Patents

Literature

31results about How to "Meet bonding needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Geopolymer-based wood adhesive and preparation method and application thereof

ActiveCN109251682AWide variety of sourcesLow priceNon-macromolecular adhesive additivesMacromolecular adhesive additivesDopantAdhesive

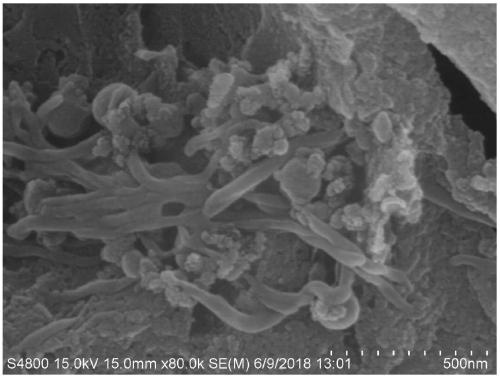

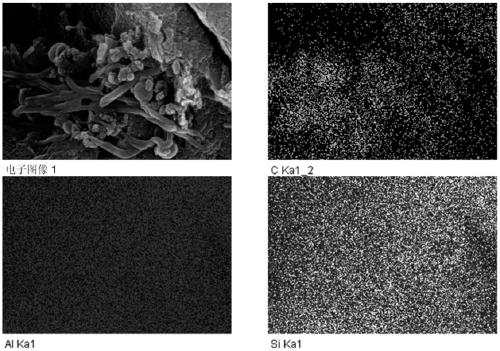

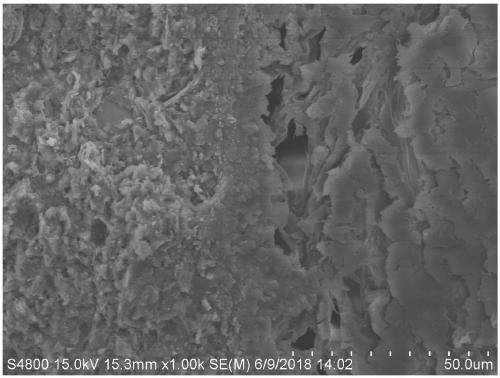

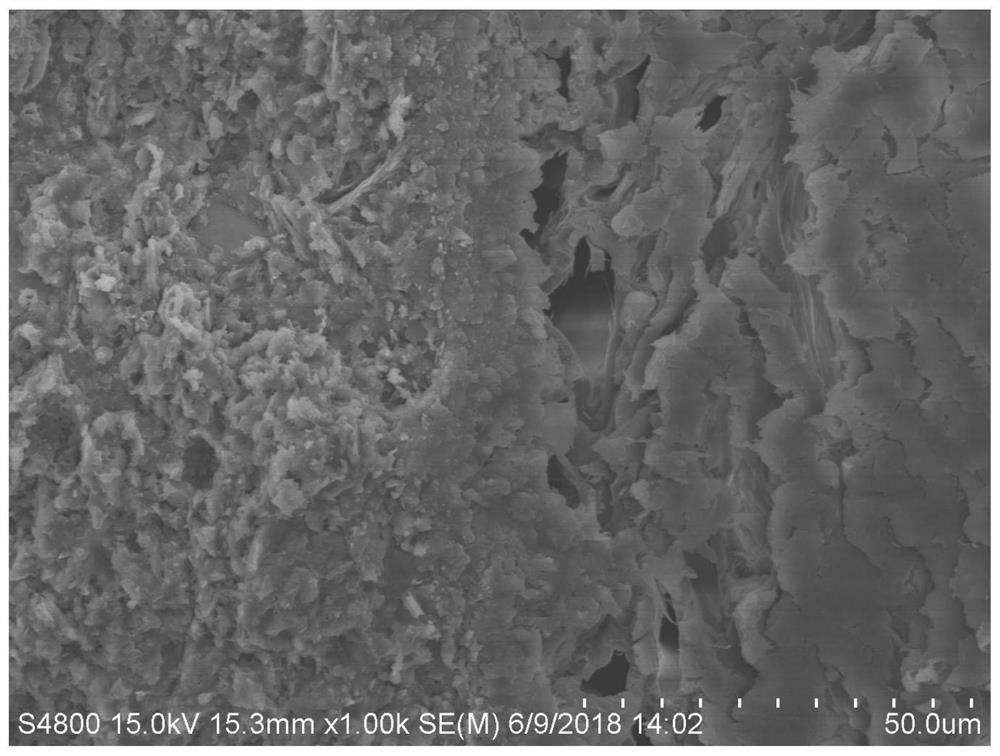

The invention relates to an environmentally-friendly high-performance geopolymer-based wood adhesive and a preparation method and application thereof. The geopolymer-based wood adhesive is prepared from the following raw materials (by weight): 100 parts of a base material, 1-20 parts of an organic dopant, 87.5-280 parts of an alkali activator, 0.3-1 part of an initiator, 1-2.4 parts of a couplingagent, 1-2.4 parts of an emulsifier, 0.4-1.6 parts of an antifoaming agent and 50-200 parts of water. After the organic dopant is solidified, a chain or net structure can be formed. Thus, the chain ornet structure and the geopolymer form interpenetrating networks to achieve the toughening modification effect, and a mechanical locking effect with the wood material can also be achieved. The geopolymer-based wood adhesive is green and environmentally friendly; the sources of raw materials are wide; production cost is low; and the process is simple. The geopolymer-based wood adhesive is non-flammable, has no release of formaldehyde and has good bonding performance. The geopolymer-based wood adhesive is instant to use when prepared and the formula can be adjusted flexibly. The geopolymer-basedwood adhesive can be used to glue wooden raw materials such as wood, bamboo, straw and the like and to prepare wooden composite materials such as particle boards, fiberboards, plywoods, reconstitutedwood / bamboo and the like, and has industrial application value.

Owner:BEIJING FORESTRY UNIVERSITY

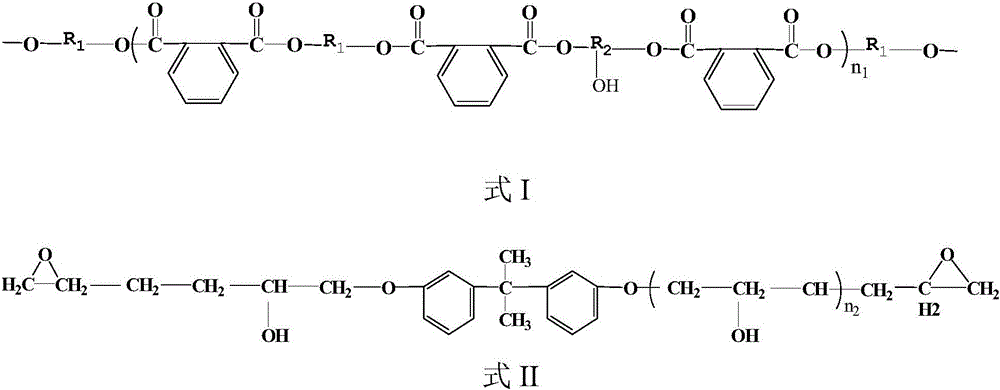

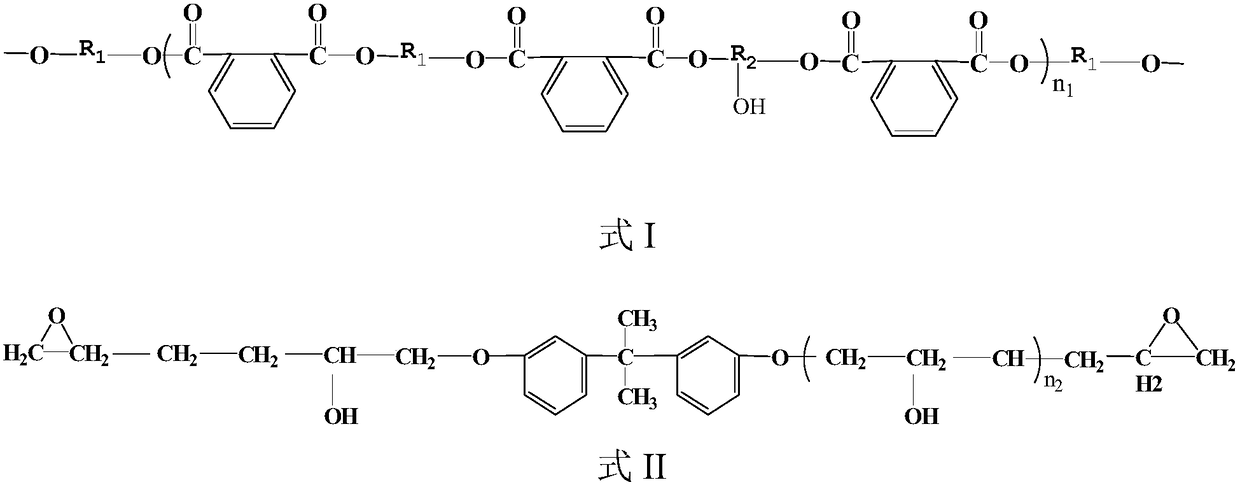

Polyurethane adhesive and method for preparing same

ActiveCN106221650AGood flexibilityImprove cohesive strengthPolyureas/polyurethane adhesivesPolyesterPolyurethane adhesive

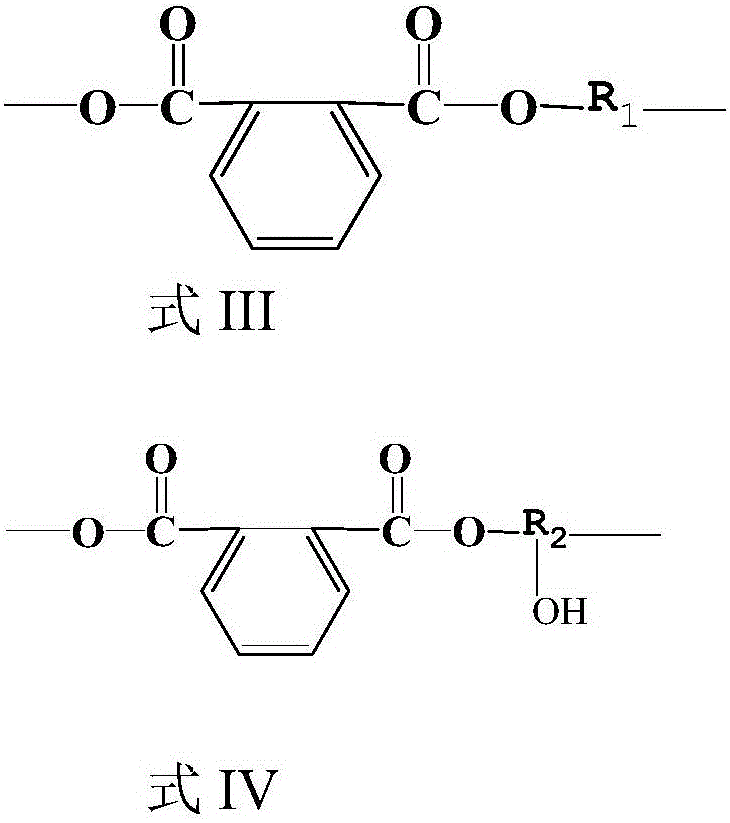

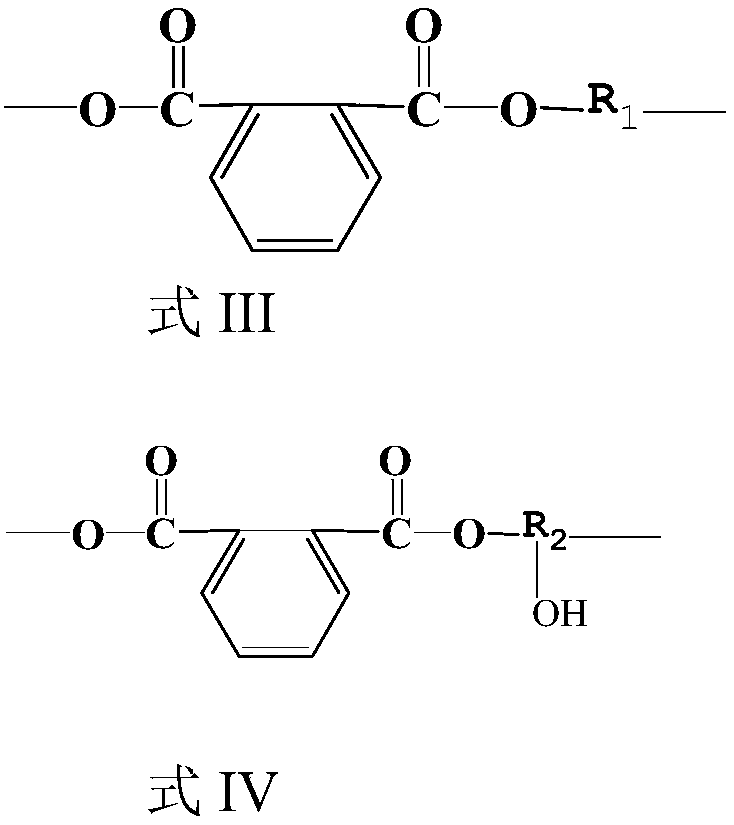

The invention discloses polyurethane, a composition with same and a method for preparing the polyurethane. The polyurethane is a random copolymer with repeat units shown as a formula I and a formula II. An R<1> in the formulas selectively represents C<2>-C<5> diol, an R<2> selectively represents R<3>CH<2>-CHR<3>-CH<2>R<3>, and the R<3> represents OCO (CH<2>) <7>CH=CHCH<2>CHOH (CH<2>) <5> CH<3>; an n<1> is selectively 1 or 2, an n<2> is selectively an integer ranging from 0 to 3, and the mass percentages of the repeat units, which are shown in the formula I, in the polyurethane range from 4% to 12%; the mass percentages of the repeat units, which are shown in the formula II, in the polyurethane range from 2% to 10%. The polyurethane, the composition and the method have the advantages that the polyurethane is doubly modified by the aid of polyester polyol modified by castor oil and bisphenol A type epoxy resin in polyurethane preparation procedures, accordingly, the cohesion strength, the water resistance and the heat resistance of adhesive can be obviously improved, and base material surface adhesive force of the adhesive can be obviously increased.

