Stirring jacketed pot

A technology of sandwich pot and stirring shaft, which is applied in household utensils, food preparation, food science, etc. It can solve the problems of uneven stirring and mixing of materials, uneven heating of materials, uneven stirring and mixing, etc., and achieve uniform stirring and easy heating temperature Control, temperature equalization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further elaborated below in conjunction with accompanying drawing, wherein, the direction of the present invention is with figure 1 as standard.

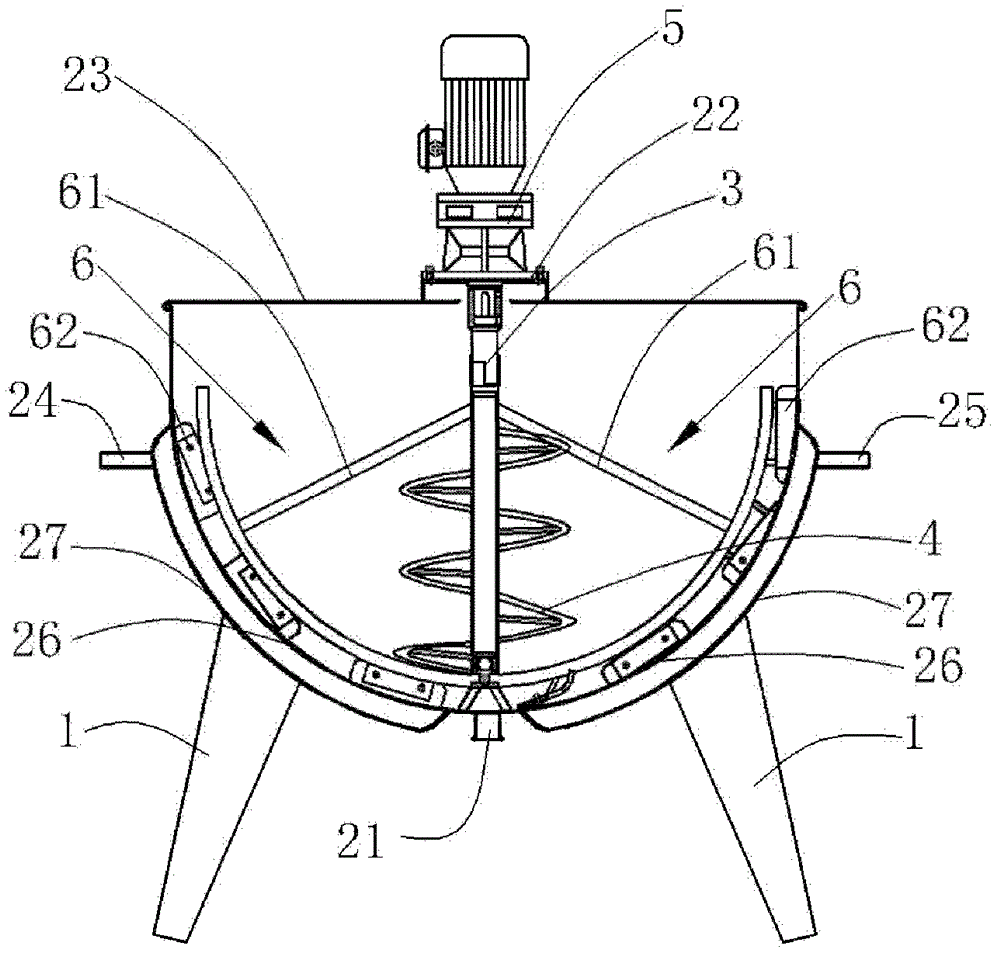

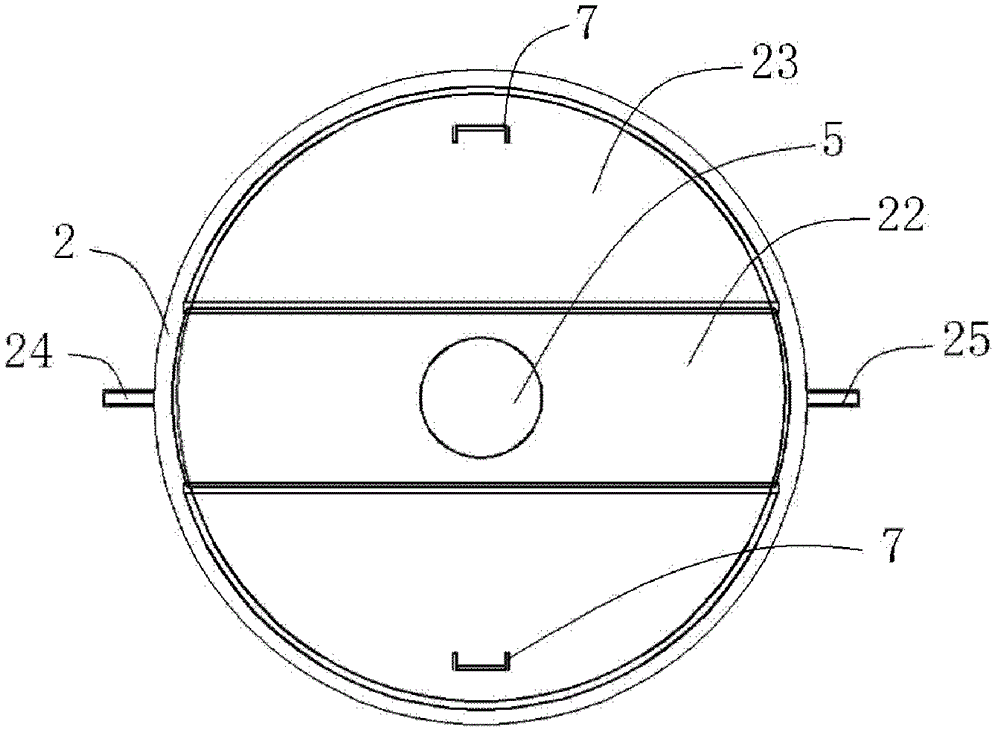

[0014] like figure 1 and figure 2 As shown, the stirring jacketed pot of the present invention comprises a frame 1 and a pot body 2 installed on the frame 1, the upper end of the pot body 2 is provided with an opening, the opening of the pot body 2 is fixed with a mounting plate 22, and on the mounting plate 22 A vertically arranged stirring shaft 3 and a drive mechanism 5 that drives the rotation of the stirring shaft 3 are fixed, the stirring shaft 3 is located in the pot body 2, the driving mechanism 5 is located outside the pot body 2, and the stirring shaft 3 is equipped with a Spiral stirring blade 4 and several radial stirring blades 6, and a discharge port 21 is formed on the pot body 2. Wherein, the axis of the spiral stirring blade 4 coincides with the axis of the stirring shaft 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com