Surface treatment fluid for surface treatment of magnesium alloy and aluminum alloy composite parts and method

A surface treatment liquid and surface treatment technology, applied in the direction of surface reaction electrolytic coating, anodic oxidation, electrolytic coating, etc., can solve the problems of many steps and cumbersome operation, and achieve the effect of reducing surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

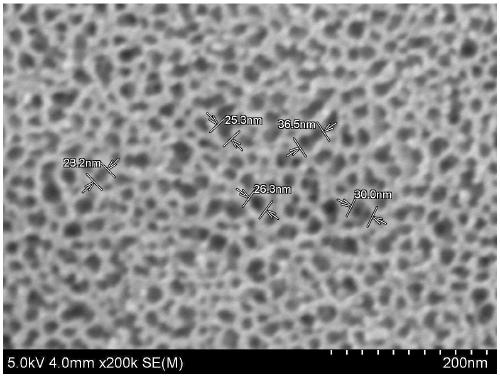

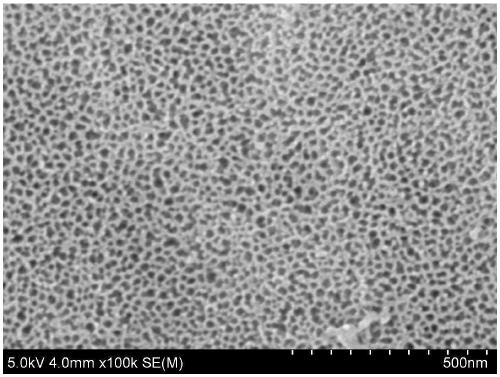

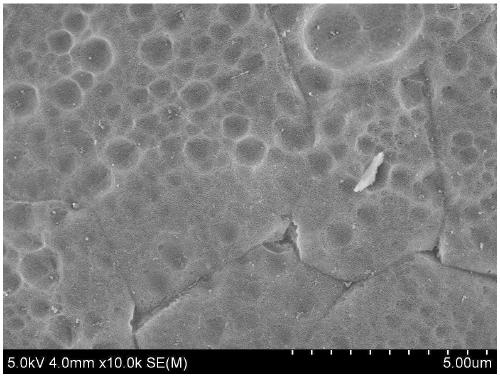

[0050]The composition of the surface treatment solution: phosphoric acid is 120g / L, fluozirconic acid is 15g / L, sodium tungstate is 5g / L, phytic acid is 5g / L, and glycerol is 5g / L. The flow chart of the processing process is shown in Table 1. The composite part is a tablet computer frame, the frame is 6063 aluminum alloy, and the middle plate is AZ91D magnesium alloy. Special injection molding positions for thrust measurement are reserved on the aluminum alloy and magnesium alloy parts. Refer to Table 1 for the specific processing process, and the process is as follows:

[0051] Degreasing and degreasing: Hang the composite part firmly on the titanium rack, soak it in a commercially available neutral degreaser (CW-6007 produced by Huiling Technology) for 300 seconds, then wash it with water, and set the temperature to 60°C;

[0052] Immersion activation: soak the composite parts after degreasing and degreasing in 25% hydrofluoric acid aqueous solution for 40 seconds, then wash...

Embodiment 2

[0059] The difference from Example 1 is that in the present example, the composition of the surface treatment solution is adjusted as follows: phosphoric acid is 120g / L, fluozirconic acid is 15g / L, sodium molybdate is 2g / L, sodium tungstate is 4g / L L, phytic acid is 6g / L, and glycerol is 5g / L. Other treatment methods and processes are completely the same as in Example 1. The measured bonding strength between the aluminum alloy part and the plastic PPS on the composite part is 42.6MPa, and the bonding strength between the magnesium alloy part and the plastic PPS is 25MPa.

Embodiment 3

[0061] The difference from Example 1 is that in this example, the composition of the surface treatment solution is adjusted as follows: phosphoric acid is 180g / L, fluosilicic acid is 3g / L, fluotitanic acid is 10g / L, sodium molybdate is 5g / L L, phytic acid is 5g / L, polyethylene glycol is 8g / L. Other treatment methods and processes are exactly the same as in Example 1. The measured bonding strength between the aluminum alloy part and the plastic PPS on the composite part is 41.8MPa, and the bonding strength between the magnesium alloy part and the plastic PPS is 27MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com