Infiltration tank for cable processing and assembly line

A cable and groove technology, which is applied in the field of cable processing and application, can solve problems such as hidden dangers of cable waterproofing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The following is attached Figure 1-9 The application is described in further detail.

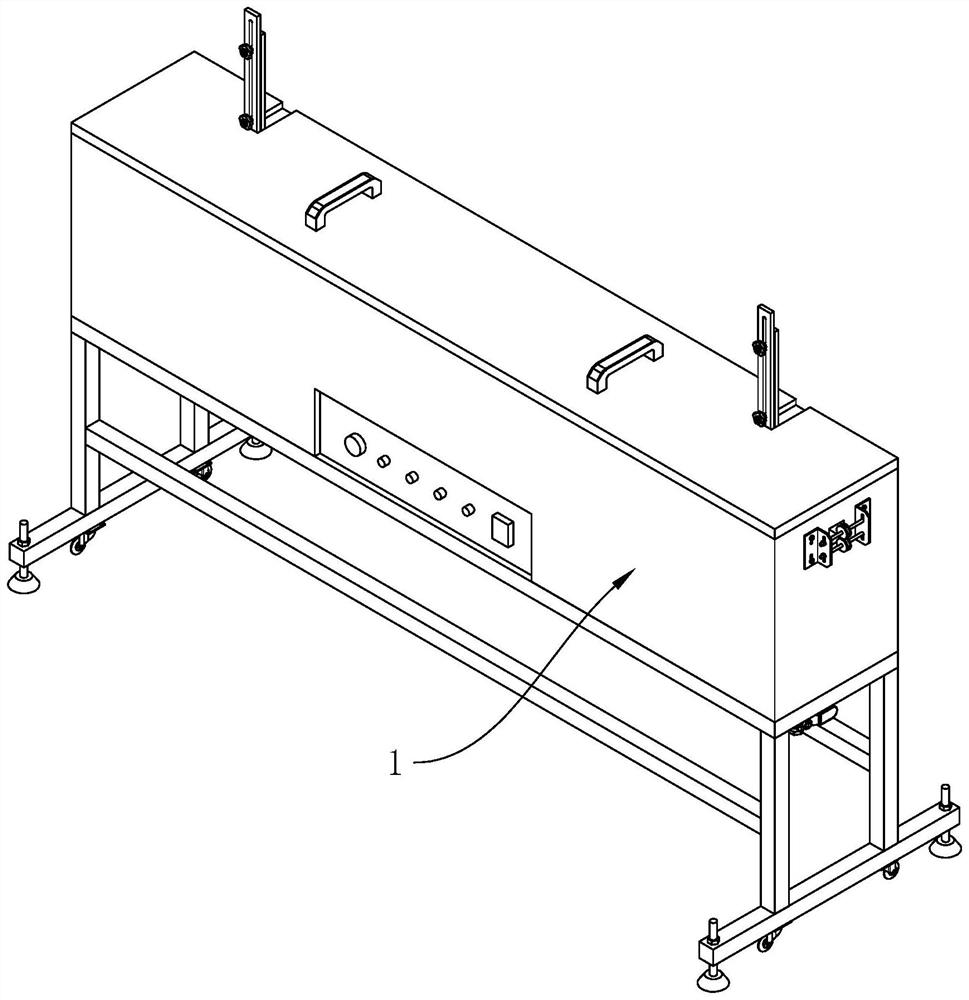

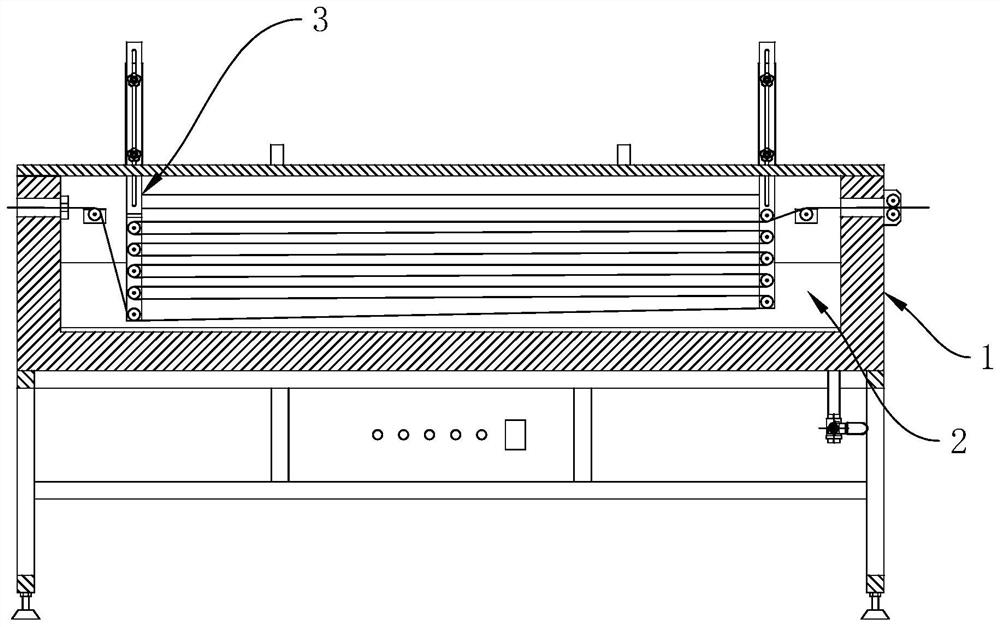

[0065] The embodiment of the present application discloses an infiltration tank for cable processing. refer to figure 1 and figure 2 , the infiltration tank 4 includes a tank body 1, a heating assembly 2 and a tensioning assembly 3; wherein, the tank body 1 is used to