Owner:中科华宇(福建)科技发展有限公司

Long-operation-time two-component acrylate structural adhesive and preparation method thereof

InactiveCN111662654ALong operating timeStrong bonding abilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesiveOligomer

The invention discloses a long-operation-time two-component acrylate structural adhesive and a preparation method thereof. The two-component acrylate structural adhesive is composed of a component A and a component B, and the component A and the component B are used in cooperation according to the volume ratio of 1: 1; the component A comprises the following raw materials in parts by weight: 35-65parts of a (methyl) acrylate monomer, 8-25 parts of a toughening agent, 0.1-2 parts of a stabilizer, 2-15 parts of an accelerant, 3-15 parts of an oxidant, 3-10 parts of a urethane acrylate oligomerand 1-5 parts of an auxiliary agent; and the component B comprises the following raw materials in parts by weight: 30-70 parts of a (methyl) acrylic monomer, 5-20 parts of a toughening agent, 0.1-2 parts of a stabilizer, 1-10 parts of an accelerant, 3-18 parts of a reducing agent, 3-10 parts of a urethane acrylate oligomer and 1-5 parts of an auxiliary agent. The adhesive not only has long operation time, but also has ideal adhesive ability to common base materials, has high strength, and is suitable for working conditions of large-area adhesion.

Owner:BEIJING COMENS NEW MATERIALS

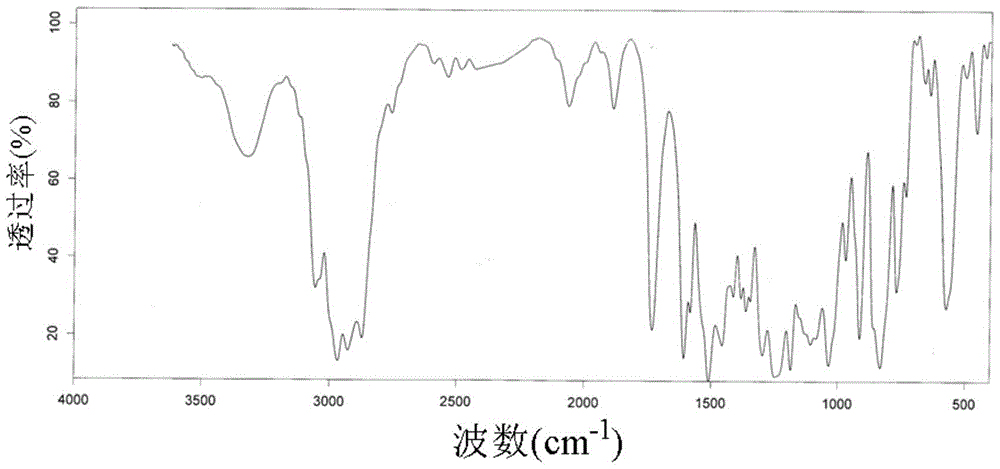

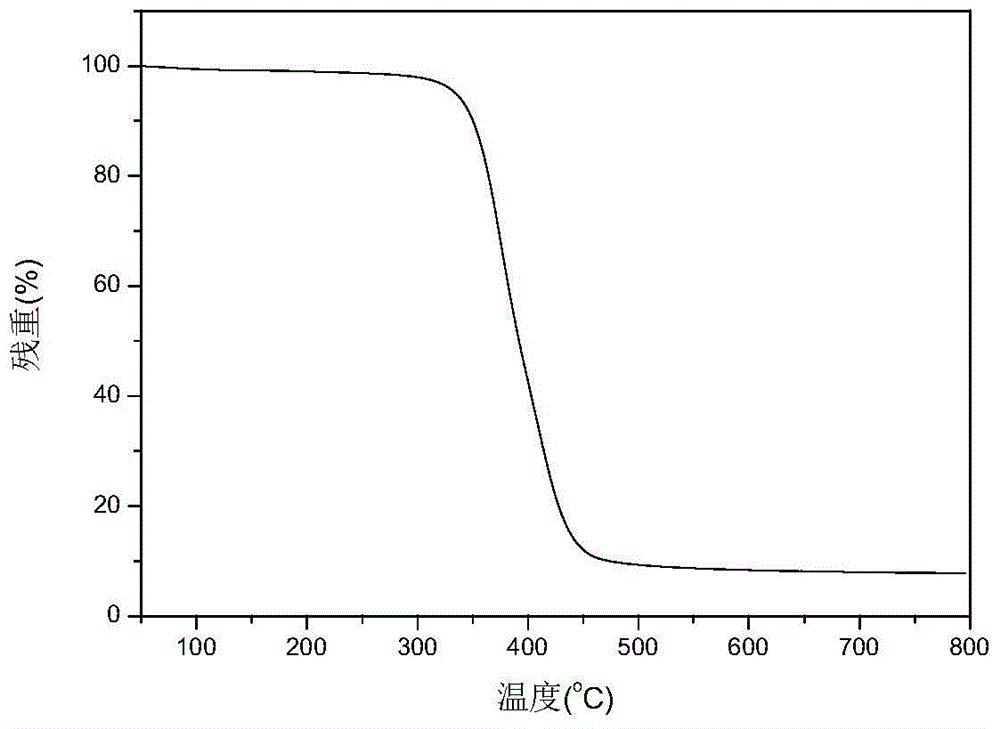

Normal-temperature solidification instant-high-temperature-resistant high-flexibility epoxy adhesive and preparing method thereof

InactiveCN104927755AImprove flexibilityHigh strengthNon-macromolecular adhesive additivesCouplingAccelerant

The invention provides a normal-temperature solidification instant-high-temperature-resistant high-flexibility epoxy adhesive and a preparing method thereof and relates to an epoxy adhesive and a preparing method thereof. The epoxy adhesive and the preparing method thereof aim at solving the problems that existing normal-temperature solidification epoxy resin is poor in flexibility and cannot resist instant high temperatures. The normal-temperature solidification instant-high-temperature-resistant high-flexibility epoxy adhesive is prepared from, by weight, 50-100 parts of polyether modified epoxide resin, 60-120 parts of flexible curing agent, 10-30 parts of phenolic resin, 1-3 parts of accelerant, 1-3 parts of coupling agent. The preparing method comprises the steps that firstly, materials are weighed; secondly, the polyether modified epoxide resin and the phenolic resin are mixed and then ground through a three-roller grinding machine, then the flexible curing agent, the accelerant and the coupling agent are added and evenly mixed, and the normal-temperature solidification instant-high-temperature-resistant high-flexibility epoxy adhesive is obtained. The normal-temperature solidification instant-high-temperature-resistant high-flexibility epoxy adhesive can be obtained.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

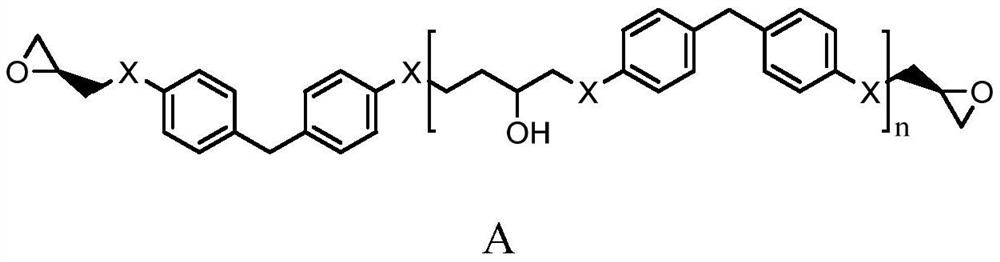

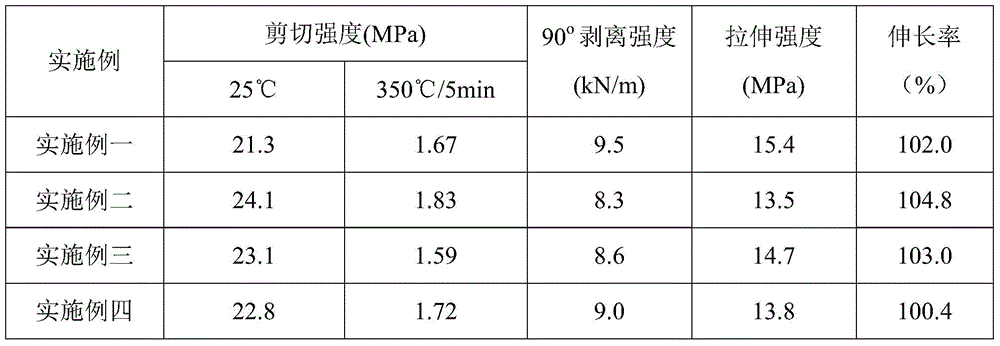

Fast-curing high-strength epoxy adhesive

ActiveCN113549417AFast curingMeet bonding needsMacromolecular adhesive additivesEpoxy resin adhesivesPolymer scienceFirming agent

