Formation process for improving cycle thickness expansion of soft package lithium-ion battery

A lithium-ion battery and soft pack technology, applied in the field of lithium-ion batteries, can solve the problems of easy deformation of the battery, increase the deformation of the battery, affect the electrical performance of the battery, etc., so as to improve the electrochemical performance, reduce the thickness expansion rate, and ensure the infiltration effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

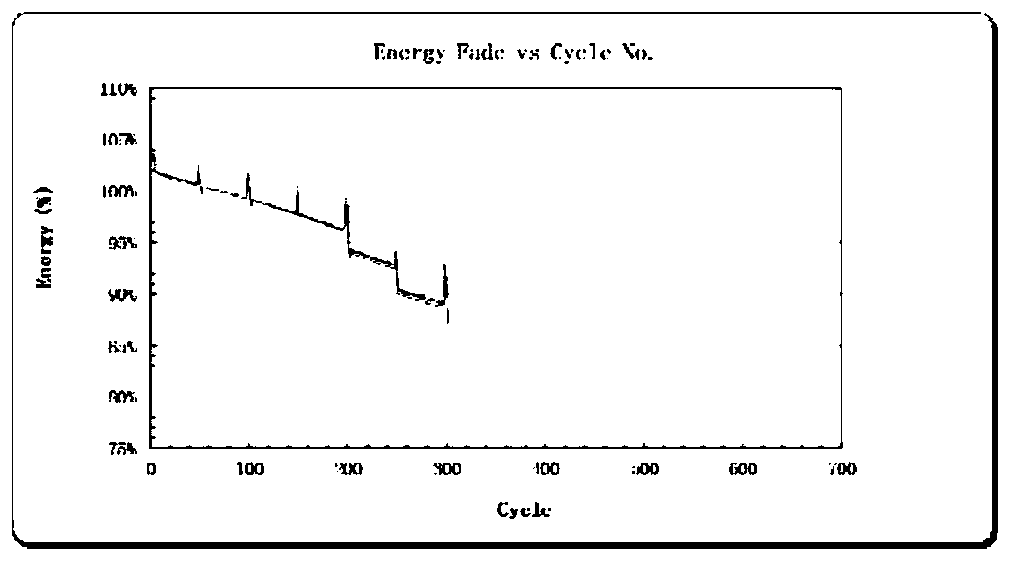

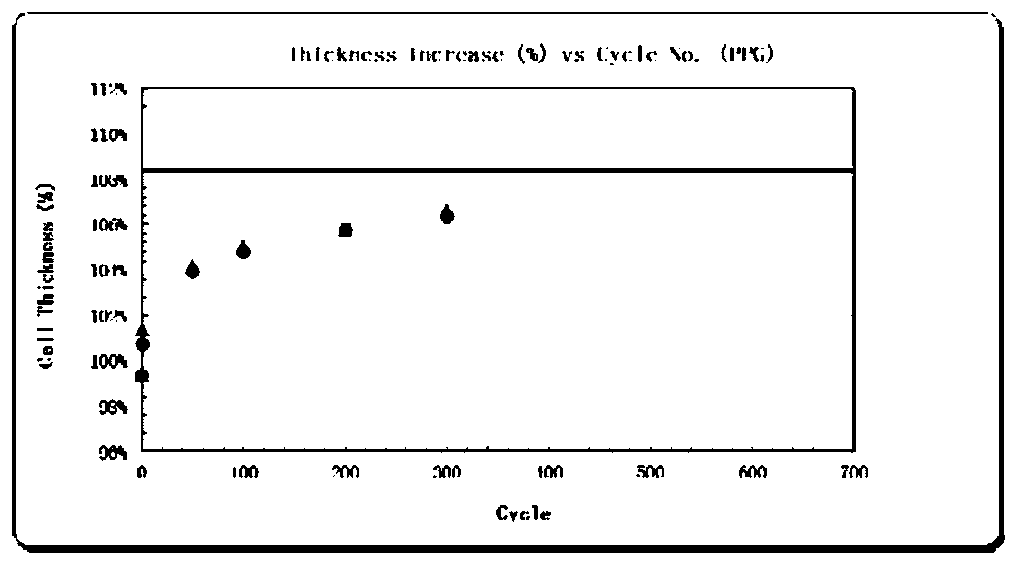

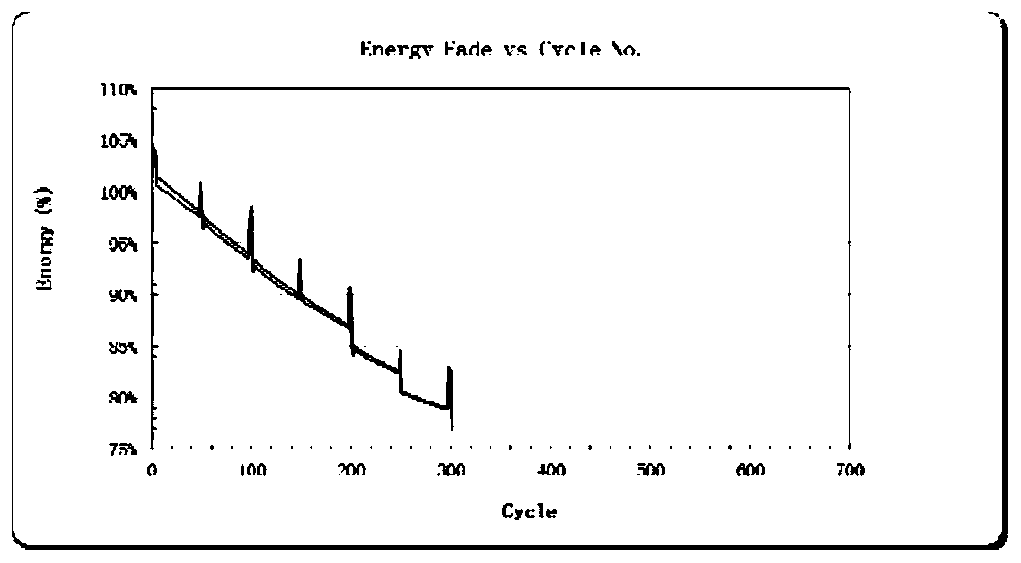

[0014] A formation process for improving the cycle thickness expansion of a soft-packed lithium-ion battery, comprising the following steps: using an Arbin system to monitor the voltage of the static battery after filling the battery cell, and using a fixture formation device to perform formation under a specific pressure, temperature and charging system.

[0015] Wherein, the standing time is when the slope of the Arbin curve is 1;

[0016] In the operation of lithium battery formation, the temperature of the fixture is 40°C, the pressure exerted by the fixture on the cell body is 2Mpa / 2pcs, and the charging system is step constant current charging. In a charging operation, the current level is 0.05 C, and the battery is charged to 3% SOC. In the secondary charging operation, the current level is 0.7C, and the battery is charged to 49% SOC. After the second charge, the cell was removed and placed in a constant temperature and humidity environment for vacuuming, the vacuum de...

Embodiment 2

[0018] A formation process for improving the cycle thickness expansion of a soft-packed lithium-ion battery, comprising the following steps: using an Arbin system to monitor the voltage of the static battery after filling the battery cell, and using a fixture formation device to perform formation under a specific pressure, temperature and charging system.

