High-solarization red reactive dye and preparation method thereof

A reactive dye and red technology, applied in the direction of reactive dyes, azo dyes, organic dyes, etc., can solve the problems of poor light fastness and difficulty in meeting customer light fastness performance requirements, to improve rubbing fastness, Excellent color synchronization and high level dyeing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

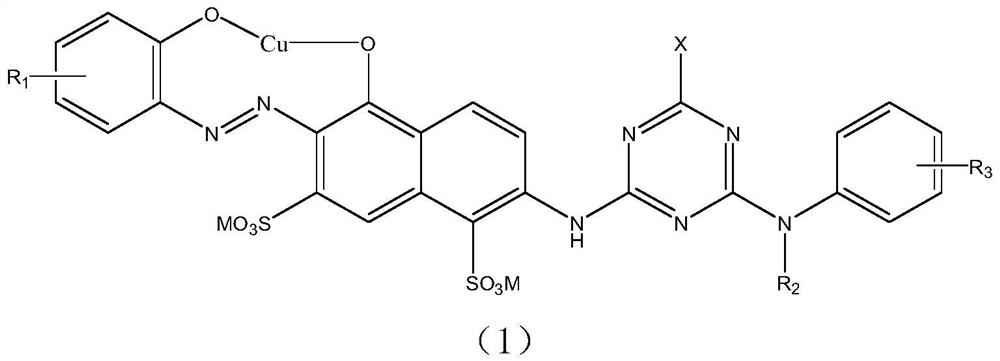

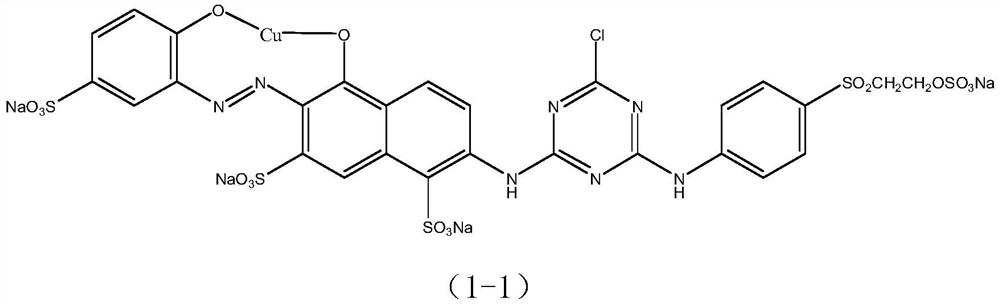

[0062] A kind of high solarization red reactive dye, is made up of the compound of simple formula (1-1) structure:

[0063]

[0064] (1-1) Its synthetic method step of the compound of structure is as follows:

[0065] 1. Diazo reaction: add ice water 100g in a beaker, add 2-aminophenol-4-sulfonic acid of 25g, beat for 1 hour, then add 12g hydrochloric acid (30%), slowly add dropwise 28g sodium nitrite solution (30 %), carry out the diazonium reaction, control the temperature at 0-20° C., and control the pH value at 0.5-1.5, and make the starch potassium iodide test paper microscopically blue, and the Congo high sun red test paper microscopically blue. After the sodium nitrite solution is added dropwise, keep the temperature at 8-10° C., control the pH value at 0.5-1.5, stir and react for 30 minutes, and then use 0.5 g of sulfamic acid to balance the excess sodium nitrite. The diazonium reaction formula is shown in formula (a):

[0066]

[0067] 2. Coupling reaction: Ad...

Embodiment 2

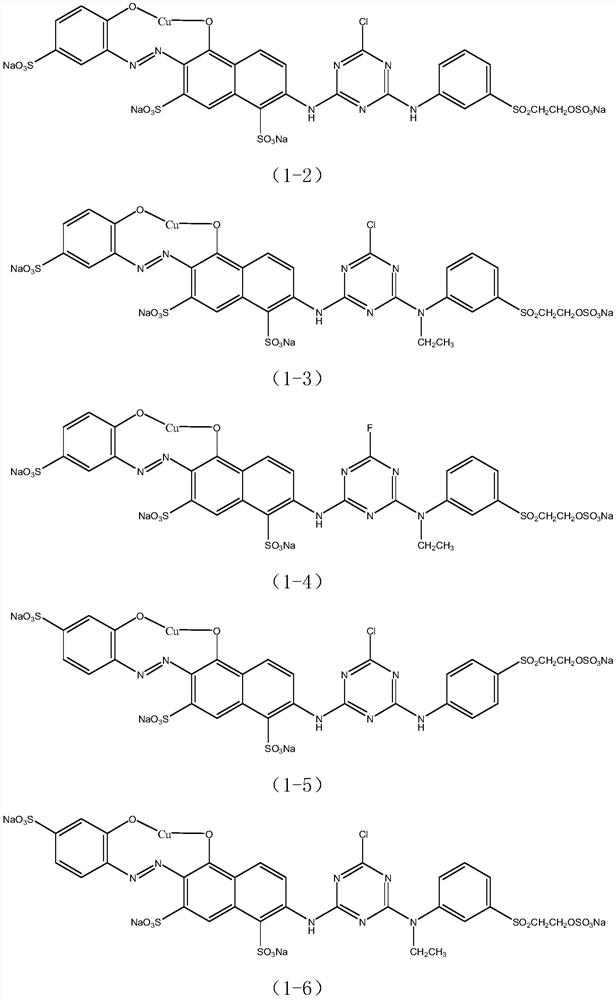

[0076] A kind of high solarization red reactive dye, is made up of the compound of simple formula (1-6) structure:

[0077]

[0078] (1-6) Its synthetic method step of the compound of structure is as follows:

[0079] 1. Diazo reaction: add ice water 100g in a beaker, add 2-aminophenol-5-sulfonic acid of 25g, beat for 1 hour, then add 12g hydrochloric acid (30%), slowly add dropwise 28g sodium nitrite solution (30 %), carry out the diazonium reaction, control the temperature at 0-20° C., and control the pH value at 0.5-1.5, and make the starch potassium iodide test paper microscopically blue, and the Congo high sun red test paper microscopically blue. After the sodium nitrite solution is added dropwise, keep the temperature at 8-10° C., control the pH value at 0.5-1.5, stir and react for 30 minutes, and then use 0.5 g of sulfamic acid to balance the excess sodium nitrite. The diazonium reaction formula is shown in formula (a):

[0080]

[0081] 2. Coupling reaction: Ad...

Embodiment 3

[0090] A kind of high solarization red reactive dye, is made up of the compound of simple formula (1-12) structure:

[0091]

[0092] (1-12) Its synthetic method step of the compound of structure is as follows:

[0093] 1. Diazo reaction: add ice water 100g in a beaker, add 2-aminophenol-4-sulfonic acid of 25g, beat for 1 hour, then add 12g hydrochloric acid (30%), slowly add dropwise 28g sodium nitrite solution (30 %), carry out the diazonium reaction, control the temperature at 0-20° C., and control the pH value at 0.5-1.5, and make the starch potassium iodide test paper microscopically blue, and the Congo high sun red test paper microscopically blue. After the sodium nitrite solution is added dropwise, keep the temperature at 8-10° C., control the pH value at 0.5-1.5, stir and react for 30 minutes, and then use 0.5 g of sulfamic acid to balance the excess sodium nitrite. The diazonium reaction formula is shown in formula (a):

[0094]

[0095] 2. Coupling reaction: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com