Fiber wound reinforced self-lubricating composite bearing and manufacturing method thereof

A technology of composite bearings and manufacturing methods, applied in the direction of carbon fiber, fiber type, fiber treatment, etc., can solve the problem of high cost, achieve high bearing capacity, good wear resistance, and ensure wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

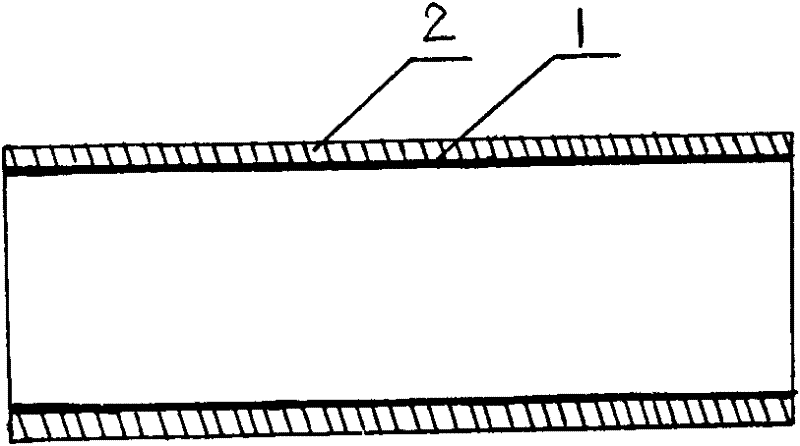

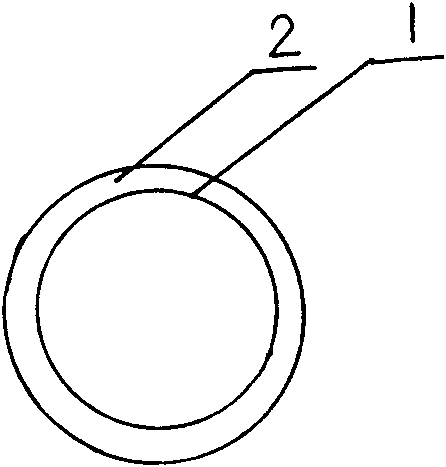

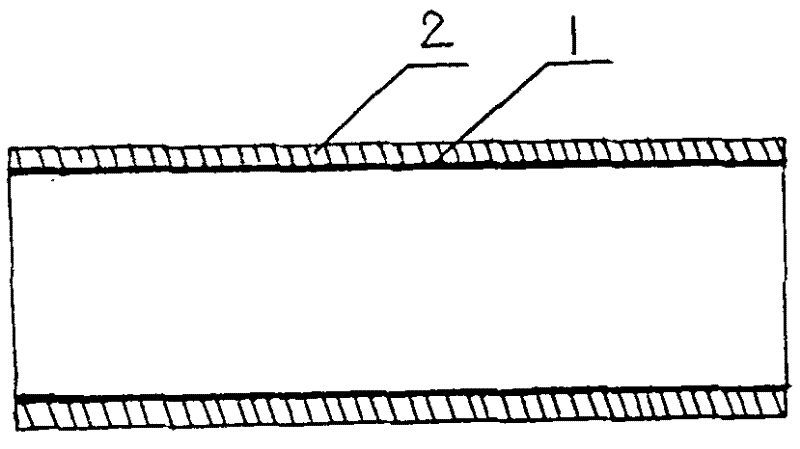

[0024] As shown in the figure, a wound fiber reinforced self-lubricating composite bearing of the present invention includes an inner winding layer 1 (bearing inner layer) and an outer winding layer 2 (backing layer), and its manufacturing method includes the following process steps:

[0025] 1. Preparation of resin glue.

[0026] Epoxy resin E44, methyltetrahydrophthalic anhydride (MeTHPA), 2-ethyl-4 methylimidazole, quartz sand, polyethylene glycol octylphenyl ether, γ-aminopropyltriethoxysilane (KH550 ) are weighed according to the ratio in the table below, and stirred with a high-speed stirrer. After being uniform, put it into the glue pool in the winding machine for use.

[0027] Component

Proportion (in parts by mass)

Epoxy resin E44

100

Methyltetrahydrophthalic anhydride (MeTHPA)

60

2-Ethyl-4 methylimidazole

1.0

Quartz sand

5

Polyethylene glycol octylphenyl ether

0.5

γ-Aminopropyltriet...

Embodiment 2

[0041] A method for manufacturing a fiber-wound reinforced self-lubricating composite bearing, comprising the following process steps:

[0042] 1. Preparation of resin glue.

[0043]Epoxy resin E51, hexahydrophthalic anhydride (HHPA), 2,4,6-tris(dimethylaminomethyl)phenol (DMP-30), molybdenum disulfide, nonionic siloxane copolymer ( Troysol S366), γ-glycidyl etheroxypropyl trimethoxysilane (KH560), weighed according to the ratio in the table below, and stirred with a high-speed stirrer. use.

[0044] Component

Proportion (in parts by mass)

Epoxy resin E51

100

Hexahydrophthalic anhydride (HHPA)

90

2,4,6-tris(dimethylaminomethyl)phenol (DMP-30)

4.0

Molybdenum disulfide

15

Non-ionic siloxane copolymer (Troysol S366)

1.5

γ-Glycidyloxypropyltrimethoxysilane (KH560)

0.5

[0045] 2. Mandrel preparation.

[0046] Before winding, the mandrel is polished and cleaned to ensure the surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com