Adhesive sheet for tire

A label and tire technology, applied to tire parts, adhesives, tire sidewalls, etc., can solve problems such as easy peeling, and achieve an easy-to-adjust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

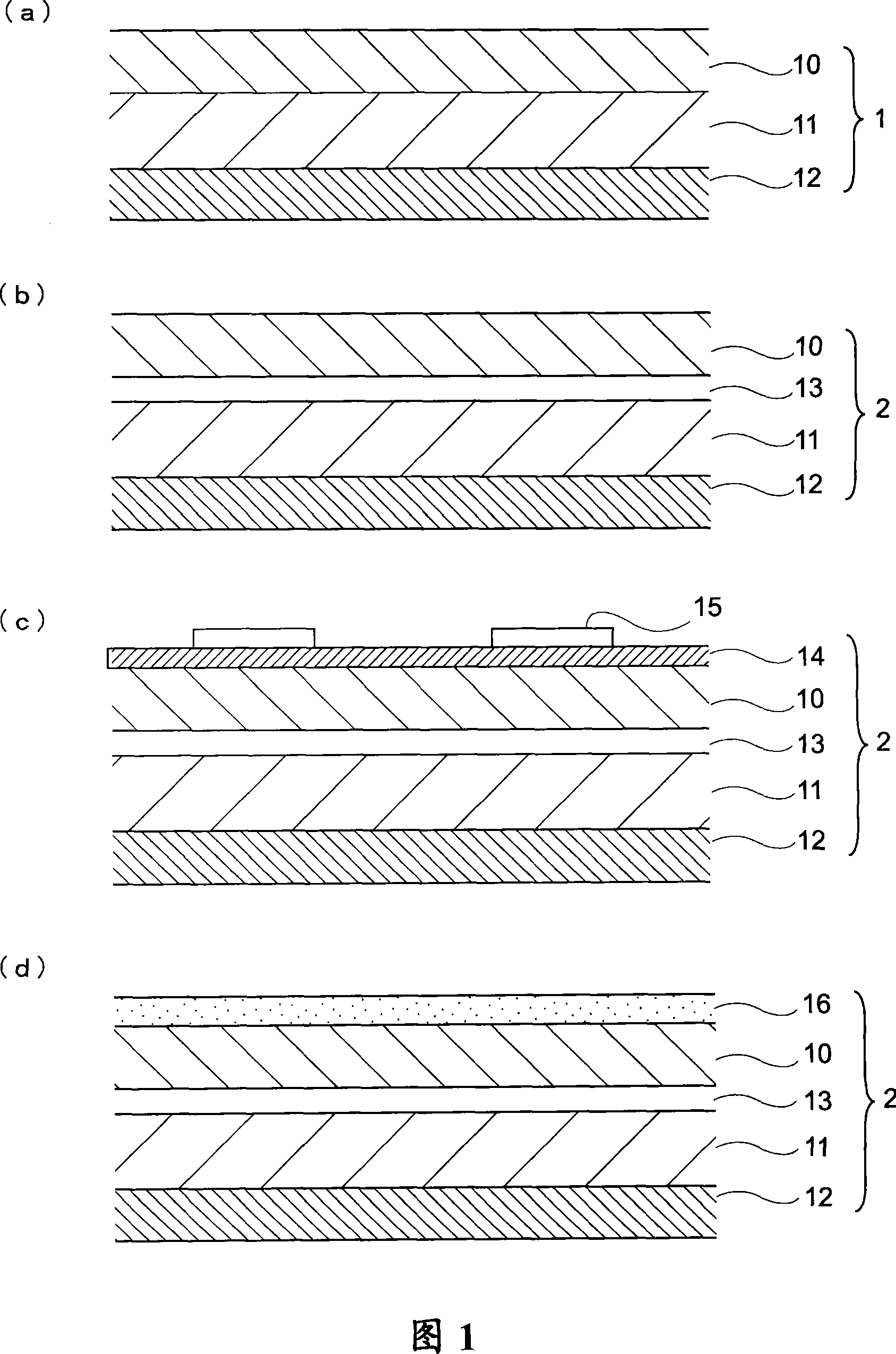

[0051] The first embodiment, as shown in FIGS. 1( a ) to ( d ), is tire adhesive labels 1 and 2 including a base material 10 and an adhesive layer 11 , and it can be provided that the adhesive layer contains a heat-melt adhesive An adhesive label for tires characterized by satisfying the following adhesive properties (A) and (B) while simultaneously satisfying the following adhesive properties (A) and (B) can solve the above-mentioned problems.

[0052] (A) The adhesive force to the SBR plate at 5° C. is a value of 7 N / 25 mm or more.

