Lithium ion battery silicon-carbon composite negative electrode material composite conductive agent, negative electrode plate and preparation method of negative electrode plate

A technology of silicon-carbon composite materials and lithium-ion batteries, which is applied in the direction of battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of not having or meeting the conductive agent for lithium-ion batteries, achieve low impedance, and improve market application Foreground, effect of improving discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

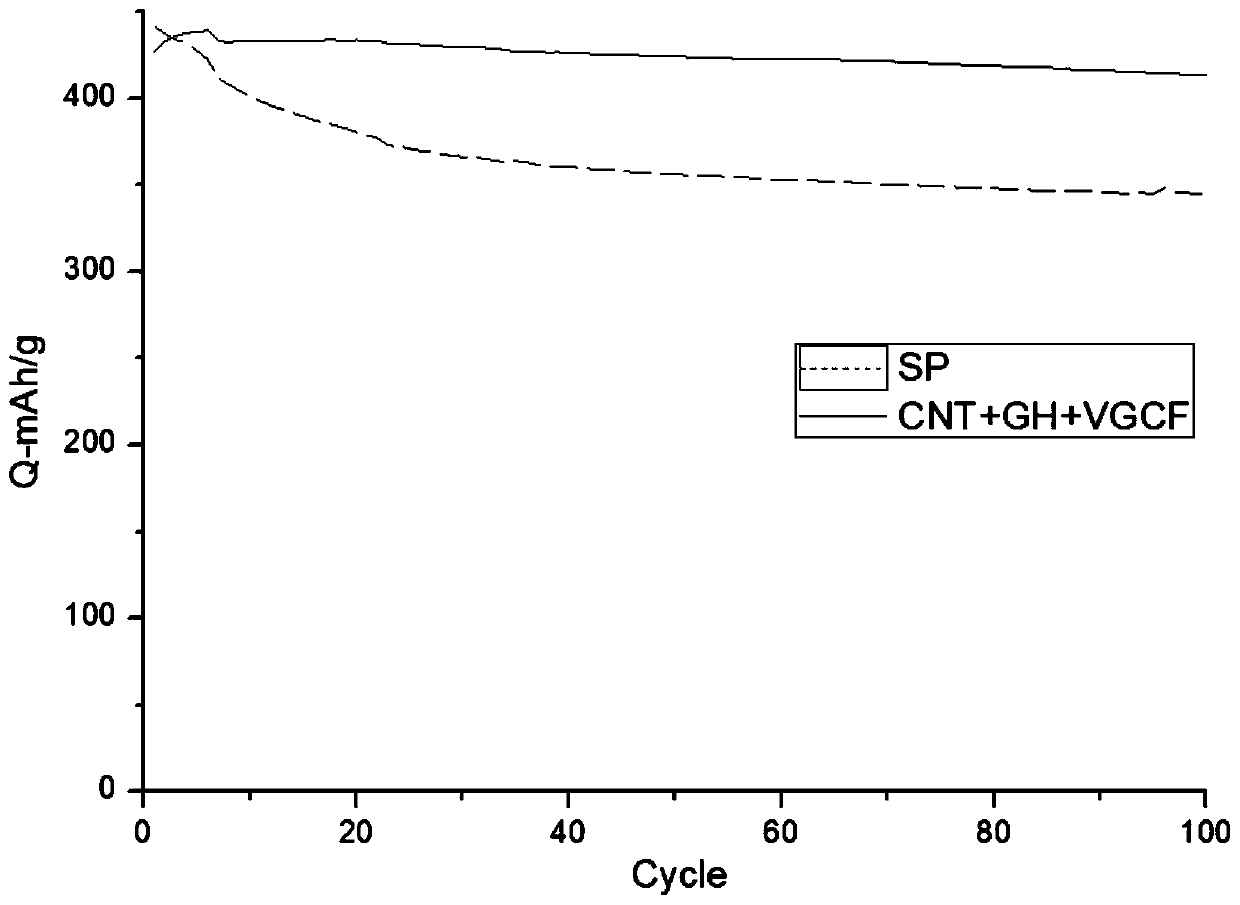

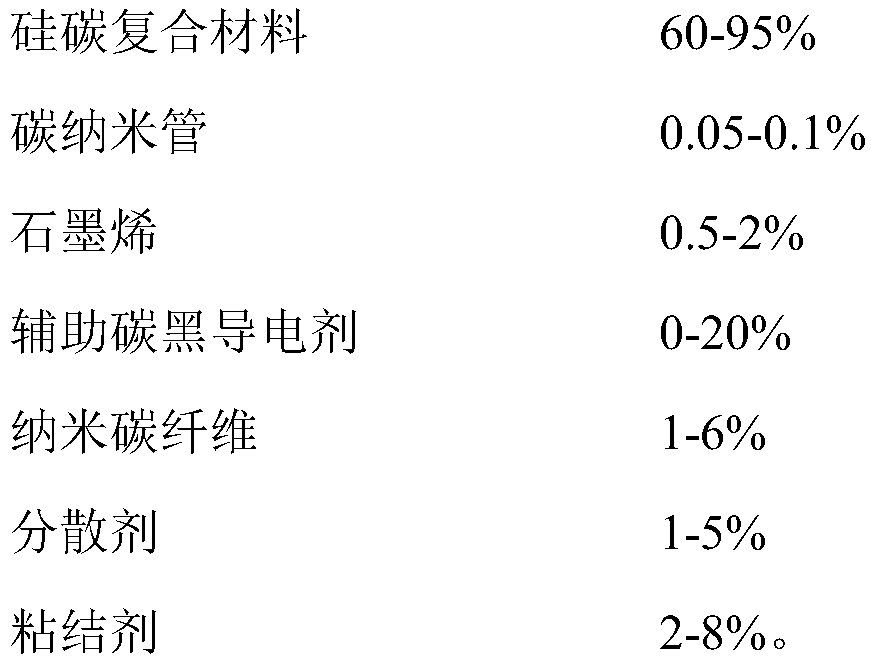

[0035] In this embodiment, the composite conductive agent coated on the negative electrode sheet of the silicon-carbon composite negative electrode material for lithium-ion batteries includes the following components:

