Upper-drawing casting device for the silicon bronze bar blank

A silicon bronze and traction device technology, which is applied in the field of casting devices, can solve the problems of high technical level requirements, low cooling intensity, high casting temperature, etc., and achieve the effects of good production safety, prevention of dangerous accidents, and fast traction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

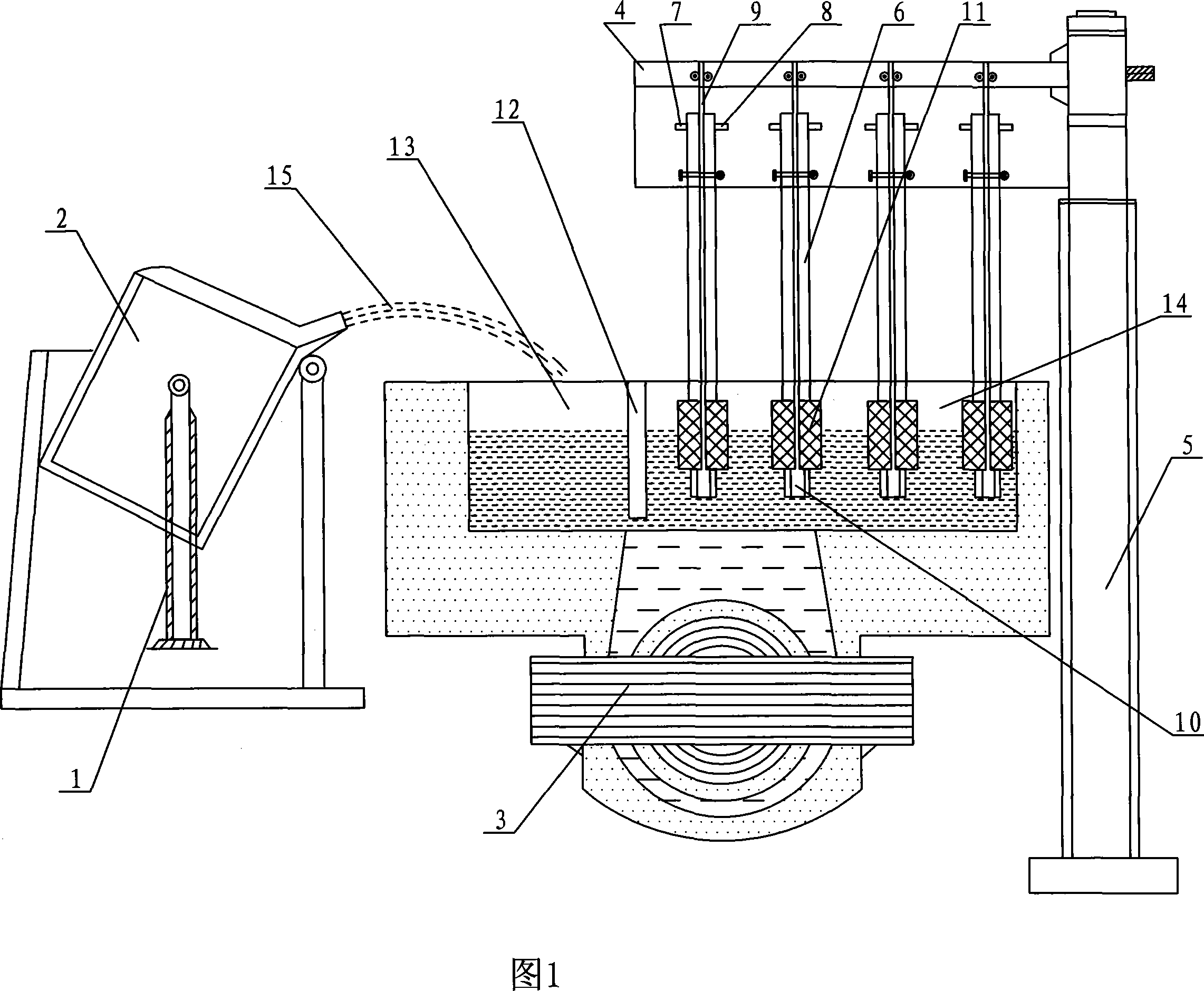

[0012] As shown in Figure 1: the upward casting device for silicon bronze billets includes an intermediate frequency melting furnace 2 arranged on the lifting control device 1, and a power frequency holding furnace 3 with an iron core is arranged on the side of the intermediate frequency melting furnace 2, and the power frequency has an iron core. A partition wall 12 is arranged in the iron core holding furnace 3, and the partition wall 12 divides the power frequency iron core holding furnace 3 into two cavities connected at the bottom. There are four traction devices 4, and the number of traction devices 4 can be set arbitrarily according to actual needs. The traction device 4 is arranged on the rotating lifting frame 5, and the crystallizer 6 is arranged on the traction device 4, and the upper end of the crystallizer 6 is respectively provided with an advanced The nozzle 7 and the drain 8, the dummy bar 9 on the traction device 4 are installed in the crystallizer 6, a graphit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com