Shaking vacuum sealing device of PEEK (Polyether-Ether-Ketone) sealing framework

A vacuum sealing and skeleton technology, which is applied to the sealing of engines, engine components, mechanical equipment, etc., and can solve problems such as poor vacuum sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

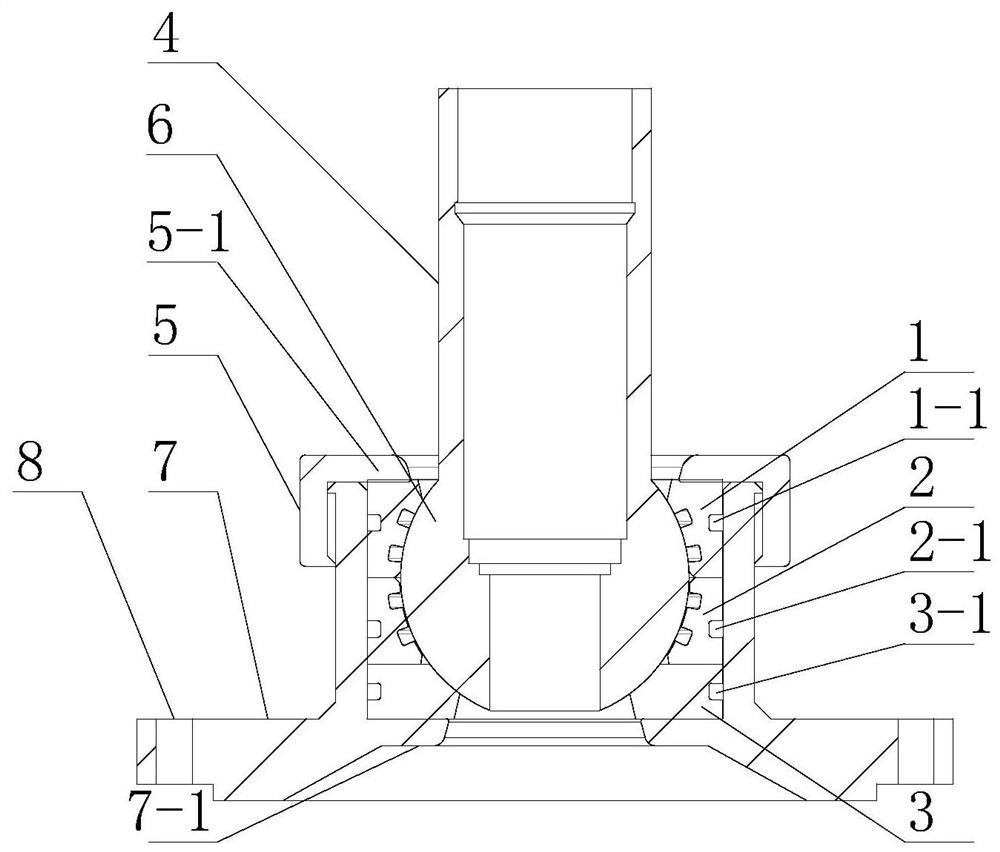

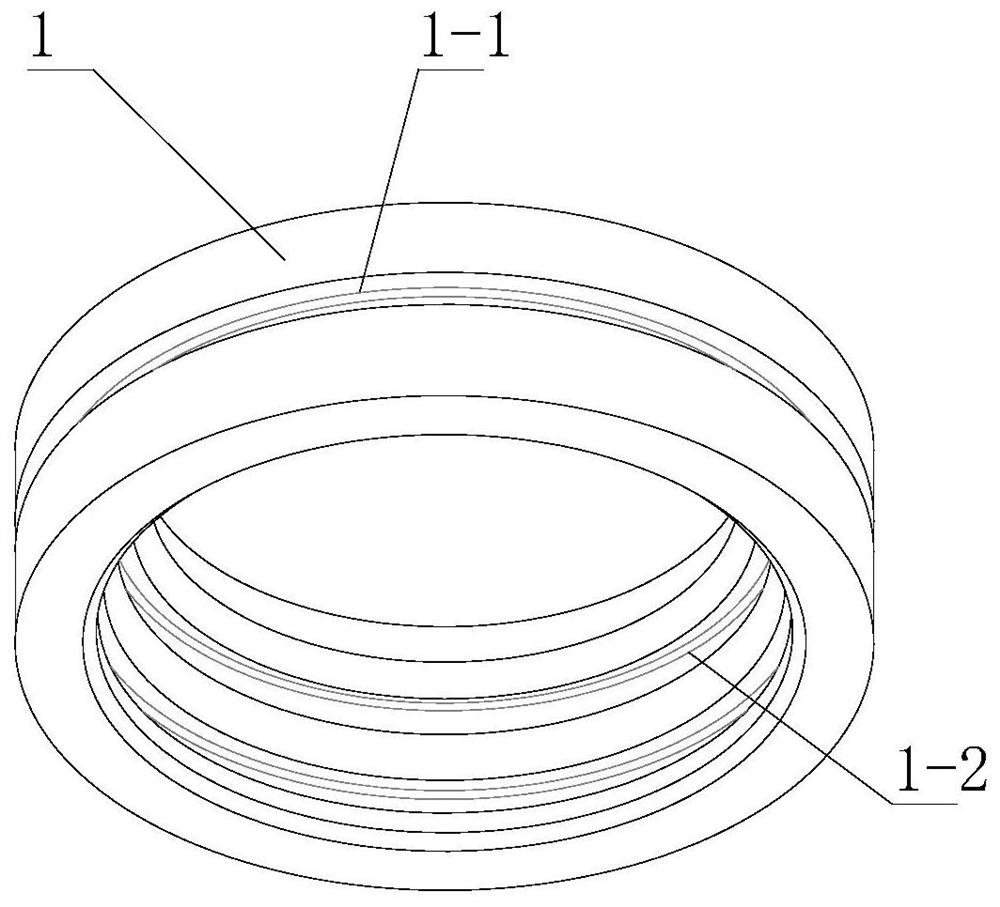

[0034] Such as figure 1 with figure 2 As shown, a shaking vacuum sealing device of a PEEK sealing frame includes a rocker 4, a ball core 6, an upper frame 1, a middle frame 2, and a lower frame 3, and the upper frame 1, the middle frame 2, and the lower frame 3 start from the top The bottom is coaxially arranged, and the upper frame 1, the middle frame 2, and the lower frame 3 are adjacent to each other from top to bottom to form a sealed cavity. The sealed cavity is set as a spherical cavity that matches the shape of the ball core 6. The ball core 6 The outside is set as a spherical structure as a whole, the ball core 6 is embedded in the sealed cavity, the rocker 4 is set as a hollow cylindrical sleeve structure, and the inside of the ball core 6 is provided with a hollow cylindrical cavity that is consistent with the inner cavity of the rocker 4. That is, the upper end of the ball core 6 is connected to the rocker 4, the inner chamber of the sleeve of the rocker 4 extends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com