Patents

Literature

80results about How to "Guaranteed wettability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-temperature conductive silver paste for HIT solar cell and preparation method thereof

ActiveCN110136863AGood flexibilityImprove anti-agingNon-conductive material with dispersed conductive materialPhotovoltaic energy generationSilver pasteOrganic solvent

The invention discloses a low-temperature conductive silver paste for an HIT solar cell and a preparation method thereof. The low-temperature conductive silver paste for the HIT solar cell is preparedby the following components including, by weight, 27 to 46 Parts of flake silver powder, 46 to 65 parts of spherical silver powder, 1.5 to 3.5 parts of thermosetting resin, 0.5 to 1.5 parts of reactive diluents, 2 to 4 parts of organic solvents, 0.65 to 0.75 part of curing agent, 0.05 to 0.15 part of imidazole curing accelerator, 0.35 to 0.45 part of dispersing agent, 0.01 to 0.6 parts of thixotropic agent, 0 to 2.4 parts of epoxy toughening agents and 0.5 to 1.5 parts of polymers, and the total composition is 100 parts. The low-temperature conductive silver paste prepared by using the formula of the invention can form a bond with a substrate and has good wettability to the substrate, therefore, the filling factor of the solar cell is improved, and the photoelectric conversion efficiencyof the solar cell is improved.

Owner:NANTONG T SUN NEW ENERGY CO LTD

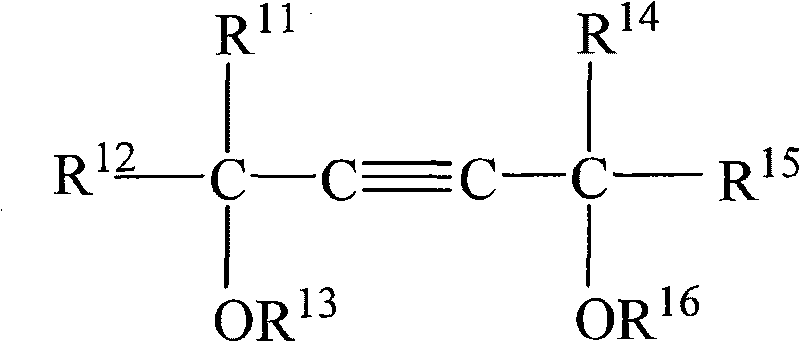

Adhesive for polarizing plate, polarizing plate, manufacturing method therefor, optical film and image display

ActiveCN101692133AUneven suppressionIncrease production capacityNon-macromolecular adhesive additivesSynthetic resin layered productsTectorial membranePolyvinyl alcohol

To provide an adhesive agent for a polarizing plate capable of satisfying a wetting property when a transparent protection film is coated with it and satisfying an optical characteristic, in which the obtained polarizing plate has water-resistance at a high temperature. The adhesive agent for the polarizing plate used for providing the transparent protection film on at least one surface of a polarization element is a resin solution containing a polyvinyl alcohol based resin, a crosslinking agent and a leveling agent containing a compound having an acetylene skeleton. The leveling agent is formulated at a ratio of 0.01-10 pts.wt. relative to 100 pts.wt. of the polyvinyl alcohol based resin.

Owner:NITTO DENKO CORP

Double-component epoxy structural adhesive and preparation method thereof

InactiveCN102408861AThixotropicImpact resistantNon-macromolecular adhesive additivesEpoxy resin adhesivesGlass fiberPolymer science

The invention provides a double-component epoxy structural adhesive and a preparation method thereof. The structural adhesive is prepared from a component A and a component B in a weight ratio of 1:1, wherein the component A comprises 100 parts by weight of modified bisphenol A epoxy resin and 40-100 parts by weight of active filler; and the component B comprises 30-40 parts by weight of modified fatty amine, 10-25 parts by weight of toughener, 1.5-5 parts by weight of coupling agent and 75-140 parts by weight of thixotropic filler. The double-component epoxy structural adhesive is curable at normal temperature, can be cured quickly at moderate temperature, and can be completely cured at 80 DEG C within 1 hour or at 100 DEG C within half an hour. The adhesive has thixotropy, and the adhesive liquid does not flow when being cured at normal temperature and raised temperature; and the double-component epoxy structural adhesive has the advantages of shock resistance, vibration resistance and high bonding strength, and has favorable effects on bonding glass fiber reinforced plastics, steel, aluminum and other metal profiles.

Owner:BEIJING QINGDA SUNKIST NEW MATERIAL TECH

Environment-friendly bulk coal overlapping restrainer and method of producing the same

InactiveCN101429421AWith bondingWith thickeningOther chemical processesCarboxymethyl celluloseOrganic matter

The invention discloses an environment-friendly type separate coal covering inhibitor, which comprises the following components in weight percentage: 0.05 to 2.00 percent of carboxymethyl cellulose, 0.50 to 2.50 percent of glycerin, and the balance being water. The invention also provides a method for preparing the environment-friendly type separate coal covering inhibitor. The preparation method comprises the followings steps: a reaction kettle is added with water accounting for 80 percent of total water quantity, added with the carboxymethyl cellulose, started to be stirred, added with the glycerin when the carboxymethyl cellulose is completely dissolved, evenly stirred, added with the remained water accounting for 20 percent of total water quantity, and evenly stirred so as to obtain the finished product. The inhibitor has reasonable formula and is easy to purchase; because the materials are organic matters, the inhibitor does not affect the fuel value of coal after spraying; moreover, the inhibitor also has the advantages of low cost, convenient use, obvious dustlaying and loss prevention effects, obvious economic and ecological benefits, simple production process, no secondary pollution during processing and using, safe use and no toxic and side effects.

Owner:XIAN UNIV OF SCI & TECH

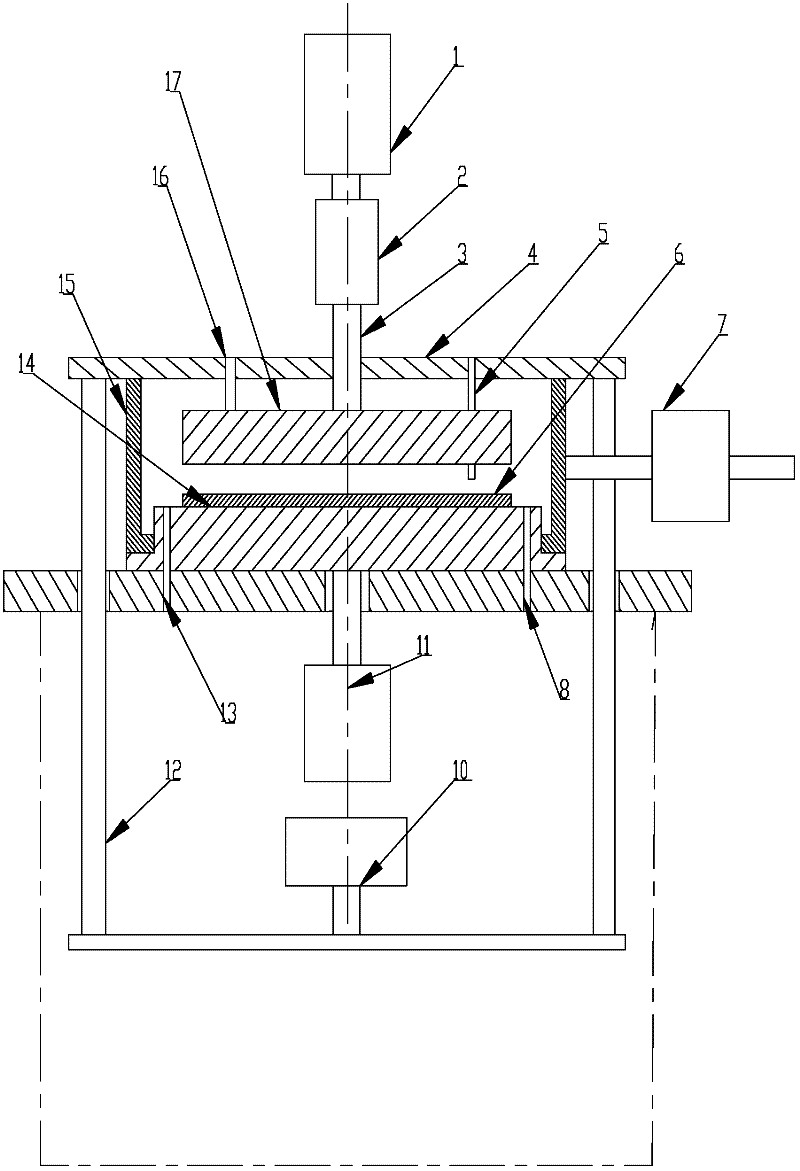

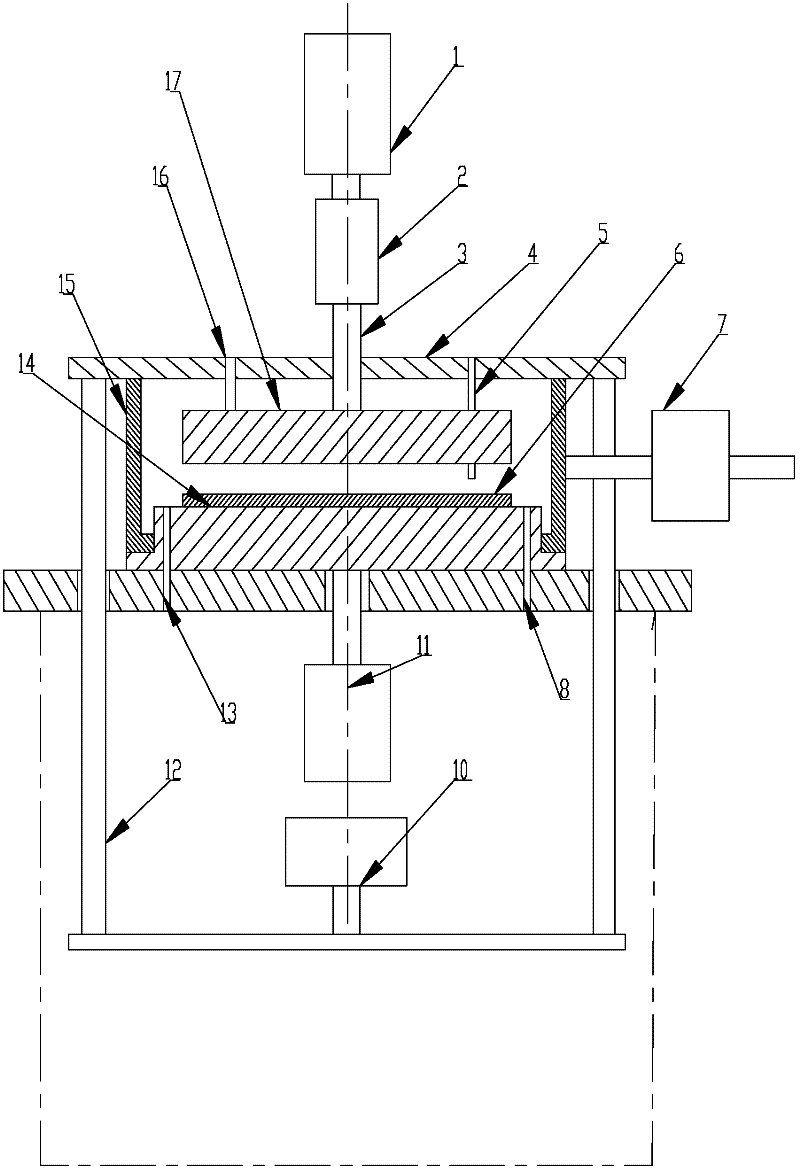

Eutectic welding machine for die bonding of LED (Light Emitting Diode) chip

ActiveCN102522348AImprove directivityReduce heat damageSemiconductor/solid-state device manufacturingSemiconductor devicesResonanceHeat conducting

The invention relates to a eutectic welding machine for die bonding of an LED (Light Emitting Diode) chip. The eutectic welding machine comprises a eutectic tray on which a step motor feeding mechanism capable of driving the eutectic tray to move horizontally is arranged, a target heating plate which is arranged below the eutectic tray and on which a heating plate drive cylinder used for driving the target heating plate to cling to the bottom of the eutectic tray is arranged, a sealing flat plate which is arranged above the eutectic tray, is connected with a sealing flat plate cylinder and is tightly combined with the upper end of the eutectic tray under the driving effect of the sealing flat plate cylinder to form a sealed cavity body, a chip compacting heat-conducting plate which is arranged in the sealed cavity body and is provided with a temperature sensor, a resonance energy conversion assembly which is connected with the chip compacting heat-conducting plate and is provided with a resonance cylinder, and an air pipeline assembly communicated with the inner part and the outer part of the sealed cavity body. Compared with the prior art, the eutectic welding machine for the die bonding of the LED chip has the advantages of good eutectic welding interface wettability, stable welding quality, small heating temperature balance error and the like.

Owner:SHANGHAI GONGJING ELECTRONICS TECH

Acid surface active agent oil well leaking stoppage technology and its formula

The invention relates to a technique used acidity surfactant to remove oil well blocking and its formula and manufacturing method. The feature of the acidity surfactant formula is that its material weight ratio is as follows: polyoxy propylene-polyoxy ethylene glycerin ether 10-40%, polyoxy propylene-polyoxy ethylene phenol amine resin 10-45%, FC-NO1 fluorocarbon surfactant 0.0001%-0.035%, FC-3B fluorocarbon surfactant 0.0001%-0.05%, hydrochloric acid 3-10%, nitric acid 2-10%, and water 30-55%. The feature of the technique is as follows: the made-up 0.4%-0.6% acidity surfactant can be injected from hollow while running; then it can be replaced by 10-20m3 clear water. The invention has good effect and can improve yield.

