Ultrasonic generator

A generator and ultrasonic technology, applied in the field of ultrasonic cleaning, can solve the problems of increasing the maintenance cost and service life of the ultrasonic generator, and operating errors, etc., and achieve the effect of prolonging the service life and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below by means of specific embodiments:

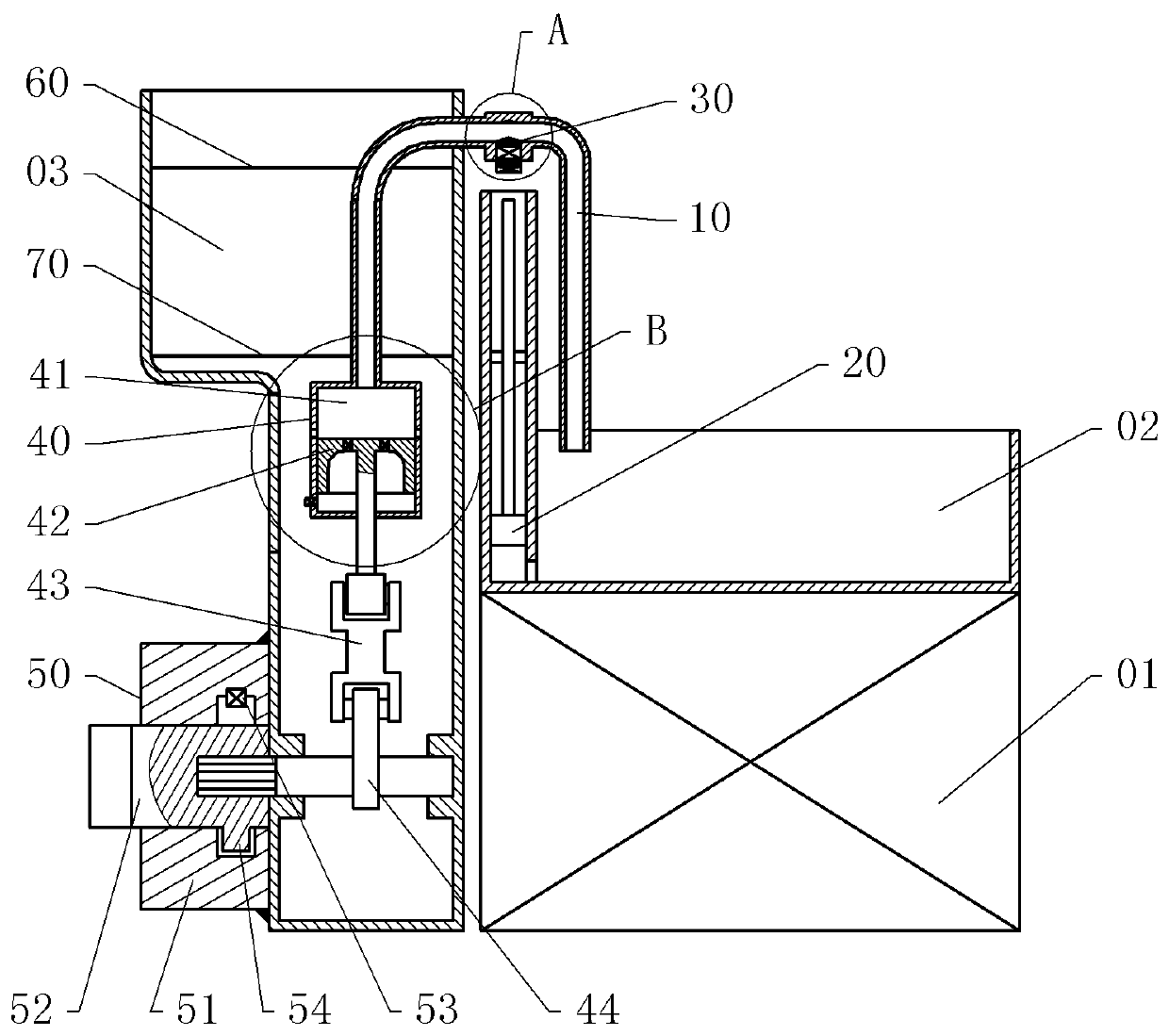

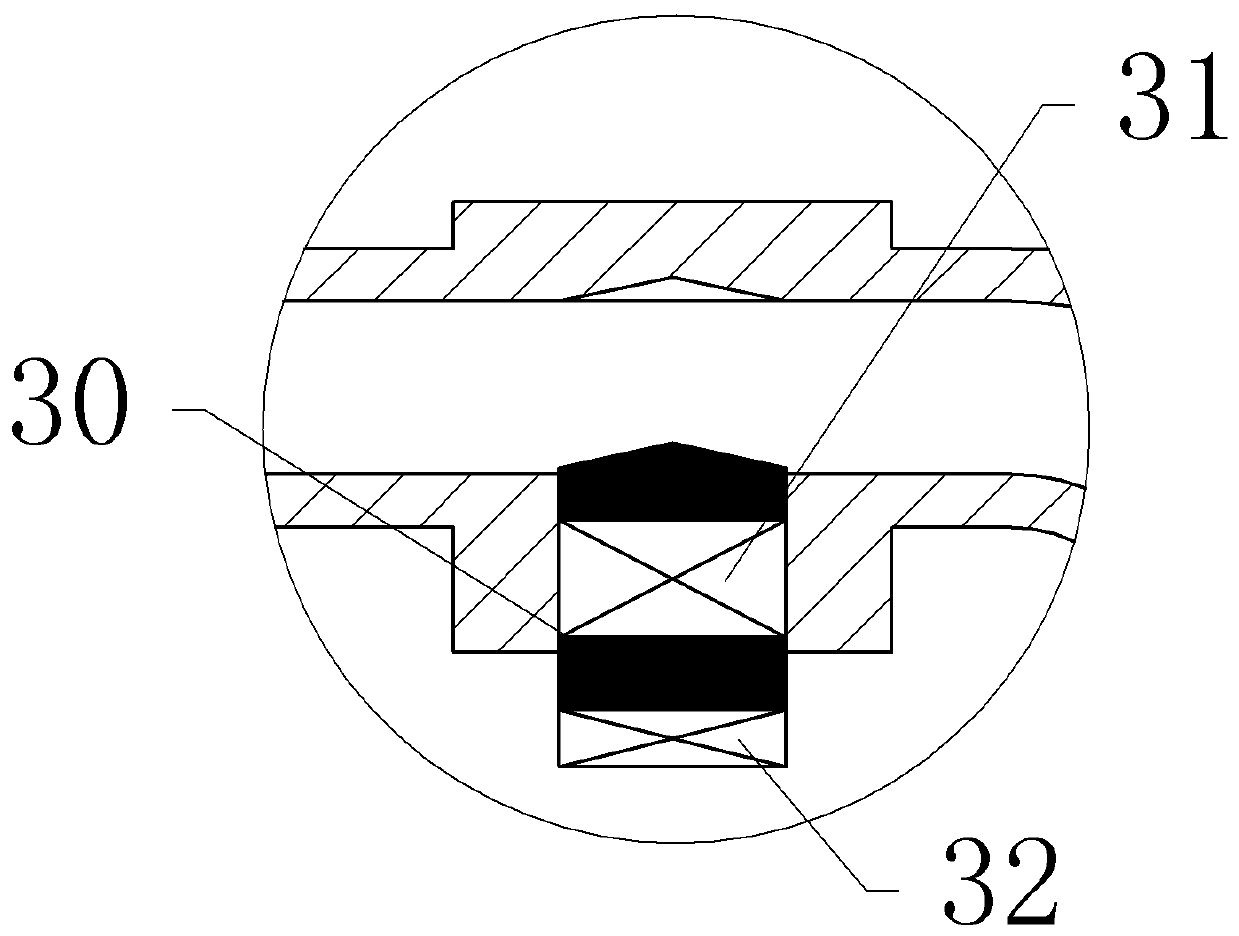

