / min.

[0071] Ⅱ) Pre-baking: focus on anti-dye migration. After the fabric is colored, it is dried by infrared rays at a drying temperature of 80°C.

[0072] Ⅲ) Hot-melt color fixing and set...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com