Owner:PETROCHINA CO LTD

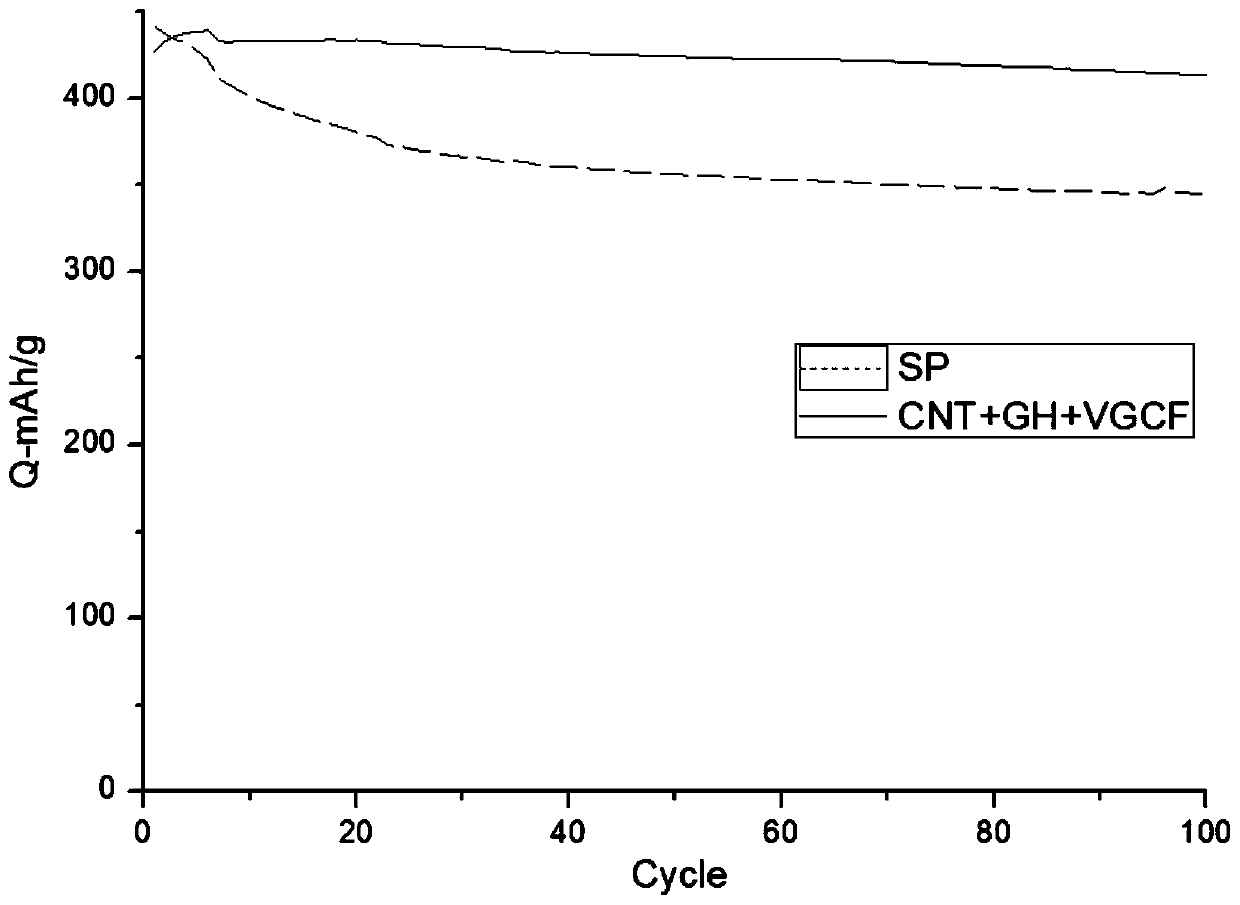

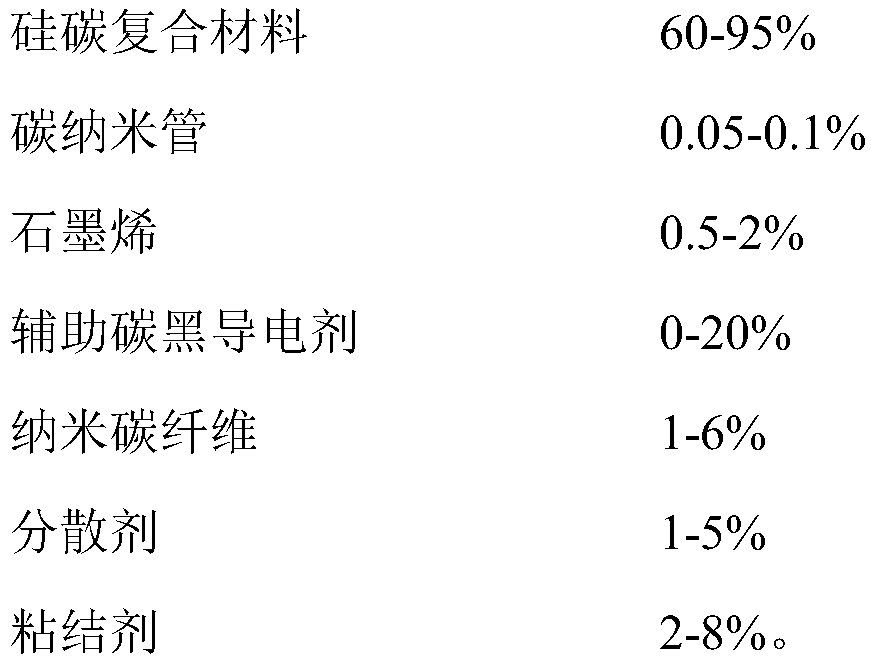

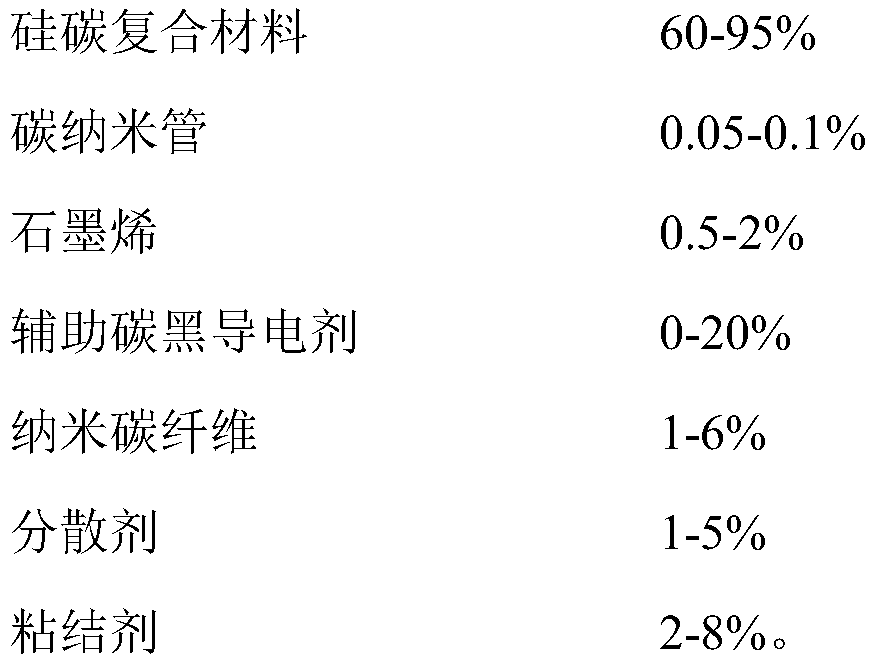

Lithium ion battery silicon-carbon composite negative electrode material composite conductive agent, negative electrode plate and preparation method of negative electrode plate

InactiveCN111244455AImprove performanceAvoid reunionSecondary cellsNegative electrodesCarbon compositesCarbon nanofiber

The invention discloses a lithium ion battery silicon-carbon composite negative electrode material composite conductive agent, a negative plate and a preparation method of the negative plate. In termsof mass percentage, the composite conductive agent comprises the following solid components: 60-95% of a silicon-carbon composite material, 0.05-0.1% of carbon nanotubes, 0.5-2% of graphene, 0-20% ofan auxiliary carbon black conductive agent, 1-6% of carbon nanofibers, 1-5% of a dispersing agent and 2-8% of a binder. The invention also discloses a negative plate of the composite conductive agentand a preparation method of the negative plate. The lithium ion battery using the silicon-carbon composite negative electrode material composite conductive agent for the lithium ion battery providedby the invention is low in impedance and long in cycle life; and the overall performance of the lithium ion battery is greatly improved, the long-time use requirements of electronic products can be met, the market application prospect of products of battery manufacturers can be improved, and the important production practice significance exists.

Owner:SHANGHAI ELECTRICGROUP CORP

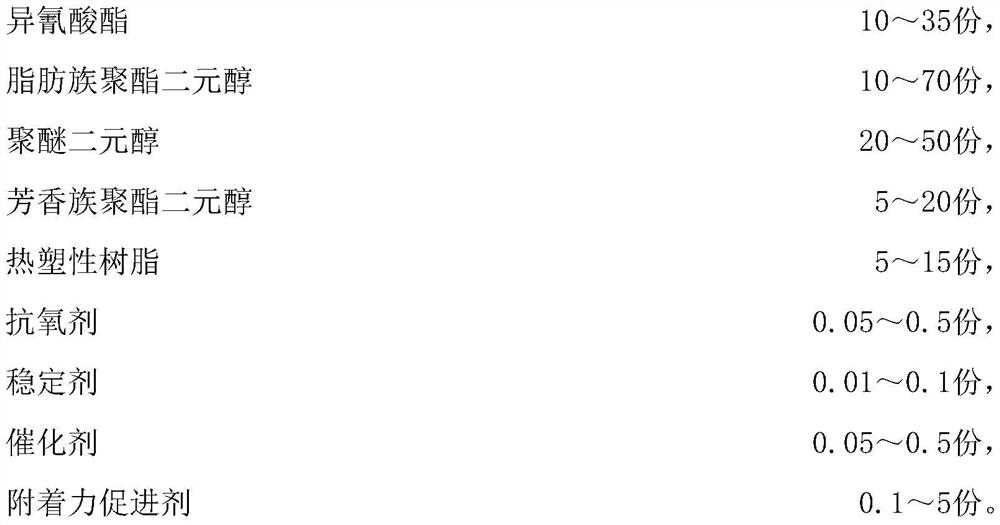

Reactive polyurethane hot melt adhesive for bonding aluminum plate and wood veneer and preparation method of reactive polyurethane hot melt adhesive

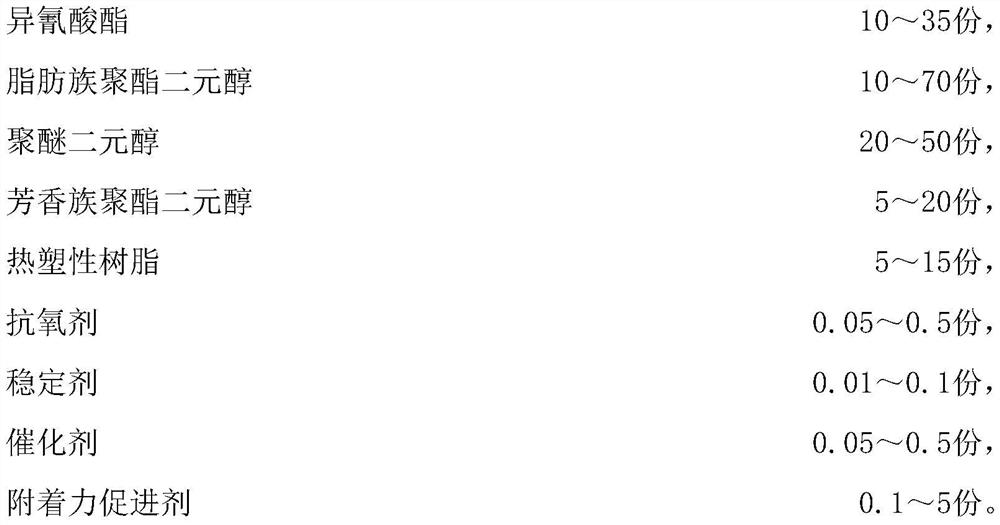

InactiveCN111662671AMeet bonding needsReduce dosageNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterWood veneer

The invention discloses a reactive polyurethane hot melt adhesive for bonding an aluminum plate and a wood veneer and a preparation method of the reactive polyurethane hot melt adhesive. The reactivepolyurethane hot melt adhesive is prepared from the following raw materials in parts by weight: 10-35 parts of isocyanate, 10-70 parts of aliphatic polyester diol, 20-50 parts of polyether diol, 5-20parts of aromatic polyester diol, 5-15 parts of thermoplastic resin, 0.05-0.5 part of an antioxidant, 0.01-0.1 part of a stabilizer, 0.05-0.5 part of a catalyst and 0.1-5 parts of an adhesion promoter. The adhesive has high initial adhesion and good later adhesion, can meet the adhesion requirement of an aluminum plate and a wood veneer, and can improve the working efficiency in the adhesion process.

