Flushing system and flushing method of lubricating oil system of turbogenerator set

A technology of steam turbine generator set and flushing system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

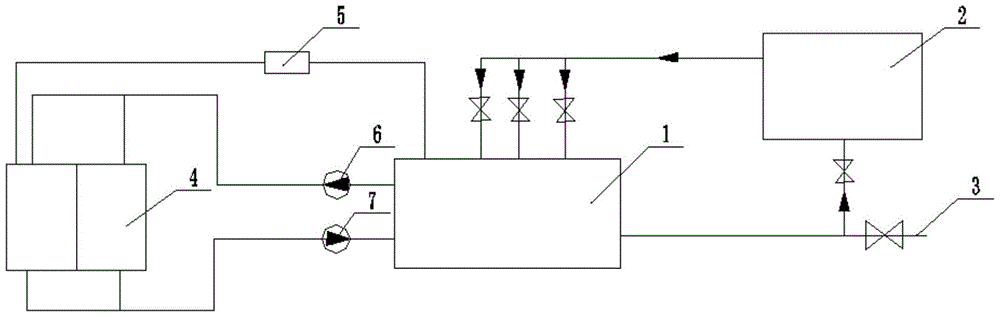

[0030] The present invention will be further described below with reference to the drawings and embodiments.

[0031] The flushing method of the lubricating oil system of the steam turbine generator set includes:

[0032] Step 1: Connect the oil return pipe of the bearing seat to the bearing seat according to the designed working state; in this way, there is no need to connect a temporary pipe outside the bearing seat;

[0033] The main oil tank 1 is connected to the oil inlet of the first oil filter 2 through an oil pipeline. The first oil filter 2 adopts a large flow oil filter (such as a large flow flushing oil filter for the DHCX-600 turbine oil system). The output port of the oil machine is connected to three branches in parallel. One branch is a self-circulating pipeline, which is directly connected to the main tank 1 as a self-circulating flushing source of the fuel tank. The branch is equipped with a valve, and one branch is connected to the oiler and then the main The inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com