Fiber reinforced resin matrix self-lubricating compound sliding bearing and manufacturing method thereof

A technology of fiber-reinforced resin and sliding bearings, which is applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of high material cost and unsuitability for application, and achieve the effect of good self-lubricating performance, low cost, and guaranteed smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

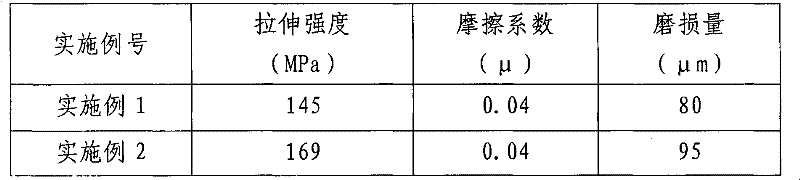

[0023] Embodiment 1 The manufacturing method of fiber-reinforced resin-based self-lubricating composite sliding bearing, comprising the following process steps:

[0024] 1. Preparation of epoxy resin glue: epoxy resin E44, methyltetrahydrophthalic anhydride (MeTHPA) (curing agent), 2-ethyl-4-methylimidazole (curing accelerator), quartz sand (filler), poly Ethylene glycol octyl phenyl ether (wetting agent for organic auxiliaries) and γ-aminopropyltriethoxysilane (KH550) (coupling agent for organic auxiliaries) are weighed according to the following table, using high-speed stirring Stir it with the machine, and after it is uniform, put it into the glue pool in the winding machine and wait for it to be used.

[0025] Product Category

Proportion (in parts by mass)

epoxy resin E44

100

Methyltetrahydrophthalic anhydride (MeTHPA)

60

2-Ethyl-4-methylimidazole

1.0

Quartz sand

10

polyethylene glycol octyl phenyl et...

Embodiment 2

[0032] Embodiment 2 The manufacturing method of fiber-reinforced resin-based self-lubricating composite sliding bearing, comprising the following process steps:

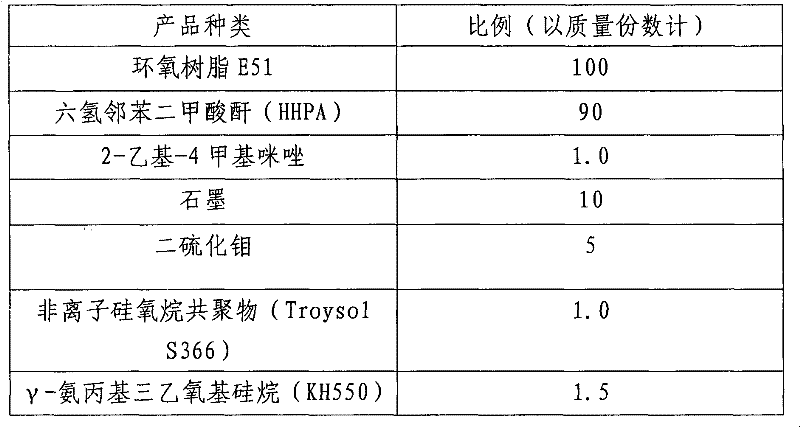

[0033] 1. Preparation of epoxy resin glue: epoxy resin E51, hexahydrophthalic anhydride (HHPA) (curing agent), 2-ethyl-4-methylimidazole (curing accelerator), graphite (filler), Molybdenum disulfide (filler), nonionic siloxane copolymer (Troysol S366) (wetting agent for organic auxiliaries) and γ-aminopropyltriethoxysilane (KH550) (coupling agent for organic auxiliaries) Weigh it according to the following table, stir it with a high-speed mixer, and after it is uniform, put it into the glue pool in the winding machine for use.

[0034]

[0035] 2. Prepare the mandrel: grind and clean the mandrel; apply dimethyl silicone oil on the outer surface of the mandrel.

[0036] 3. Preparation of bearing inner layer material: After mechanical mixing of suspended self-lubricating polytetrafluoroethylene (PTFE) resin powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com