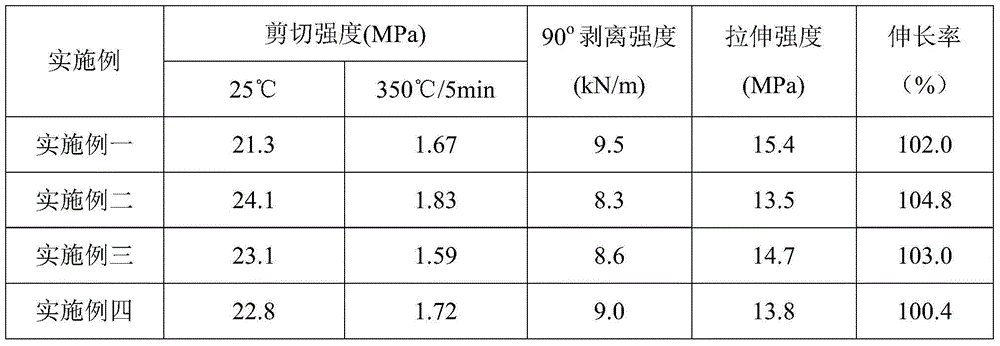

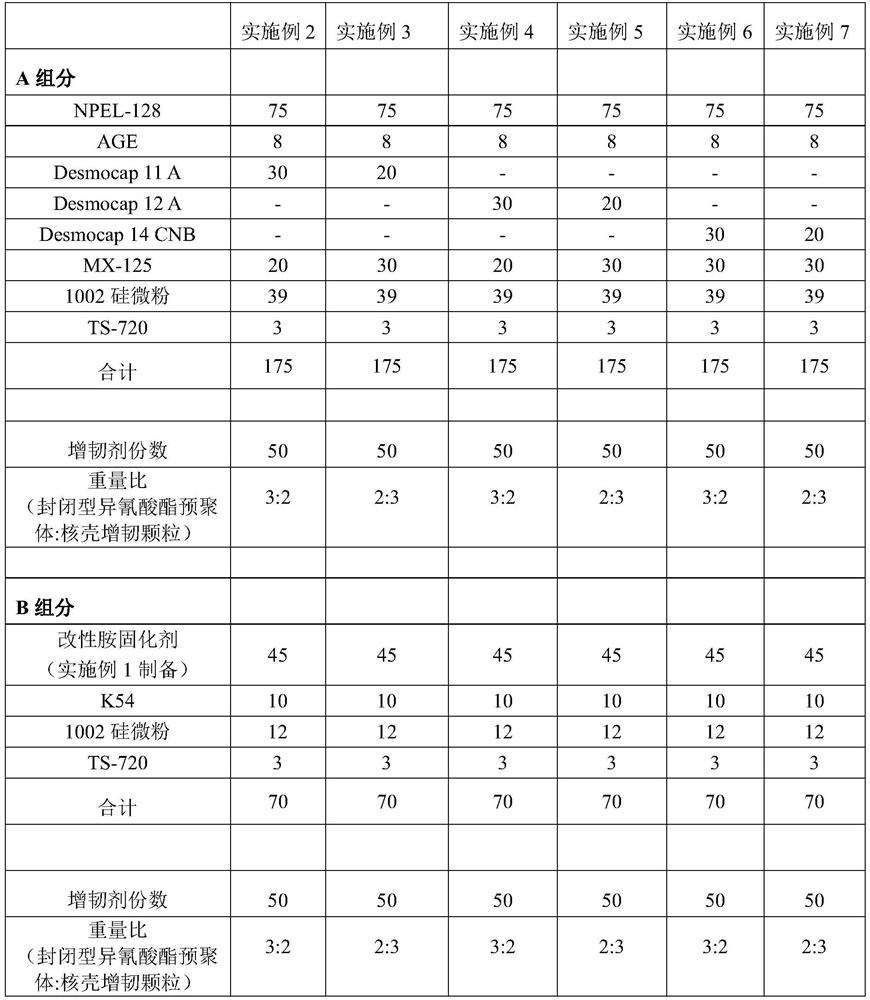

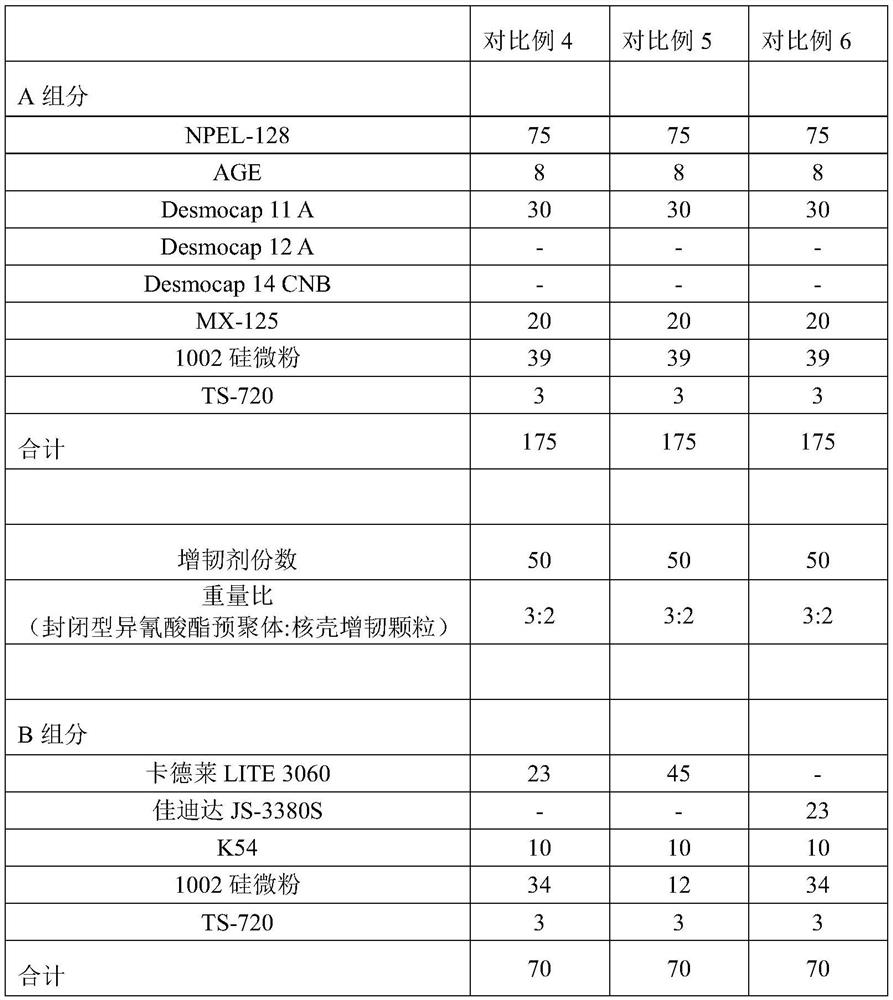

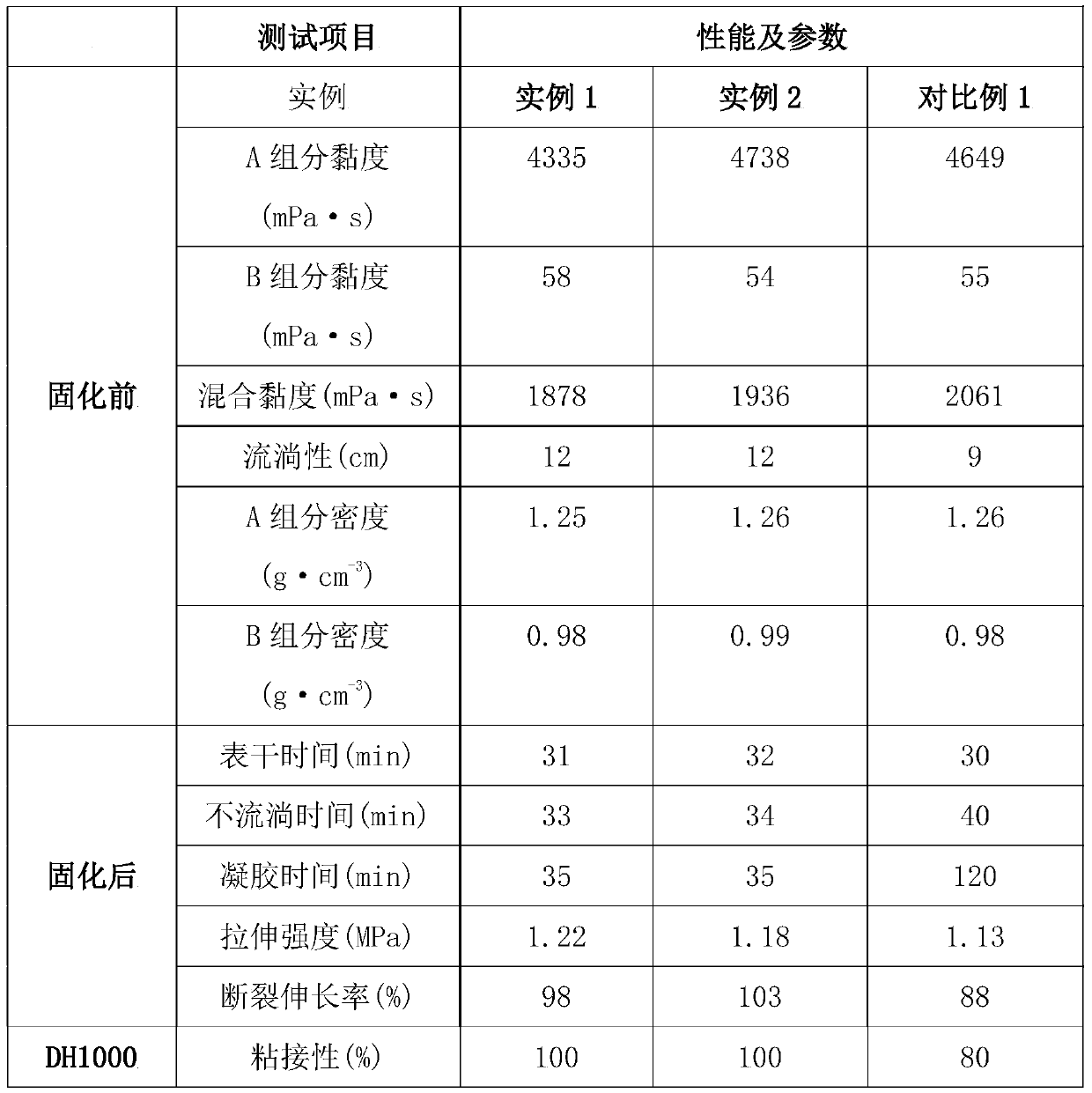

The invention discloses a fast-curing high-strength epoxy adhesive which comprises a component A and a component B. The component A comprises the following components in parts by weight: 60-100 parts of epoxy resin, 1-10 parts of an epoxy diluent, 30-60 parts of a toughening composition, 5-50 parts of filler and 1-5 parts of a thixotropic agent. The component B is prepared from the following components in parts by weight: 30 to 70 parts of amine curing agent, 1 to 20 parts of curing accelerator, 1 to 20 parts of filler and 1 to 5 parts of thixotropic agent. According to the fast-curing high-strength epoxy adhesive, the blocked polyurethane prepolymer and the core-shell rubber particle dispersion liquid are compounded and combined to be used as a toughening agent, so that the impact toughness of the adhesive is improved while the shear strength is rapidly established.

Owner:GUANGDONG HENGDA NEW MATERIALS TECH

Inner and outer synchronously cured double-component organic silicon pouring sealant and preparation method thereof

InactiveCN109777343AImprove the level ofMeet curing needsNon-macromolecular adhesive additivesArray data structureAlcohol

The invention discloses an inner and outer synchronously cured double-component organic silicon pouring sealant which comprises a component A and a component B in a weight ratio of (5.5-6.5):1, wherein the component A comprises the following components in parts by weight: 100 parts of alpha,omega-dyhydroxy polydimethyl siloxane, 20-90 parts of a filler, 1-20 parts of a plasticizer, 0.5-5 parts ofa curing promoter and 0-10 parts of a pigment; the component B comprises the following components in parts by weight: 100 parts of a curing agent carrier, 40-60 parts of a silane cross-linking agent,10-20 parts of a silane coupling adhesion promoter and 0.05-1 part of a catalyst; the curing promoter is an organic silicon modified thioether alcohol solution; the weight percentage concentration ofthe organic silicon modified thioether alcohol solution is 60-90%. The invention further discloses a preparation method of the inner and outer synchronously cured double-component organic silicon pouring sealant. The double-component organic silicon pouring sealant disclosed by the invention has the advantages of being simple in production process, feasible in inner and outer synchronously curing,wide in adhesion range, excellent in storage property, and the like, and can be applied to sealing of structures with complex inner structures and relatively rich micro-pore structures.

Owner:西卡(江苏)工业材料有限公司

Manufacturing method of artificial marble plate adhesive

InactiveCN101323768ADoes not affect the visual effectMeet bonding needsEster polymer adhesivesMetallurgyAdhesive

The invention relates to a manufacturing method of a scagliola adhesive, which is characterized in that: the manufacturing method comprises the steps as follows: (1) manufacturing color master batch: calculated by weight, 60 pbw (parts by weight) to 75 pbw of aluminum hydroxide, 25 pbw to 40 pbw of unsaturated polyester resin, 0 pbw to 15 pbw of toner, 0.5 pbw to 4 pbw of curing agent are taken, mixed and cast for curing and then the obtained lump material is crashed; (2) preparing by mixing: 75 pbw to 99 pbw of acrylate resin high molecular polymer, 0 pbw to 8 pbw of color paste and 0.1 pbw to 25 pbw of the color master batch are taken and mixed so as to obtain the scagliola adhesive. The manufacturing method of the invention introduces the color master batch structure resembling the structure of the scagliola to the adhesive, thus ensuring the color to be the same as that of scagliola boards after re-bonding and joints to have the same visual effects as the scagliola boards.

Owner:姚志明

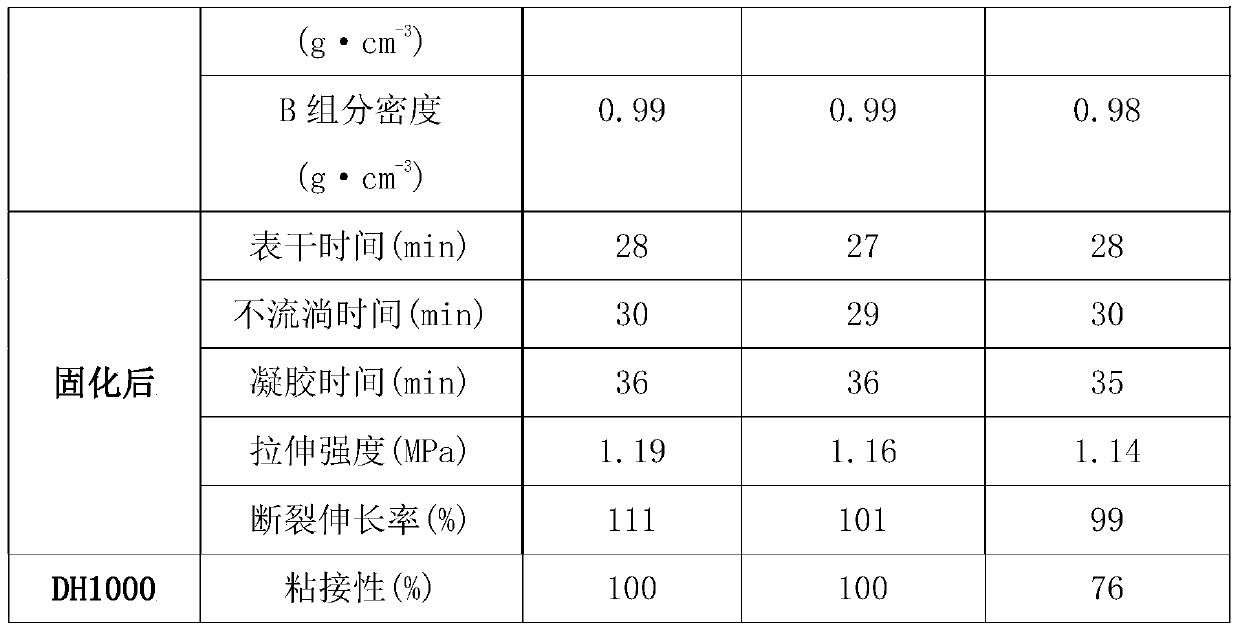

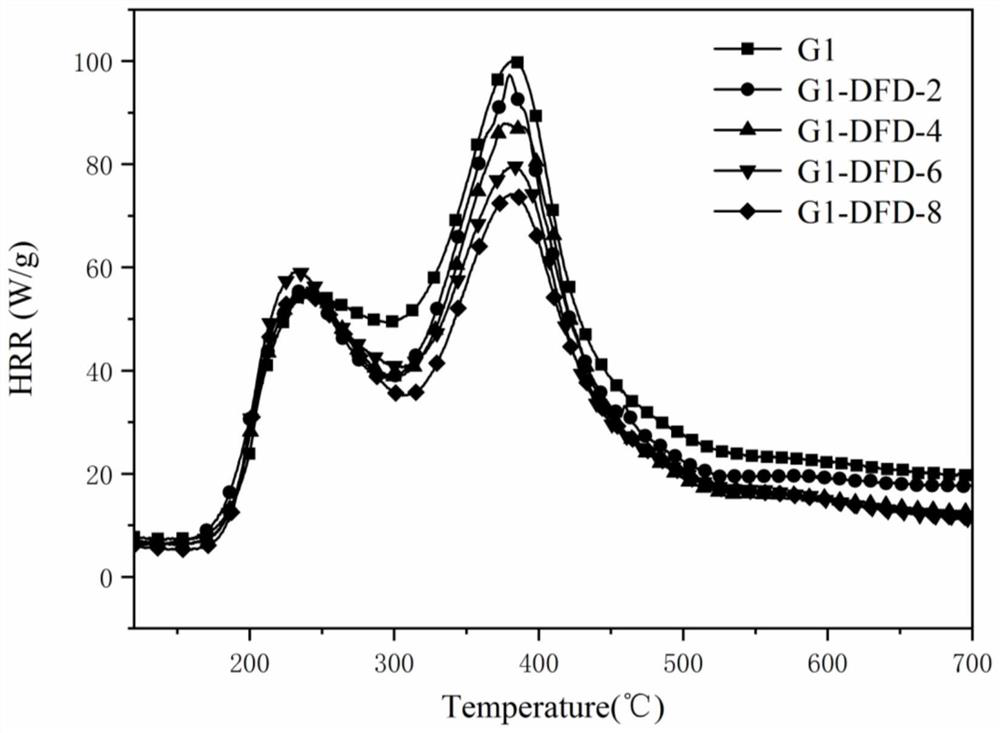

Preparation of novel flame retardant and application of novel flame retardant in flame-retardant adhesive

ActiveCN112646510AImprove flame retardant performanceGood effectNon-macromolecular adhesive additivesGroup 5/15 element organic compoundsAdhesive cementSimple Organic Compounds

The invention relates to preparation of a novel flame retardant and application of the novel flame retardant in a flame-retardant adhesive. The flame retardant is prepared from an amino-containing organic compound through a one-step reaction, the synthesis conditions are simple and controllable, and the synthesis efficiency is high; and after the flame retardant and the adhesive are blended, the high-flame-retardant adhesive can be obtained. The high-flame-retardant adhesive synthesized by the invention can be directly used as an adhesive of a high polymer material, and has high bonding strength; the adhesive can also be used as a basic formula, and can be used as a composite adhesive after other fillers are added; and the high-flame-retardant adhesive can also be used as a bottom coating agent to realize surface modification of a high polymer material so as to meet different requirements of various special occasions.