Owner:BEIJING COMENS NEW MATERIALS

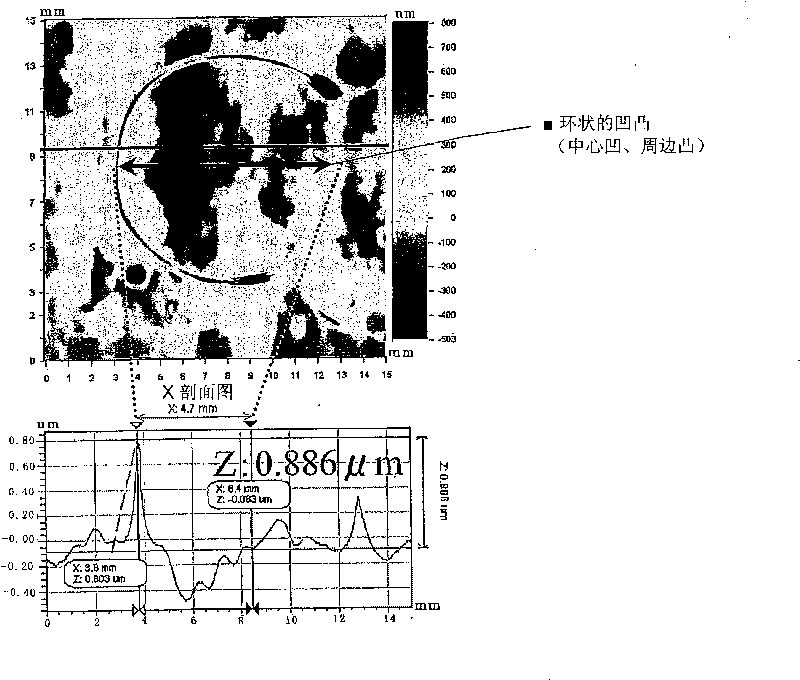

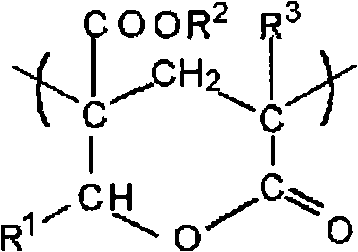

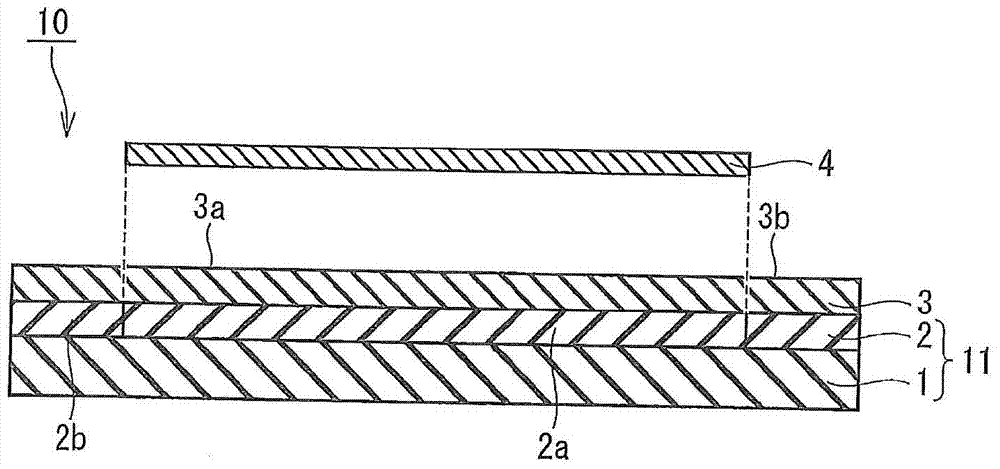

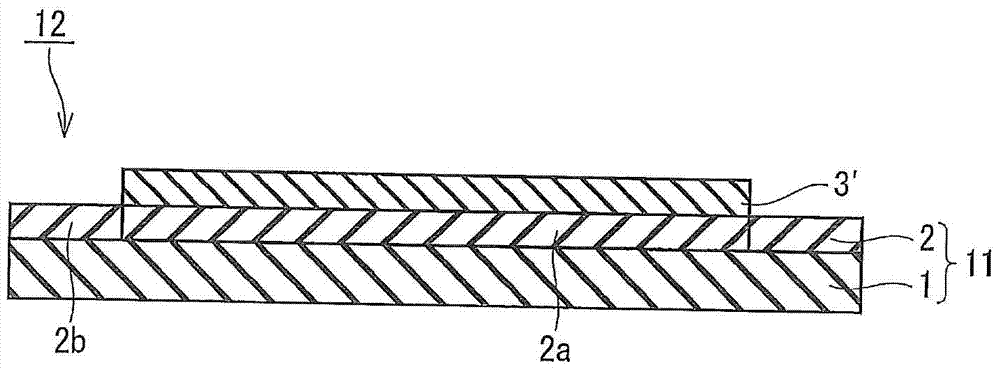

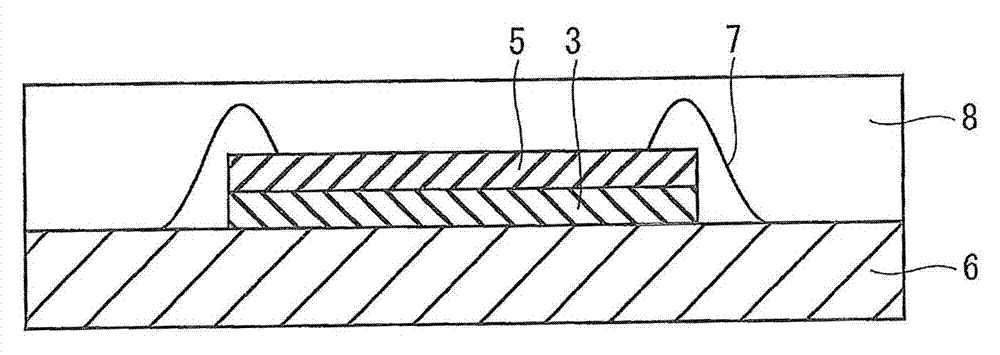

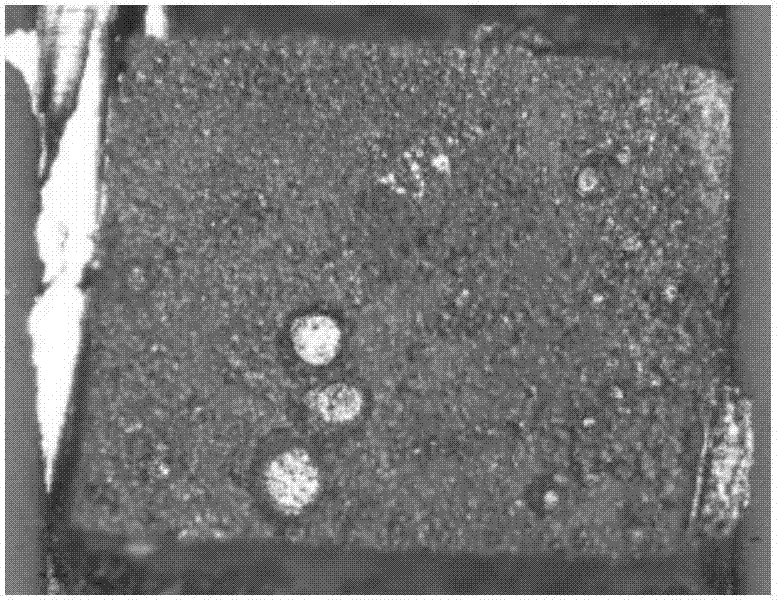

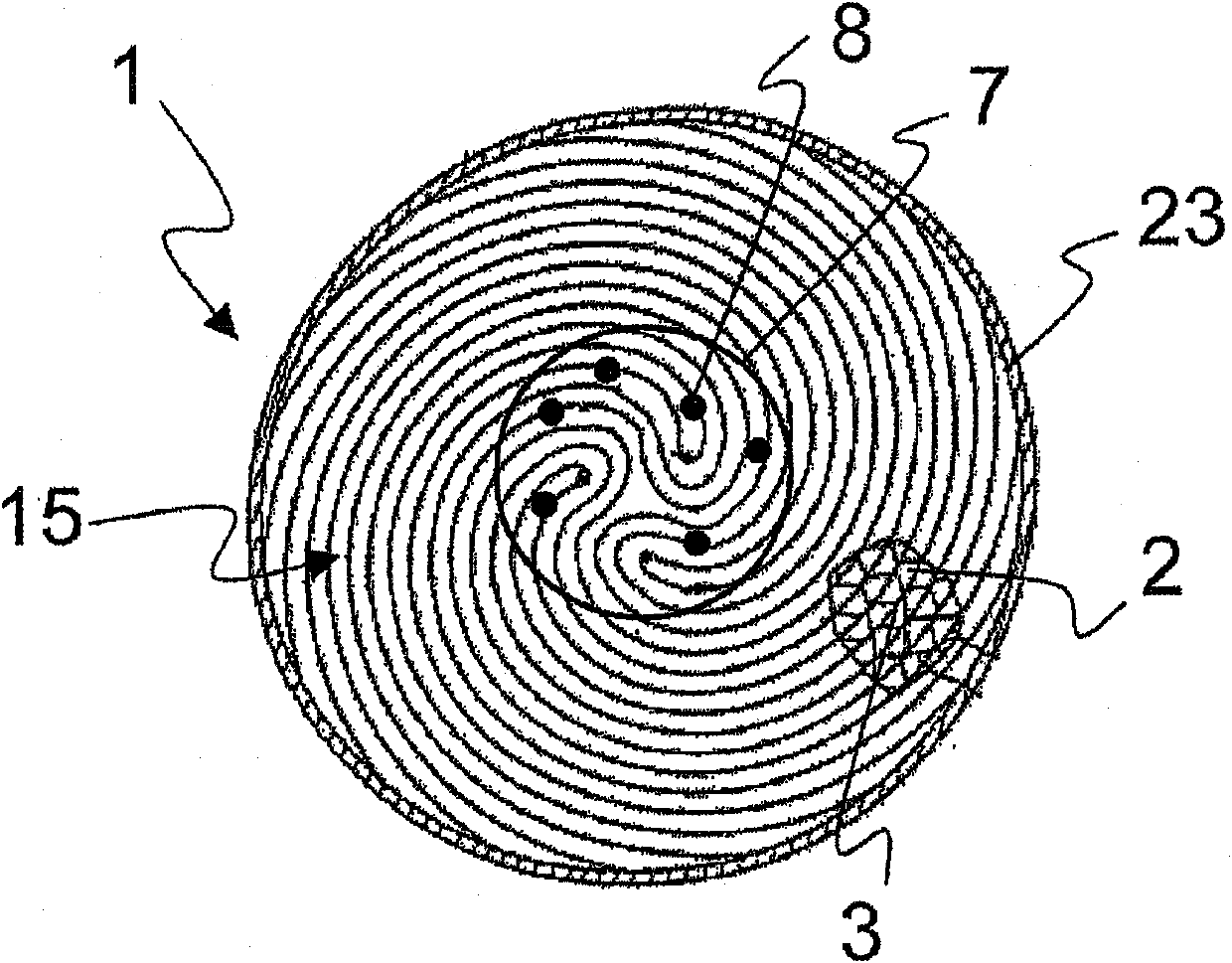

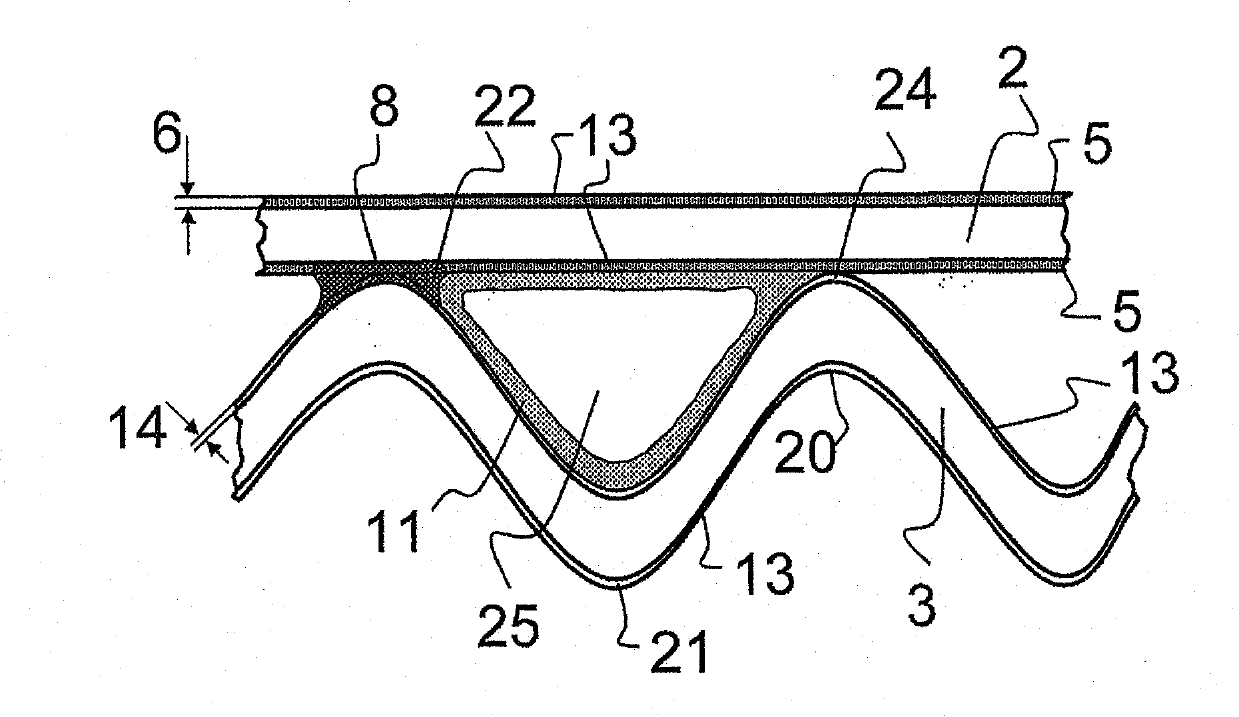

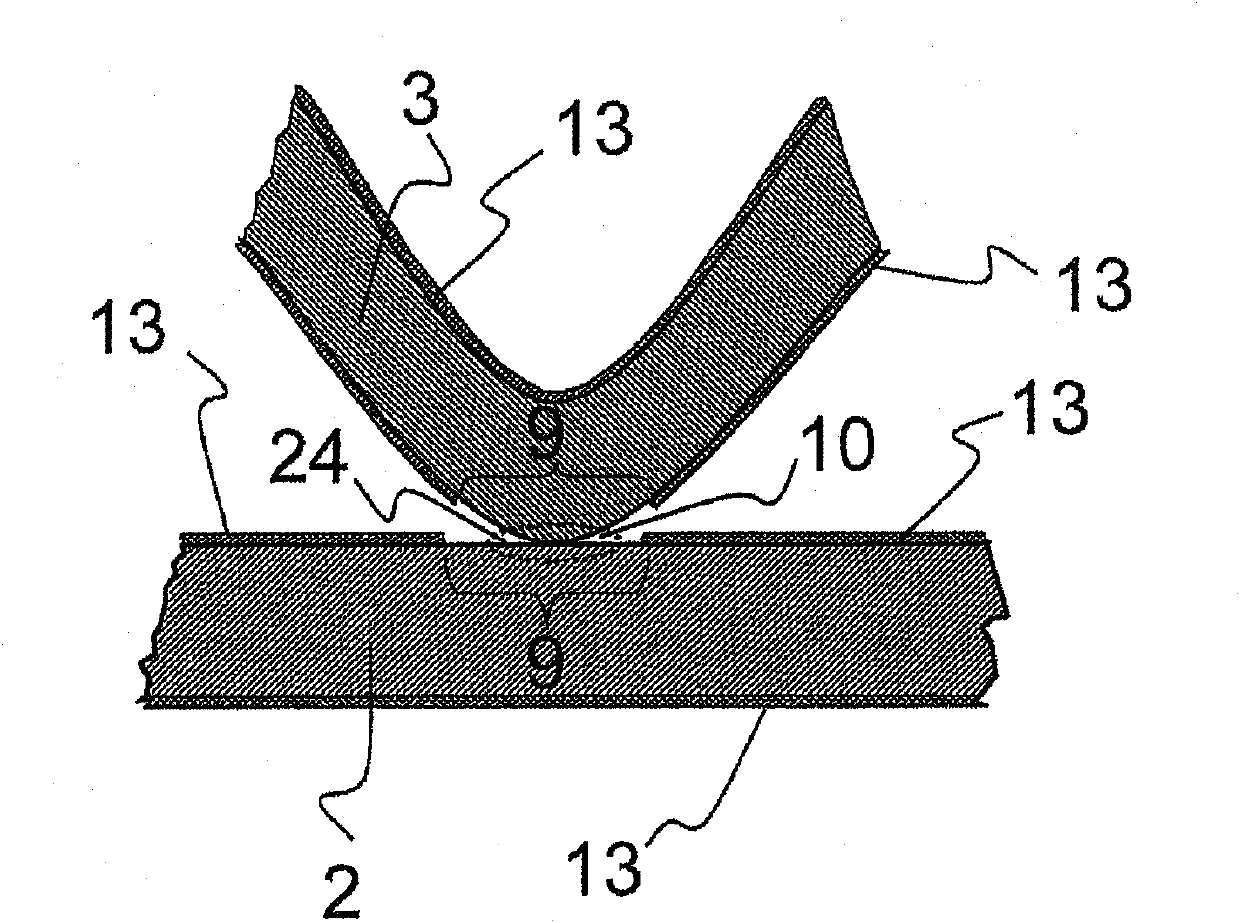

Thermosetting chip bonding film, chip bonding film with cutting disc, and manufacturing method of semiconductor device