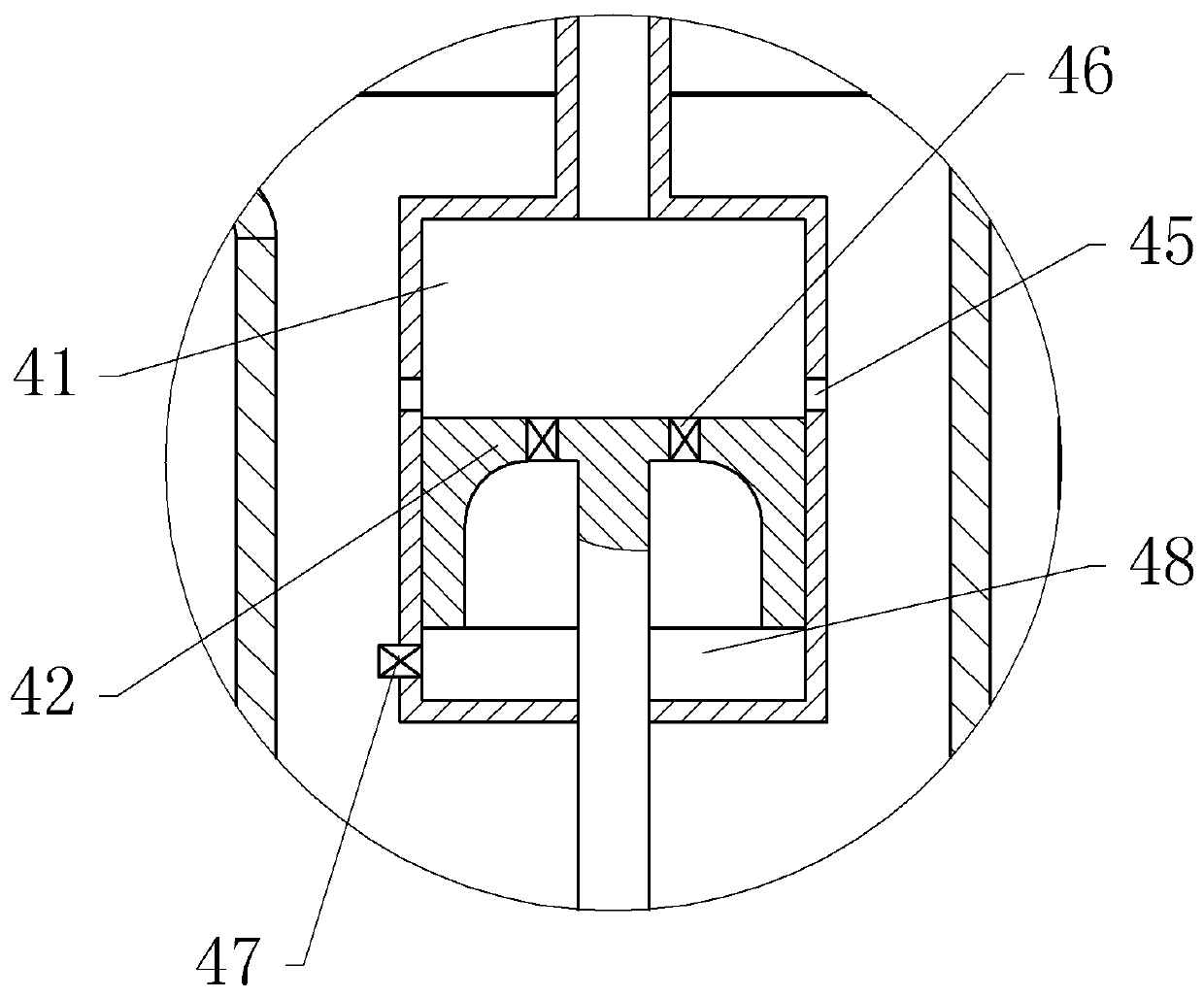

[0025] The reference signs in the drawings of the specification include: electronic box 01, cleaning box 02, water storage tank 03, siphon 10, float 20, valve core 30, pressure relief valve 31, contact switch 32, water level raising part 40, sleeve 41 , piston 42, connecting rod 43, crank 44, water inlet 45, first one-way valve 46, second one-way valve 47, water suction cavity 48, control knob 50, seat body 51, rotating body 52, push switch 53, convex Play 54, reed 55, wedge groove 56, upper water level 60, lower water level 70.

[0026] Such as figure 1 As shown, the ultrasonic generator of this embodiment includes an electronic box 01, a water storage tank 03, a cleaning box 02 arranged on the electronic box 01, and a vibrating plate located at the bottom of the cleaning box 02 to connect the water storage box 03 and the cleaning box 02. The water level control device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com