Owner:SHANDONG UNIV

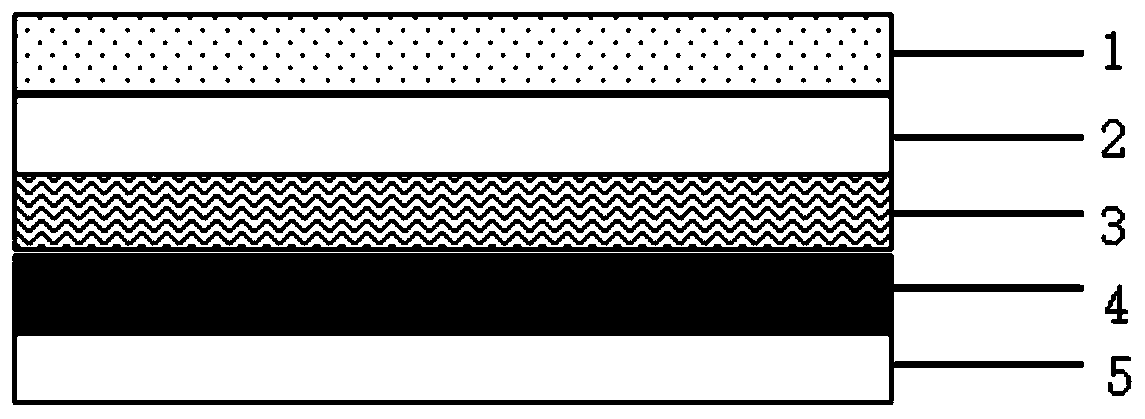

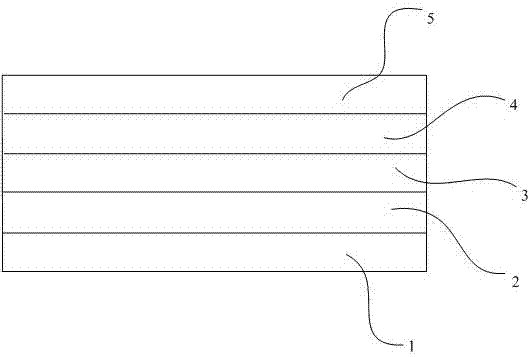

Film material and preparation method thereof

PendingCN111100566AImprove production yieldWon't breakPolyureas/polyurethane adhesivesHeat-activated film/foil adhesivesPolymer scienceThin membrane

A film disclosed by the invention comprises a multilayer structure which is arranged in sequence. The multilayer structure at least comprises a hot melt adhesive layer, a TPU substrate layer and a UVadhesive microstructure coating, wherein the UV adhesive microstructure coating is provided with a surface microstructure, and the microstructure comprises CD lines or drawn wires or concave-convex lines, an NCVM plating layer and an ink layer. The film provided by the scheme of the invention has good toughness, is beneficial to subsequent processing, and has good matching and fitting performancefor PC, glass materials and other materials.

Owner:江苏晶华新材料科技有限公司

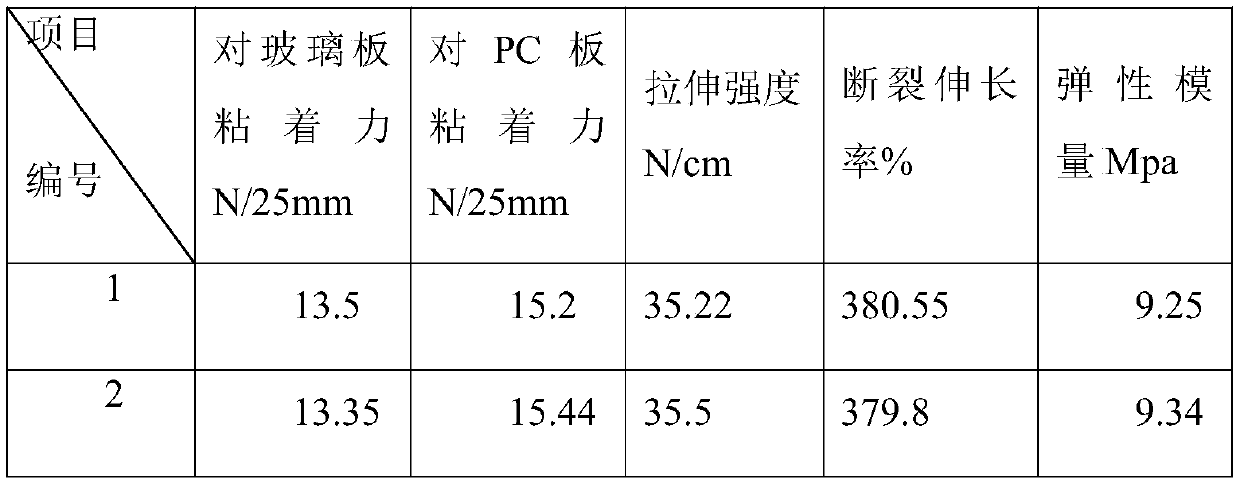

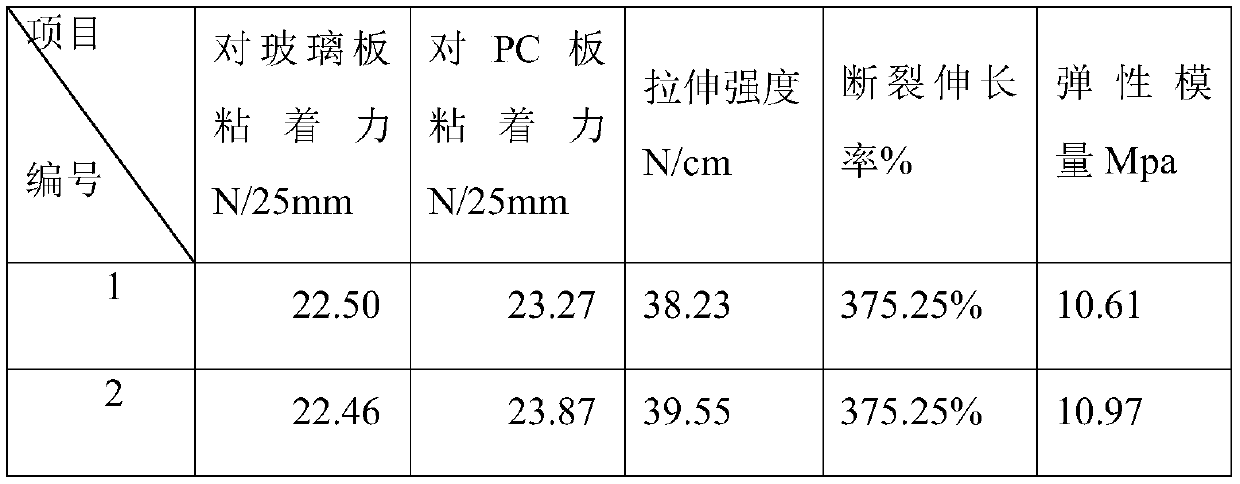

Two-in-one primer glue color sheet and manufacturing method thereof

InactiveCN107443836AImprove versatilityReduce the number of layersLamination ancillary operationsPolyureas/polyurethane adhesivesPolymer scienceColor film

The invention discloses a two-in-one primer glue color sheet. The two-in-one primer and glue color sheet comprises a back paint layer, a substrate, a primer glue layer, a color film layer and a protective film layer, which are sequentially arranged from bottom to top, wherein a formula of the primer glue layer comprises the following components: 30 to 40 percent of polyester resin, 5 to 10 percent of melamine resin, 40 to 50 percent of a solvent, 5 to 10 percent of an additive and 5 to 10 percent of pigment. According to the two-in-one primer and glue color sheet, the problems of poor universality of a glue layer of a color sheet in the prior art and high production cost caused by adoption of twice drying and twice coating in a production and processing process are solved.

Owner:青岛河钢复合新材料科技有限公司 +1

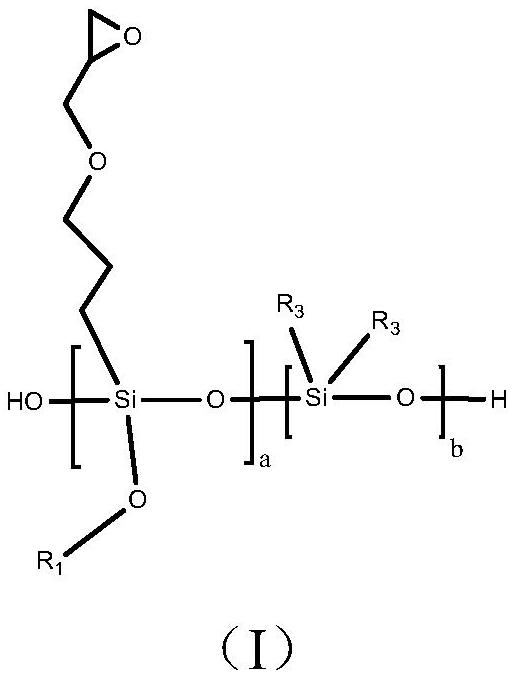

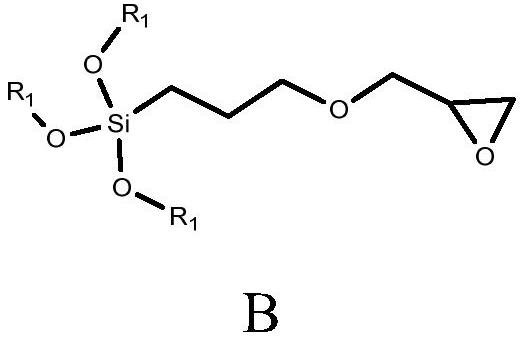

Organic silicon prepolymer, organic silicon modified epoxy resin, adhesive, colloid and preparation method thereof

ActiveCN112759765AImprove impact toughnessGood high and low temperature resistanceNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyAdhesive cement

The invention relates to an organic silicon prepolymer, organic silicon modified epoxy resin, an adhesive, colloid and a preparation method thereof, and the organic silicon modified epoxy resin is mainly prepared from the following reaction raw materials in parts by weight: 35-55 parts of epoxy resin, 5-20 parts of siloxane, 5-20 parts of silicone oil, 0.1-3 parts of a catalyst and 0-10 parts of water. The organic silicon modified epoxy resin has high temperature resistance, still has excellent mechanical properties under high temperature conditions, and can meet the bonding requirements of devices with high calorific value.

