Transverse segmental prefabricated prestressed concrete bent cap structure and assembling method thereof

A segmented prefabricated and prestressed technology, used in the erection/assembly of bridges, bridges, bridge parts, etc., can solve the problems of poor resistance to out-of-plane force, high requirements for lifting equipment, and heavy prefabricated cover beams, so as to improve civilization. The effect of construction, reducing construction workload and accelerating construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

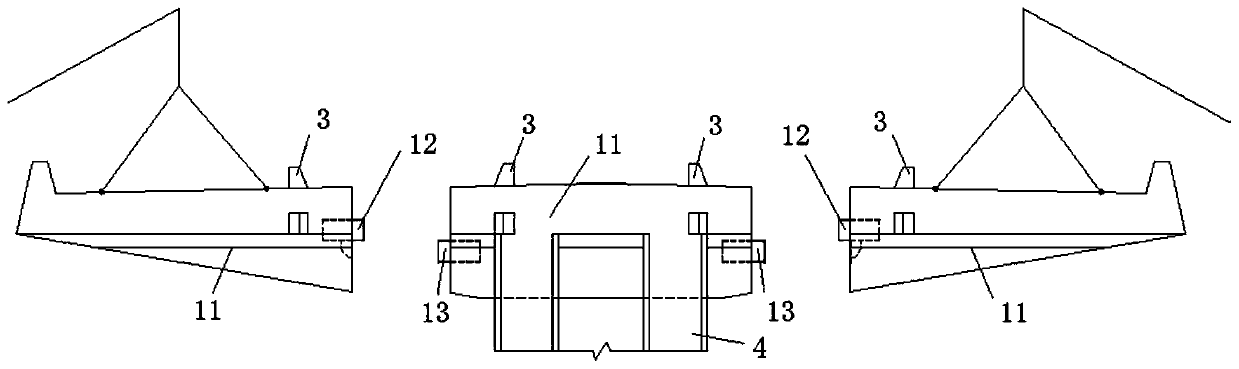

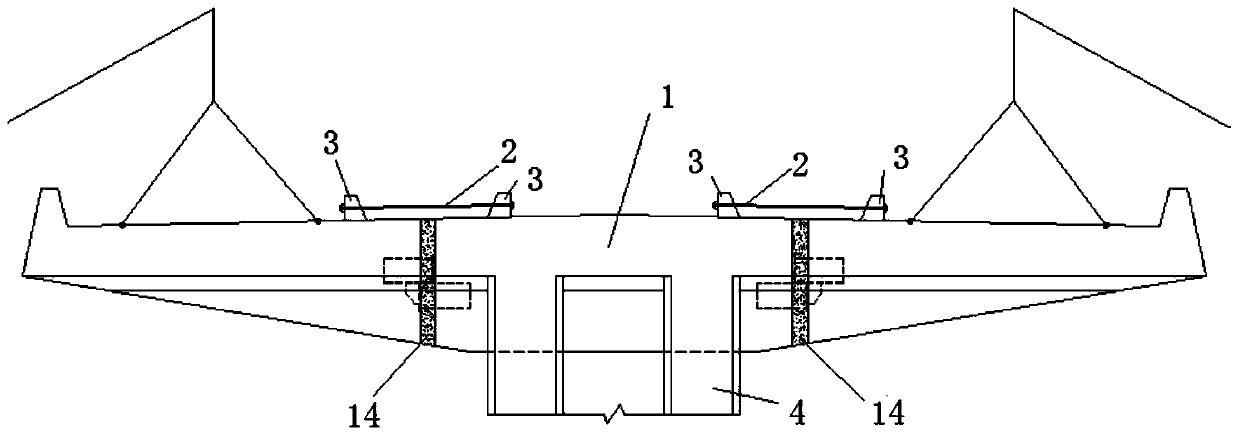

[0029] like Figure 1 to Figure 4 As shown, the transversally segmented prefabricated prestressed concrete cover beam structure includes a cover beam main body 1 and a prefabricated column 4 for supporting the cover beam main body 1 .

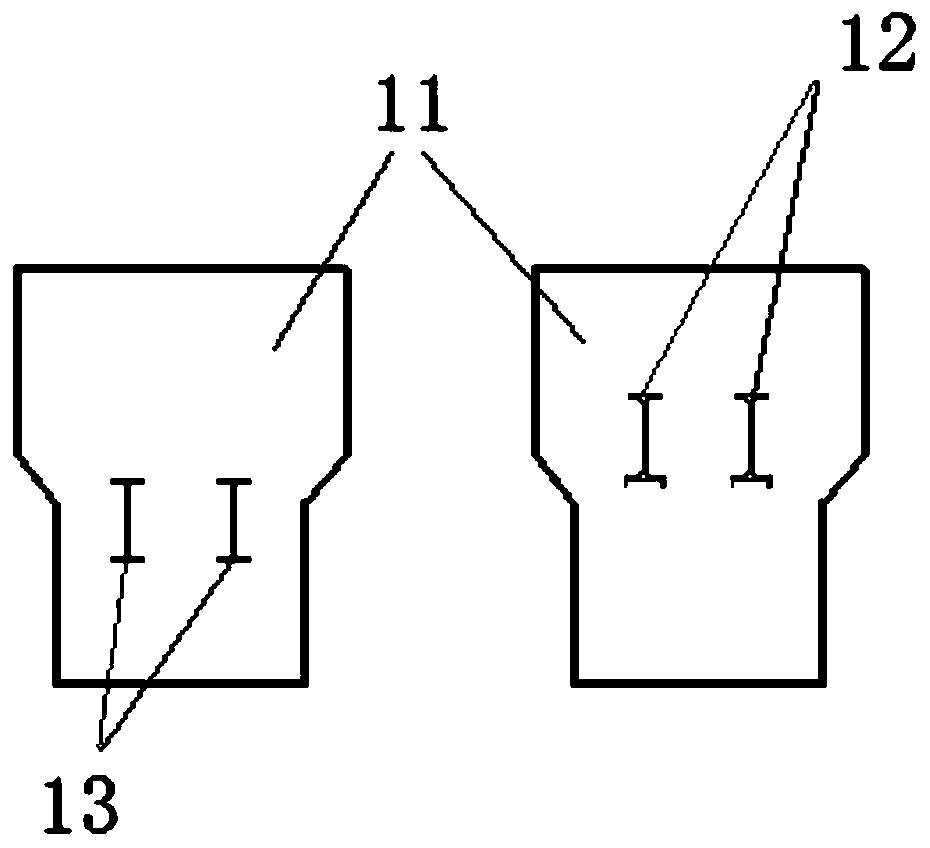

[0030] Among them, the cover beam main body 1 includes a number of prefabricated segments 11 spliced along the transverse direction; each prefabricated segment 11 is reserved for piercing steel strand 15 holes; every two adjacent prefabricated segments 11 pass through wet joints 14 connection; every two adjacent prefabricated segments 11 are pre-embedded with matching upper-section steel lap joint structures 12 and lower-section steel lap joint structures 13 on the joint surfaces near both sides of the wet joint segment 14;

[0031] Several transverse reinforcing bars on the top, bottom and facade of each prefabricated section 11 extend to the range of the corresponding wet joint section 14, and several transverse reinforcing bars of each pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com