Production process and production equipment for secondary shaping of PVC (Polyvinyl Chloride) foaming core plate

A technology for secondary shaping and production process, applied in the field of PVC foam board production, can solve the problems of reducing the shrinkage ratio and arch bending rate, shrinkage deformation and arch bending of PVC foam core board, so as to improve product quality, Eliminate stretching deformation and overcome the effect of shrinking deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

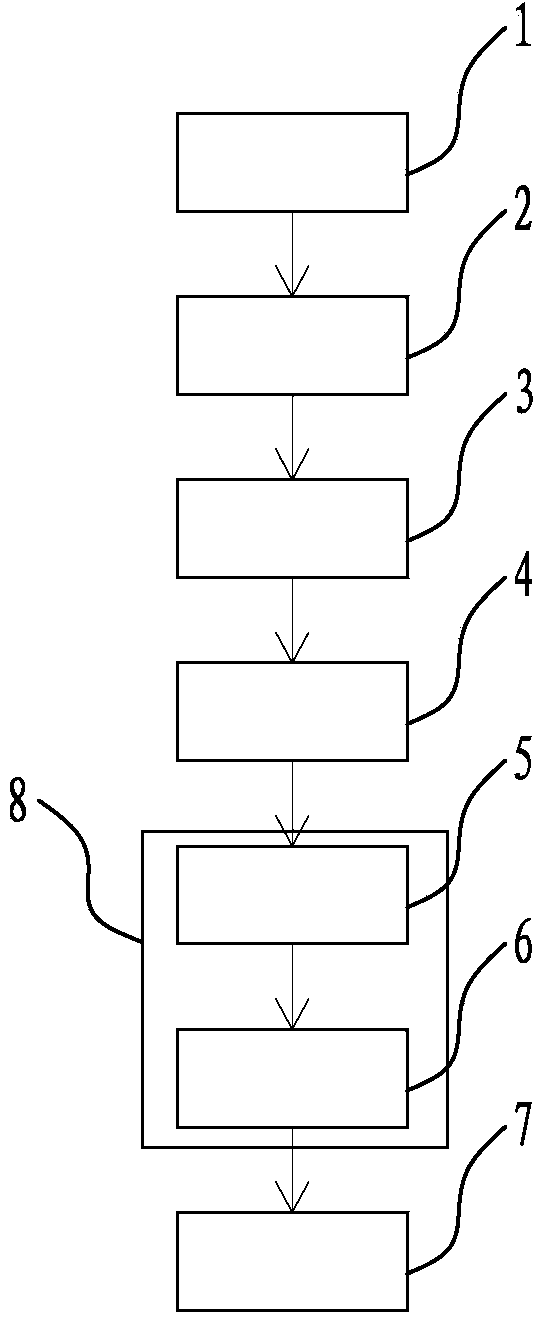

[0026] Such as figure 1 As shown, a schematic diagram of production equipment for secondary shaping of PVC foam core boards, including extruder 1, mold 2, cooling and shaping device 3, first tractor 4, secondary shaping device 8, arranged in a straight line and sequentially connected, The second tractor 7. Wherein the secondary setting device 8 is composed of a heating device 5 and a secondary cooling device 6 connected front and rear in a straight line; the traction speed of the first tractor 4 is slightly higher than that of the second tractor 7 .

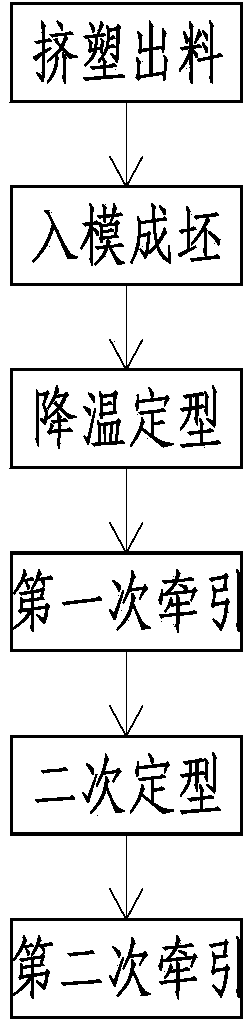

[0027] corresponds to figure 1 The production equipment shown, a production process for secondary shaping of PVC foam core board is as follows figure 2 shown, including the following steps in order:

[0028] 1) Extrusion material: The PVC material added with foaming agent is continuously fed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com