[0036]

[0037] In the silicon-carbon composite material, the addition of SiOx or Si is less than 5%, and the designed gram capacity is 450mAh / g.

[0038] The preparation of the negative electrode sheet of the silicon-carbon composite negative electrode material for the above-mentioned lithium ion battery comprises the following steps:

[0039] (1) Configure carboxymethyl cellulose CMC glue, add 0.04kg of CMC powder into deionized water, adjust the solid content of the CMC glue to 5%, stir at 1000rpm for 5 hours, and stir to obtain 0.8kg of CMC glue;

[0040] (2) 0.001kg single-walled carbon nanotubes, 0.02kg graphene, 0.02kg carbon nanofibers and 0.8kg of CMC glue prepared in step (1) were mixed, stirred at 1500rp speed for 1h, to obtain conductive glue;

...

Embodiment 2

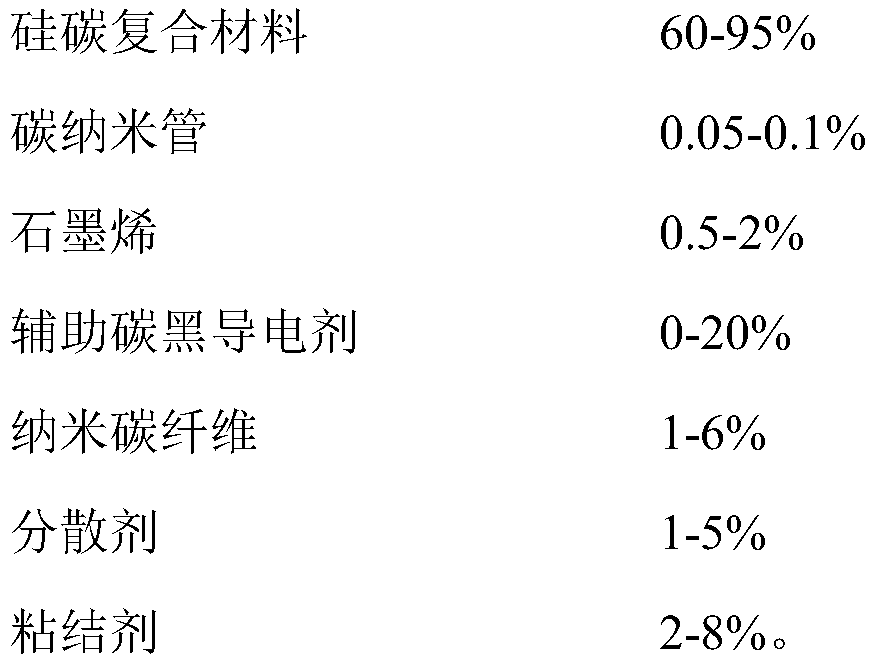

[0045]In this embodiment, the composite conductive agent coated on the negative electrode sheet of the silicon-carbon composite negative electrode material for lithium-ion batteries includes the following solid components:

[0046]

[0047] In the silicon-carbon composite material, the addition of SiOx or Si is less than 5%, and the designed gram capacity is 450mAh / g.

[0048] The preparation of the negative electrode sheet of the silicon-carbon composite negative electrode material for the above-mentioned lithium ion battery comprises the following steps:

[0049] (1) Configure carboxymethyl cellulose CMC glue, add 0.04kg of CMC powder into deionized water, adjust the solid content of the CMC glue to 5%, stir at 1000rpm for 5 hours, and stir to obtain 0.8kg of CMC glue;

[0050] (2) 0.001kg of single-walled carbon nanotubes, 0.02kg of graphene, 0.02kg of superconducting carbon black SuperP and the 0.8kg of CMC glue prepared in step (1) were mixed, and stirred for 1h at a s...

Embodiment 3

[0055] In this embodiment, the composite conductive agent coated on the negative electrode sheet of the silicon-carbon composite negative electrode material of the lithium-ion battery includes the following solid components:

[0056]

[0057] In the silicon-carbon composite material, the addition of SiOx or Si is less than 5%, and the designed gram capacity is 450mAh / g.

[0058] The preparation of the negative electrode sheet of the silicon-carbon composite negative electrode material for the above-mentioned lithium ion battery comprises the following steps:

[0059] (1) Configure carboxymethyl cellulose CMC glue, add 0.04kg of CMC powder into deionized water, adjust the solid content of the CMC glue to 5%, stir at 1000rpm for 5 hours, and stir to obtain 0.8kg of CMC glue;

[0060] (2) 0.04kg of superconducting carbon black SuperP and the 0.8kg of CMC glue prepared in step (1) were mixed, and stirred at a speed of 1500rp for 1h to obtain conductive glue;

[0061] (3) Add 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com