Device for controlling gel content of in-situ solidifying fiber placement machine

An in-situ solidification and control device technology, applied in the field of composite material manufacturing, can solve the problems of affecting the performance of composite materials, low precision, and large fiber damage, etc., to ensure infiltration and uniformity, stability and accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

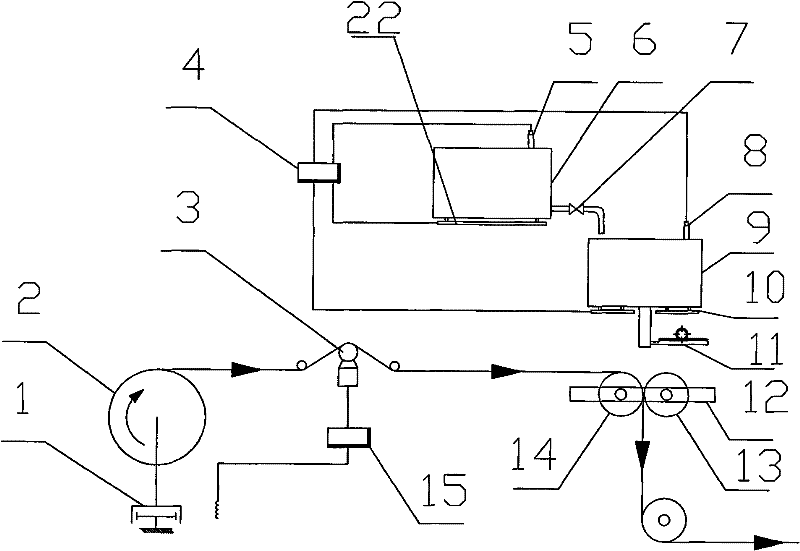

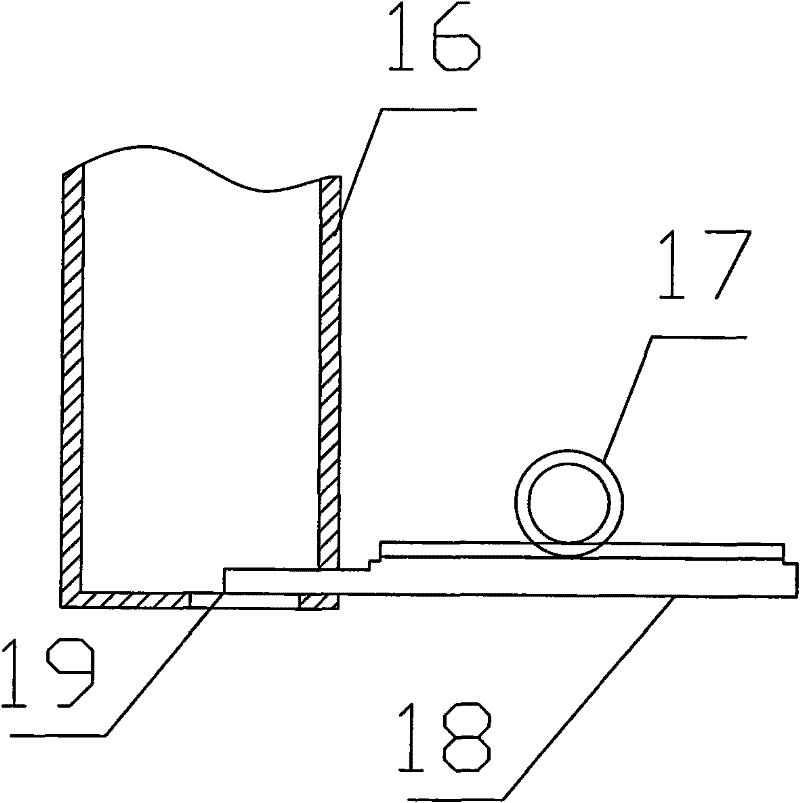

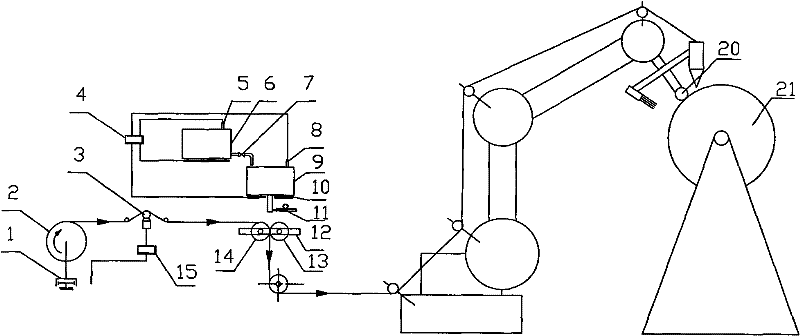

[0018] The present invention is described in further detail below in conjunction with accompanying drawing:

[0019] refer to figure 1 , 2 As shown, an in-situ curing fiber placement machine glue content control device includes a resin replenishment control mechanism, a glue extrusion mechanism, a tension control system and a flow control mechanism 11, and is characterized in that: a resin is arranged above the glue extrusion mechanism Supplementary control mechanism; the front end of the extruding mechanism is provided with a tension control system, the tension control system is used to adjust the system tension of the control device; the bottom of the resin supplementary control mechanism is provided with a flow control mechanism 11, and the flow control mechanism 11 is used to control the amount of water poured onto the glass. The flow rate of the resin on the fiber; the flow control mechanism 11 pours the resin onto the glass fiber, and the extrusion mechanism evenly sque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com