A kind of resin matrix composite material, preparation method and used vacuum bag

A composite material and vacuum bag technology, which is applied in the field of composite material manufacturing, can solve the problems of not being able to ensure the excellent internal quality of the product, composite materials containing air bubbles, and long molding time of materials, so as to improve the impact resistance and damage resistance, prolong the service life, The effect of improving internal quality and load-carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Preparation of Epoxy-based Carbon Fiber Composite Parts

[0043] The part requires a thickness of 80mm, using dry carbon cloth as the reinforcing material, and epoxy resin cured at 240°C as the matrix. Carbon cloth needs to be laid 300 layers;

[0044] For the selection of vacuum bags, refer to the curing temperature of the resin, choose a grafted modified polypropylene film with a melting temperature of 190°C and a thickness of 0.05mm as the inner bag, and choose a high temperature resistant polyimide film as the outer bag;

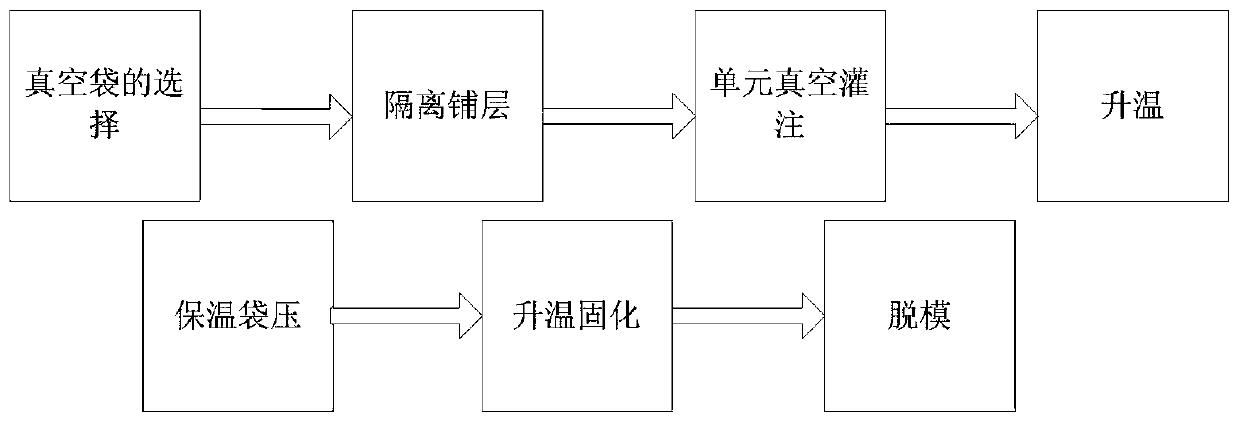

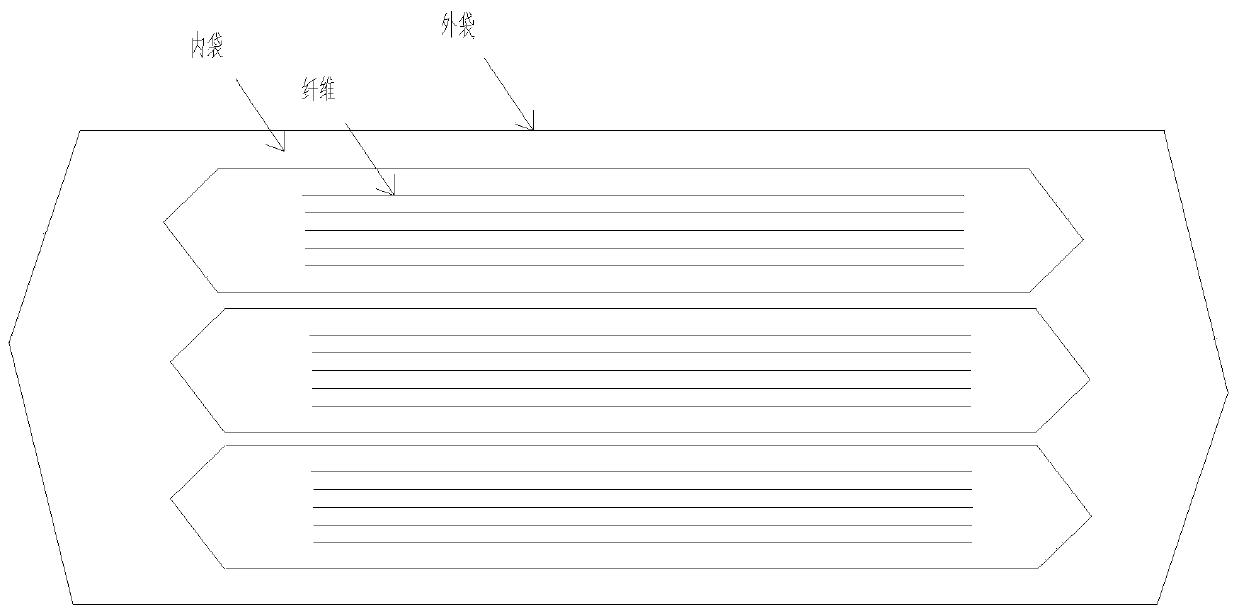

[0045] Isolation layup, see figure 2 The schematic diagram of the design, with 10 layers of carbon cloth as a thin-layer unit, a total of 30 units are prepared; each unit should be sealed with a hot-melt gun, and a glue injection tube and a vacuum tube are pre-embedded at both ends; finally, all the thin-layer The units are placed in the order of layers, sealed with an outer bag, and the two ends are also pre-embedded with rubber pipes and vacu...

Embodiment 2

[0051] Preparation of Polyimide Resin-Based Carbon Fiber Composite Parts

[0052] The part requires a thickness of 50mm, using dry carbon cloth as a reinforcing material, and polyimide resin cured at 260°C as a matrix. Carbon cloth needs to be laid 200 layers.

[0053] For the selection of vacuum bags, refer to the curing temperature of the resin, choose a grafted modified polypropylene film with a melting temperature of 110°C and a thickness of 0.05mm as the inner bag, and choose a high temperature resistant polyimide film as the outer bag;

[0054] Isolation layup, see figure 2 The schematic diagram of the design, with 10 layers of carbon cloth as a thin-layer unit, a total of 20 units are prepared; each unit should be sealed with a hot-melt gun, and a glue injection tube and a vacuum tube are pre-embedded at both ends; finally, all the thin-layer The units are placed in the order of layers, sealed with an outer bag, and the two ends are also pre-embedded with rubber pipe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com