Solder alloy, solder paste, and electronic circuit board

一种线路基板、焊锡膏的技术,应用在印刷电路、印刷电路制造、用电元件组装印刷电路等方向,能够解决耐疲劳性耐冷热疲劳性劣化、连接不良、降低银等问题,达到抑制气孔、确保润湿性、低成本化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~41 and comparative example 1~7

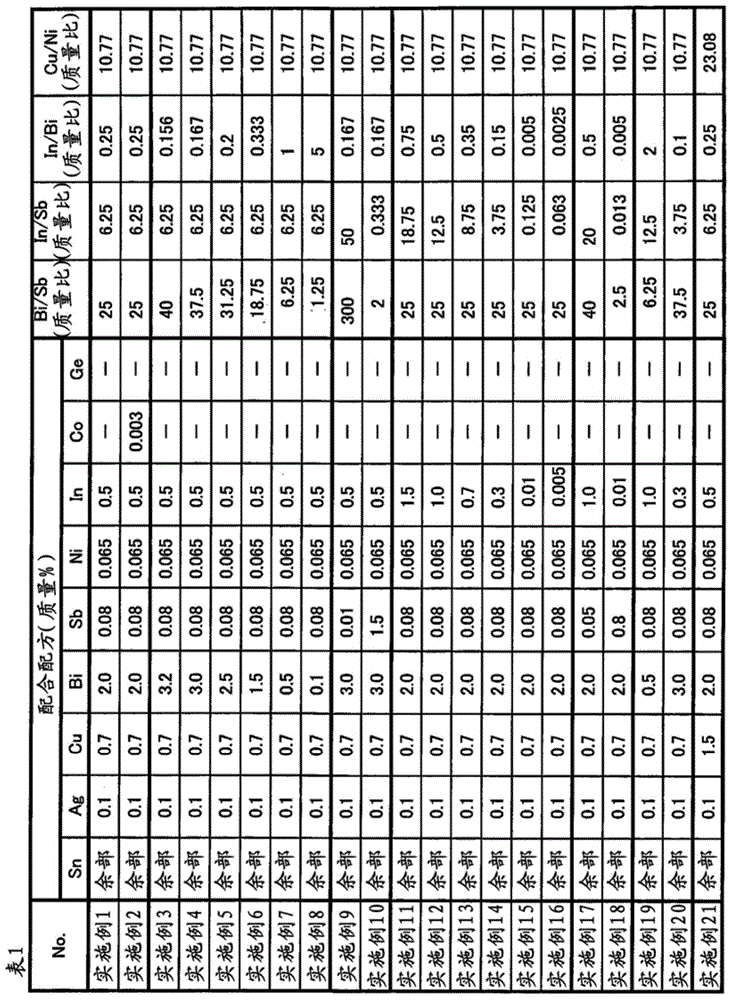

[0100] Modulation of Solder Alloy

[0101] Powders of the respective metals listed in Tables 1 to 3 were mixed according to the compounding ratios listed in Tables 1 to 3, and the obtained metal mixture was melted and homogenized in a melting furnace to prepare a solder alloy. The compounding ratio of tin (Sn) in the compounding formula of each embodiment and each comparative example is to subtract each metal (silver (Ag), copper (Cu), bismuth (Bi), antimony (Sb) recorded in Tables 1 to 3 ), nickel (Ni), indium (In), cobalt (Co) and germanium (Ge)) in the proportion (mass %) of the remainder.

Embodiment 1

[0102] In the solder alloy of Example 1, each metal of Ag, Cu, Bi, Sb, Ni, and In was mixed in the ratio shown in Table 1, and the remainder was Sn. In Example 2, Co was further added to the formulation of Example 1.

[0103] Examples 3-8 are the examples of the formulation which changed the compounding ratio of Bi from the formulation of Example 1.

[0104] Examples 9 and 10 are examples of formulations in which the compounding ratio of Sb and the value of the mass ratio Bi / Sb of the compounding amounts of Bi and Sb are changed from the compounding ratio of Example 4.

[0105] Examples 11 to 16 are examples of formulations in which the mixing ratio of In is changed from the formulation of Example 1.

