Reactive polyurethane hot melt adhesive for bonding aluminum plate and wood veneer and preparation method of reactive polyurethane hot melt adhesive

A polyurethane hot-melt adhesive and reactive technology, applied in the direction of polyurea/polyurethane adhesive, adhesive type, adhesive, etc., can solve the problems of affecting the bonding force, high crystallization shrinkage, and unstable bonding. Achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

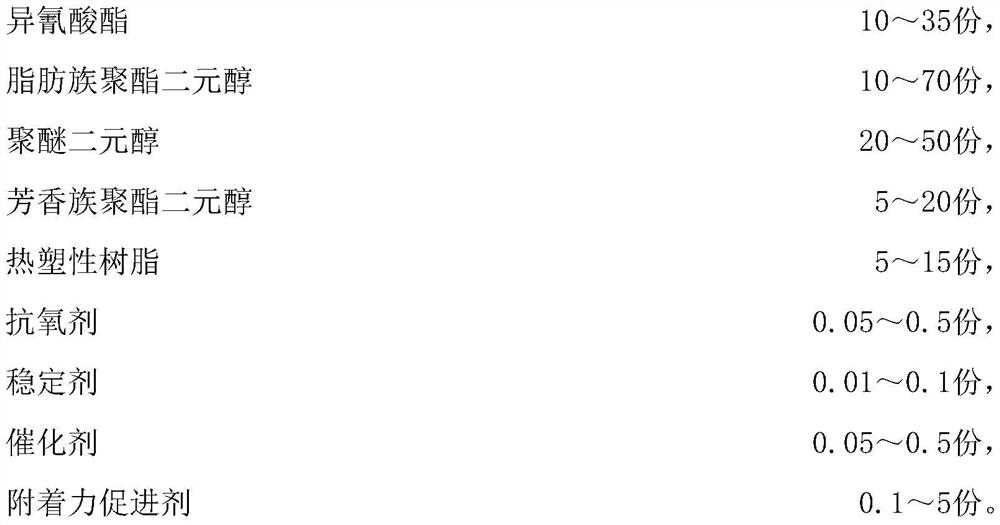

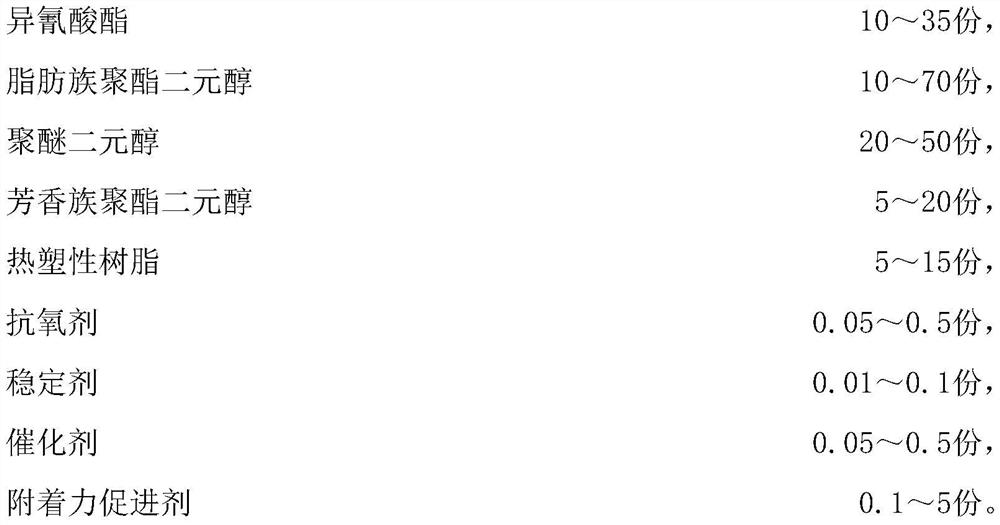

[0031] (1) The isocyanate is one or more of diphenylmethane-4,4-diisocyanate, isophorone diisocyanate, toluene diisocyanate, and hexamethylene diisocyanate.

[0032] (2) The aliphatic polyester diol is polyadipate-1,6-hexanediol, polyadipate-neopentyl glycol, polyadipate-1,4 - Butylene glycol ester diol, polyadipate-diethylene glycol ester diol, polyadipate-diethylene glycol-neopentyl glycol ester diol, polyadipate-hexanediol-neopentyl glycol One or more of ester diols.

[0033] (3) The polyether diol is mainly composed of propylene oxide, and its relative molecular weight is 1000-5000.

[0034] (4) The aromatic polyester diol is polydiethylene glycol phthalate, polyphthalate-1,6-hexanediol, polyphthalic acid Neopentyl glycol ester diol, polyneopentyl glycol phthalate diol, polyterephthalate-neopentyl glycol ester diol, polyphthalic anhydride-neopentyl glycol ester diol, polyphthalic anhydride-diol One or more of ethylene glycol ester diol and polyneopentyl isophthalate dio...

Embodiment 1

[0052] A reactive polyurethane hot-melt adhesive bonded to an aluminum plate and a veneer, the preparation method of which may comprise the following steps:

[0053] Step 1. Weigh 12kg of diphenylmethane-4,4-diisocyanate, 20kg of polyadipate-neopentyl glycol ester diol, 10kg of polyadipate-1,6-hexanediol ester diol, polyether Diol 20kg, polyneopentyl glycol phthalate diol 9kg, thermoplastic acrylic resin 8Kg, antioxidant 1010 0.05kg, phosphoric acid 0.01kg, dibutyltin dilaurate 0.05kg, silane coupling agent KH-550 0.5kg. The number average molecular weight of the polyether glycol that the embodiment of the present invention uses is 2000, and the number average molecular weight of polyadipate-neopentyl glycol ester diol is 2500, and the number average molecular weight of polyphthalate neopentyl glycol ester diol The number average molecular weight is 5500, and the number average molecular weight of polyadipate-1,6-hexanediol ester diol is 2000.

[0054] Step 2, polyadipate-ne...

Embodiment 2

[0059] A reactive polyurethane hot-melt adhesive bonded to an aluminum plate and a veneer, the preparation method of which may comprise the following steps:

[0060] Step 1, weigh diphenylmethane-4,4-diisocyanate 10kg, polyadipate-diethylene glycol-neopentyl glycol ester diol 18kg, polyadipate-1,4-butylene glycol ester diol 7kg, polyether diol 25kg, polyphthalic anhydride-diethylene glycol ester diol 10kg, thermoplastic acrylic resin 7Kg, antioxidant 1035 0.05kg, phosphoric acid and benzoic acid mixture 0.01kg, dimorpholine triethyl ether 0.1kg , Silane coupling agent A-172 0.5kg. The number average molecular weight of the polyether glycol that the embodiment of the present invention uses is 3000, polyadipate-diethylene glycol-neopentyl glycol ester diol (the mol ratio of diethylene glycol and neopentyl glycol is 1:2 ) has a number average molecular weight of 3500, polyadipate-1,4-butylene glycol ester diol has a number average molecular weight of 3000, polyphthalic anhydride...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com