Kettle-pressure extrusion integrated micro-foaming extrusion forming device and kettle-pressure extrusion integrated micro-foaming extrusion forming method

An extrusion molding and micro-foaming technology, which is used in household appliances, other household appliances, flat products, etc., can solve the problems of high equipment renovation cost, poor controllability of cells, low production efficiency, etc. High foaming quality and good product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

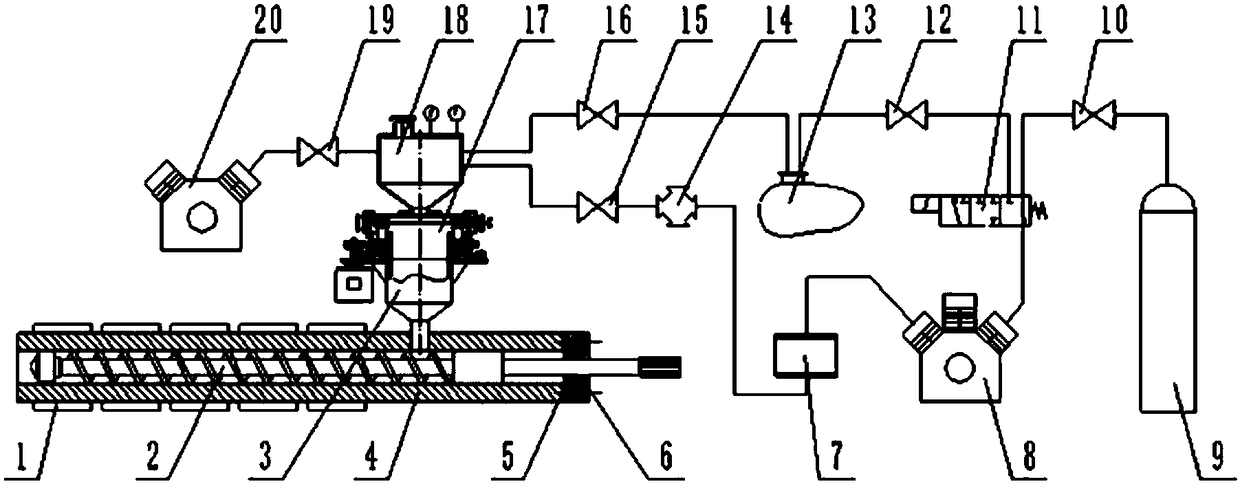

[0026] The present invention relates to an integrated autoclave pressure extrusion molding device for supercritical gas recycling, which is mainly composed of a gas supply system, a material supply system and an extrusion system.

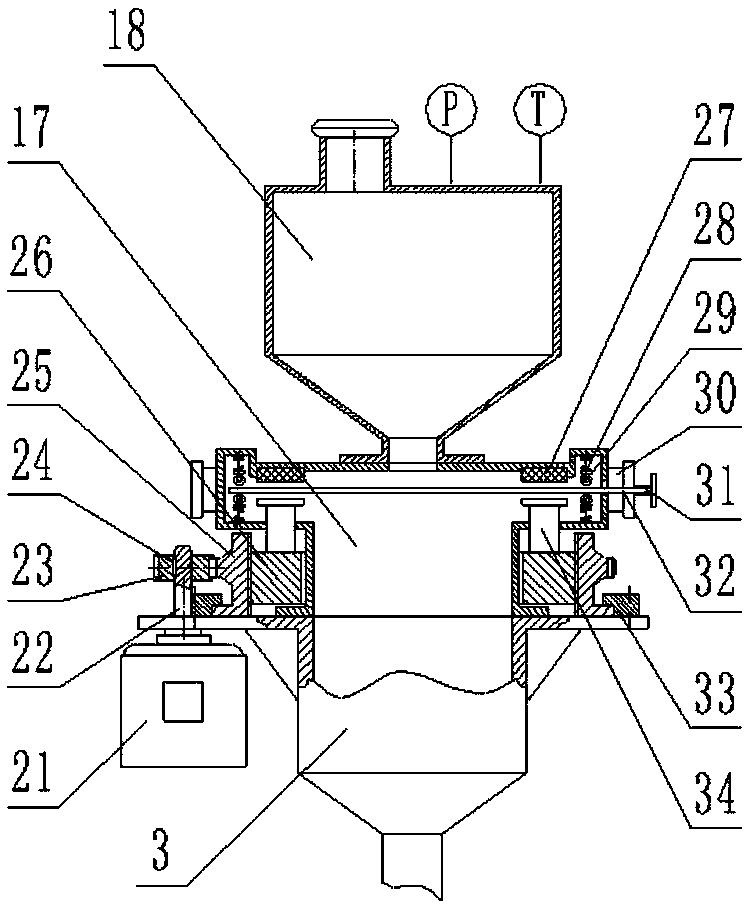

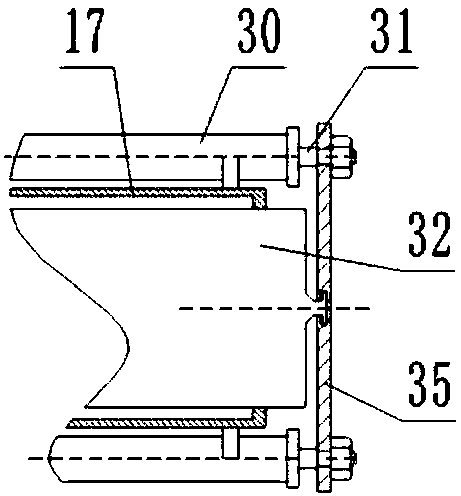

[0027] The present invention is a kind of autoclave pressure extrusion integrated micro-foaming extrusion molding device for supercritical gas recycling, and its feeding system is as follows: figure 1 and figure 2Shown, mainly by storage hopper 3, motor 21, motor drive shaft 22, gear 23, key 24, transmission part 25, pressurizing part 26, sealing cylinder 17, permeation still 18, gasket 27, spring 28, roller 29, Cylinder 30, cylinder pull rod 31, sealing plate 32, limit block 33 and pressure rod 34 are formed. Wherein, the storage hopper 3 is fixed on the upper part of the machine barrel 4, the sealing cylinder 17 is fixed on the upper part of the storage hopper 3, and the permeation kettle 18 is fixed on the upper part of the sealing cylinder 17,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com