Owner:GUANGZHOU BAIYUN CHEM IND

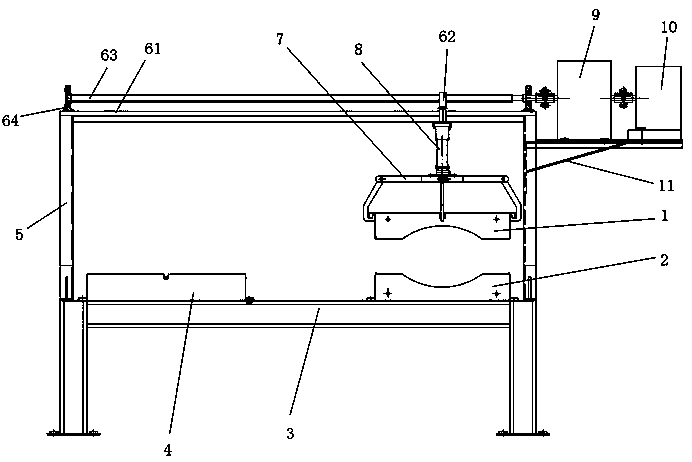

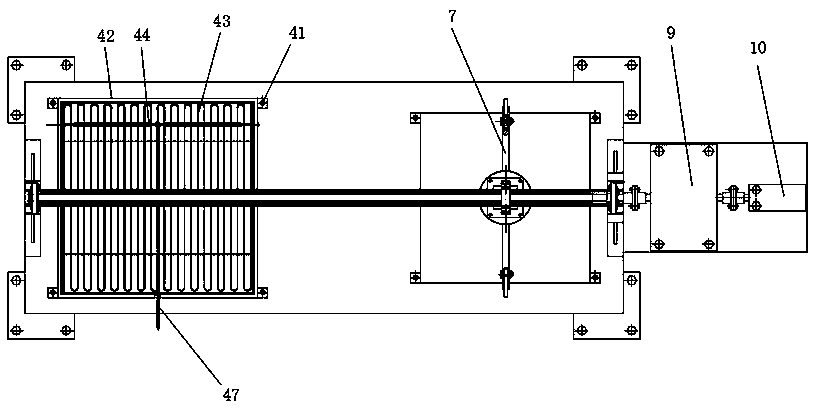

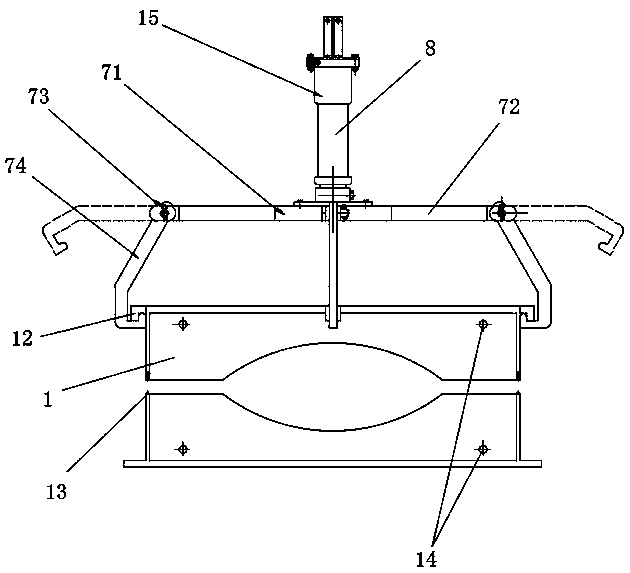

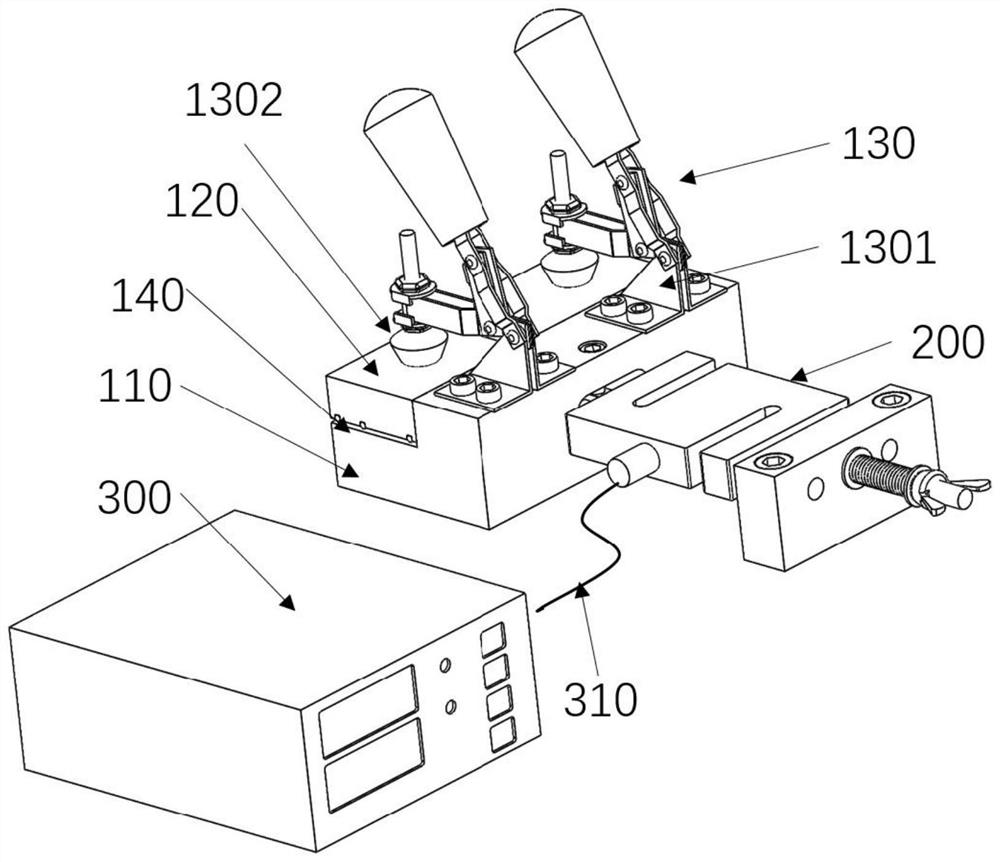

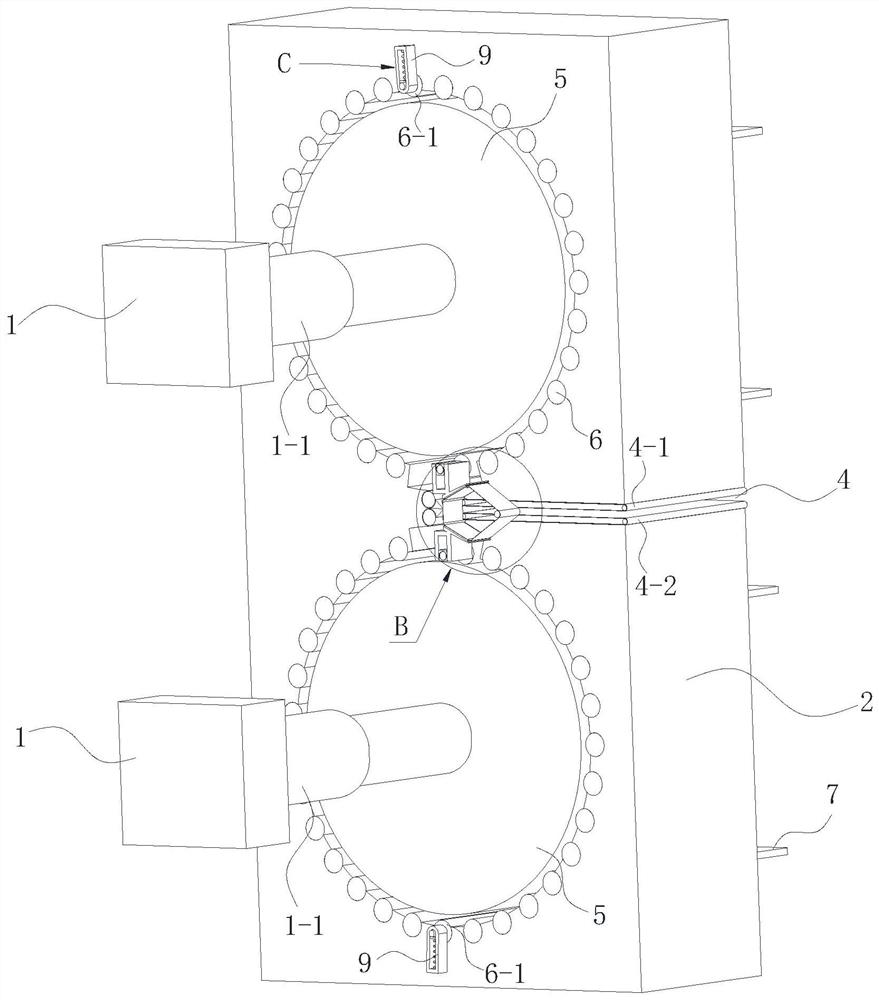

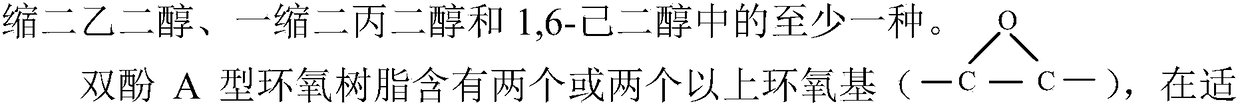

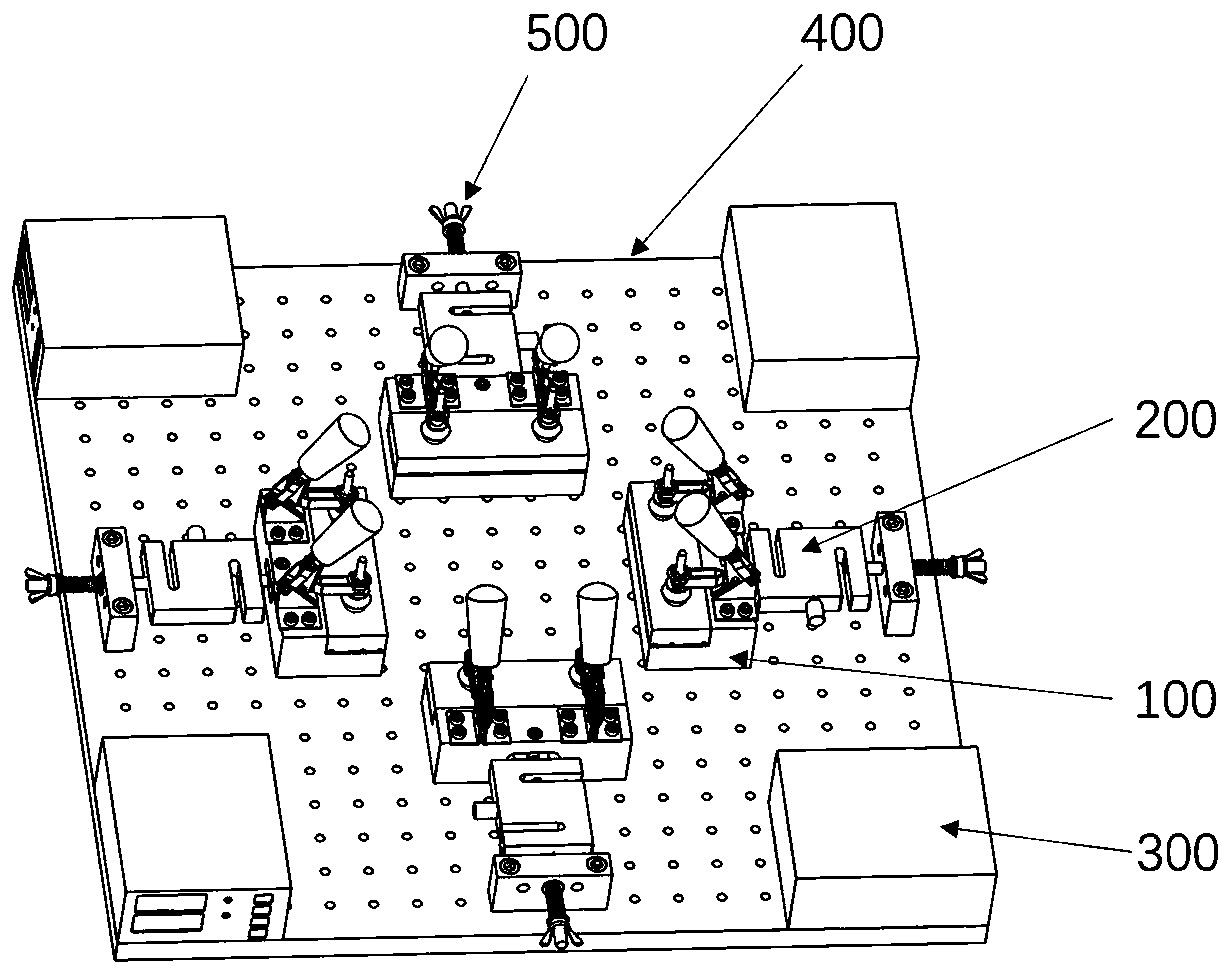

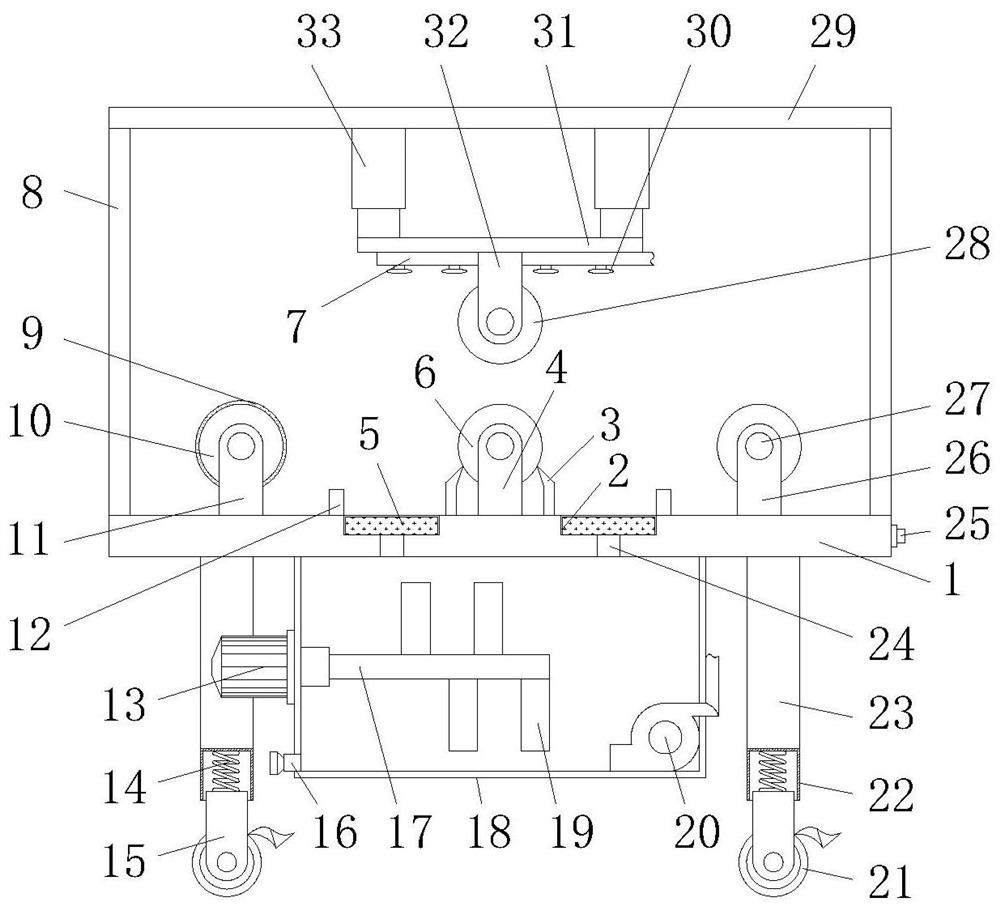

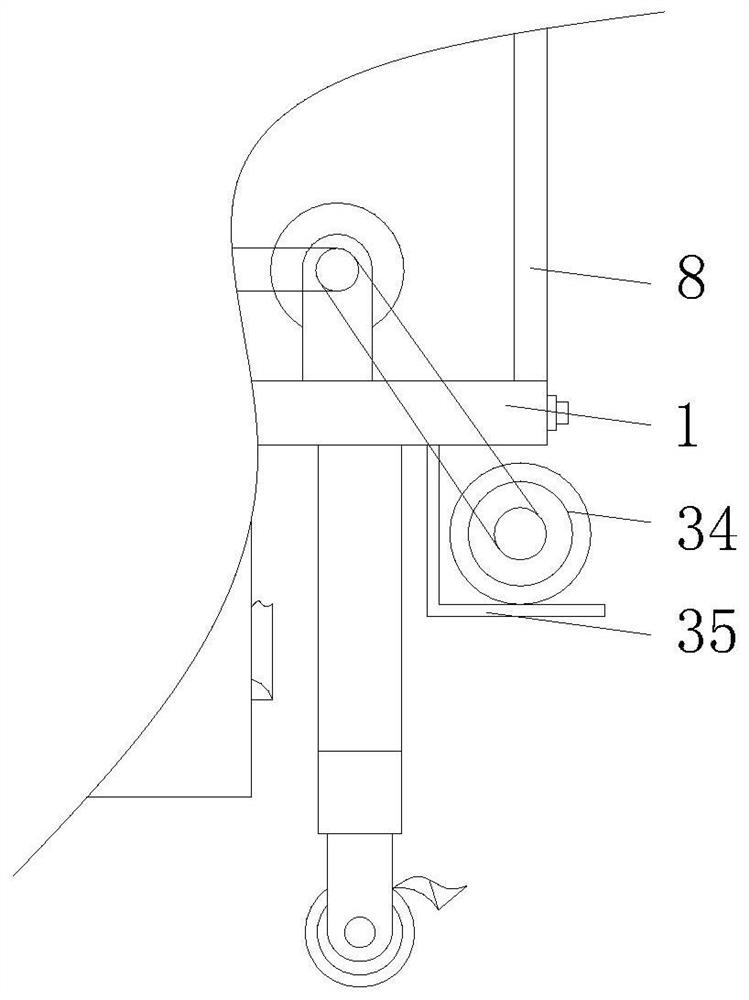

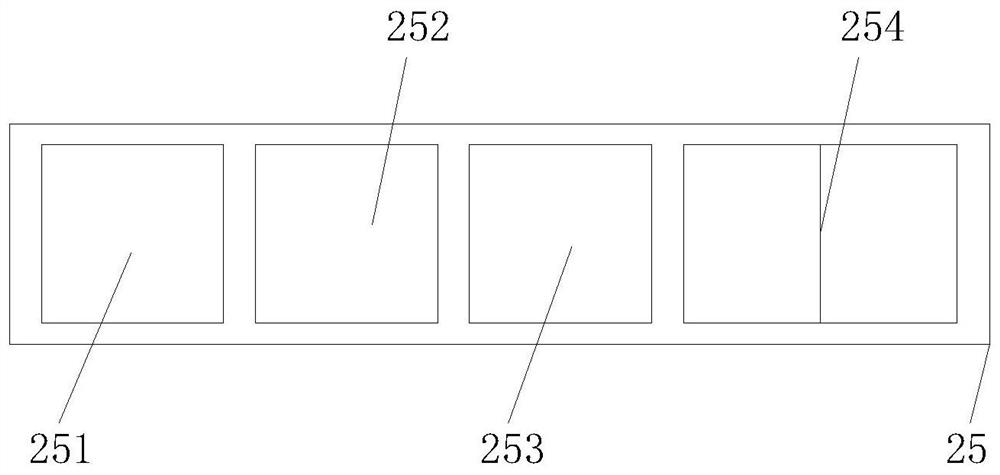

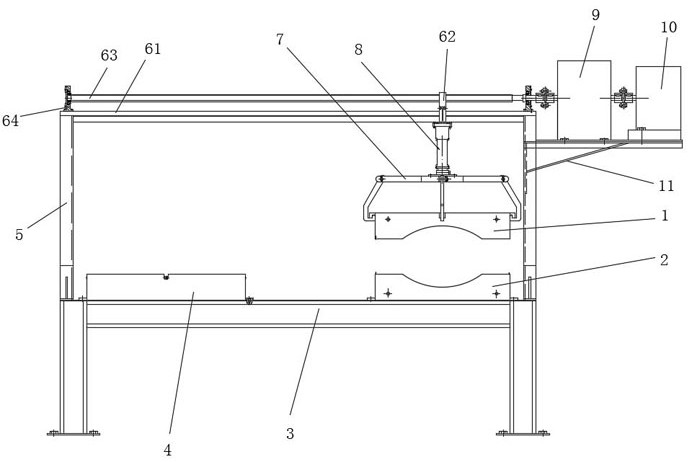

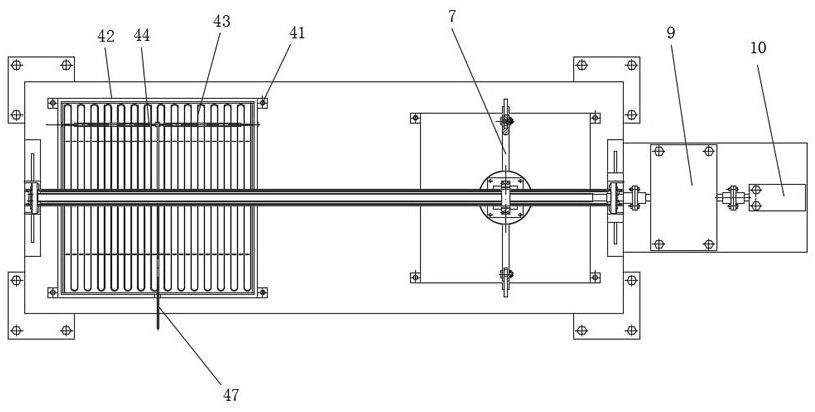

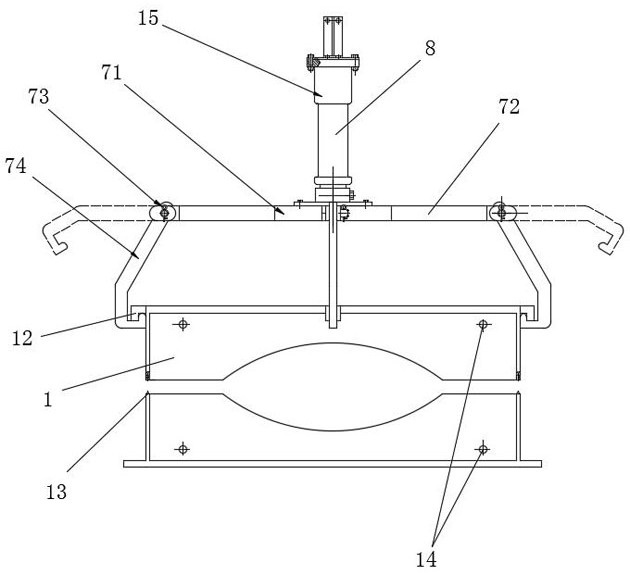

Foam model bonding machine for lost foam casting

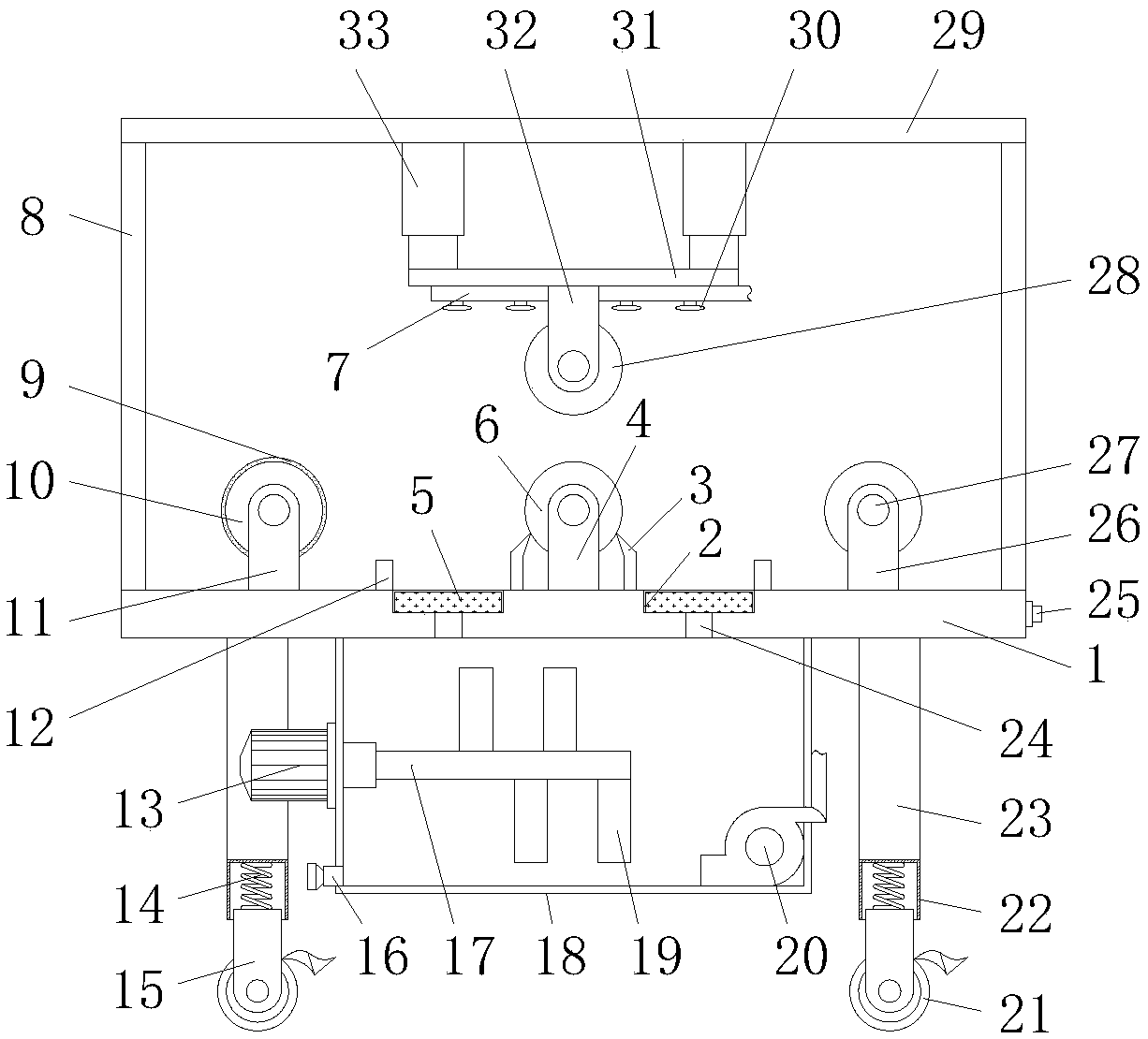

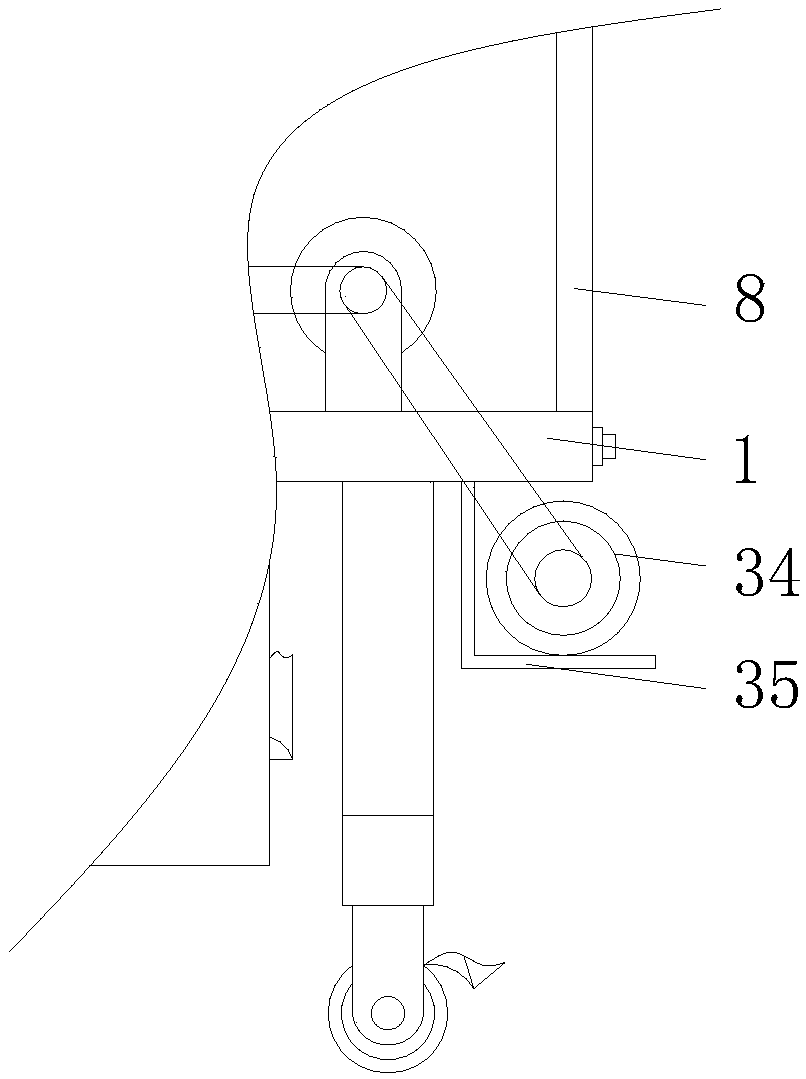

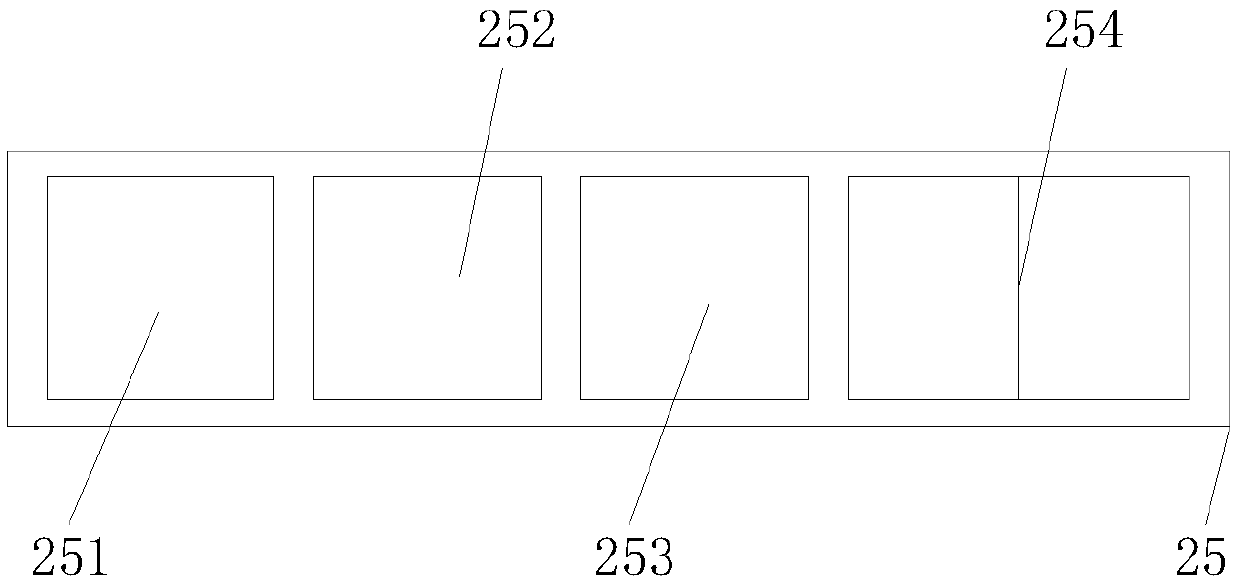

ActiveCN109434018AMeet Bonding NeedsSimple designFoundry moulding apparatusEngineeringLost-foam casting

The invention provides a foam model bonding machine for lost foam casting. The foam model bonding machine comprises an upper model box and a lower model box, the lower model box is fixed to a worktable, a glue brushing pool is fixed to the worktable, a model box conveying mechanism is connected to the worktable through a bracket, the upper model box is clamped through a box-type fixture and then suspended on the model box conveying mechanism, and the upper model box is driven by themodel box conveying mechanism to move between the upper part of the lower model box and the upper part of thegluebrushing pool. Compared with the prior art, the foam model adhesive machine for lost foam casting has the beneficial effects that overall design is simple, integration of glue brushing, assembling and shaping of a foam model is realized, and the foam model adhesive machine has the advantages of high assembly and bonding accuracy and high speed, the bonding requirements of foam models with different shapes can be met, and the problems of low efficiency, poor quality stability, and uneven glue application in the process of glue brushing as well as the problem ofbonding precision of the upper and lower foam models are solved.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

