Embedded steel column leg with steel pin

An embedded steel column foot and steel dowel technology, applied in the direction of construction and building structure, can solve the problems of unfavorable construction, complicated column foot method, large pull-up force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

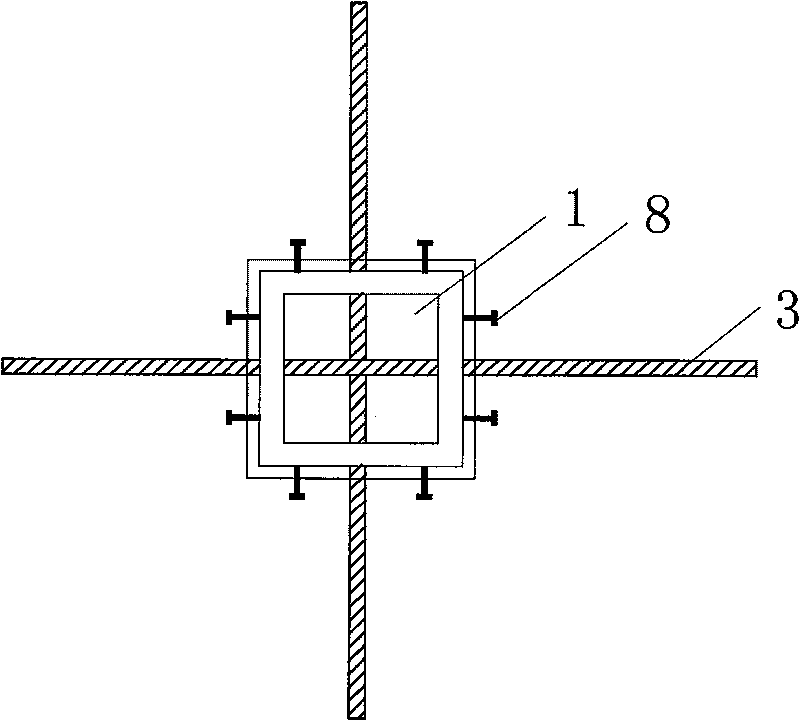

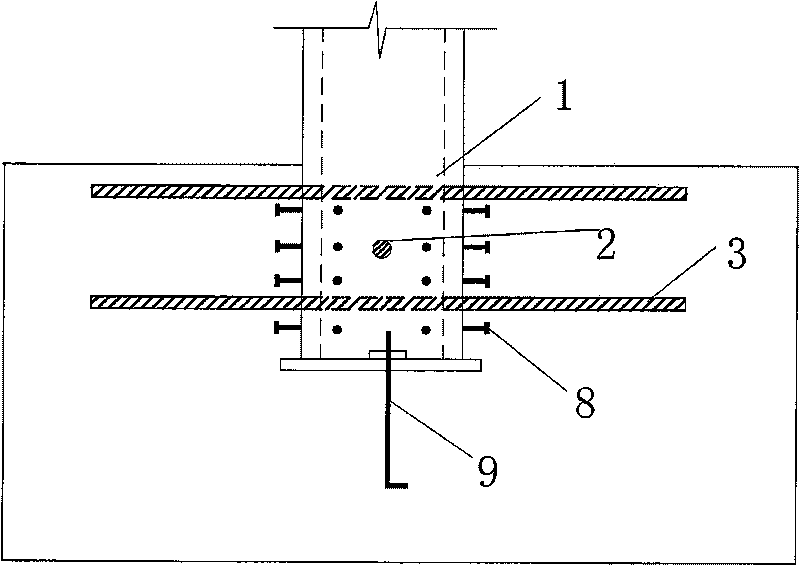

[0024] Such as figure 1 , figure 2 As shown, in this embodiment, horizontal through holes 2 are opened in the embedded part of the steel column foot 1, and the horizontal through holes 2 are evenly distributed along the height direction. Then penetrate steel pins in the hole 2 (it can be steel bars 3, variable-section steel rods 4 or various types of steel 5, the diameter can be selected according to the force requirements and should not be less than 18mm, and the vertical center distance of the steel pins should not be less than 500mm , the anchorage length of both ends of the steel pin in the foundation should not be less than 30d (d is the diameter of the steel pin), and the two adjacent steel pins along the height direction should be placed alternately and should be connected with the steel bars in the foundation. The part of the steel plate embedded in the foot of the steel column should be Thicken or add stiffeners or stiffeners at the openings to prevent extrusion or ...

Embodiment 2

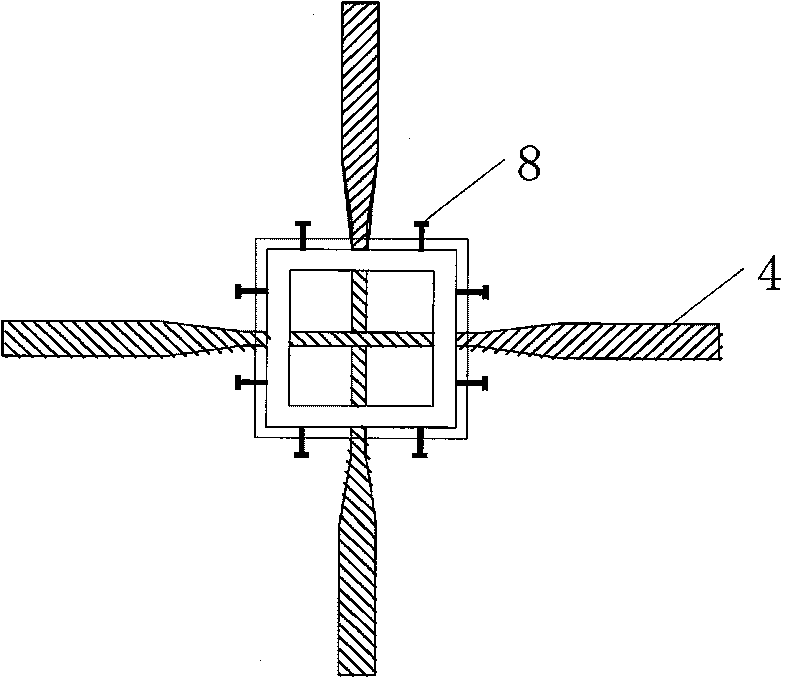

[0029] Such as image 3 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the only difference is that the steel rod has a variable cross-section. This kind of steel bar needs to be divided into two sections to make. During construction, the longer section is first passed through the steel column, and then the shorter section of steel bar is welded to the longer steel bar at the joint. This kind of variable cross-section steel rod can reduce the weakening of the steel column by the opening, and at the same time, the contact surface between the steel rod and the concrete becomes larger, which can provide greater pull-out resistance. However, it is necessary to check the bearing capacity at the variable section of the steel bar and at the weld.

Embodiment 3

[0031] Such as Figure 4 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the only difference is that the steel pins implementing the present invention are I-beams, and the openings of the steel columns should be changed accordingly during construction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com