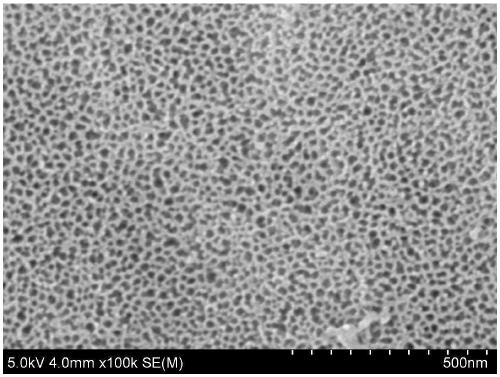

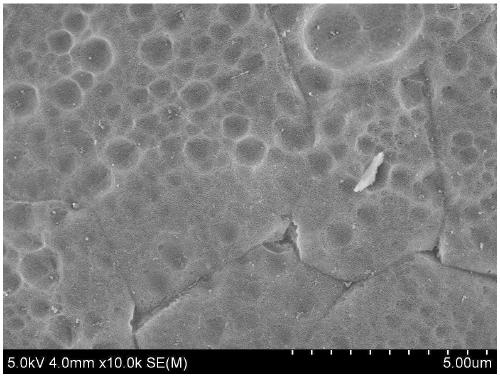

InactiveCN104212369AGuaranteed wettabilityGood adhesionFilm/foil adhesivesSemiconductor/solid-state device detailsMelt viscosityEngineering

The invention provides a thermosetting chip bonding film, a chip bonding film with a cutting disc, and a manufacturing method of a semiconductor device. The thermosetting chip bonding film is advantaged by high heat conductivity, and can be fully attached to the concave and convex shape of an adherend when attached to the adherend. The heat conductivity coefficient of the thermosetting chip bonding film is above 1W / mK after being thermosured, the thermosetting chip bonding film contains heat conductive particles with the heat conductivity coefficient of 12W / mK and above 75% of the integral weight relative to the thermosetting chip bonding film, and the detected melt viscosity of the thermosetting chip bonding film is below 200 PaS with the cutting rate of 50 sec-1 at a temperature of 130 DEG C.

Owner:NITTO DENKO CORP

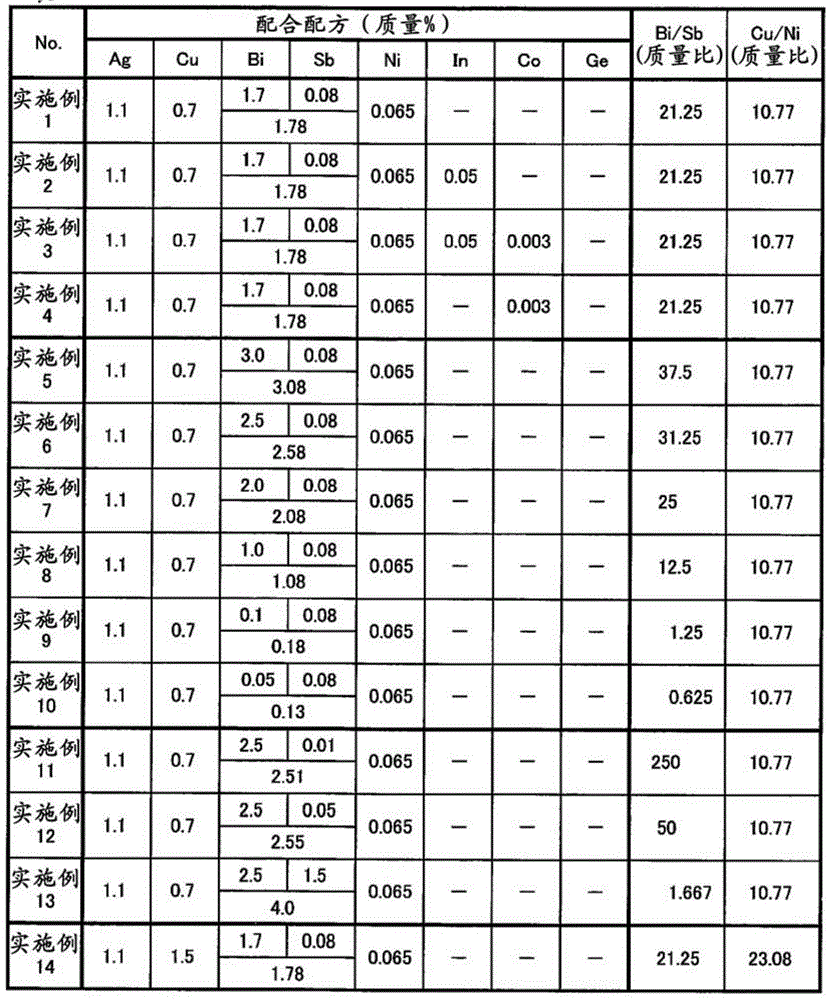

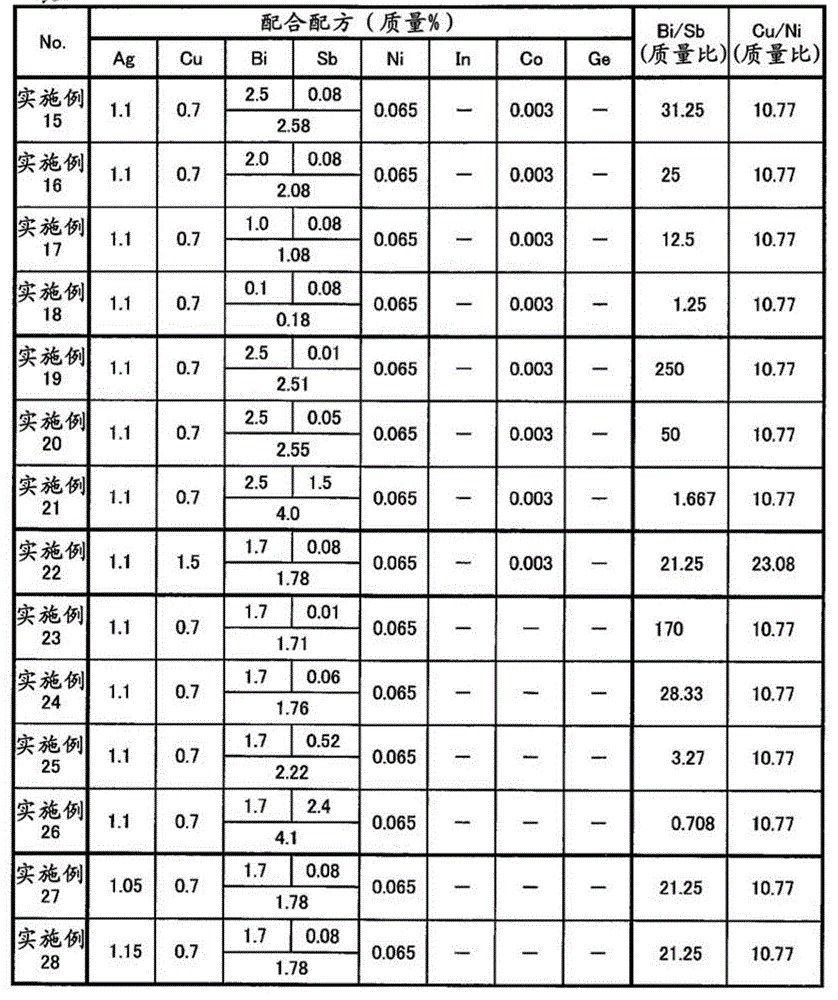

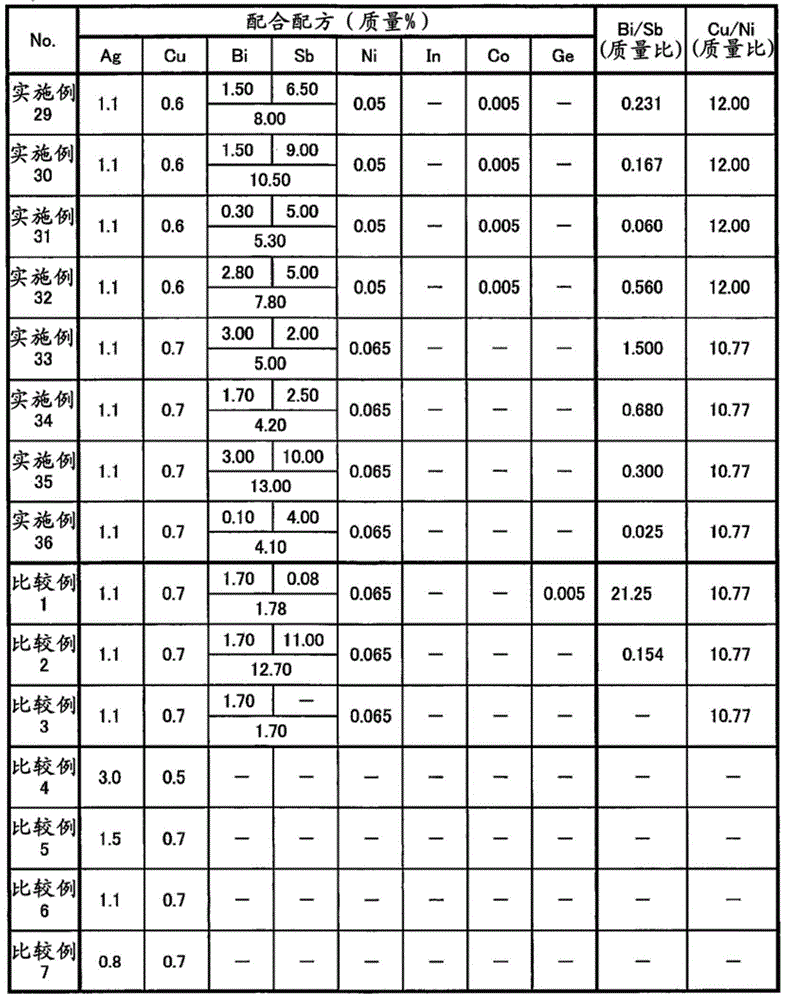

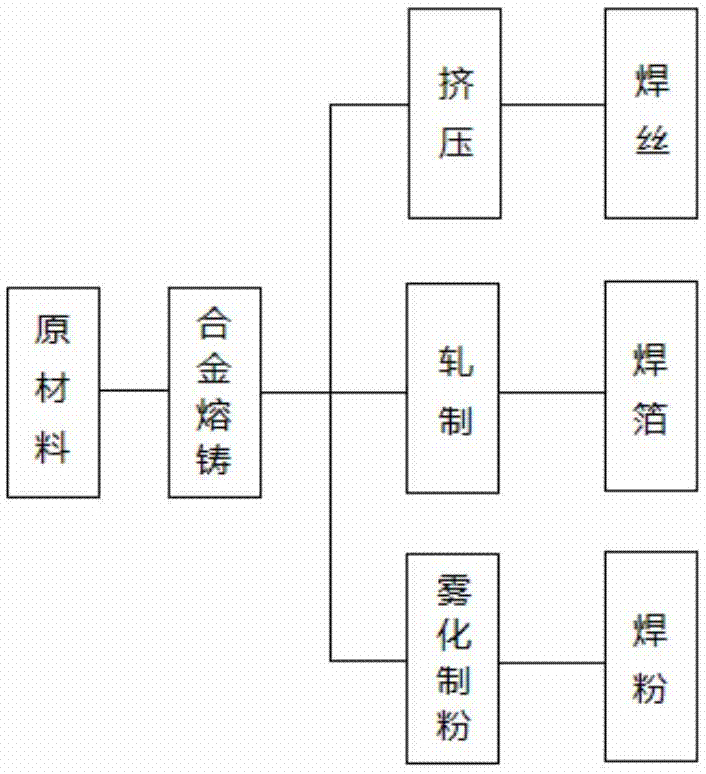

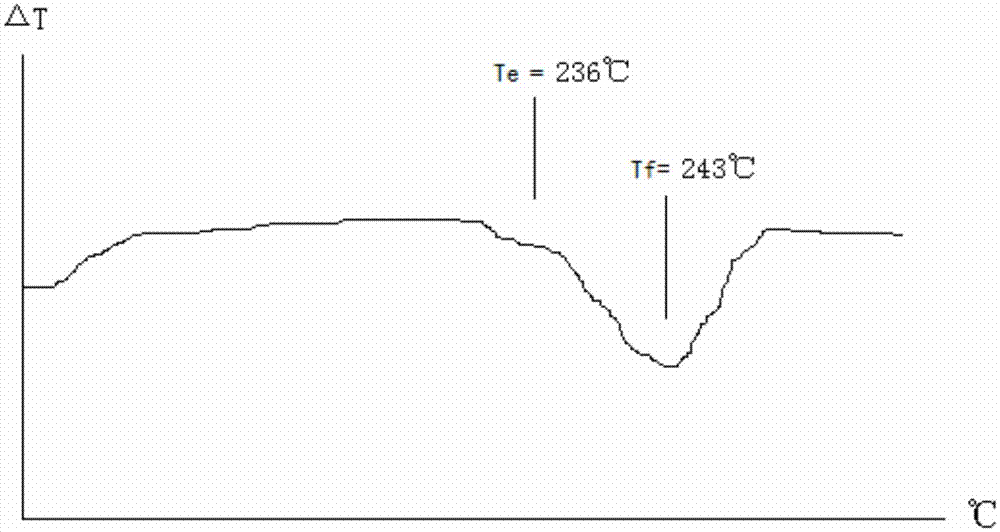

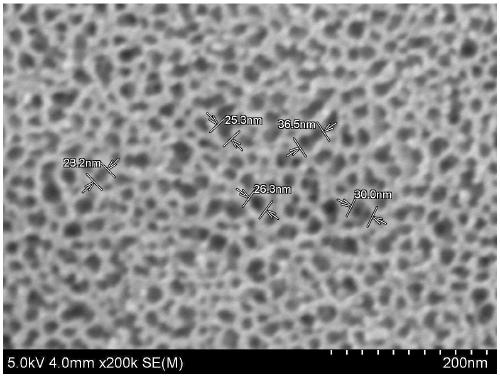

Solder alloy, solder paste, and electronic circuit board

InactiveCN104487203AContains a low proportionLow costPrinted circuit assemblingPrinted circuit detailsTin-silver-copperCopper

This solder alloy is a tin-silver-copper-based solder alloy, contains tin, silver, antimony, bismuth, copper, and nickel, essentially does not contain germanium, and with respect to the total quantity of solder alloy, has a silver content of 1.0-1.2 mass% exclusive, an antimony content of 0.01-10 mass% inclusive, and a bismuth content of 0.01-3.0 mass% inclusive.