[0053] (B) Adhesion to the SBR plate at 40° C. is a value of 7 N / 25 mm or more.

[0054] 1( a ) to ( d ) respectively show a schematic cross-sectional structure in a state where a release film 12 is provided on the surface of the adhesive layer 11 .

[0055] 1. Substrate

[0056] (1) Type

[0057] The type and structure of the substrate 10 constituting a part of the adhesive label for tires shown in Figure 1 (a) to (d) are not particularly li...

Embodiment 1

[0142] 1. Production of adhesive labels for tires

[0143] 20.8% by mass of Clayton (KRATON) D-1112 (SIS, double block copolymer content: 40% by mass, styrene content: 15% by mass, Japan Clayton Polymer Co., Ltd. (KRATON POLYMER JAPAN), hereinafter referred to as "D-1112"), T-480X (softening point: 80°C aliphatic / aromatic copolymer petroleum resin, manufactured by Mitsui Chemicals Co., Ltd.) 44.5% by mass as an adhesion imparting agent, and PENSEL D- 125 (softening point: 125°C, polymerized rosin ester, manufactured by Arakawa Chemical Industries, hereinafter referred to as "D-125") 12.9% by mass, and Pureflex-SNH-100SP (paraffin-based lubricating oil, Sankyo Oil & Chemical Industry Co., Ltd. (hereinafter referred to as "SNH-100SP") 20.8% by mass, and 1% by mass of Irganox 1010 (hindered phenolic oxidation inhibitor, manufactured by Chiba Special Chemicals Co., Ltd.) as an oxidation inhibitor were uniformly mixed, and prepared as shown in Table 1. Matching hot-melt adhesive i...