[0019] Wherein, the standing time is when the Arbin curve slope is 0.5;

[0020] In the operation of lithium battery formation, the temperature of the fixture is 60°C, the pressure exerted by the fixture on the cell body is 1Mpa / 2pcs, and the charging system is step constant current charging. In a charging operation, the current level is 0.1 C, and the battery is charged to 5% SOC. In the secondary charging operation, the current is 1C, and the battery is charged to 65% SOC. After recharging, the cell was removed and placed in a constant temperature and humidity environment for vacuuming, the vacuum degree was maintained a...

Embodiment 3

[0022] A formation process for improving the cycle thickness expansion of a soft-packed lithium-ion battery, comprising the following steps: using an Arbin system to monitor the voltage of the static battery after filling the battery cell, and using a fixture formation device to perform formation under a specific pressure, temperature and charging system.

[0023] Wherein, the standing time is when the slope of the Arbin curve is 0;

[0024] In the operation of lithium battery formation, the temperature of the fixture is 90°C, the pressure exerted by the fixture on the cell body is 0.2MPa / 2pcs, and the charging system is step constant current charging. In a charging operation, the current level is 0.3C, and the battery is charged to 7% SOC. In the secondary charging operation, the current is 1.5C, and the battery is charged to 75% SOC. After the second charge, the battery cell was removed and placed in a constant temperature and humidity environment for vacuuming. The vacuum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com