Owner:HARIMA CHEM INC

Method for preparing refractory brick in isostatic compaction mode

The invention belongs to the field of refractory materials, and provides a method for preparing a refractory brick in an isostatic compaction mode. The method provided by the invention comprises the steps of composition of raw materials, preparation of sludge and formation of the refractory brick. The refractory brick is prepared from the following raw materials in percentage by mass: 45-65% of particle material with the particle size of 0.1-3mm, and 35-55% of matrix fine powder with the particle size of less than 0.044mm. The refractory brick is also additionally prepared from a binder, wherein the binder comprises a solid binder and water. The method comprises the following steps: stirring the particle material and solid binder in a runner wheel machine so that the solid binder is uniformly distributed in the particle material, adding the water, milling together, finally adding the matrix fine powder, and milling to obtain the sludge; and directly adding the sludge into a mold, and forming. The method shortens the sludge preparation period and production cost, is simple to operate, and has the characteristic of high yield.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Surface modification method for diamond micropowder for ultra-fine diamond wire saw

The invention discloses a surface modification method for diamond micropowder for an ultra-fine diamond wire saw and belongs to the technical field of diamond micropowder production. By the adoption of the surface modification method for the diamond micropowder for the ultra-fine diamond wire saw, the problems that in the prior art, diamond micropowder is poor in dispersity and prone to accumulation and agglomeration are solved. The surface modification method comprises the following steps that (1) the diamond micropowder subjected to chemical plating is calcinated; (2) the calcinated diamond micropowder is pickled for activation through composite acid, and filtration and deacidification are conducted after activation; (3) dispersing treatment is conducted on the deacidified diamond micropowder through a cationic surface active agent; and (4) the dispersed diamond micropowder and the cationic surface active agent are added into electroplate liquid and evenly stirred and dispersed for later use. The surface modification method is suitable for surface modification of the diamond micropowder for the ultra-fine diamond wire saw.

Owner:山东山田新材科研有限公司 +1

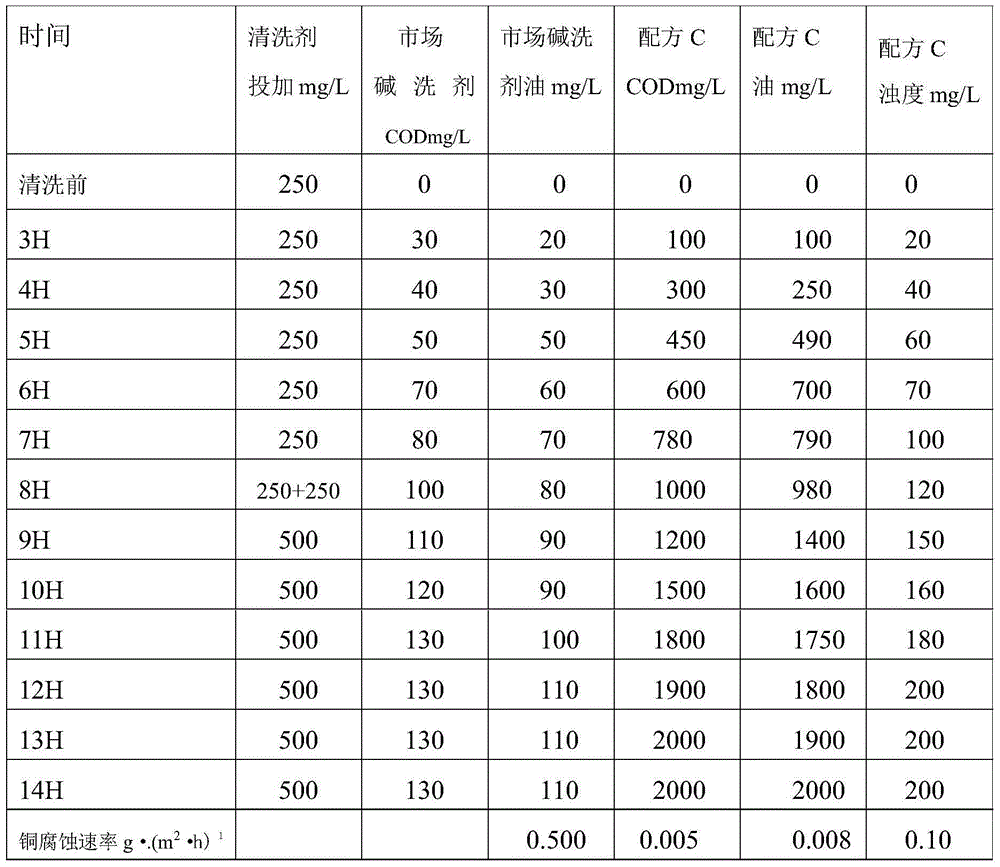

Efficient detergent used in industrial circulating water and preparation method of efficient detergent

InactiveCN104357260AWettability hasImprove decontamination abilitySurface-active non-soap compounds and soap mixture detergentsManufacturing technologyCleansing Agents

The invention belongs to the technical field of design and manufacturing of chemical products and particularly relates to an efficient detergent used in industrial circulating water and a preparation method of the efficient detergent. The detergent is prepared from the following materials in parts by weight: 5-10 parts of polyoxyethylene fatty alcohol ether, 4-6 parts of polyoxyethylene octyl phenolic ether, 5-8 parts of triethanolamine oleate soap, 15-20 parts of isopropyl alcohol, 5-10 parts of trisodium phosphate, 2-4 parts of sodium tripolyphosphate, 3-5 parts of sodium carbonate, 3-5 parts of sodium hydroxide, 10-15 parts of sodium dodecylbenzenesulfonate and 35-48 parts of tap water. The preparation method comprises the step of synthesizing the materials under a certain condition. The efficient detergent is mainly used for cleaning an oil cooler in the industrial circulating water.

Owner:新疆水处理工程技术研究中心有限公司

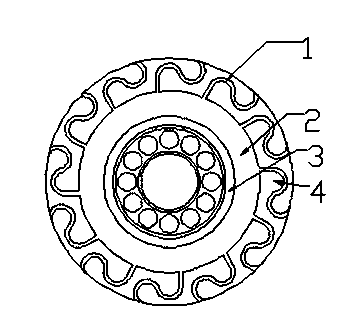

Self-lubricating wirerope guide wheel

The invention relates to a self-lubricating wirerope guide wheel which comprises a rolling outer frame and a rotary shaft installation hole, wherein the rolling outer frame is used for dragging a wirerope and the rotary shaft installation hole is formed in the middle of the guide wheel. The guide wheel further comprises an oil storage cavity and oil leakage grooves, the oil storage cavity is arranged between the rolling outer frame and the rotary shaft installation hole, the oil leakage grooves are formed in the rolling outer frame and used for communicating the oil storage tank and a groove-shaped seam in the outer wall of the rolling outer frame, the number of the oil leakage grooves is at least two, and the oil leakage grooves are distributed in an annular array relative to the center of the guide wheel. By means of centrifugal force during rotation of the guide wheel and siphon force of the oil leakage grooves, lubricating oil can leak to the wirerope through the oil leakage grooves, the effect of preventing the wirerope from rusting is achieved, certain lubrication is provided, and good economic benefits and social benefits are achieved.

Owner:NANTONG WEIMING FINISHING MACHINERY

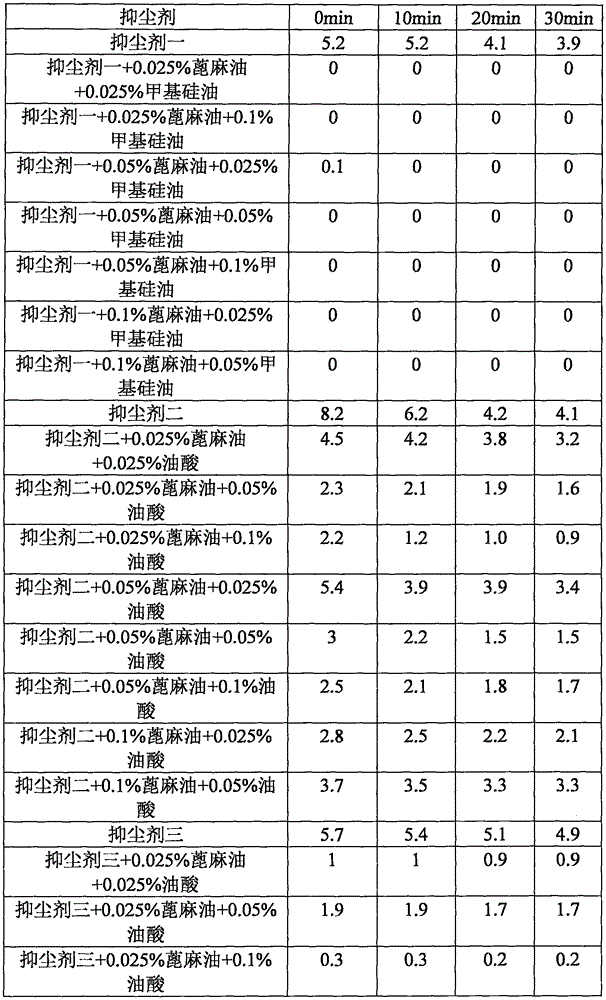

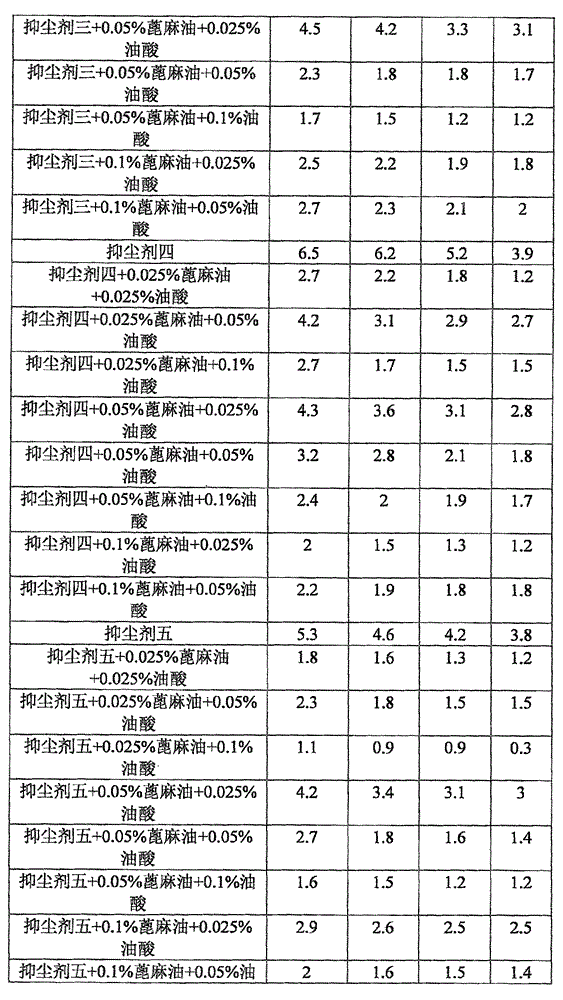

Antifoaming dust suppressant and preparation method thereof

InactiveCN105062424AGuaranteed homogeneityGuaranteed stabilityOther chemical processesAlcoholSilicone oil

The invention discloses an antifoaming dust suppressant and a preparation method thereof. The antifoaming dust suppressant comprises, by mass, 50-89.99% of a dust suppressant, 0.01-20% of an antifoaming agent, and the balance of water, wherein the antifoaming agent is selected from one or more of alkyl silicone oil, alcohols, castor oil, palm oil and oleic acid. The antifoaming dust suppressant can eliminate foams in the dust suppressant or keep moderate foams in the dust suppressant to guarantee the homogeneousness and the stability of the dust suppressant and the wetting performance of the dust suppressant to dusts.

Owner:舒新前

Preparation method of siliceous hot repairing material with low cost and low water demand

The invention relates to a preparation method of a siliceous hot repairing material with low cost and low water demand, and belongs to the field of refractory materials. The siliceous hot repairing material is prepared from 30-65 wt% of fused quartz, 15-40 wt% of silica, 10-20 wt% of waste silica bricks, 6-15 wt% of silica micro-powder, 1-6 wt% of a mineralizing agent, 4-10 wt% of a binding agent,1-5 wt% of a sintering aid and 0.1-1 wt% of a superplasticizer. The waste silicon bricks are used as a raw material, so that the material cost is obviously reduced; the construction water demand is 7-11%, so the secondary damage degree to a furnace wall is reduced; the siliceous hot repairing material has a high bonding strength with the silicon bricks, and has small corrosivity, and the siliceous hot repairing material and the silicon bricks have thermal expansion synchronism; and the product provided by the invention has the characteristics of good wear resistance, high softening temperature under load, good thermal shock stability, high wall-climbing rate and the like.

Owner:江苏诺明高温材料股份有限公司

Pb-Sn-Sb-Ag alloy brazing filler metal and manufacturing method thereof

ActiveCN104741819AAvoid excessive erosionInhibit erosionWelding/cutting media/materialsSoldering mediaSolderingFiller metal

Pb-Sn-Sb-Ag alloy brazing filler metal is mainly used for soldering of metal coatings of an electronic device. The brazing filler metal comprises, by weight, 15.5-16.5wt % of Sn, 7.0-8.0wt% of Sb, 0.01-1.2wt% of Ag and the balance of Pb. The brazing filler metal is moderate in melting temperature, has excellent wettability for the metal coatings, and is good in brazing process and applicable to soldering of silver (alloy) coatings, gold coatings and copper of electronic devices, and thermal impact resistance of brazing seams is good.

