Premixed fluororubber with high thermal conductivity and preparation method of premixed fluororubber

A technology of fluororubber raw rubber and fluororubber, which is applied in the direction of chemical instruments and methods, heat exchange materials, etc., can solve the problems of inability to achieve high thermal conductivity of nanostructures, high product costs, and expensive carbon nanotubes, etc., to achieve Excellent mechanical properties, good thermal conductivity, and the effect of maintaining thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

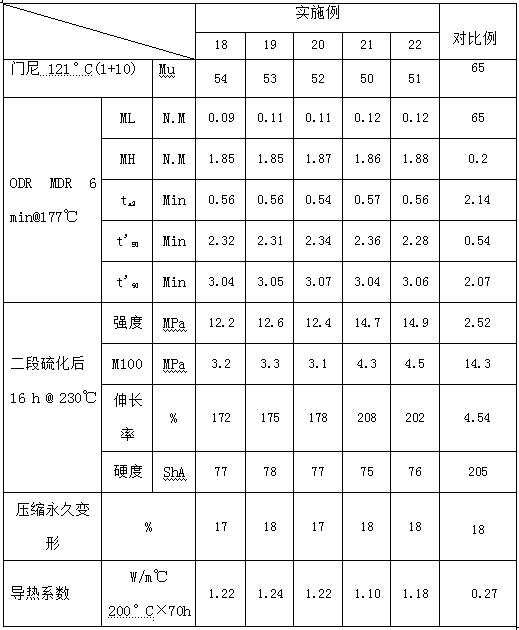

Examples

Embodiment 1

[0037] This embodiment proposes a high thermal conductivity fluororubber premix, which includes the following components in parts by weight:

[0038] 50 parts of masterbatch, 0.1 part of PFPE derivative, 3 parts of long-chain perfluoroacrylate, 0.1 part of fatty alcohol and 3 parts of silane coupling agent, wherein each masterbatch includes the following components in parts by weight: 1 part of bisphenol AF, 0.2 part of vulcanization accelerator BBP, 1 part of multilayer graphene, 50 parts of fluororubber raw rubber.

[0039] Among the above components, PFPE derivatives are polymers with perfluoropolyether end groups capped with 18 amino groups; long-chain perfluoroacrylates are C16 perfluoroacrylates; fatty alcohols are alcohol mixtures, including 15% C 18 -OH, 15% C 20 -OH, 70% C 22 -OH; the silane coupling agent is an aminosilane coupling agent; bisphenol AF is 2,2-bis-(4-hydroxyphenyl) hexafluoropropane; the vulcanization accelerator BBP is benzyl triphenyl phosphorus chlo...

Embodiment 2

[0041] This embodiment proposes a high thermal conductivity fluororubber premix, which includes the following components in parts by weight:

[0042] 100 parts of masterbatch, 1.5 parts of PFPE derivatives, 10 parts of long-chain perfluoroacrylate, 1.5 parts of fatty alcohol and parts of silane coupling agent, wherein, each part of masterbatch includes the following components in parts by weight: bis 3 parts of phenol AF, 1 part of vulcanization accelerator BBP, 5 parts of multi-layer graphene, 100 parts of fluororubber raw rubber.

[0043] Among the above components, PFPE derivatives are polymers with perfluoropolyether end groups terminated with 18 amino groups; long-chain perfluoroacrylates are C18 perfluoroacrylates; fatty alcohols are alcohol mixtures, including 15% C 18 -OH, 15% C 20 -OH, 70% C 22 -OH; silane coupling agent is epoxy silane coupling agent; bisphenol AF is 2,2-bis-(4-hydroxyphenyl) hexafluoropropane; vulcanization accelerator BBP is benzyl triphenylphosp...

Embodiment 3

[0045] This embodiment proposes a high thermal conductivity fluororubber premix, which includes the following components in parts by weight:

[0046] 80 parts of masterbatch, 1.0 part of PFPE derivative, 6 parts of long-chain perfluoroacrylate, 1.2 parts of fatty alcohol and 4 parts of silane coupling agent, wherein each masterbatch includes the following components in parts by weight: 2 parts of bisphenol AF, 0.8 parts of vulcanization accelerator BBP, 3 parts of multi-layer graphene, 60 parts of fluororubber raw rubber.

[0047] Among the above components, PFPE derivatives are polymers with perfluoropolyether end groups capped with 18 amino groups; long-chain perfluoroacrylates are C16 perfluoroacrylates; fatty alcohols are alcohol mixtures, including 15% C 18 -OH, 15% C 20 -OH, 70% C 22 -OH; silane coupling agent is vinyl silane coupling agent; bisphenol AF is 2,2-bis-(4-hydroxyphenyl) hexafluoropropane; vulcanization accelerator BBP is benzyl triphenyl phosphorus chlorid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com