Electrical hydraulic combined discharging device

An unloading device, electro-hydraulic technology, applied in the direction of transportation and packaging, loading/unloading, conveyor objects, etc., can solve the problem of the gravity impact of coal blocks on the belt, the accumulation of splashing and scattering, the inability to solve the problem of belt gravity impact, splashing and scattering Accumulation and conveying machinery require high synchronization to achieve the effect of ensuring force balance and operating safety, improving operating efficiency, and good overall mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

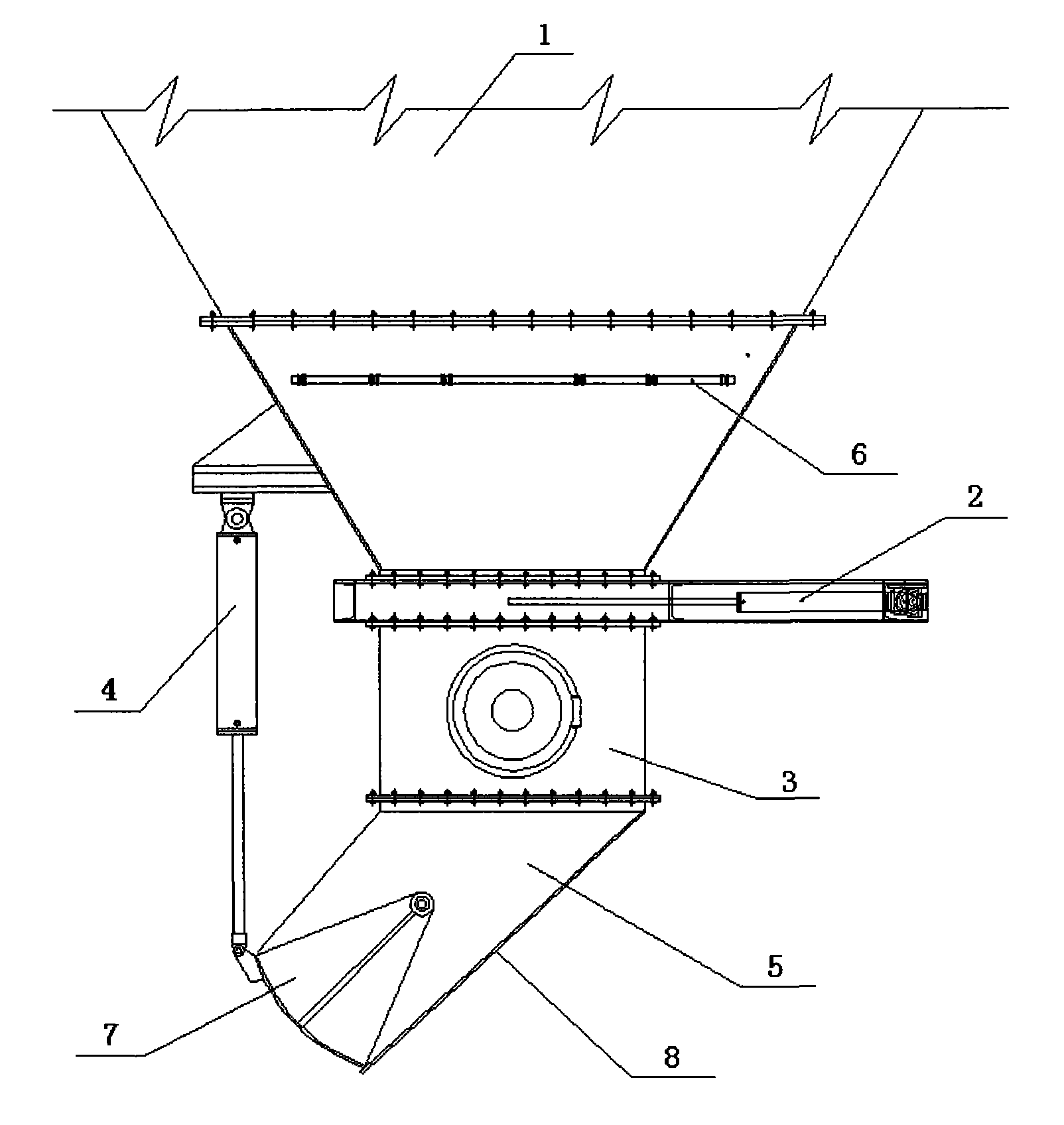

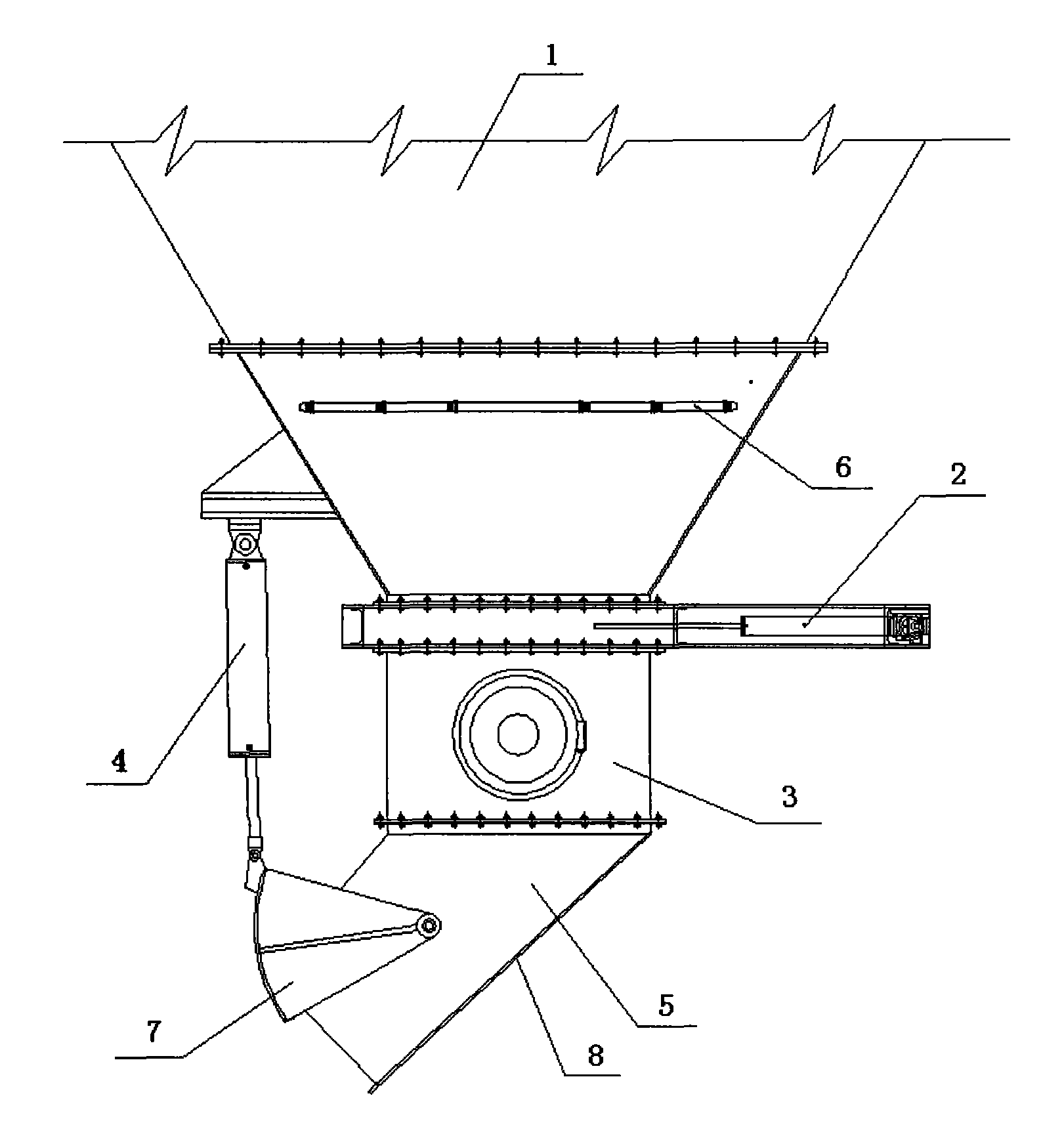

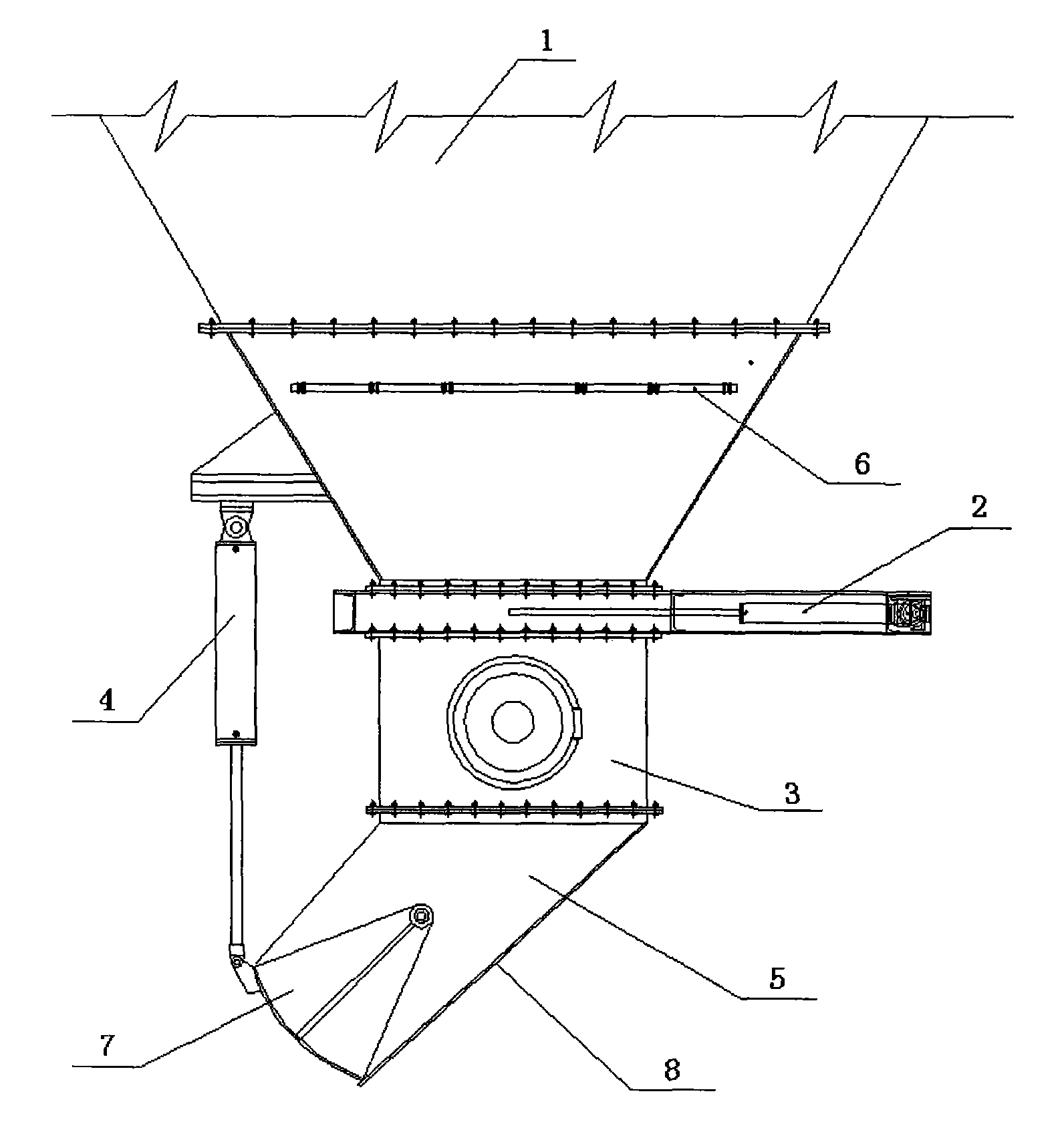

[0017] The present invention will be further described below in conjunction with accompanying drawing, so that structure and function of the present invention are better understood:

[0018] refer to figure 1 , figure 2 , an electro-hydraulic combined unloading device, comprising a material receiving bin 1, a material volume adjusting device 2, a spiral blanking cylinder 3, an electro-hydraulic push rod 4, a buffer chute cylinder 5, a humidifying and spraying device 6, a sector gate valve 7 and Protective layer 8, the described feed adjustment device is set 2 between the receiving bin 1 and the spiral feeding barrel 3; the described humidifying and spraying device 6 is arranged on the inner wall of the receiving bin 1 and connected The external waterway is connected, and the receiving bin 1 is box-shaped funnel-shaped; the buffer chute tube 5 is connected with the spiral blanking tube 3, and the axis line of the buffer chute tube 5 is connected with the spiral blanking tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com