Electrochemical device

An electrochemical, lithium-ion battery technology, applied in electrochemical generators, batteries, circuits, etc., can solve the problems of immature safety technology, safety problems, lithium-ion batteries, explosions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-60

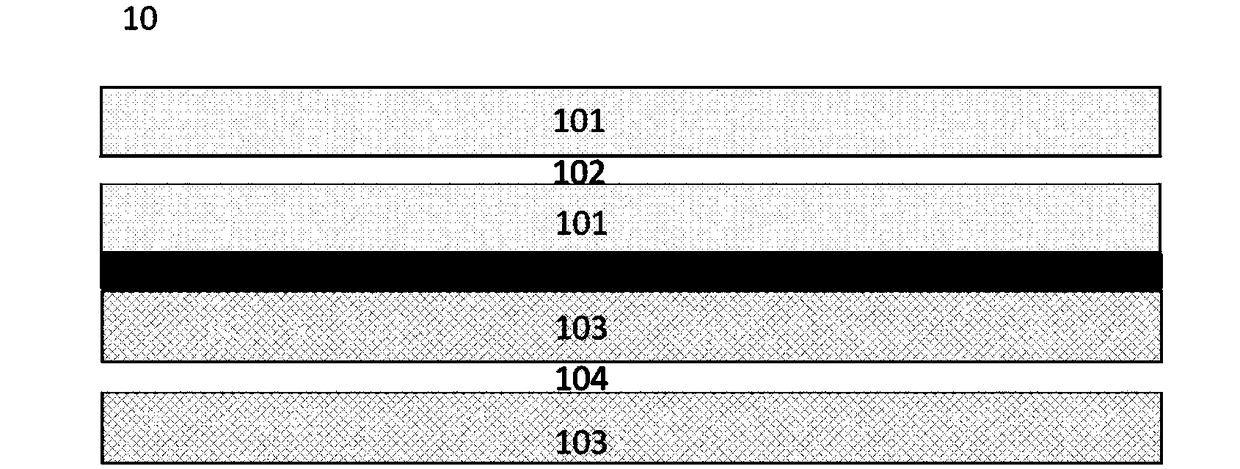

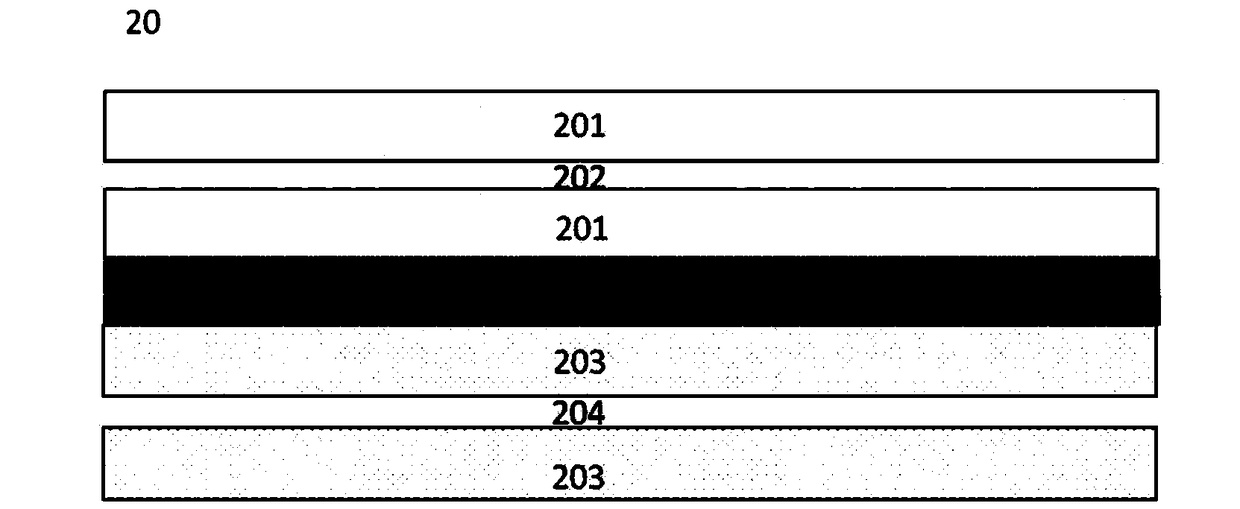

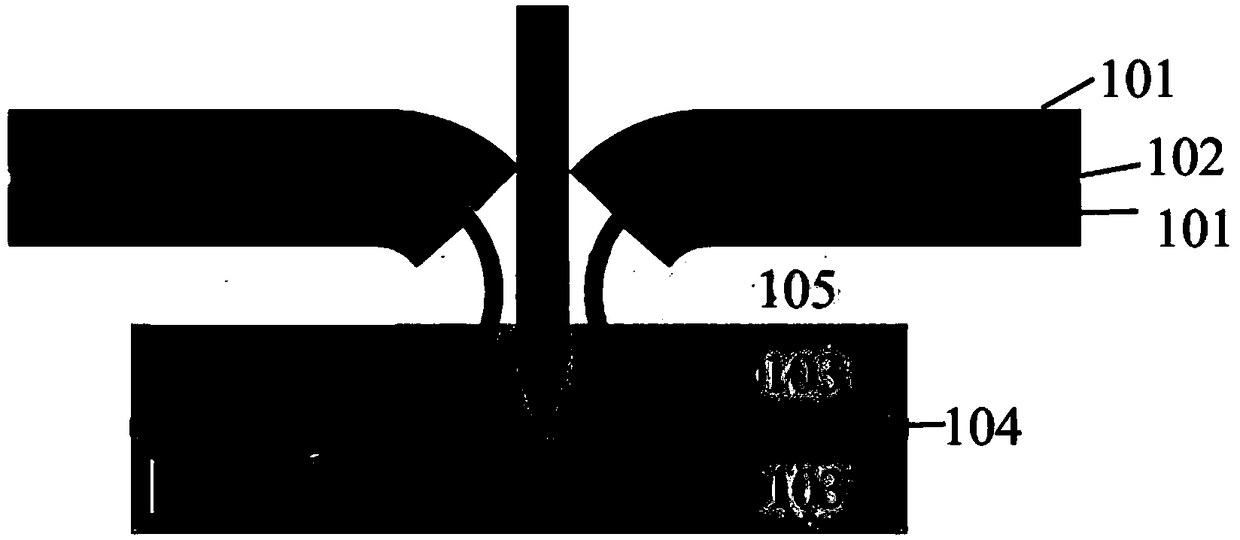

[0087] Aluminum foil is used as the positive electrode current collector, and lithium cobalt oxide slurry is uniformly coated on both surfaces of the aluminum foil. The composition of the lithium cobalt oxide slurry is 97.8wt% LiCoO 2 (LCO), 0.8wt% polyvinylidene fluoride (PVDF), and 1.4wt% conductive carbon black are dried and then cold pressed to prepare a positive pole piece. Using copper foil as the negative electrode current collector, the two surfaces of the copper foil are uniformly coated with artificial graphite slurry. The composition of the slurry is 97.7wt% artificial graphite, 1.3wt% carboxymethyl cellulose (CMC) and 1.0wt% styrene-butadiene The combination of rubber (SBR) is cold pressed and slit after drying; polymer particles (Examples 1-9 and 11-60) or block polymethyl methacrylate (molecular weight 7W) (implementation Example 10) Add polyvinylidene fluoride and about 65% by weight of N-methylpyrrolidone (NMP), disperse at a constant speed to obtain a coating sl...

Embodiment 61-63

[0091] Aluminum foil is used as the positive electrode current collector, and lithium cobalt oxide slurry is uniformly coated on both surfaces of the aluminum foil. The composition of the lithium cobalt oxide slurry is 97.8wt% LiCoO 2 (LCO), 0.8wt% polyvinylidene fluoride (PVDF) and 1.4wt% conductive carbon black, after drying, are cold pressed to prepare a positive pole piece. Using copper foil as the negative electrode current collector, the two surfaces of the copper foil are uniformly coated with artificial graphite slurry. The composition of the slurry is 97.7wt% artificial graphite, 1.3wt% carboxymethyl cellulose (CMC) and 1.0wt% styrene-butadiene The combination of rubber (SBR), followed by cold pressing and slitting, prepares a negative pole piece. The polymer particles are added to polyvinylidene fluoride and about 65% by weight of N-methylpyrrolidone (NMP), dispersed at a constant speed to obtain a polymer layer slurry, and a layer of polymerization is uniformly coated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com