Packaging technology and packaging structure of ceramic chip

A technology of chip packaging structure and packaging technology, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve the problems of contaminating the connection area of ceramic chips, reducing labor and transportation costs, etc., and achieve product yield improvement, The effect of reducing labor and transportation costs and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

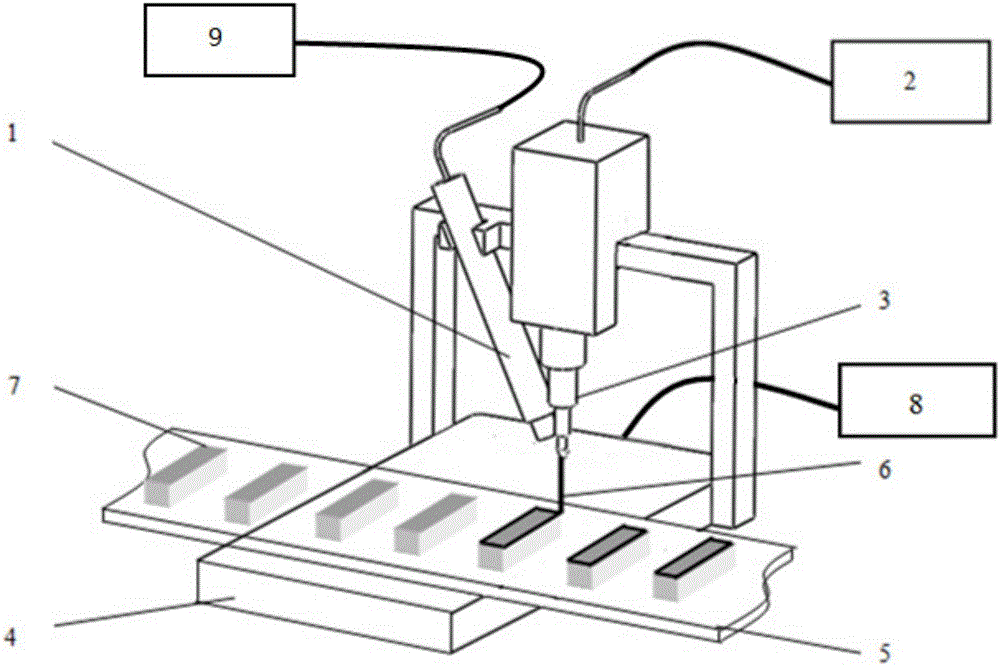

[0032] This embodiment is a packaging process for ceramic chips, such as figure 1 shown, including the following steps:

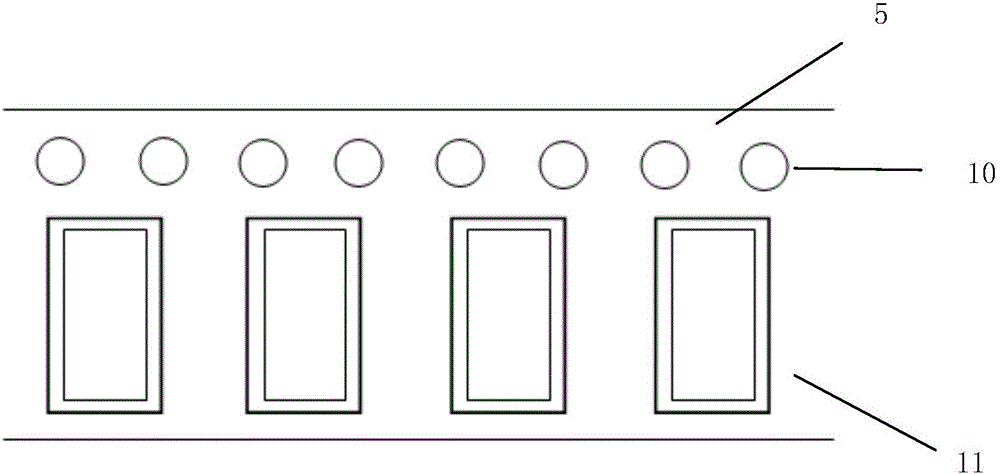

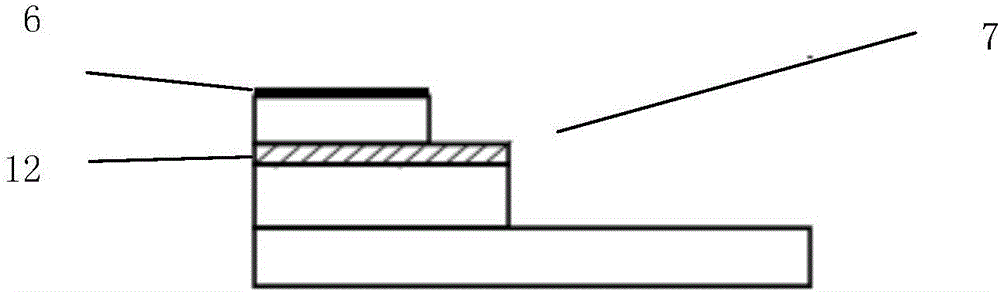

[0033] (1) Dispensing and film formation: Before chip assembly, apply liquid dual-cure sealant to the outer edge of the side of the ceramic carrier that needs to be packaged with the cover plate through a dispenser, and cure the dual-cure sealant by UV light irradiation Shaped to form a structural adhesive film on the ceramic carrier; the dispenser includes a horizontal moving platform 4 whose displacement and direction are controlled by the first controller 8, a dispensing head 3 whose glue output is controlled by the second controller 2, and a horizontal moving platform 4 The displacement and direction are controlled by the first controller 8; the glue output of the dispensing head 3 is controlled by the second controller 2; the glue is applied to the outer edge 7 of the ceramic carrier through the dispensing head 3 to form a horizontal glue line 6, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com