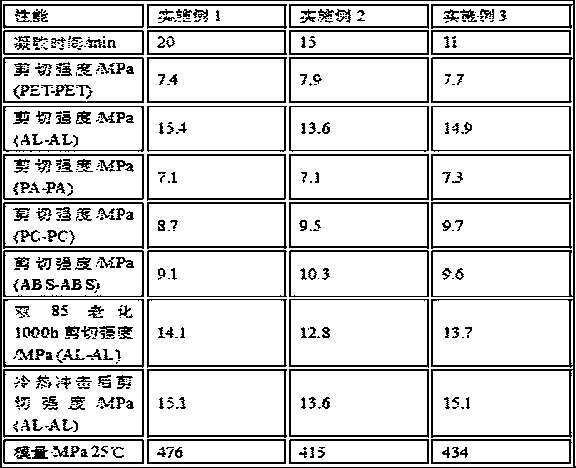

High weather resistant polyurethane adhesive

InactiveCN109517569AEasy to operateMeet bonding needsNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolyurethane adhesive

The invention relates to a high weather resistant polyurethane adhesive. The adhesive is prepared from the following components: 70-80 parts of polyurethane prepolymer, 20-30 parts of flame retardant,25-42 parts of fat based polyol, 15-20 parts of bulky side chain modified polyester diol, 0.5-1 part of adhesion promoter, 17-20 parts of flame retardant, 20-25 parts of calcium powder, 2.5-4 parts of gaseous silicon, 0.05-0.1 part of a catalyst and 3-5 parts of polycarbodiimide. The high weather resistant polyurethane adhesive has low modulus and excellent adhesion performance on various materials, has the shearing strength on a PET film being more than 7MPa, the shearing strength on unprocessed AL being more than 13MPa, the shearing strength on PA being more than 7MPa, the shearing strengthon PC being more than 8MPa and the shearing strength on ABS being more than 8MPa; and the strength retention rate of the high weather resistant polyurethane adhesive is more than or equal to 90 percent after aging treatment at the temperature of 85 DEG C and humidity of 85 percent for 1000 hours and 200 circulation at negative 40-100 DEG C (2h / cycle).

Owner:YANTAI DARBOND TECH

Ceramic tile adhesive

A ceramic tile adhesive is composed of the following raw materials in parts by weight: 8-14 parts of crystalline sodium carbonate, 3-8 parts of borax, 5-9 parts of butyl cellosolve, 1-6 parts of sodium percarbonate, 5-9 parts of graphite powder, 3-5 parts of silica, 1-4 parts of kaolin, 2-5 parts of manganese oxide, 9-16 parts of epoxy resin, 4-8 parts of ethylene triamine, 3-9 parts of disodium EDTA, 4-6 parts of tricalcium phosphate, 2-8 parts of titanium dioxide and 1-3 parts of boric acid. The beneficial effects are that: the ceramic tile adhesive is good in adhesive performance, can satisfy the people demand for bonding of ceramic tiles, and is acid, alkali and dirty corrosion resistant.

