Large-displacement horizontal well continuous tubing drilling robot

A horizontal well and extended displacement technology, which is applied in drilling equipment, directional drilling, wellbore/well components, etc., can solve problems such as difficulty in running coiled tubing, achieve various operating modes and solve jamming effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

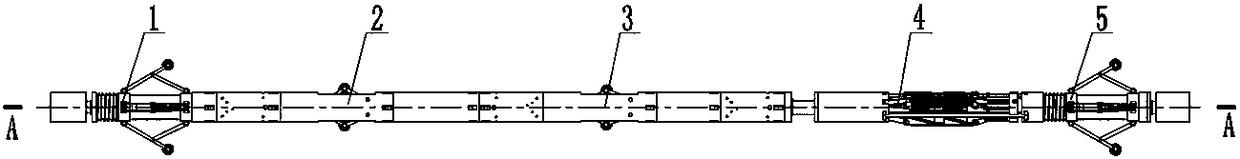

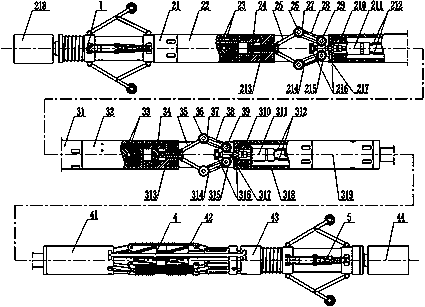

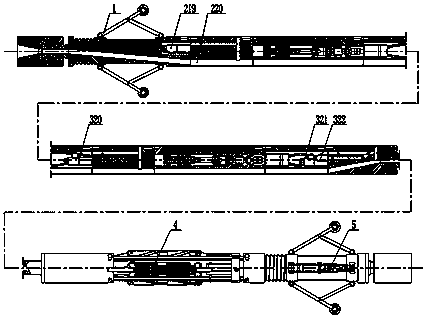

[0035] Such as Figure 1~3 As shown, the extended-displacement horizontal well coiled tubing drilling robot includes a front centralizer 1, a rear centralizer 5, a front kinematic short joint 2, a rear kinematic short joint 3 and a telescopic short joint 4; The moving sub-joint 3 and the telescopic sub-joint 4 are connected sequentially; the front centralizer 1 and the rear centralizer 5 are respectively installed at the front end and the rear end of the front moving sub-joint 2 and the telescopic sub-joint 4;

[0036] The front kinematic joint 2 includes a control barrel A21, a control valve seat A22, a front hydraulic flow channel 23, a front support piston 24, a front support rod A25, a front driven sprocket 26, a front wheel 27, a front chain 28, a front drive Sprocket 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com