Diaphragm with excellent cohesiveness and air permeability and preparation method thereof

A gas-permeable and cohesive technology, applied in the direction of separators/films/diaphragms/spacers, electrical components, structural parts, etc., can solve the problems of poor comprehensive performance of the diaphragm, achieve a small cross-overlapping range, and ensure stability performance, to ensure the effect of breathability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present application also provides a method for preparing a membrane with good adhesion and air permeability, comprising the following steps:

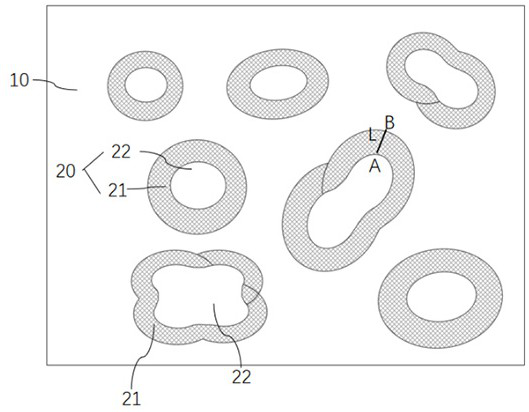

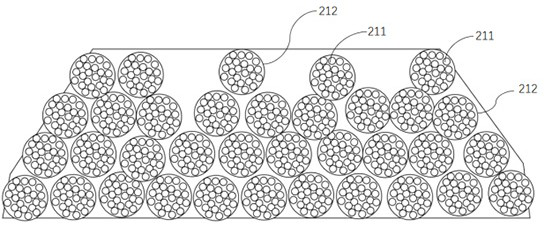

[0040]S1. Prepare PVDF primary particles 211 by emulsion polymerization, the particle diameter D50 of the primary particles 211 is 50nm-500nm, and polymerize the primary particles 211 into secondary particles 212, the particle diameter D50 of the secondary particles 212 is 0.5μm-20μm; S2. Mix the secondary particles 212, PMMA microspheres, binder, and deionized water according to a preset weight ratio. The particle size of the added PMMA microspheres is 1-15 μm, and the PMMA content accounts for 5-30% of PVDF. The solid content of the slurry is 10-30%, and the binder accounts for 1-20% of the secondary particles 212. Stir to form a uniform bonding slurry; S3. Spray the bonding slurry on one side of the base film using a rotating nozzle On 10, the spraying flow rate of the rotary nozzle is 50-500ml / min, and the rotation speed ...

Embodiment 1

[0049] S1. Preparation of secondary particles 212

[0050] PVDF primary particles 211 were prepared by emulsion polymerization, D50 was 240nm, washed, spray-dried, and sieved to obtain PVDF secondary particles 212, wherein the PVDF powder particle diameter D50 was 6.2 μm.

[0051] S2. Configure bonding slurry

[0052] A binder solution with a mass fraction of 15%, the binder is styrene-butadiene latex, mix PVDF, binder, and deionized water, and form a uniform slurry by stirring, the mixer speed is 700rpm, and the solid content of the slurry is 20% , where the binder accounts for 7.5% of the PVDF mass.

[0053] S3, spraying

[0054] Uniformly spray the slurry on one side of the 9-micron PE base film 10, the flow rate of a single rotary spraying equipment is 150 ml / min, and the rotation speed is 10000 rpm;

[0055] S4, dry and prepare diaphragm B1

[0056] Place the coated separator in an oven and fully dry it at 60°C to obtain separator B1 after drying, with a polymer coati...

Embodiment 2

[0058] The difference from Example 1 is that the secondary particles 212 of PVDF are not piled up, and the primary particles 211 are directly used for subsequent spraying slurry preparation, and the other steps are unchanged, and the separator B2 is obtained. The polymer coating load after drying is 0.64g / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com