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH +1

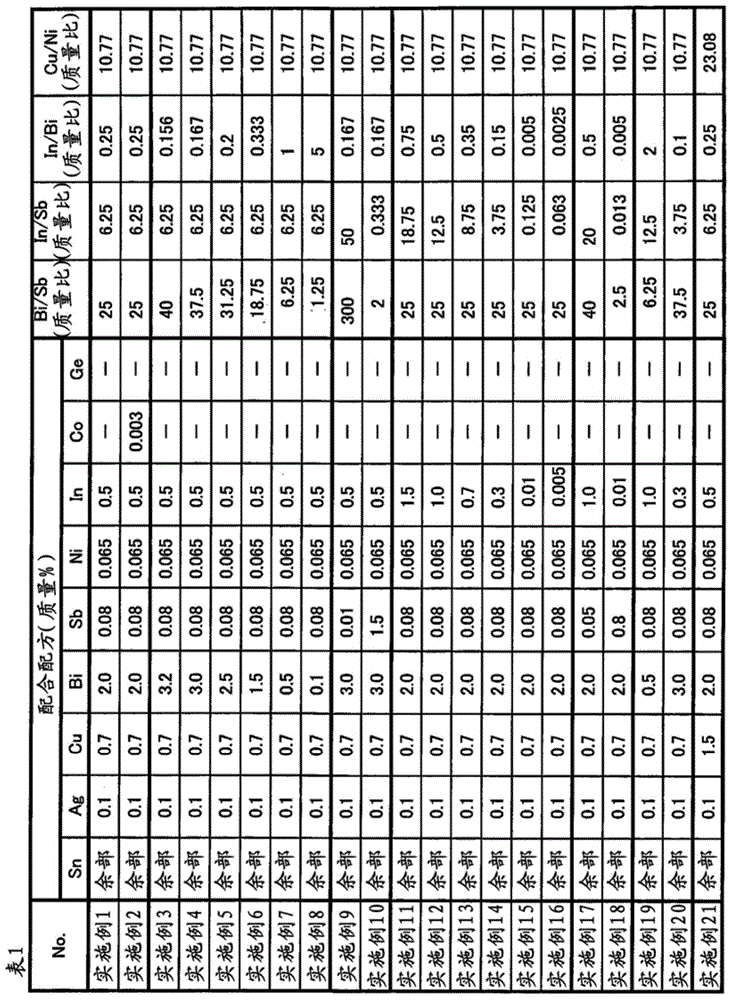

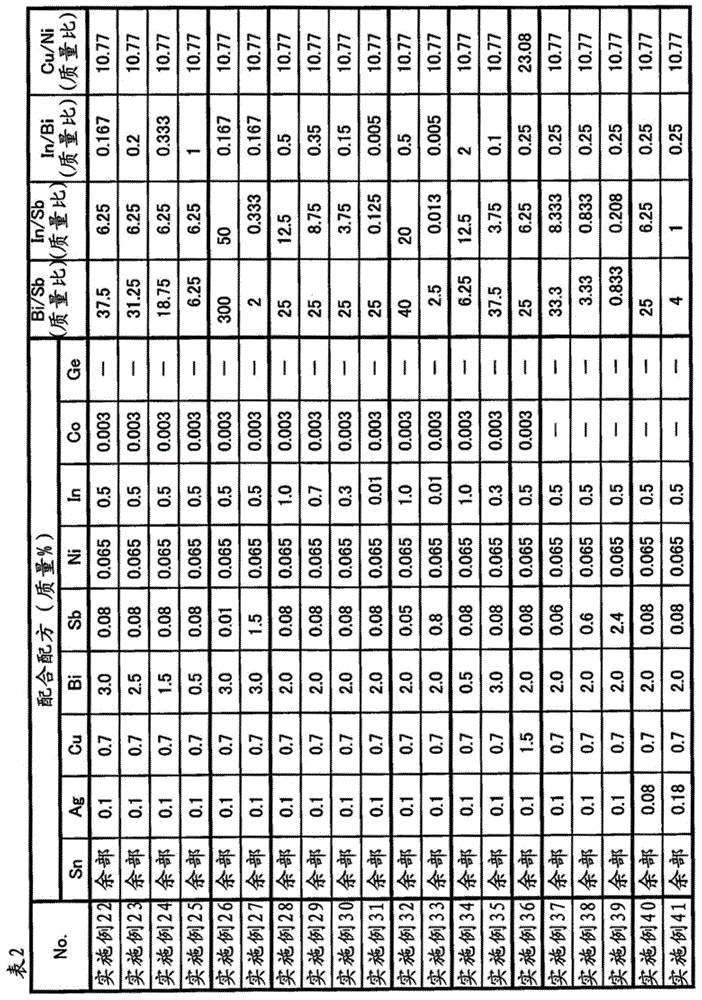

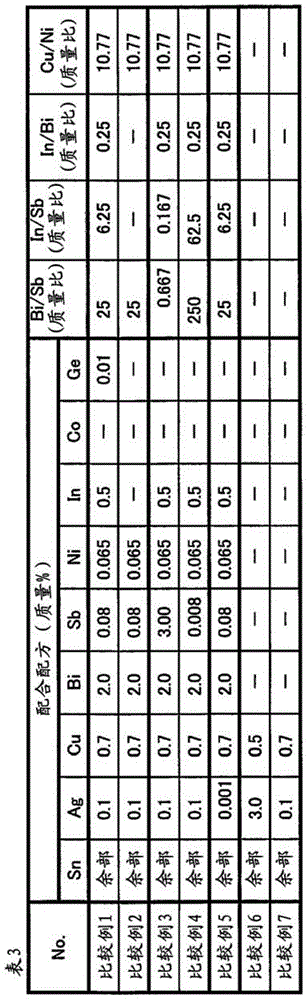

Solder alloy, solder paste, and electronic circuit board

ActiveCN104487202AContains a low proportionLow costPrinted circuit assemblingWelding/cutting media/materialsIndiumTin-silver-copper

Owner:HARIMA CHEM INC

Surface treatment fluid for surface treatment of magnesium alloy and aluminum alloy composite parts and method

ActiveCN109913923AAvoid blackeningPrevent the dissolution rate from being much faster than the generation rate, resulting in problems such as no oxide film on the surfaceAnodisationAlloy compositeInjection moulding

The invention discloses surface treatment fluid for surface treatment of magnesium alloy and aluminum alloy composite parts and a method. The surface treatment fluid comprises inorganic acid, fluoride, a corrosion inhibition film-forming agent and an addition agent. The surface treatment fluid cannot cause the phenomenon that the aluminum alloy portions and the magnesium alloy portions on the composite parts are blackened and excessively corroded. By the adoption of the method of direct forming combination of the magnesium alloy and aluminum alloy composite parts treated by the surface treatment fluid and plastic, the magnesium alloy and aluminum alloy composite parts can be subjected to anodic oxidation in the same surface treatment fluid at the same time under the condition that a covering method and other methods are not used, and therefore uniform holes or a uniform rough surface is generated on the surface, and the magnesium alloy and aluminum alloy composite parts and the plasticare prompted to be subjected to direct injection molding and have the high binding strength. By the adoption of the method, the operating steps of nanometer injection molding of the magnesium alloy and aluminum alloy composite parts are simplified, the cost is reduced, and the production efficiency and the yield are effectively improved.

Owner:东莞市慧泽凌化工科技有限公司

Plant extract nutrient bath cream and preparation method thereof

InactiveCN107233249AWettabilityGuaranteed wettabilityCosmetic preparationsToilet preparationsWater balanceSkin clean

The invention provides plant extract nutrient bath cream comprising the following raw materials in percentage by weight: 1-5% of wormwood extract and 0.4-10% of fat agent, wherein the fat agent is at least one of glyceryl oleate, dodecyl lactate, tridecanyl lactate, olive oil PEG-7 ester and PEG-7 glyceryl cocoate. The invention also provides a preparation method of the plant extract nutrient bath cream. The bath cream provided by the invention adopts the wormwood extract has the effect of sterilizing and relieving itching and the fat agent capable of effectively maintaining water balance of human skin as the raw materials, so that the effects of sterilizing, relieving itching and nourishing skin are provided while the requirement of cleaning the skin is met, the materials such as a non-irritant preservative substituent, a skin conditioner providing skin nutrition and a mild and high foaming surfactant are cooperated to use, and thus the effects of deeply cleaning the skin, nourishing the skin and maintaining the skin smooth and soft are achieved.

Owner:曾万祥

Reactive polyurethane hot melt adhesive for low-temperature coating and preparation method thereof

ActiveCN111978909ALow viscosityImprove liquidityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention discloses a reactive polyurethane hot melt adhesive for low-temperature coating and a preparation method of the reactive polyurethane hot melt adhesive. The reactive polyurethane hot melt adhesive for low-temperature coating is prepared from the following raw material in parts by weight: 10-35 parts of isocyanate, 10-70 parts of aliphatic polyester diol, 20-50 parts of polyether diol, 5-20 parts of aromatic polyester diol, 0.05-0.5 part of antioxidant, 0.01-0.1 part of stabilizer, 0.05-0.5 part of catalyst and 0.1-5 parts of adhesion promoter. The adhesive provided by the invention has good fluidity and low viscosity at low temperature, and ensures later adhesive strength.

Owner:BEIJING COMENS NEW MATERIALS

Plant extract rinse-free hand sanitizer and preparation method thereof

InactiveCN113181096AImprove the bactericidal effectGood touchCosmetic preparationsToilet preparationsBiotechnologyIlex kudingcha

The invention discloses a plant extract rinse-free hand sanitizer and a preparation method thereof, and relates to the technical field of hand sanitizers. The hand sanitizer comprises the following raw materials in percentage by weight: 6-10% of a plant extract, 0.5-1.5% of a humectant, 2-3.5% of lauryl sodium sulfate, 1.5-4% of sodium chloride, 0.5-2% of a pH regulator, 3-4% of a slippery reduction agent and the balance of distilled water. According to the hand sanitizer, the broadleaf holly leaf and Chinese ilex leaf extract is used as a bacteriostatic agent, so that the hand sanitizer has good bactericidal ability; the slippery reduction agent can locally form high surface tension in a system, the contact feeling between skins is obviously improved, the effect is mild; the hand sanitizer not only has good cleaning feeling, but also reduces the smooth phenomenon in the washing process; besides, the sorbitol is used as a humectant, wehrein a layer of protective film can be left after moisture on the surface of skin volatilizes, so that loss of moisture in the skin is prevented or slowed down, the wettability of the skin is kept, fragrant and sweet smell can be increased, and a good skin care effect is achieved.

