Degradable heat sealing film for compounding and preparation method thereof

A heat-sealing film and heat-sealing layer technology, applied in chemical instruments and methods, applications, household appliances, etc., can solve problems such as poor heat-sealing properties of films, limited application, easy wrinkling, etc., to achieve improved temperature control accuracy, surface The effect of good gloss and good switching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

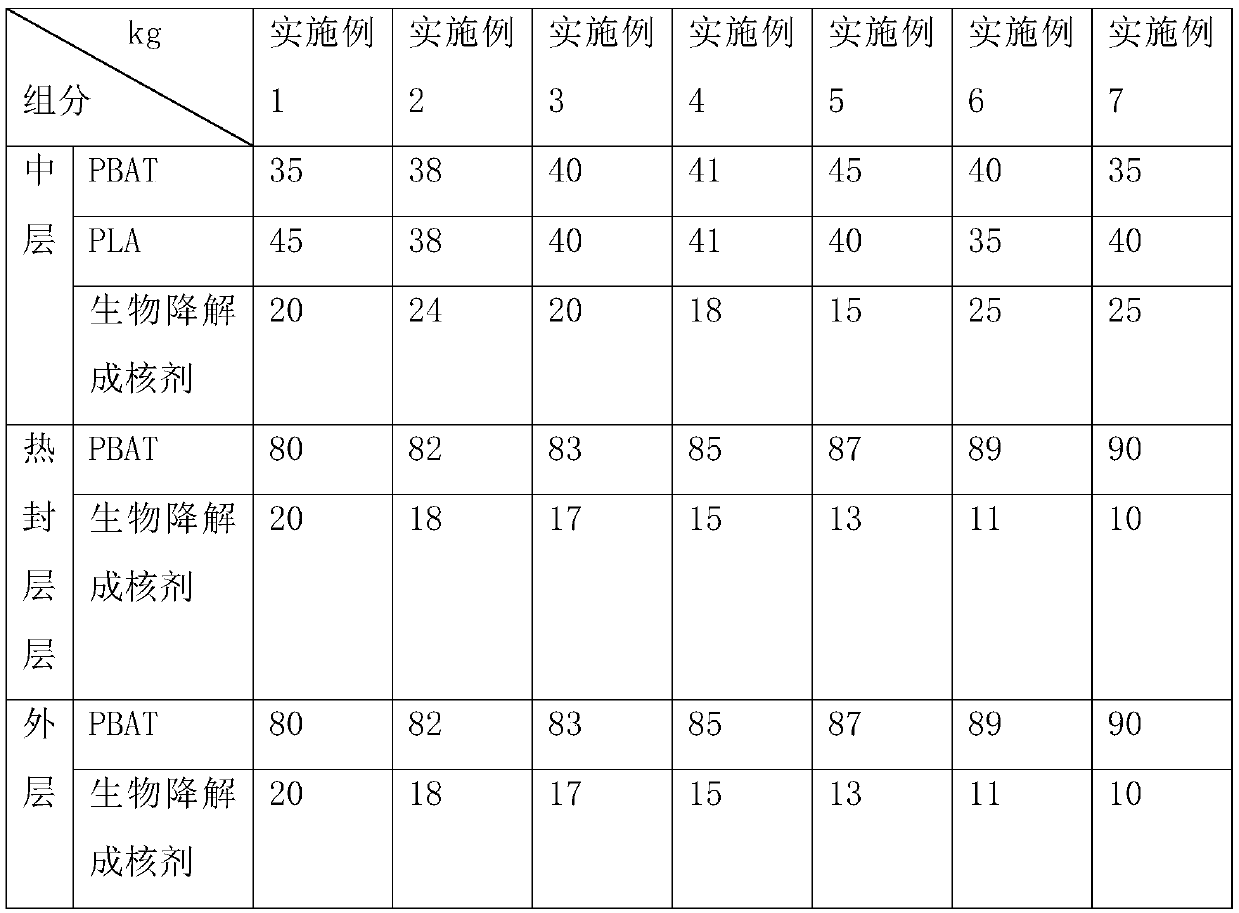

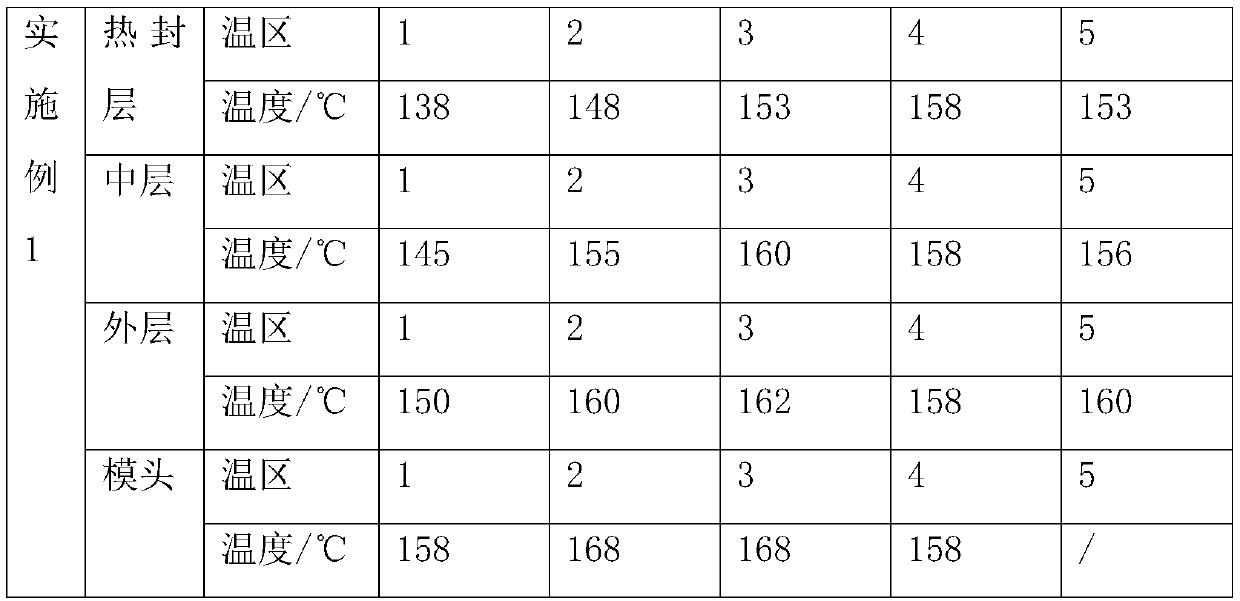

Embodiment 1

[0043] Example 1: A degradable heat-sealable film for composites, including a heat-seal layer, a middle layer and an outer layer connected in sequence, the thickness ratio of the middle layer, the heat-seal layer and the outer layer is 4:3:3, the heat-seal layer, the middle layer The ratio of raw materials to the outer layer is shown in Table 1, wherein the weight average molecular weight of PBAT is 60,000, and the density of PLA is 1.24g / cm 3 , the melt flow rate (190°C / 5kg) is 7.5g / 10min, and the melt volume flow rate (190°C / 5kg) is 3.0cm 3 / 10min;

[0044] The preparation method of the degradable heat-sealing film for composite comprises the following steps:

[0045] S1. Pre-drying: Mix the raw materials used in the heat-sealing layer, the middle layer and the outer layer separately, and carry out drying treatment. The drying temperature is 60 ° C, and the drying time is 24 hours to prepare the heat-sealing layer pretreatment material and the middle layer pretreatment. ma...

