Waterless printing method for bio-based nylon 56 fabric

A bio-based nylon, waterless printing technology, applied in transfer printing, printing, dyeing and other directions, can solve the problem of no thermal stability treatment, easy thermal oxidation and thermal degradation, affecting product color fastness and physical machinery. performance and other issues, to achieve the effect of good coloring rate, good quality and high color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A kind of bio-based nylon 56 fabric waterless printing method, comprises the following steps:

[0044] 1) Anti-phenol yellowing finishing of bio-based nylon 56 fabric during whitening treatment, which can protect nylon material during heat transfer printing: FK-162A is 3% of fabric weight, citric acid 0.2g / l, treatment The temperature is 70°C, the soaking time is 20 minutes, and the obtained bio-based nylon gray fabric has a grade 4-5 anti-phenol yellowing effect;

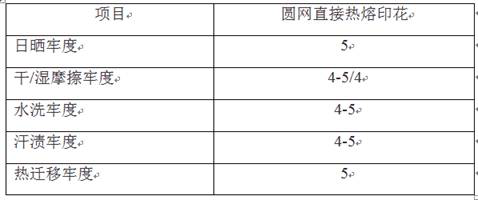

[0045] 2) Thermal transfer printing: use disperse dye digital printing transfer printing paper, the molecular weight of the disperse dye is 400, and the particle size is 200 nanometers; the printing on the paper is thermally transferred to the bio-based nylon gray fabric with anti-phenol yellowing treatment on the thermal transfer machine Above, the transfer temperature takes two conditions of 210°C and 220°C, the pressure is 0.5MPa, the pressure of the pressing machine is 0.3-0.4MPa, the pressure of the tra...

Embodiment 2

[0048] A kind of bio-based nylon 56 fabric waterless printing method, comprises the following steps:

[0049] 1) Anti-phenol yellowing finishing of bio-based nylon 56 fabric during whitening treatment: FK-162A is 3% of the weight of the fabric, citric acid is 0.2g / l, treatment temperature is 70°C, soaking time is 20min, and the obtained anti-phenol yellowing Effect 4-5 grade bio-based nylon gray fabric;

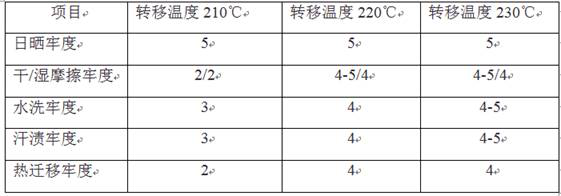

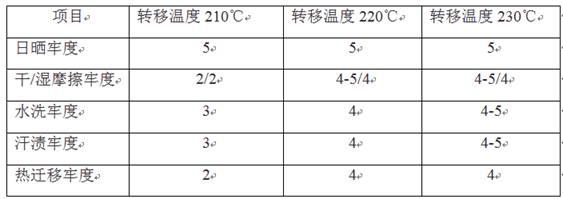

[0050] 2) Thermal transfer printing: use disperse dye gravure printing paper, the molecular weight of disperse dye is 400, and the particle size is 600 nanometers; the printing on the paper is thermally transferred to the bio-based nylon fabric treated with anti-phenol yellowing on the thermal transfer machine The transfer temperature is 210°C, 220°C, and 230°C, the pressure is 0.5MPa, the pressure of the pressing machine is 0.3~0.4MPa, the pressure of the transfer machine is 0.3~0.6MPa, and the transfer speed is 25m / min. The transfer time is 10~30s. The printed product is ...

Embodiment 3

[0053] A kind of bio-based nylon 56 fabric waterless printing method, comprises the following steps:

[0054] 1) High-stability bio-based nylon 56 fabric is used, and no anti-phenol yellowing finishing is used during whitening treatment;

[0055] 2) Thermal transfer printing: use disperse dye gravure printing paper, the molecular weight of disperse dye is 400, and the particle size is 600 nanometers; the printing on the paper is thermally transferred to the bio-based nylon fabric treated with anti-phenol yellowing on the thermal transfer machine The transfer temperature is 210°C, 220°C, and 230°C, the pressure is 0.3-3MPa, the press pressure is 0.3-1.0MPa, the transfer machine pressure is 0.3~3MPa, and the transfer speed is 25m / min. The transfer time is 10~30s. The printed product is bright in color, and the test results are as follows:

[0056]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com