Table-board manufacture technology for lead-free diode

A lead-free diode and manufacturing process technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as numerous process steps and product breakage, and achieve the effect of reducing the pickling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

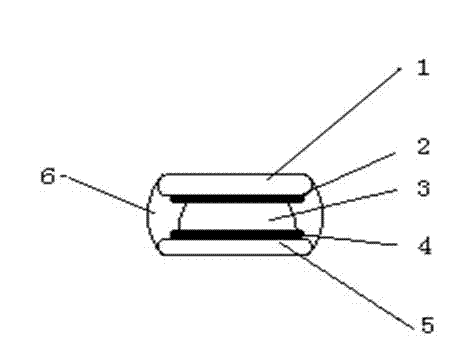

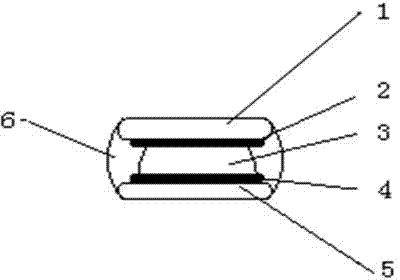

[0008] As shown in the figure, the diode is welded together by electrodes 1, soldering tabs 2, chips 3, soldering tabs 4, and electrodes 5. After welding, the two electrodes are sealed with silicone rubber or polyimide glue 6, and then placed on the The overall outer surface of its composition is encapsulated with epoxy resin.

[0009] The above chip mesa etching process is changed from traditional acid etching to alkali etching. The specific steps are as follows: there are two steps for mesa corrosion with a strong base, and the strong base used in the present invention is potassium hydroxide or sodium hydroxide solution. For the first mesa corrosion, the mass concentration of the strong alkali solution is: 8-15%, the corrosion temperature is 70-95°C, and the corrosion time for the chip mesa is 5-15 minutes; the concentration used for the second corrosion mesa is slightly lower The strong alkali solution is used for corrosion, the mass concentration of the strong alkali solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com