[0106] Examples 17 and 18 are examples of formulations in which the compounding ratio of Sb and In and the value of the mass ratio In / Sb of the compounding amounts of In and Sb are changed from the compounding ratio of Example 1.

[0107] Examples 19 and 20 are examples of for...

Embodiment 21

[0108] Example 21 is an example of a formulation in which the blending ratio of Cu was changed from the formulation of Example 1.

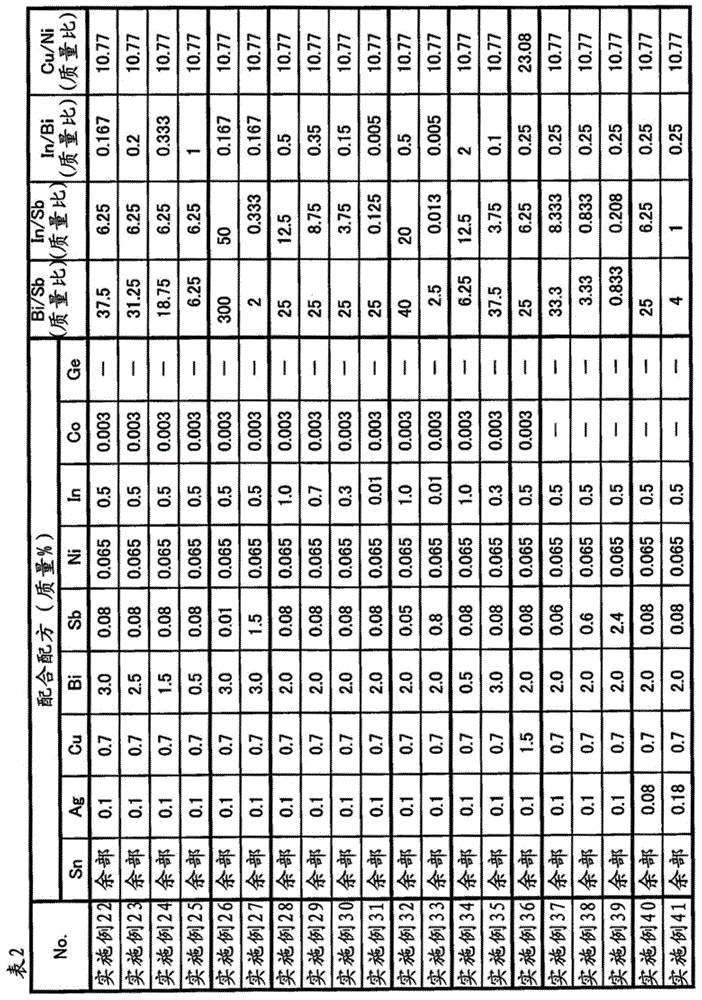

[0109] Examples 22 to 36 are examples of formulations in which Co was further blended with respect to the formulations of Examples 4 to 7, 9 to 10, 12 to 15, and 17 to 21.

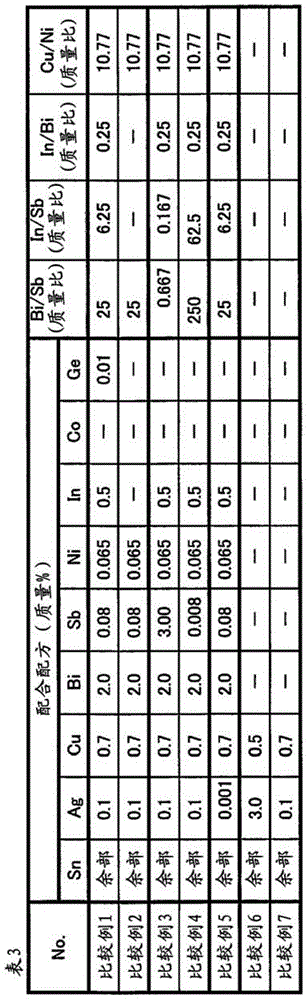

[0110] Examples 37 to 39 and Comparative Examples 3 and 4 are examples of formulations in which the compounding ratio of Sb was changed from the formulation of Example 1.

[0111] The solder alloys of Examples 40 to 41 and Comparative Example 5 are examples of formulations in which the mixing ratio of Ag is changed from the formulation of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com