Disk brake

A technology of disc brakes and brake discs, applied in the direction of brake types, mechanical brakes, brake components, etc., can solve the problems of cost increase, complex structure, etc., achieve low wear, single operation mode, and keep wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

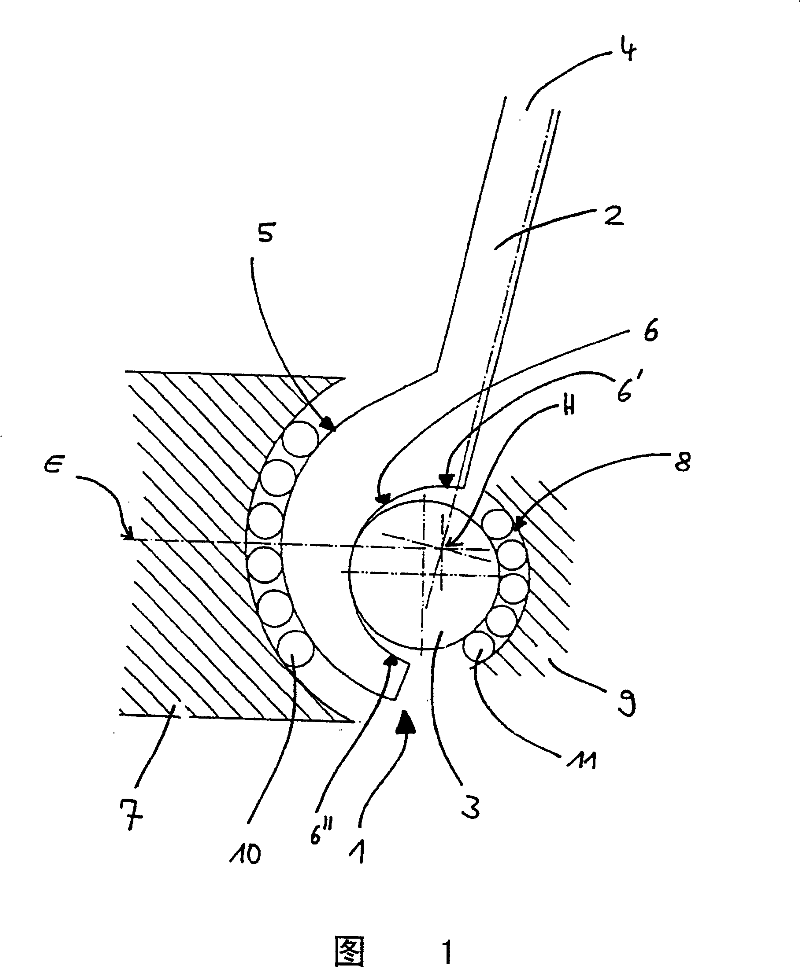

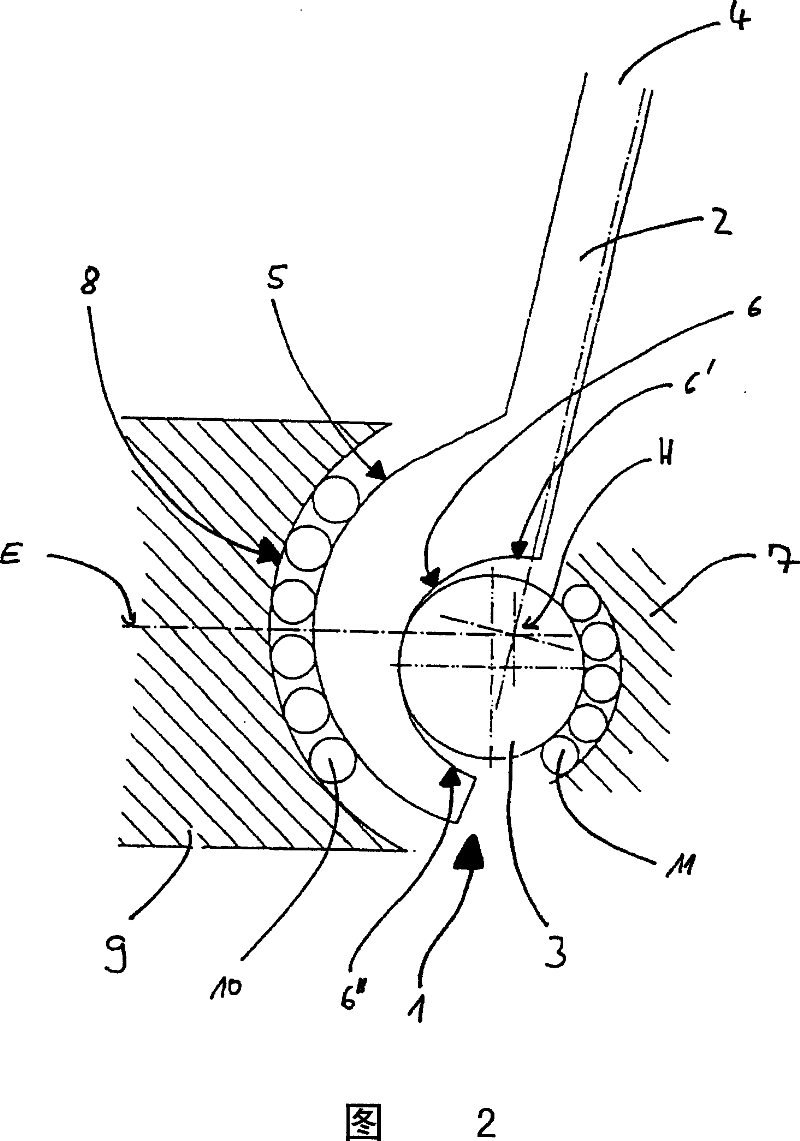

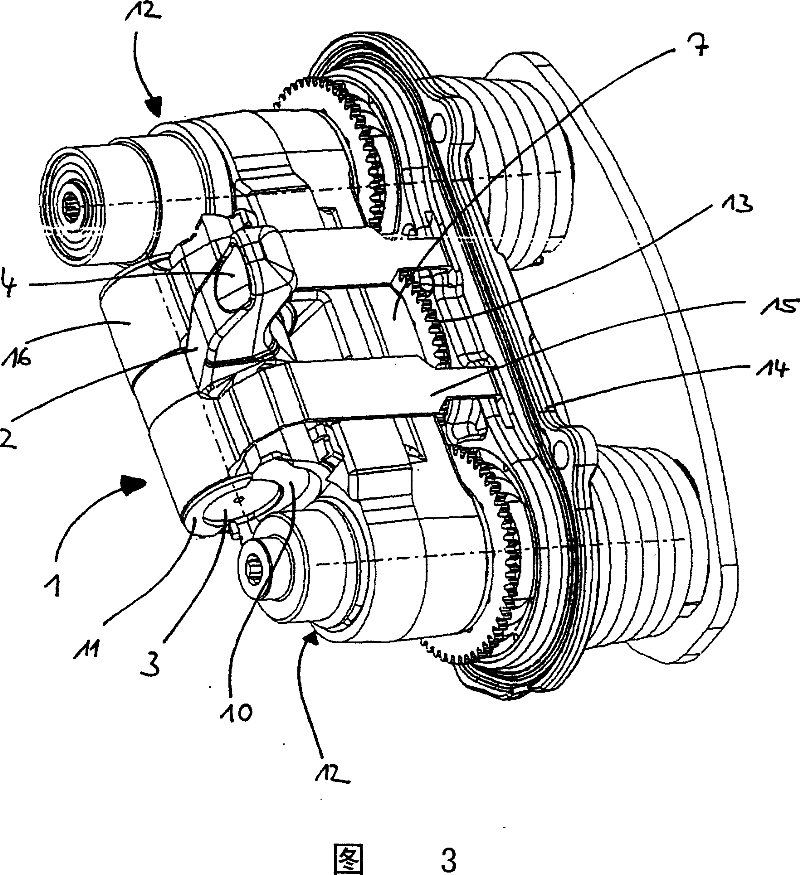

[0037] Figure 1 shows a schematic view of a structure 1 for force transmission between a braking force generating element, such as a hydraulic cylinder (not shown here), and an element transmitting braking force to a brake disc.

[0038] The structural body 1 is substantially composed of a rotating rod 2 and a rotating body 3 .

[0039] The rotary rod 2 has a first support surface 5 remote from its active end 4 , which can be acted on by a piston rod of a hydraulic cylinder, for example. The support surface 3 has a cylindrical hemispherical exterior.

[0040] The control surface 6 is radially opposite the first support surface 5 . On the one hand, the control surface 6 is positioned eccentrically on the first support surface 3 and, on the other hand, it has a concave hemispherical interior.

[0041] The rotating body is in contact with the control surface 6, that is to say that during the braking transmission and rotation of the rotating rod 2, the rotating body 3 purely rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com