Tension-controllable film drawing device

A membrane device and tension technology, applied in the direction of measuring devices, force/torque/work measuring instruments, instruments, etc., can solve the problems of uncertain force on the film, inability to grasp the tension of the film, and inability to ensure process consistency, etc., to achieve simple device , Low manufacturing cost, easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

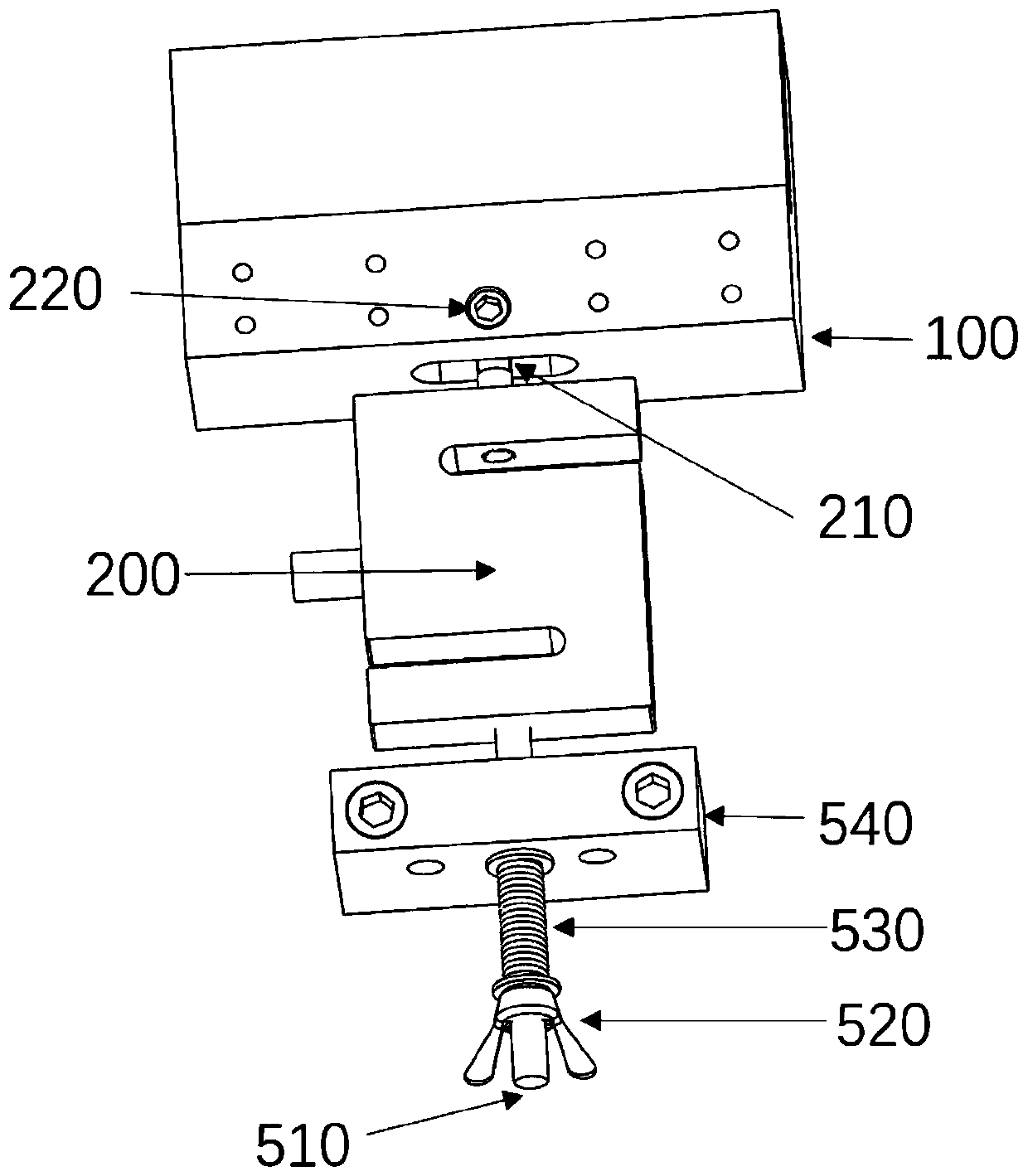

[0053] Such as image 3 As shown, according to an embodiment of the present invention, the tension sensor is connected to the film pulling module through a connecting screw 210 , the connecting screw 210 passes through the sensor 200 vertically, and is connected to the screw 510 inside the sensor. The connecting screw 210 is provided with a nut 220 above the film pulling module.