Owner:安徽彩京科技有限公司

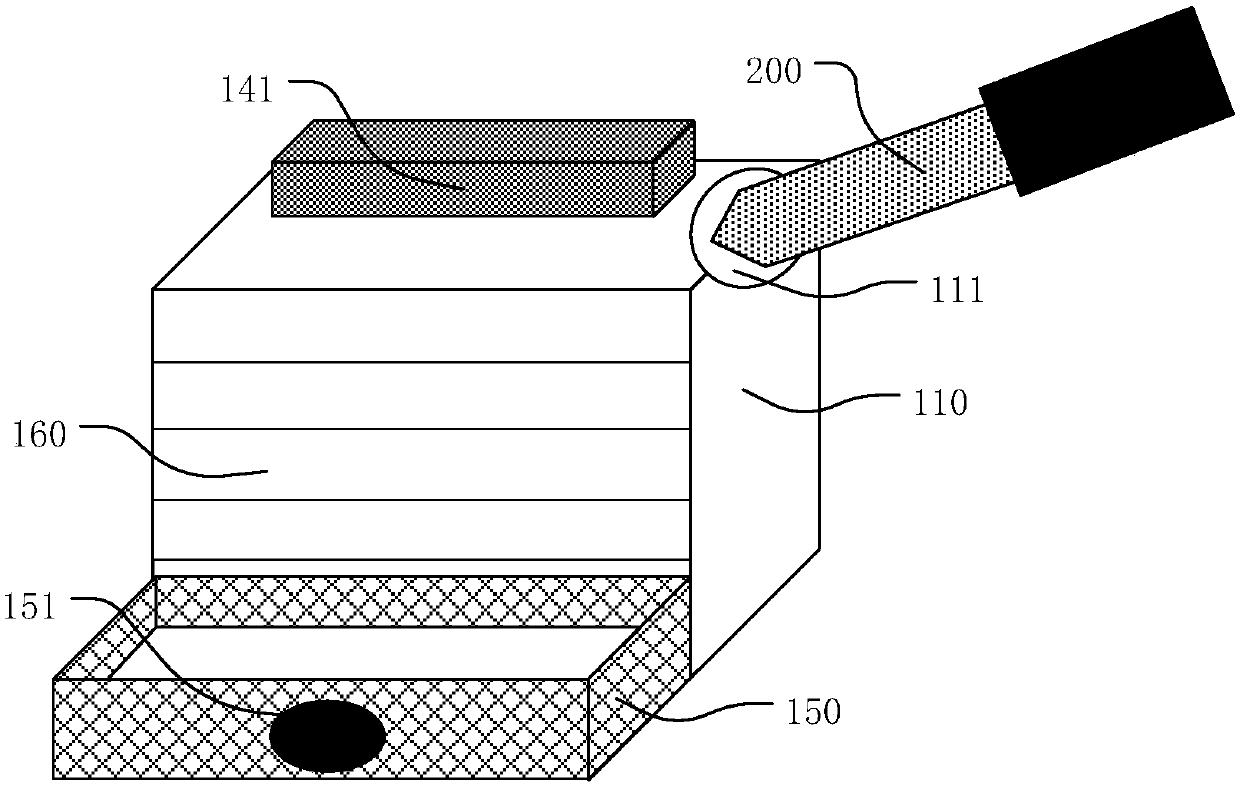

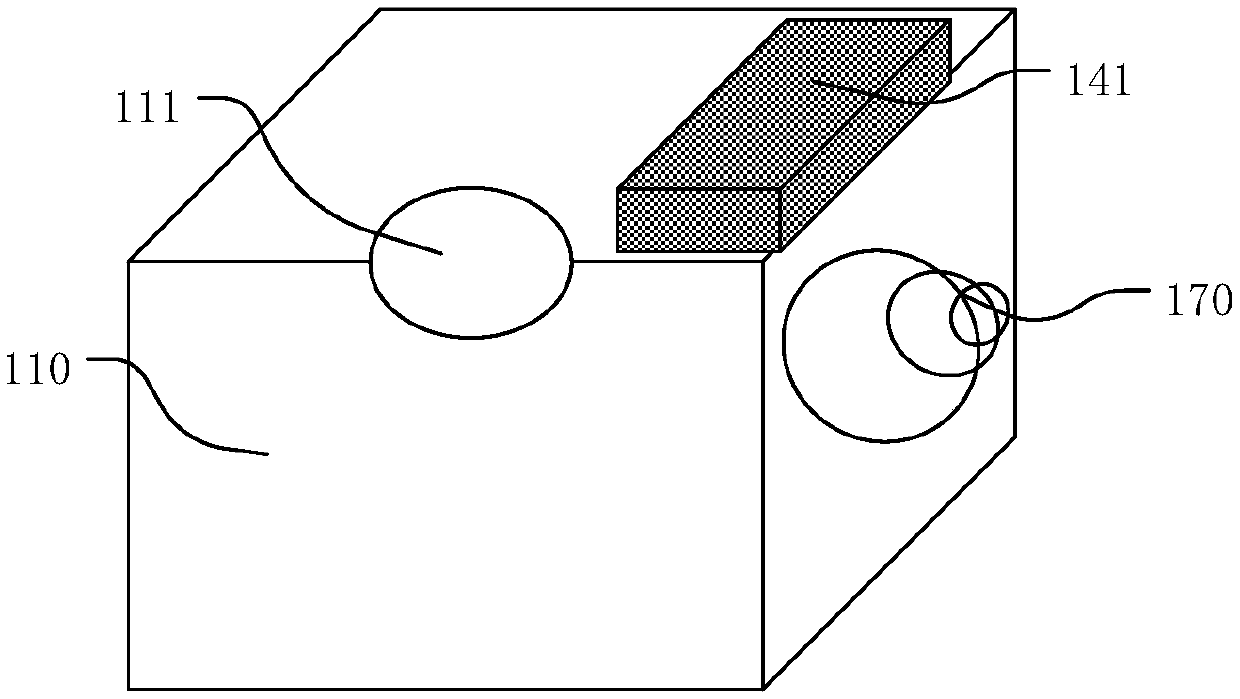

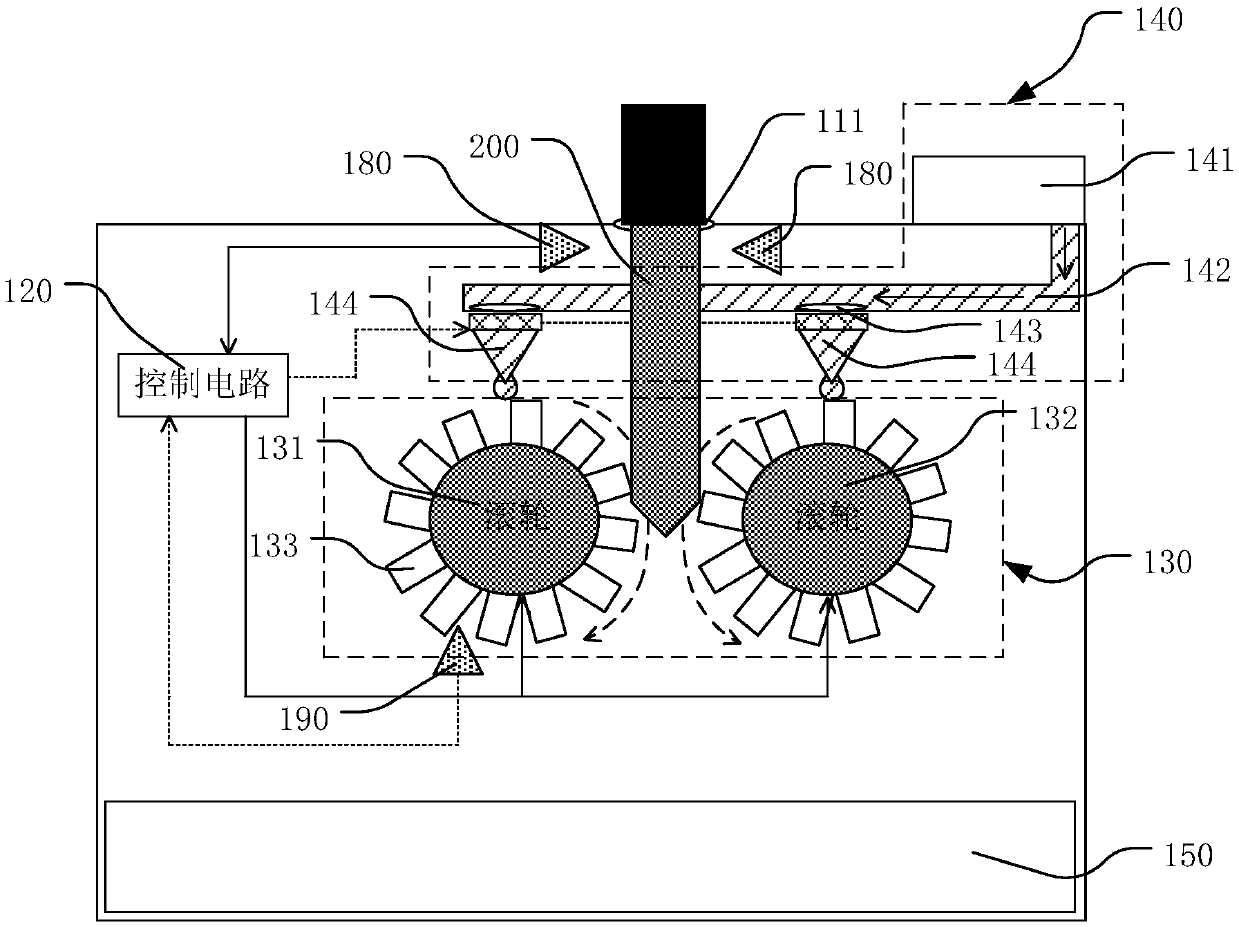

Solder tip cleaning device and cleaning method

InactiveCN108672877AGuaranteed wettabilityEasy to cleanSoldering ironSoldering auxillary devicesCleaning methodsControl circuit

The invention discloses a solder tip cleaning device and cleaning method. The cleaning device comprises a box, a cleaning device body, a waste material storage device, a water supply device and a control circuit, wherein the box is provided with a through hole; a solder tip extends into the box through the through hole; the cleaning device body is located in the box; the solder tip makes contact with the cleaning device body so as to enable waste materials on the solder tip to be removed when extending into the box; the waste material storage device is detachably mounted in the box and arranged below the cleaning device body; and the water supply device is mounted on the box, located above the cleaning device body and used for supplying water to the cleaning device body; the control circuit is connected with the cleaning device body and the water supply device and used for controlling the cleaning device body and the water supply device to operate. The solder tip cleaning device cleansthe solder tip through rotation of a rolling wheel; waste tin is collected through the box; a water box adds water to the rolling wheel automatically; the cleanliness of a working table is kept; andthe solder tip cleaning device is simple and practical.

Owner:KUSN INFOVISION OPTOELECTRONICS

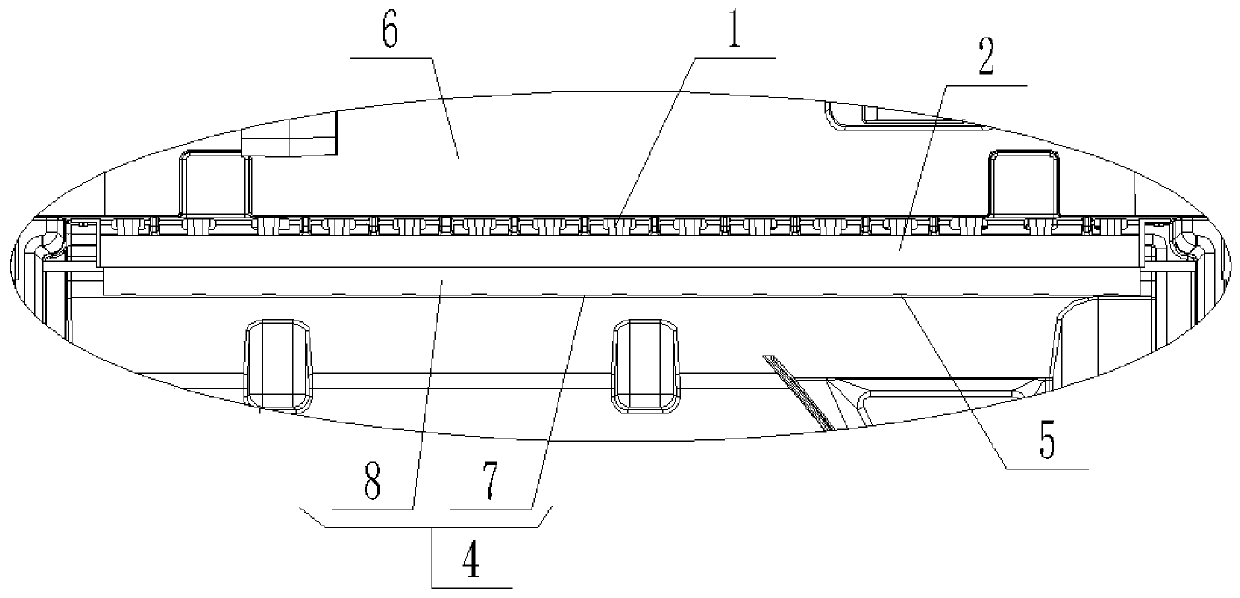

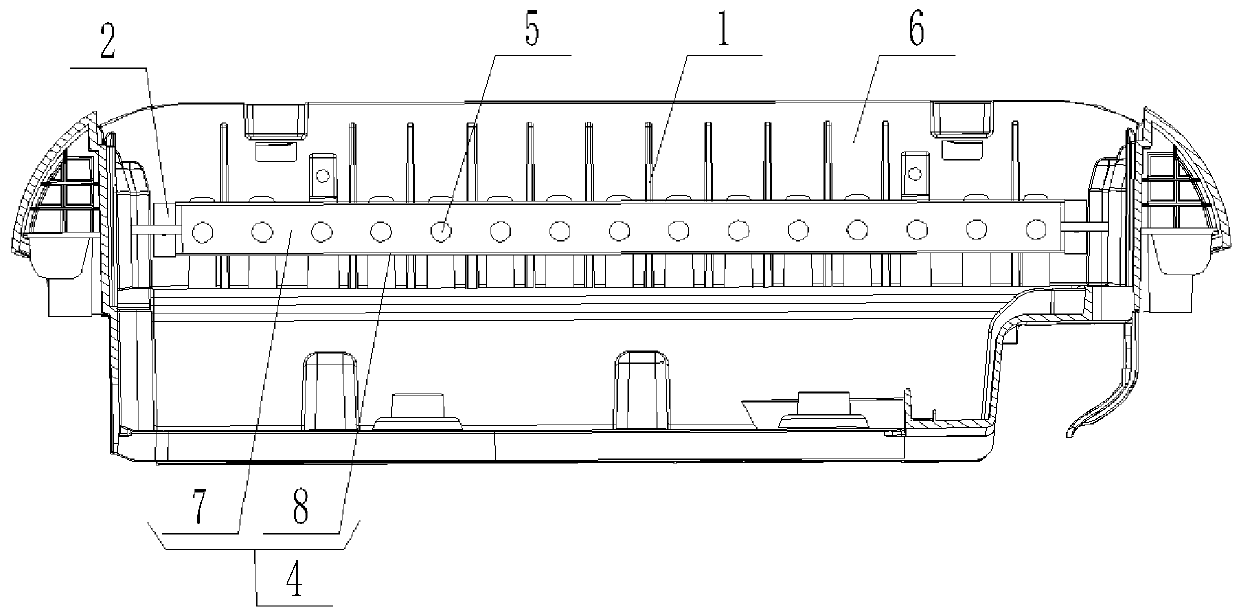

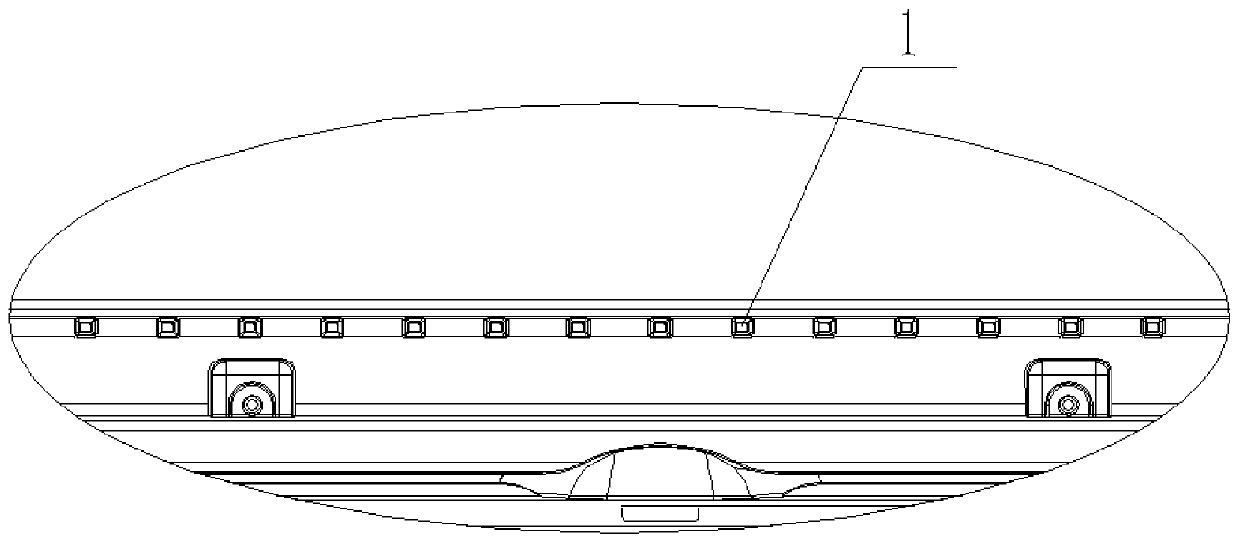

Overturning device and cooling fan

PendingCN111140967AGuaranteed wettabilityAchieve closureLighting and heating apparatusNoise suppressionDe wettingEngineering