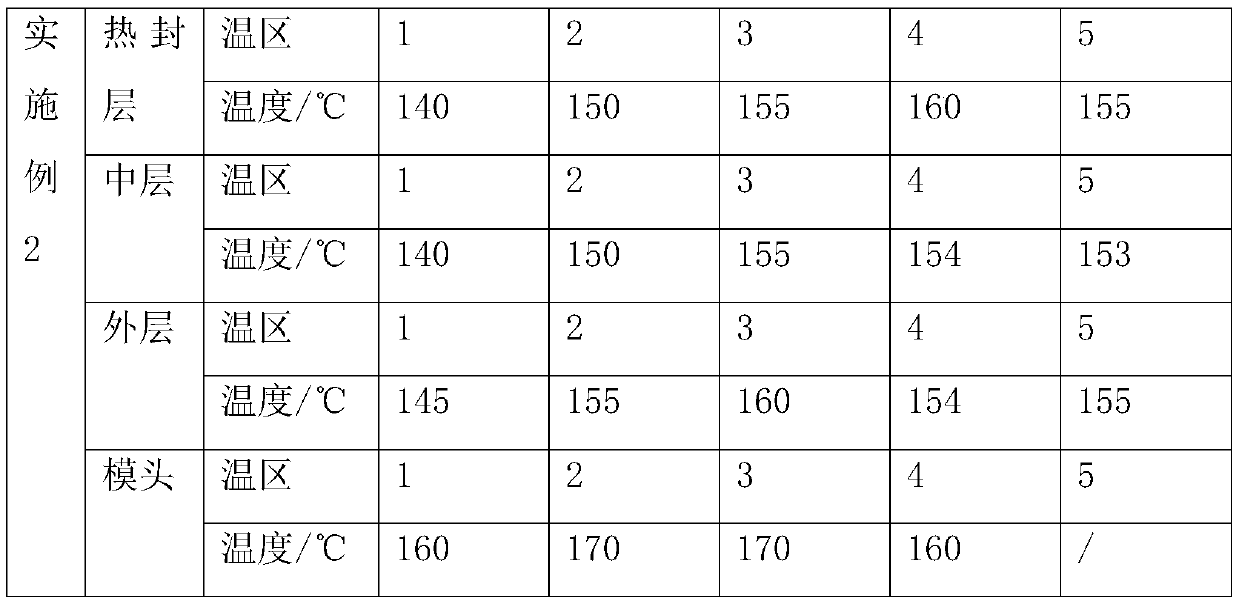

Embodiment 2

[0056] Example 2: A degradable heat-sealable film for composites, comprising a heat-seal layer, a middle layer and an outer layer connected in sequence, the thickness ratio of the middle layer, the heat-seal layer and the outer layer is 3.5:3:3.5, the heat-seal layer, the middle layer The ratio of raw materials to the outer layer is shown in Table 1, wherein the weight average molecular weight of PBAT is 80,000, and the density of PLA is 1.25g / cm 3 , the melt flow rate (190°C / 5kg) is 9.5g / 10min, and the melt volume flow rate (190°C / 5kg) is 4.5cm 3 / 10min;

[0057] The preparation method of the degradable heat-sealing film for composite comprises the following steps:

[0058] S1. Pre-drying: Mix the raw materials used in the heat-sealing layer, the middle layer and the outer layer separately, and carry out drying treatment. The drying temperature is 55 ° C, and the drying time is 26 hours, and the heat-sealing layer pretreatment material and the middle layer pretreatment are p...

Embodiment 3

[0067] Embodiment 3: A degradable heat-sealable film for composites, including a heat-seal layer, a middle layer and an outer layer connected in sequence, the thickness ratio of the middle layer, the heat-seal layer and the outer layer is 3:3.5:3.5, the heat-seal layer, the middle layer The ratio of raw materials to the outer layer is shown in Table 1, wherein the weight average molecular weight of PBAT is 100,000, and the density of PLA is 1.26g / cm 3 , the melt flow rate (190°C / 5kg) is 11.5g / 10min, and the melt volume flow rate (190°C / 5kg) is 6.5cm 3 / 10min;

[0068] The preparation method of the degradable heat-sealing film for composite comprises the following steps:

[0069] S1. Pre-drying: Mix the raw materials used in the heat-sealing layer, the middle layer and the outer layer separately, and carry out drying treatment. The drying temperature is 65 ° C, and the drying time is 22 hours to prepare the heat-sealing layer pretreatment material and the middle layer pretreat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com