Preparation method of purely fragrant cooked rice

A production method and rice technology, which is applied in food science and other fields, can solve the problems of rice cracking, not easy to be enzymatic, and rice is not pure enough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

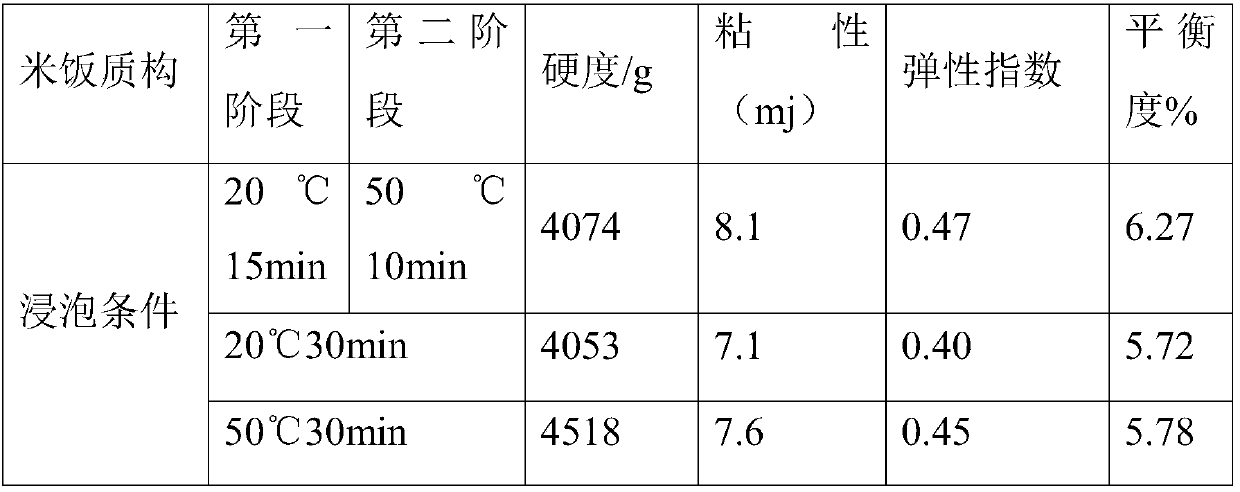

[0023] A pure fragrant rice preparation method at least includes the following stages:

[0024] (a) Fragrance making stage: first soak at 10°C to 25°C for 10 to 15 minutes, then raise the temperature to 50°C to 60°C and soak for 5 to 10 minutes, then heat to 70°C at a heating rate of 8 to 15°C / min Above, the heating power is P1;

[0025] (b) Boiling stage: heated to boiling with the heating power of P2 and kept for a period of time;

[0026] (c) Fragrance stage: heating with the heating power of P3 and keeping it for a period of time, wherein P1 is greater than P2 and greater than P3.

[0027] In the incense making stage, soak at 10°C to 25°C for 10 to 15 minutes. This step mainly spreads through the first longitudinal way, so that the gaps between cells are fully saturated with water. If the initial soaking temperature is too high High, the water absorption and swelling effect of starch granules is very obvious, causing the endosperm cells in the part of the cells that firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com