[0054] Such as Figure 4 As shown, there is a hole 2101 in the middle of the connecting screw 210 , and the screw 510 passes through the hole 2101 on the connecting screw and is connected to the film stretching module 100 .

[0055]With the above-mentioned design, the connecting screw 210 can rotate in the horizontal direction relative to the film-drawing module. While the film-drawing module moves along the direction of the screw through the telescopic module, it can also rotate to a certain extent relative to the screw and the sensor, that is, tension is generated along the direction of the screw....

Embodiment

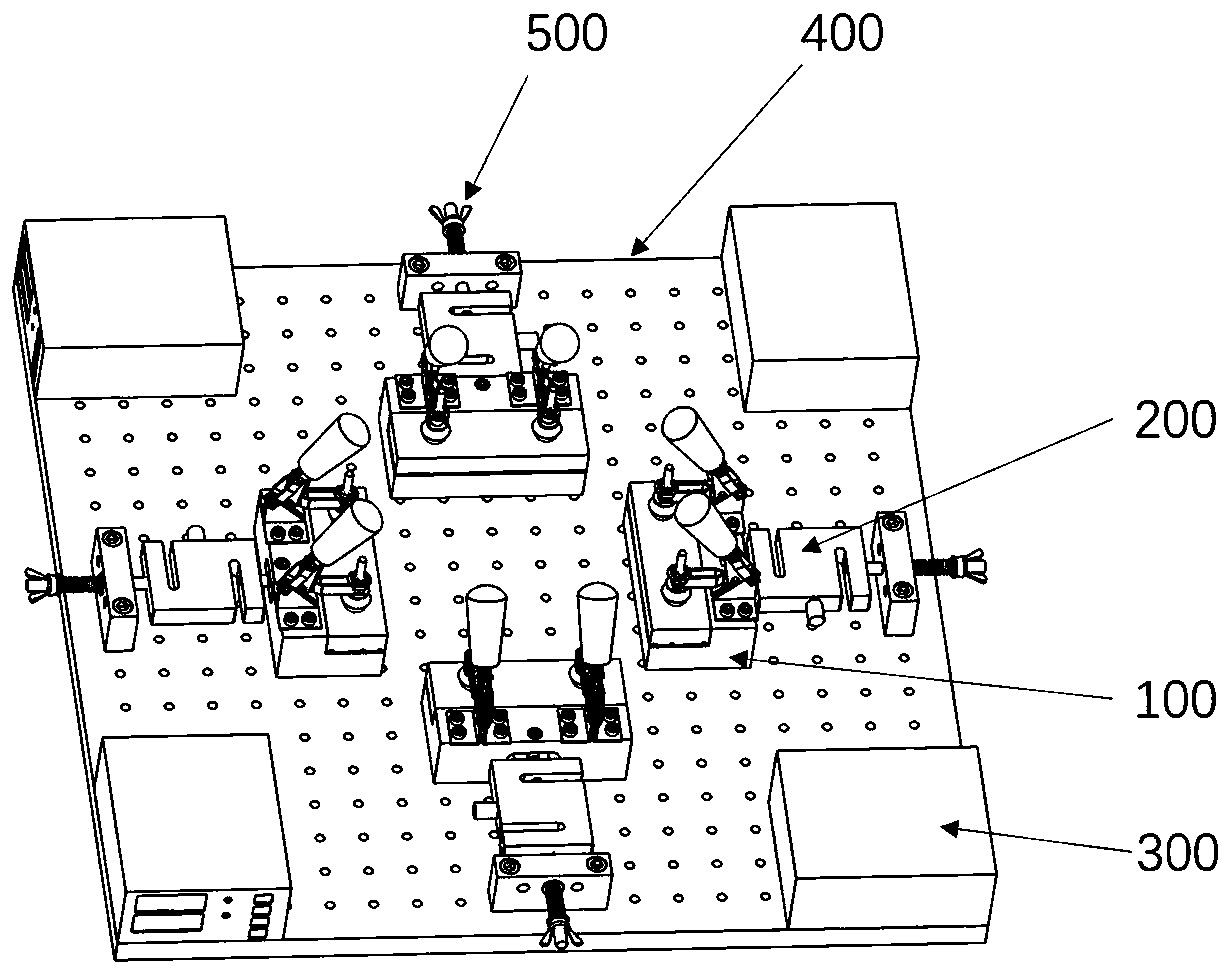

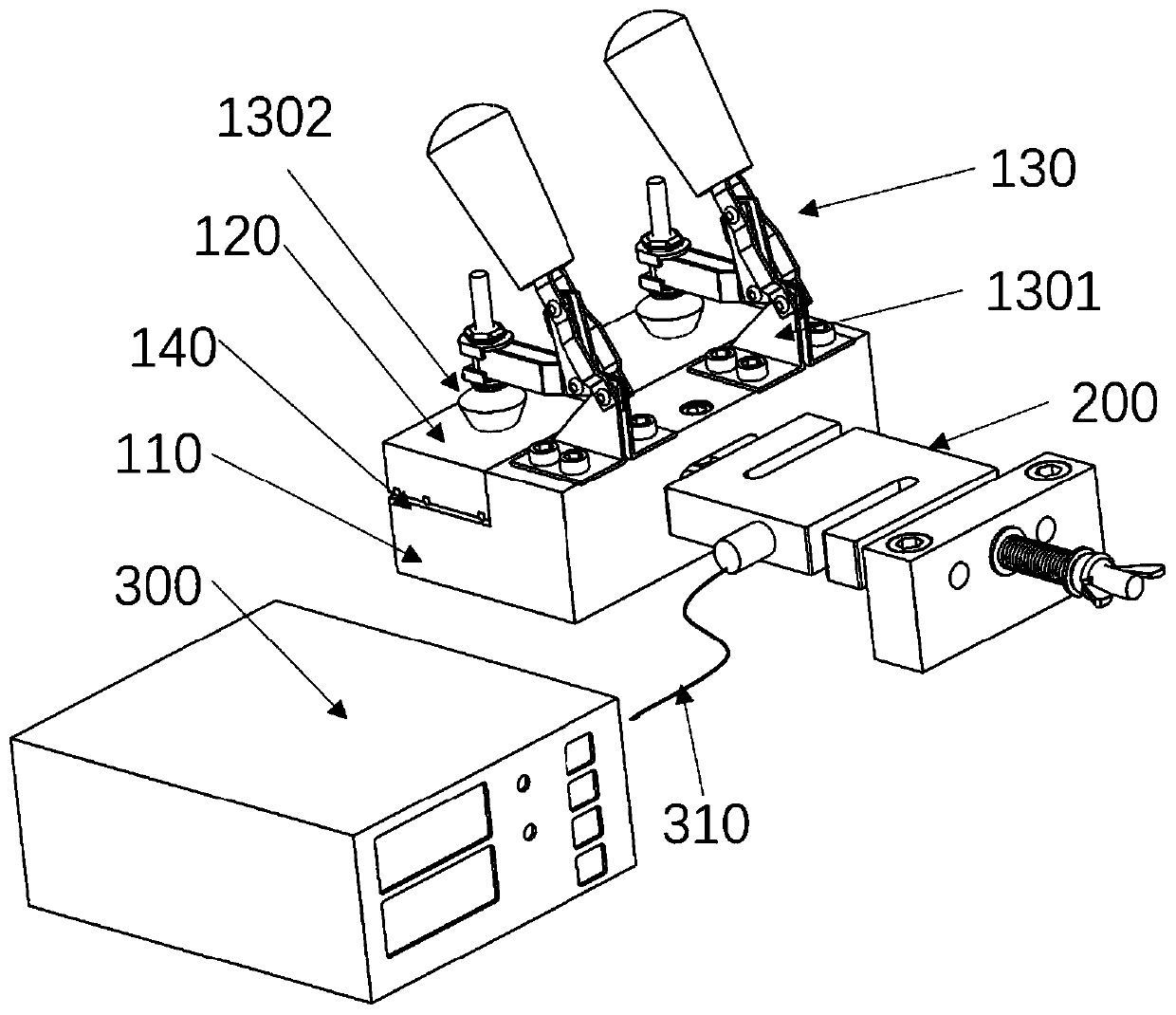

[0076] This embodiment provides a controllable tension film pulling device, such as figure 1 As shown, it mainly includes a film pulling module 100 , a tension sensor 200 , a digital display module 300 , an optical platform 400 , and a telescopic module 500 ; The film is placed between the base 110 and the pressing block 120, and the pressing block 120 is tightly pressed onto the base 110 using the quick clamp 130 to fix the film; one end of the tension sensor 200 is connected to the film pulling module 100, and the other end is connected to the telescopic screw 510 , the telescopic screw 510 drives the tension sensor 200 and the film pulling module to move backward under the tightening of the nut 520, thereby making the film tense, and at the same time, the tension value applied to the film is displayed by the digital display module 300 of the tension sensor; by adjusting The numerical value on the digital display module 300 connected with the nut 520 and the tension sensor 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com