Owner:GREE ELECTRIC APPLIANCES INC

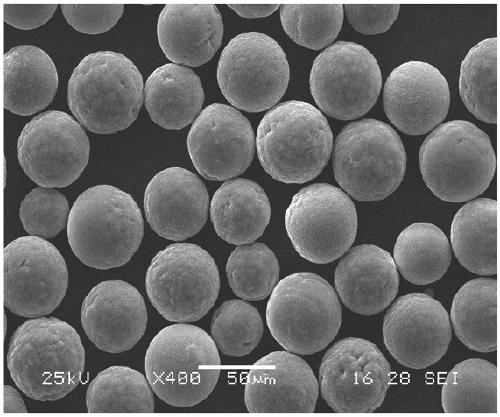

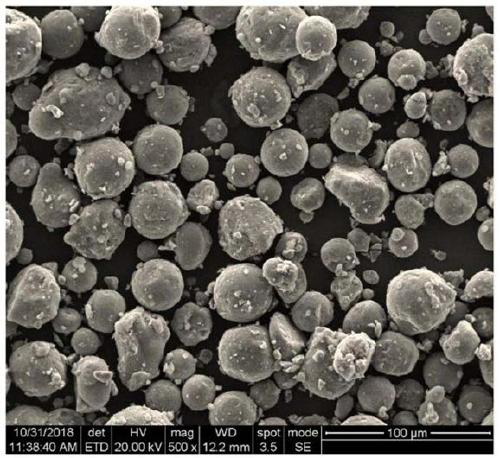

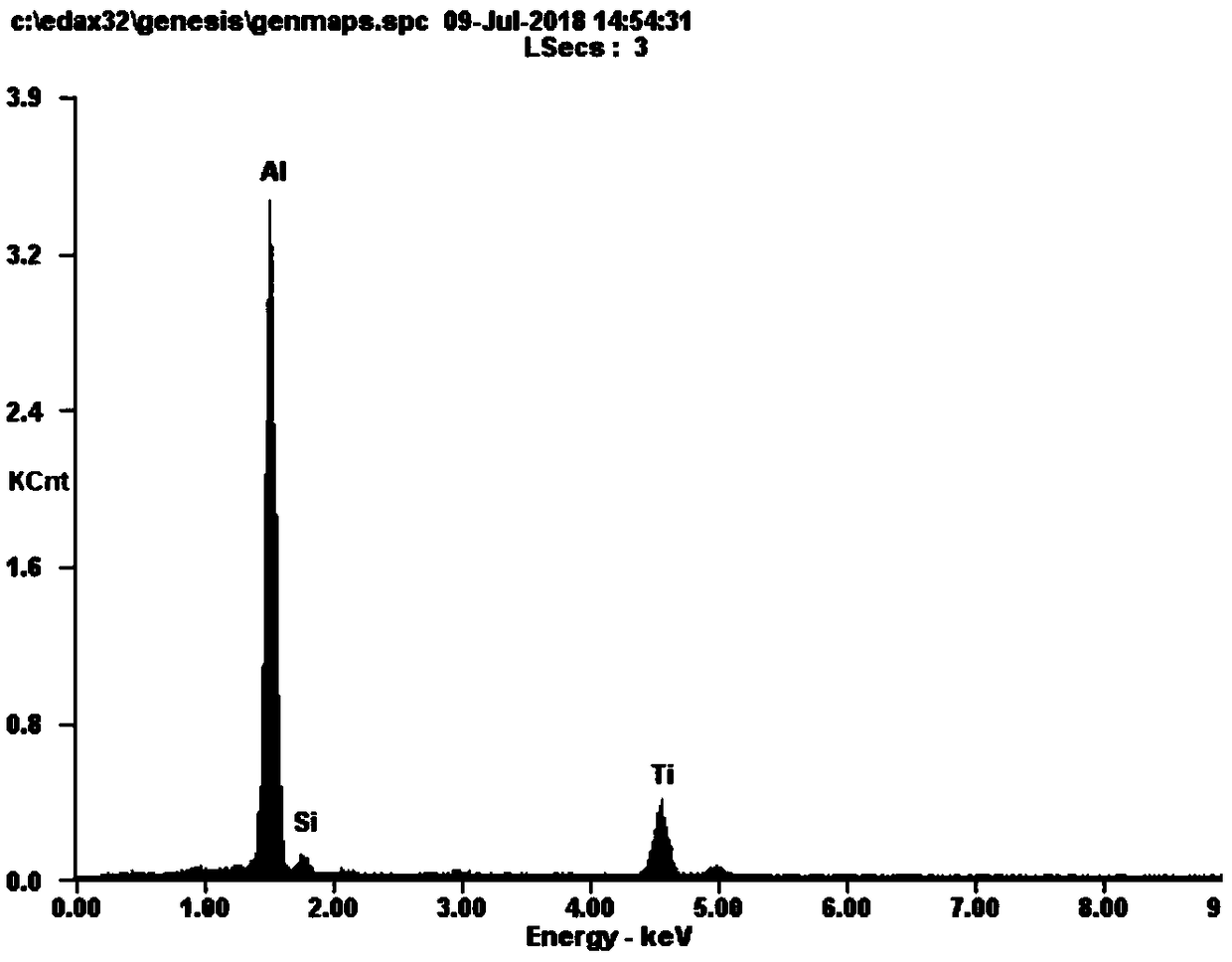

TiB2 reinforced aluminum alloy powder for additional material manufacturing and preparation method thereof

The invention provides TiB2 reinforced aluminum alloy powder for additional material manufacturing and a preparation method thereof. The preparation method comprises the following steps that (a) TiB2powder and aluminum alloy powder are mixed together to form mixed powder; (b) grinding balls and the mixed powder are mixed, and the mixture is put in a ball grinding machine for ball grinding treatment to obtain the TiB2 reinforced aluminum alloy powder. The TiB2 reinforced aluminum alloy powder prepared by adopting the method has good mechanical property, the tensile strength of the powder can reach 500 MPa or above, and the processing demand of SLM additional material manufacturing can be met.

Owner:ADVANCED FOR MATERIALS & EQUIP

Hand sanitizer

InactiveCN107998013AEnhanced water vapor transmission rateGuaranteed wettabilityCosmetic preparationsToilet preparationsHand sanitizerGlycerol

The invention belongs to the field of articles for daily life and in particular relates to a hand sanitizer. The hand sanitizer is prepared by taking sodium alginate as a film forming base material and chitosan as a raw material of a blended film; a molecular chain of the chitosan has primary amino and a molecular chain of the sodium alginate has carboxyl; under the action of an electrostatic force, a polyelectrolyte film can be formed through positive and negative charge attraction, so that one layer of protection film is formed on skin; by a low molecular weight plasticizer glycerol, a plasticizer molecule and a polymer have a mutual effect, so that a mutual action force between macromolecules is weakened and the hydrogen-bond interaction in the molecules is weakened; the ratio of a crystallization region to an amorphous region of the film is reduced and the water seepage steam penetration rate of the film is improved, so that the loss of moisture in the skin is prevented or alleviated and the wetting property of the skin is kept; rosemary essential oil is added and essential oil molecules exist in the film with a plurality of micro-pores; after active substances with a bacterium-inhibition effect in the essential oil molecules enter the film, the active substances are dispersed to the surface of the film gradually through the micro-pores, so that the antibacterial performance of the surface of the skin is improved.

Owner:袁玲燕

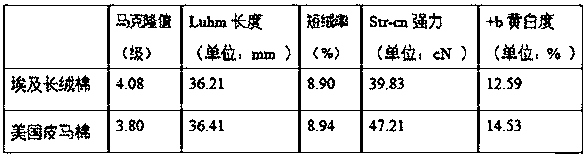

Production method of environment-friendly hygroscopic and sweat releasing fabric

InactiveCN109457365ASoft and plumpGood moisture absorptionFabric breaking/softeningDyeing processYarnEngineering

The invention discloses a production method of an environment-friendly hygroscopic and sweat releasing fabric and relates to the technical field of spinning, in particular to a production process of afunctional fabric. During spinning, a double combing-ring spinning process is adopted, and Egyptian long stapled cotton and American pima cotton are blended; in a fine spinning process, low-twisted yarns with the twist multiplier of 260 are obtained through winding formation; during warp sizing, etherified starch is adopted; during after-finishing, airflow conducted fluffing or mechanical rubbingand beating is adopted for the fabric. The formed fabric has good washability and lasting hygroscopic and sweat releasing functions, the functions of the product can be greatly improved, and the service life of the product can be greatly prolonged.

Owner:JIANGSU LIANFA TEXTILE

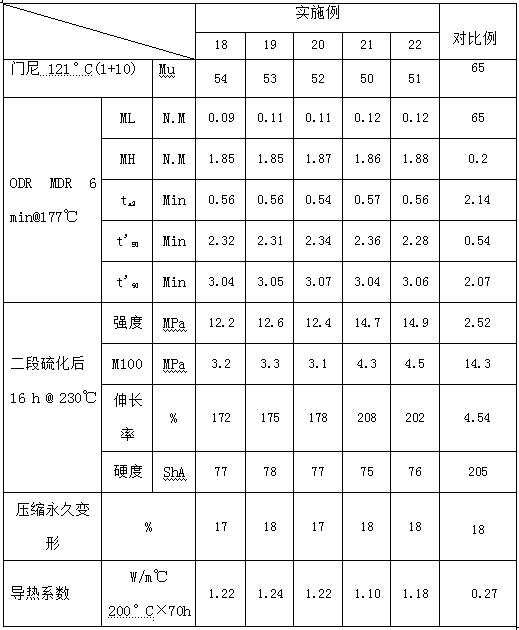

Premixed fluororubber with high thermal conductivity and preparation method of premixed fluororubber

The invention discloses premixed fluororubber with high thermal conductivity and a preparation method of the premixed fluororubber. The premixed fluororubber with high thermal conductivity is preparedfrom components in parts by weight as follows: 50-100 parts of masterbatch, 0.1-1.5 parts of a PFPE derivative, 3-10 parts of long-chain perfluoroacrylate, 0.1-1.5 parts of fatty alcohol and 3-5 parts of a silane coupling agent, wherein each masterbatch comprises 1-3 parts of bisphenol AF, 0.2-1 part of a vulcanization accelerator, 1-5 parts of multilayer graphene and 50-100 parts of raw fluororubber. The formula of the fluororubber is improved, the PFPE derivative, the long-chain perfluoroacrylate, the fatty alcohol and the silane coupling agent in proper ratios are added to the formula, thewettability of fluororubber for heat conducting filler can be improved, so that graphene added to the masterbatch and boron nitride added during rubber mixing have a synergistic effect in heat conductivity, the mechanical performance of the material can be kept while the heat conductivity of the material is ensured, the preparation cost can be effectively controlled, and the cost of the materialcan be controlled within an acceptable level.

Owner:成都晨光博达新材料股份有限公司

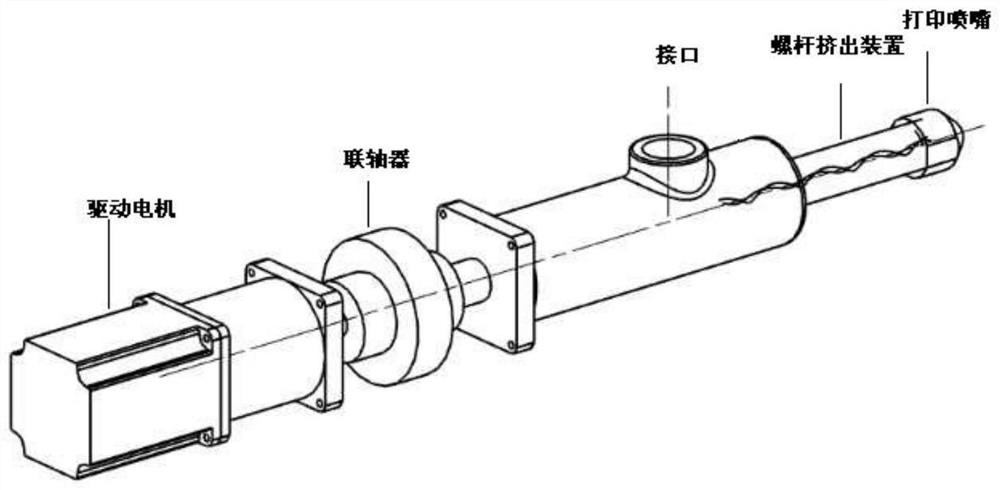

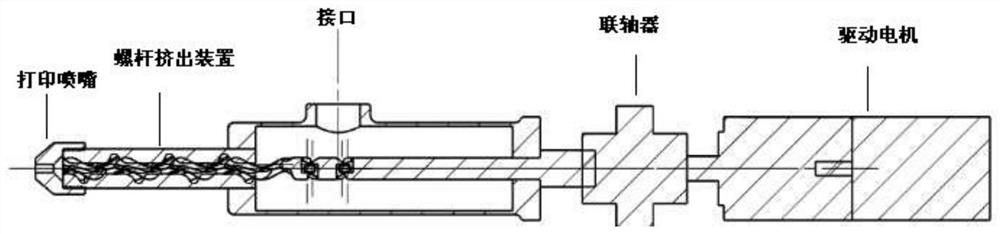

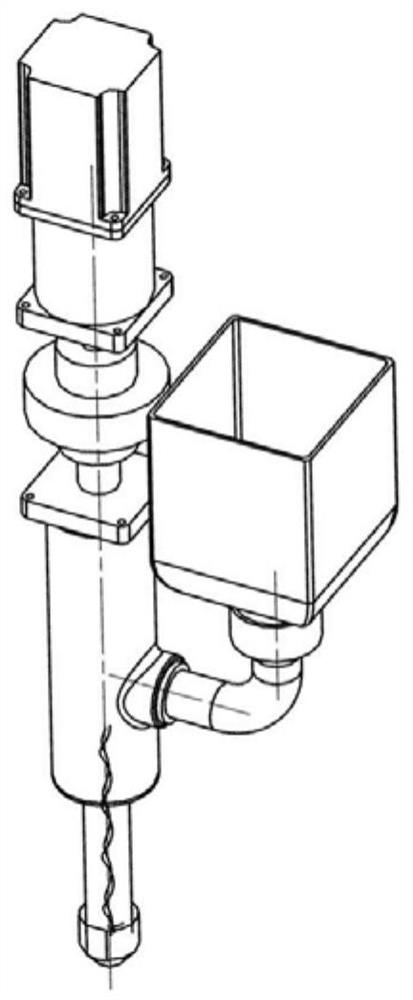

Simulated Mars soil concrete suitable for extrusion and preparation method thereof

PendingCN111925182AEasy to controlAvoid cloggingAdditive manufacturing apparatusHydroxypropylmethyl celluloseChemistry

The invention relates to a simulated Mars soil concrete suitable for extrusion and a preparation method thereof. The simulated Mars soil concrete comprises simulated Mars soil, calcium silicate, hydroxypropyl methyl cellulose and water. Calculated by taking the mass of the simulated Mars soil as 100 parts, the concrete is prepared from the following components in parts by mass: 45 to 46 parts of calcium silicate, 57 to 59 parts of water and 0.4 to 0.5 part of hydroxypropyl methyl cellulose. The concrete is added into a screw extrusion device through a feeding port in the screw extrusion device, then a driving motor is started, and the concrete is extruded and moulded.

Owner:BEIJING SATELLITE MFG FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com