hold waterproof glue, the heating assembly 2 is used to heat the waterproof glue, and the tensioning assembly 3 is used to The cable core in the tank body 1 is continuously tensioned several times.

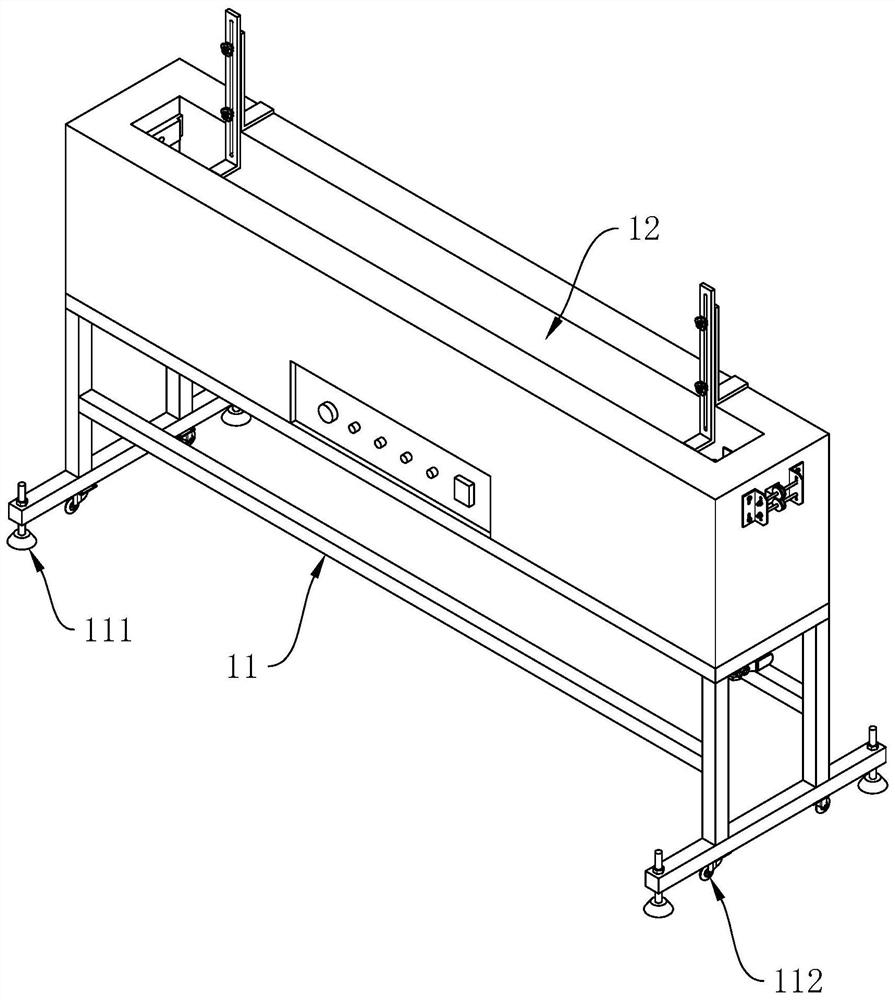

[0066] refer to image 3 and Figure 4 The tank body 1 includes a frame body 11 and a storage tank 12, the storage tank 12 is installed on the upper end of the frame body 11, and the lower end of the frame body 11 is provided with an adjustment foot 111 and a universal wheel 112, and the adjustment foot 111 is used to make The tank body 1 can maintain a horizontal and stable working state on the uneven bottom surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com