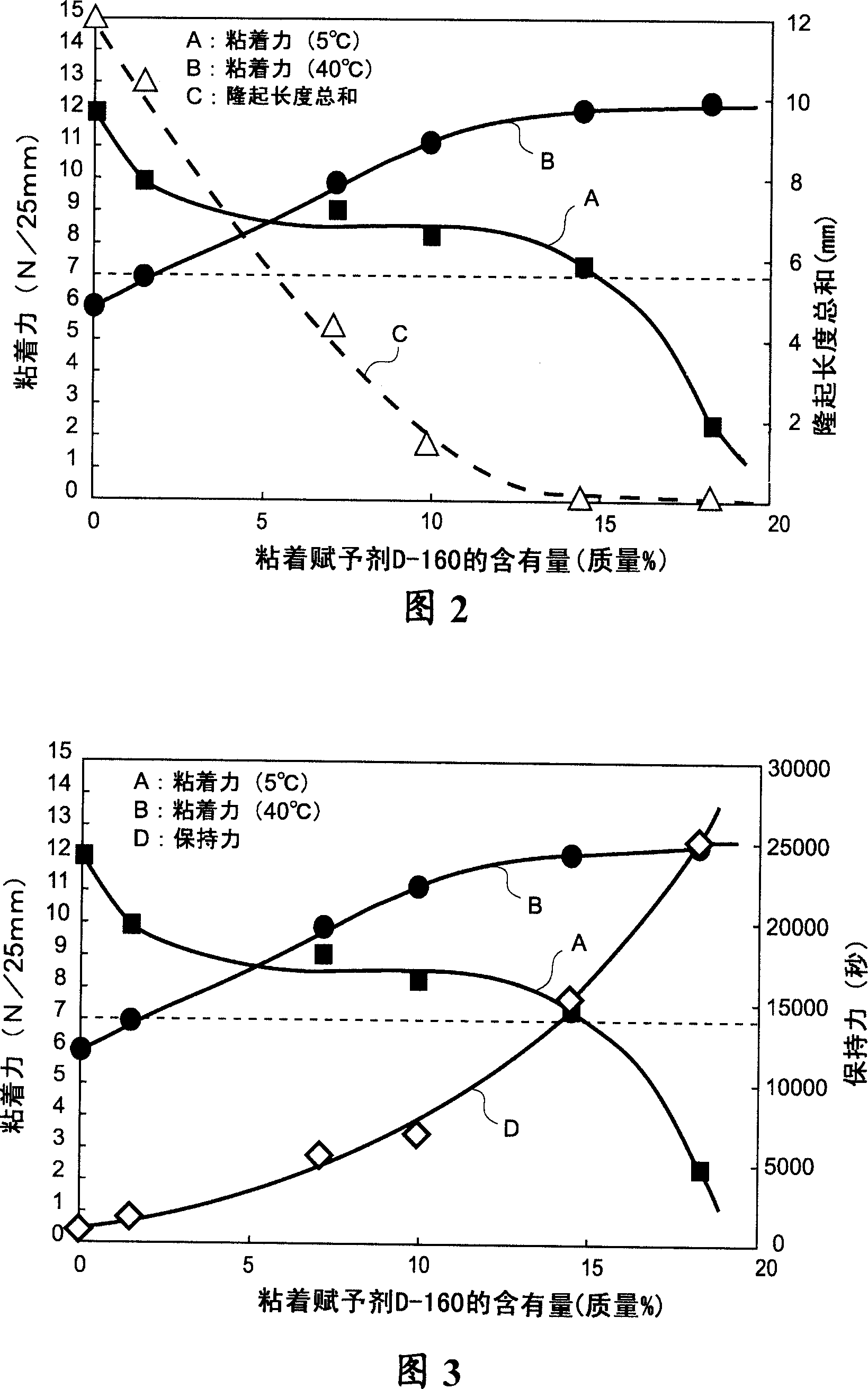

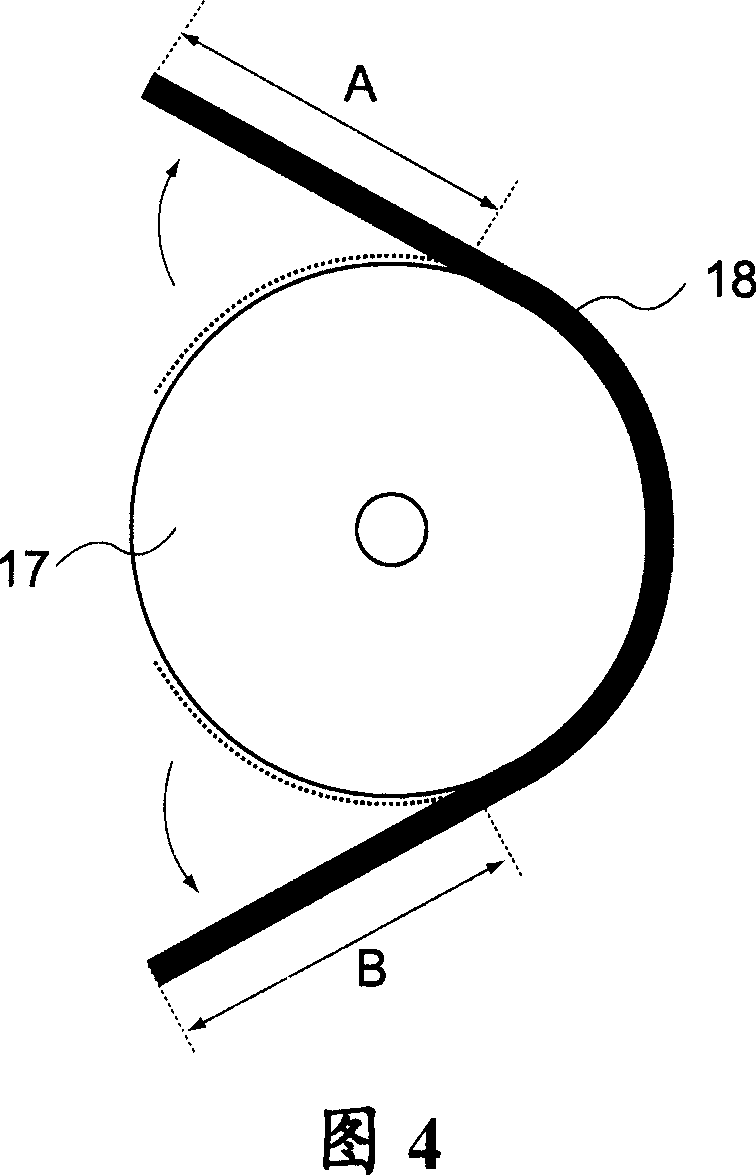

Embodiment 2~5

[0173] In Examples 2 to 5, the same as in Example 1, with a die coater at 50 g / m 2 The amount of the hot-melt adhesive prepared as shown in Table 1 is applied to the above-mentioned release film, and then it is attached to a white PET film with an aluminum vapor deposition layer to make a tire with a release film. Labels were evaluated in the same manner as in Example 1.

[0174] In addition, for the combination of hot-melt adhesive components, in addition to the materials used in Example 1, Clayton (KRATON) D-1113 (SIS, double block copolymer content: 55% by mass, Styrene content: 16% by mass, manufactured by KRATONPOLYMER JAPAN, hereinafter referred to as "D-1113"), and PENSEL D-160 (softening point: above 150°C, polymerized rosin ester , Arakawa Chemical Industries, hereinafter referred to as "D-160"). The results obtained are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com