A vacuum injection device

A vacuum injection device and vacuum pumping technology, which are applied in the manufacture of hybrid/electric double layer capacitors, sustainable manufacturing/processing, climate sustainability, etc. Expensive and other problems, to achieve precise control of injection volume, good infiltration effect, and good injection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

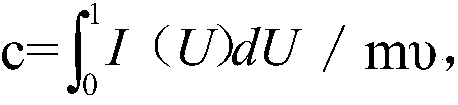

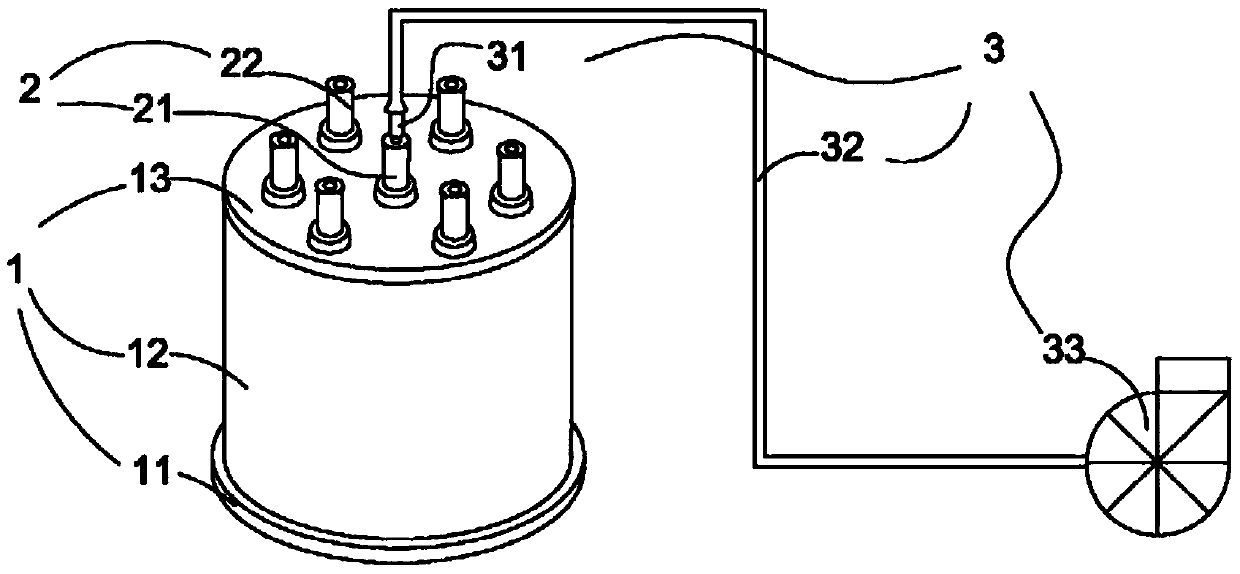

[0049] refer to Figure 1 to Figure 2 , the present embodiment provides a vacuum liquid injection device, including a vacuum chamber 1, a flexible joint 2, a vacuum member 3 and a syringe (not shown) with electrolyte, the vacuum chamber 1 is composed of a base 11, a side wall 12 and the top cover 13 are enclosed, and the corrugated joint 2 is arranged in the top cover 13 of the vacuum chamber 1, and is used to connect the vacuum pumping component 3 and the syringe containing the electrolyte to the vacuum chamber 1 respectively.

[0050] The vacuum chamber 1 is a cylindrical chamber, the base 11 is a circular base with a diameter of 105 mm, the height of the side wall 12 is 80 mm, and the top cover 13 is a circular top cover with a diameter of 95 mm. There are seven openings for inserting the Clifford joint 2.

[0051] Six battery slots 14 and a groove 15 are arranged in the base 11. The battery slots 14 are battery slots for button batteries with a diameter of 20.5mm. The dia...

Embodiment 2

[0063] The difference between this embodiment and Embodiment 1 lies in the size of the vacuum chamber.

[0064] In this embodiment, the vacuum chamber 1 is a cylindrical chamber, the base 11 is a circular base with a diameter of 80 mm, the height of the side wall 12 is 50 mm, and the top cover 13 is a circular top cover with a diameter of 70 mm.

Embodiment 3

[0066] The difference between this embodiment and Embodiment 1 lies in the size of the vacuum chamber.

[0067] In this embodiment, the vacuum chamber 1 is a cylindrical chamber, the base 11 is a circular base with a diameter of 120 mm, the height of the side wall 12 is 100 mm, and the top cover 13 is a circular top cover with a diameter of 110 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com