High-hardness high-wear-resistant surfacing electrode for multilayer surfacing

A multi-layer surfacing welding and surfacing electrode technology, which is applied in the direction of welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of difficulty in meeting wear resistance requirements, difficulty in improving welding efficiency, and low toughness of surfacing layers. problem, to achieve the effect of metallurgical combination, low price and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

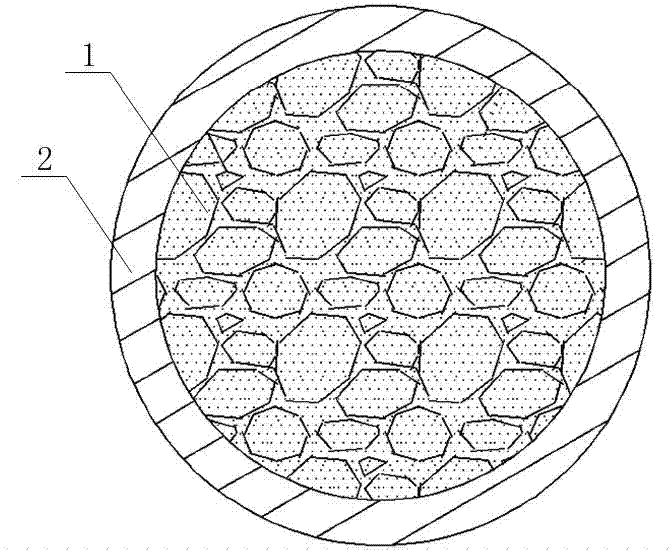

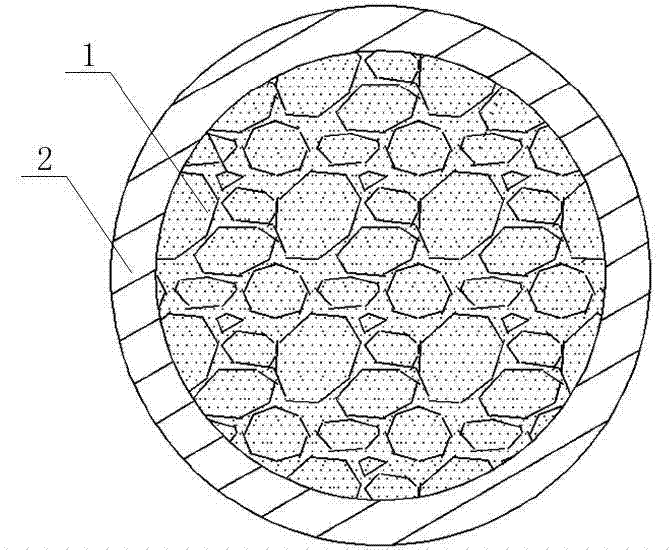

[0024] High hardness and high wear resistance welding electrodes for multi-layer surfacing, such as figure 1 As shown, it consists of a solder skin 1 and a flux core 2, the solder skin 1 is a thin-walled tube, the flux core 2 is filled inside the solder skin 1, and both ends of the solder skin 1 are sealed; the flux core 2 includes the following components , and the weight ratio of each component is:

[0025] metallized diamond 18,

[0026] Carbide 27,

[0027] Pre-alloyed powder 55.

[0028] The specific weight of each component is: 5 grams of 60 mesh synthetic diamond, 4 grams of YQ4 type 20 mesh spherical hard alloy, 3.5 grams of YQ4 type 40 mesh spherical hard alloy, and 15.3 grams of nickel-based pre-alloyed powder.

[0029] Its preparation method is as follows: firstly, according to the above formula, take the raw materials of drug core 2 and mix them evenly for use, take galvanized white iron sheet with a thickness of 0.2mm, the length of the white iron sheet is 350m...

Embodiment 2

[0031] High hardness and high wear resistance welding electrodes for multi-layer surfacing, such as figure 1 As shown, it consists of a solder skin 1 and a flux core 2, the solder skin 1 is a thin-walled tube, the flux core 2 is filled inside the solder skin 1, and both ends of the solder skin 1 are sealed; the flux core 2 includes the following components , and the weight ratio of each component is:

[0032] metallized diamond 25,

[0033] Carbide 35,

[0034] Pre-alloyed powder 38.

[0035] The specific weight of each component is: 80 mesh artificial diamond 7 grams, YQ4 type 30 mesh spherical hard alloy 5 grams, YQ4 type 60 mesh spherical hard alloy 4.8 grams, cobalt-based pre-alloyed powder 10.6 grams.

[0036] The preparation method is as follows: firstly, according to the above formula, take the raw materials of drug core 2 and mix them evenly for use; take galvanized white iron sheet with a thickness of 0.2 mm, the length of the white iron sheet is 350 mm, and the wi...

Embodiment 3

[0038] High hardness and high wear resistance welding electrodes for multi-layer surfacing, such as figure 1 As shown, it consists of a solder skin 1 and a flux core 2, the solder skin 1 is a thin-walled tube, the flux core 2 is filled inside the solder skin 1, and both ends of the solder skin 1 are sealed; the flux core 2 includes the following components , and the weight ratio of each component is:

[0039] metallized diamond 26,

[0040] Carbide 22,

[0041] Pre-alloyed powder 52.

[0042] The specific weight of each component is: 7.5 grams of 70 mesh synthetic diamond, 3 grams of YQ4 type 20 mesh spherical hard alloy, 3.4 grams of YQ4 type 60 mesh spherical hard alloy, and 15.1 grams of iron-based pre-alloyed powder.

[0043] The preparation method is as follows: firstly, according to the above formula, take the raw materials of drug core 2 and mix them evenly for use; take galvanized white iron sheet with a thickness of 0.2 mm, the length of the white iron sheet is 350...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com