Method for producing multi-specification plastic pipe material by fixed diameter-opening mould and its ram-head mould

A technology for plastic pipes and sizing molds is applied in the field of machine head molds and sizing molds to produce multi-specification plastic pipes. The effect of saving time, saving raw materials and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

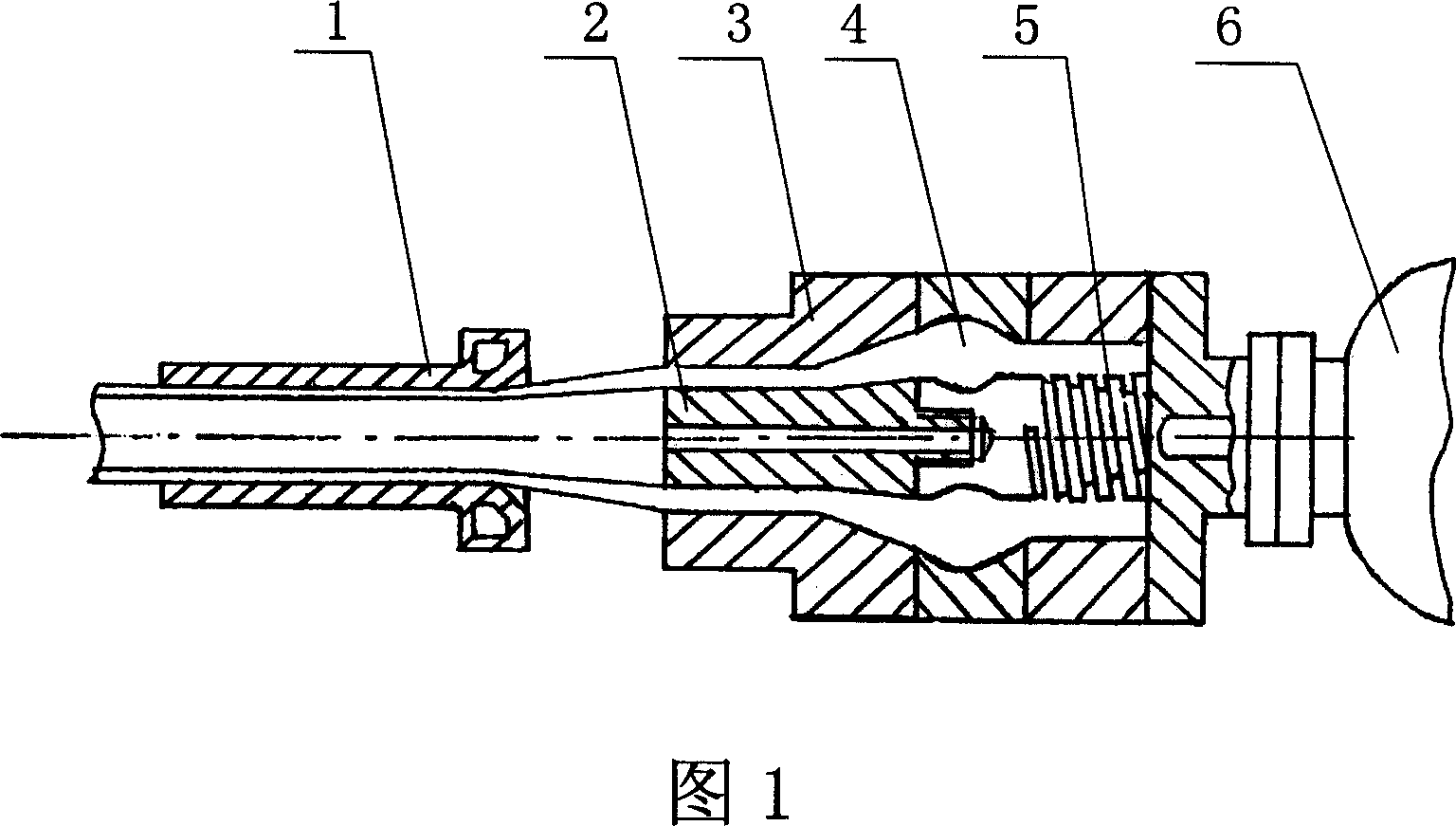

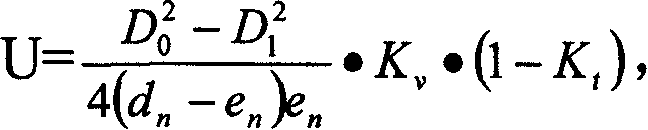

[0015] Embodiment, a method for producing multi-standard plastic pipes with a sizing die, the method includes the steps of feeding raw materials, heating and melting, extruding, sizing and cooling, pulling, and cutting to length. Cutting and other steps adopt the existing conventional processing scheme. Extrusion and sizing cooling are hot-melt raw materials extruded from the die and then drawn into the sizing die. The inner diameter of the die is larger than the inner diameter of the sizing die. The ratio of the exit line speed to the pulling line speed of the sizing cooling product U≤1, the ratio of the extrusion line speed of the hot melt material to the pulling line speed of the sizing cooling product U = D 0 2 - D 1 2 4 ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com