Owner:QINGDAO ZHIGU INNOVATION TECH

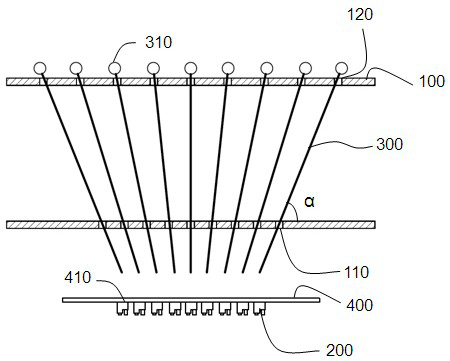

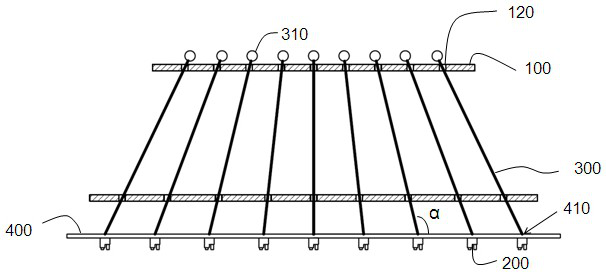

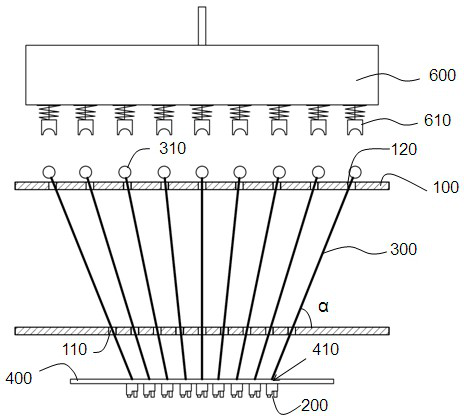

Bonding fixture, bonding equipment and bonding method for micro-luminescence device

ActiveCN108258088BMeet bonding needsIncrease productivitySolid-state devicesSemiconductor/solid-state device manufacturingStructural engineeringLight emitting device

The present invention relates to a bonding fixture for a micro-luminescent device and a bonding method thereof. It is mainly composed of several porous plates, and each porous plate is provided with perforations to accommodate thimbles that are set according to the separation points of the micro-luminescent device to be bonded. , the two ends of the thimble protrude out of the jig, which is at the end of the micro-luminescent device to be bonded, which is the contact end corresponding to the point to be separated of the micro-luminescent device to be bonded, and at the end of the needle bed, it is the spring with the needle bed. At the contact end of the needle contact, each thimble has an appropriate slope according to the point to be separated. The perforated outer edge of the perforated plate at the end of the needle bed has a positioning hole for accommodating the end of the thimble, and the depth of the positioning hole is determined according to the slope of the thimble accommodated. Make sure that the thimbles at the end of the micro-luminescence device to be bonded have the same needle length, which has the effect of improving the stability of the bonding fixture and avoiding the unevenness of the bonding arrangement of the micro-luminescence device.

