Adhesive composition and laminated film using same

A technology of adhesives and compositions, applied in the direction of adhesive types, ester copolymer adhesives, polyurea/polyurethane adhesives, etc. It is easy to produce glue residue and other problems, and achieve the effect of good peelability, less glue residue and less change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0283] Hereinafter, several examples related to the present invention will be described, but the present invention is not intended to be limited to the contents shown in the examples. In addition, unless otherwise specified, "part" and "%" in the following description and a table represent a mass basis, a solid content, or an active ingredient.

[0284] In addition, the evaluation in the Example was performed as follows.

[0285]

[0286] The laminated film obtained by reciprocating a 2kgf roller once was crimped and pasted on a glass plate, and after 24 hours after pasting, the adhesion was measured using an adhesion / coating peeling analyzer VPA-3 (manufactured by Kyowa Interface Science Co., Ltd.). force. Measurement conditions are as described below. Adhesive strength was evaluated in two modes, the case where the pulling speed and the peeling speed were set to 150 mm / min, and the case where the pulling speed and the peeling speed were set to 1200 mm / min.

[0287] ·Ten...

Synthetic example 1

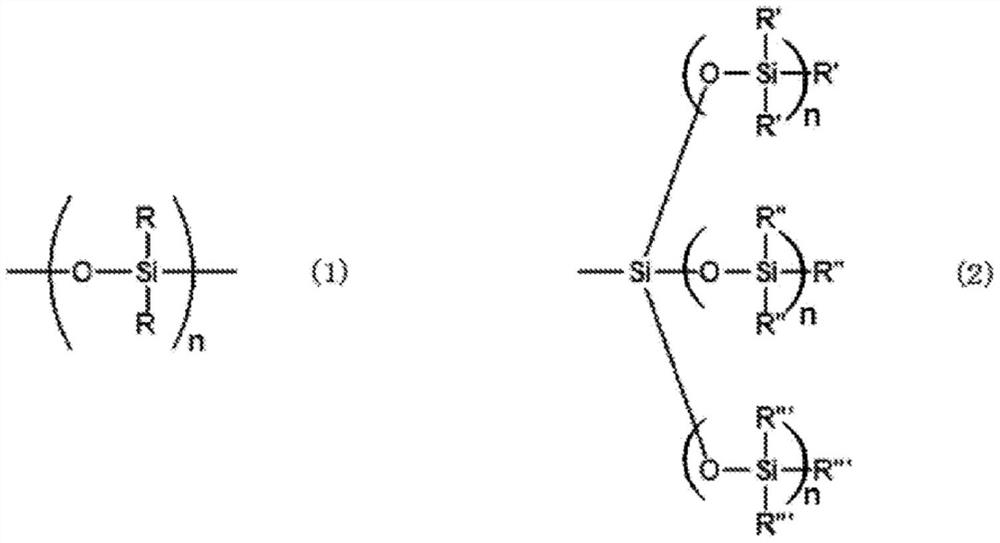

[0301] In a glass flask equipped with a stirring device, a thermometer, a cooling pipe, and a dropping device, 30 g of a block copolymer of ethylene oxide and propylene oxide represented by the following formula (1-1-1), and 2.8 g of acrylic acid 64 g of toluene as a solvent, 0.03 g of phenothiazine as a polymerization inhibitor, and 0.6 g of methanesulfonic acid as a catalyst were stirred under air flow, heated to 120° C., and refluxed for dehydration. After confirming dehydration of 0.63 g, it cooled to 65 degreeC and neutralized with triethylamine. After neutralization, the temperature was raised to 85° C., 2.3 g of ion-exchanged water was added, the liquid was separated, and the lower layer was extracted. The pH of the lower layer was measured, and the washing operation was repeated until the pH became 7 or higher. After cooling, it diluted with toluene, and obtained the toluene solution containing 55 mass % of the mixture (1-1) of 3 types represented by following formula...

Synthetic example 2

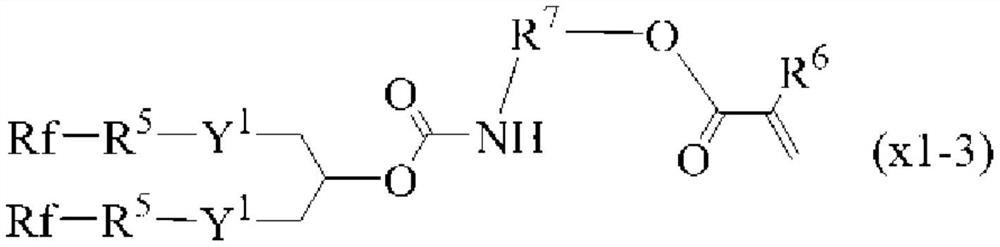

[0306] 300.00 g of toluene was added to the glass flask, and the temperature was raised to 105°C while stirring in a nitrogen stream. Then, the following dropping solution was installed on the dropping device: 42.90 g of 2-(perfluorohexyl) ethyl acrylate, 194.73 g of mixture (1-1), 129.05 g of toluene, initiator PERBUTYL O (manufactured by NOF Corporation) ) 11.25 g of the dripping solution was mixed, and the dropping solution was dripped over 4 hours while maintaining the inside of the flask at 105°C. After completion of the dropwise addition, the mixture was stirred at 105° C. for 10 hours. After completion of the reaction, the solvent was distilled off to obtain a polyoxyethylene compound (2).

[0307] When the polyoxyethylene compound (2) which is a copolymer was analyzed by GPC, the weight average molecular weight Mw was 12700.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com