Owner:HUBEI SANAN OPTOELECTRONICS CO LTD

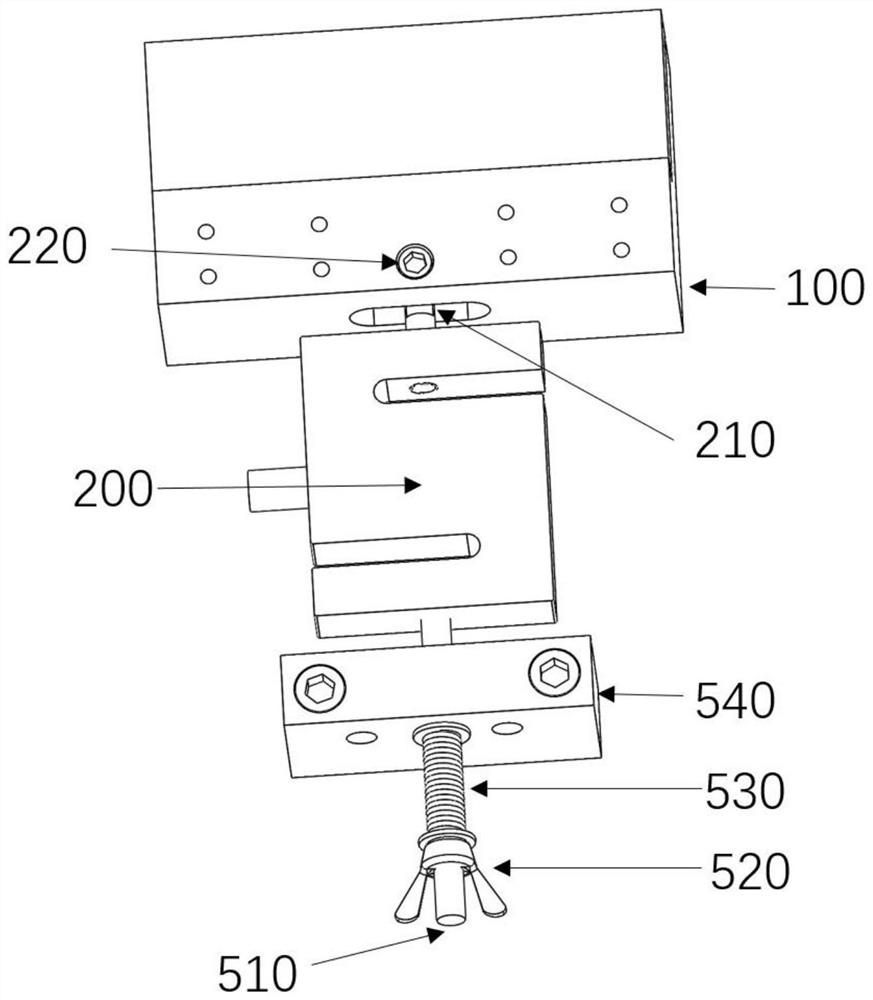

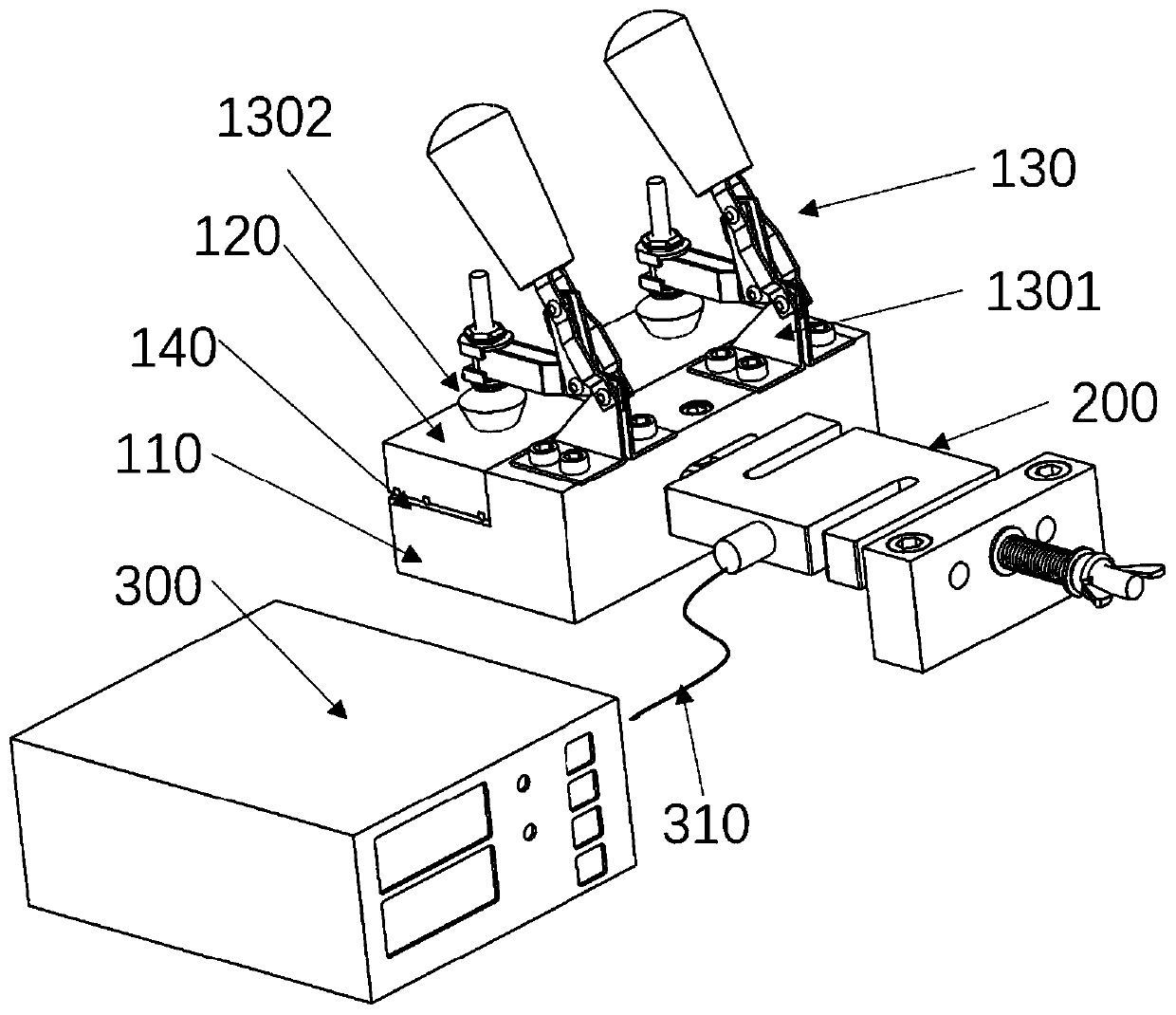

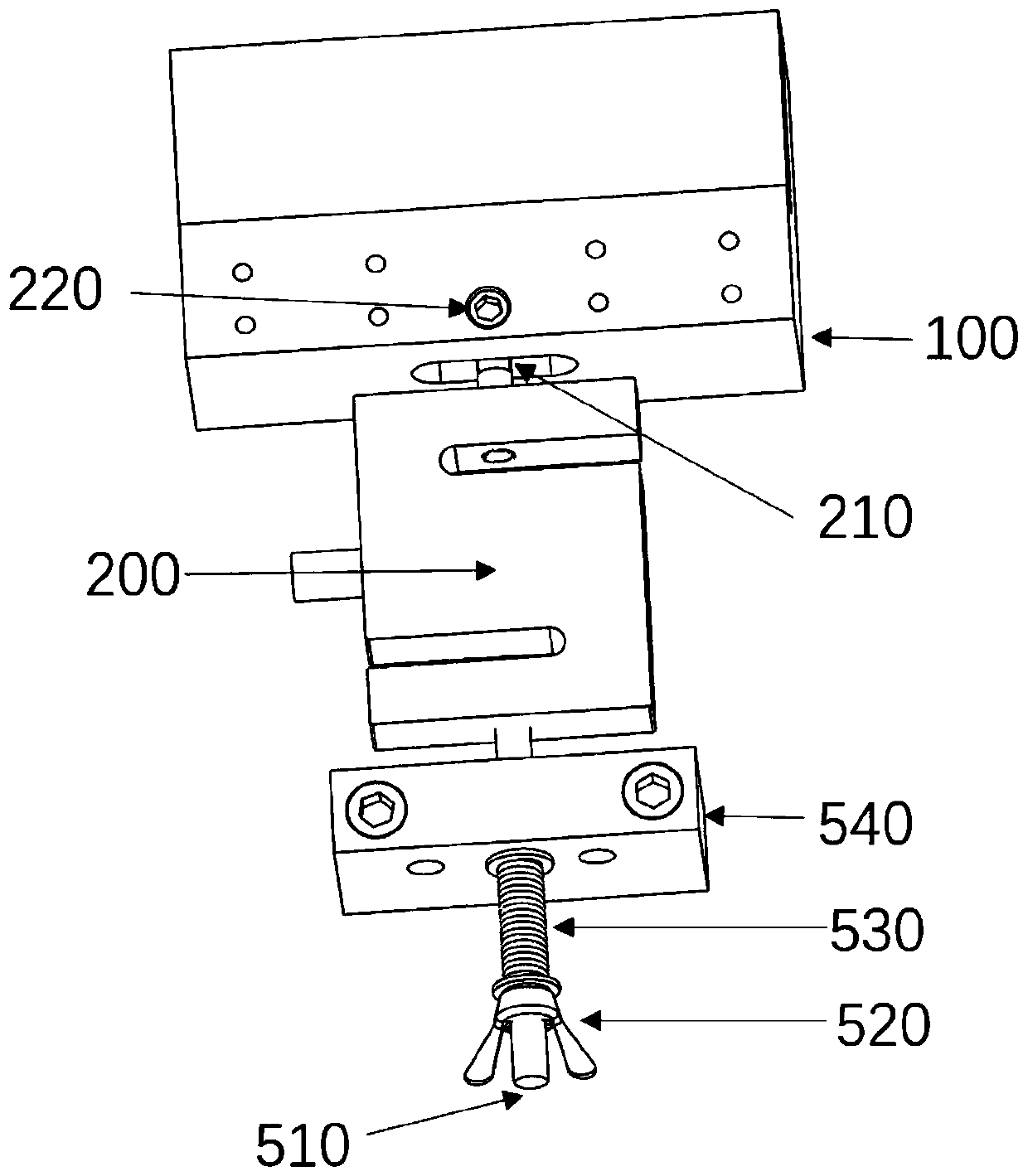

A controllable tension film pulling device

ActiveCN111307349BTension real-time detectionEasy to adjustApparatus for force/torque/work measurementClassical mechanicsThin membrane

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

A kind of preparation method of acrylamide-containing polymer emulsion

The invention relates to a preparation method of acrylamide-containing polymer emulsion. The preparation method comprises the steps of adding toluene, ethyl acetate and chlorinated polypropylene to a reaction kettle, stirring the materials, and controlling the temperature to be 60-80 DEG C; adding methyl methacrylate, an acrylic monomer and an acrylamide monomer; after heating to 85-95 DEG C, adding a vinyl acetate solution of benzoyl peroxide, and carrying out polymerization for 3-5 hours; carrying out reduced pressure distillation at 50-60 DEG C to remove 50-80% of solvents, then adding a neutralizing agent until the PH value of the system is 6.5-8.5, and carrying out salt forming reaction for 0.5-1 hour; gradually adding deionized water at 50-60 DEG C under high speed stirring, finally adding polyvinylpyrrolidone and stirring the materials, thus obtaining the acrylamide-containing polymer emulsion. The acrylamide-containing polymer emulsion prepared by the method has obvious bonding acceleration effects on EVA (ethylene-vinyl acetate copolymer) materials, and can meet the bonding requirements of hard EVA materials.

Owner:杭州象信科技有限公司

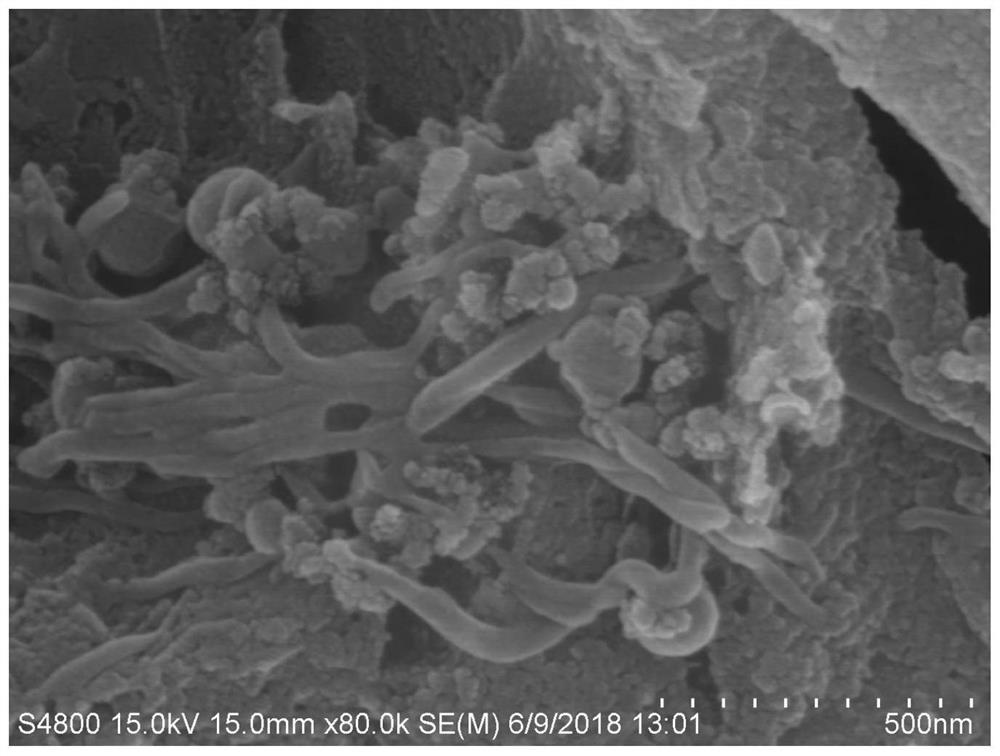

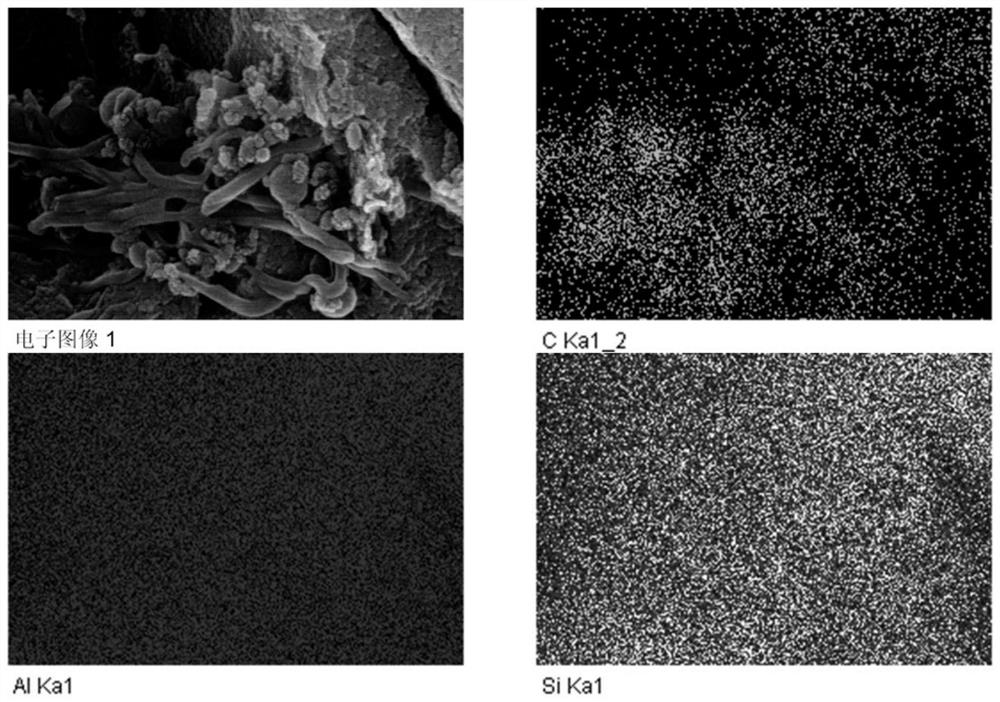

A kind of geopolymer-based wood adhesive and its preparation method and application

ActiveCN109251682BWide variety of sourcesLow priceNon-macromolecular adhesive additivesMacromolecular adhesive additivesAdhesive cementPolymer science

The invention relates to an environmentally-friendly high-performance geopolymer-based wood adhesive and a preparation method and application thereof. The geopolymer-based wood adhesive is prepared from the following raw materials (by weight): 100 parts of a base material, 1-20 parts of an organic dopant, 87.5-280 parts of an alkali activator, 0.3-1 part of an initiator, 1-2.4 parts of a couplingagent, 1-2.4 parts of an emulsifier, 0.4-1.6 parts of an antifoaming agent and 50-200 parts of water. After the organic dopant is solidified, a chain or net structure can be formed. Thus, the chain ornet structure and the geopolymer form interpenetrating networks to achieve the toughening modification effect, and a mechanical locking effect with the wood material can also be achieved. The geopolymer-based wood adhesive is green and environmentally friendly; the sources of raw materials are wide; production cost is low; and the process is simple. The geopolymer-based wood adhesive is non-flammable, has no release of formaldehyde and has good bonding performance. The geopolymer-based wood adhesive is instant to use when prepared and the formula can be adjusted flexibly. The geopolymer-basedwood adhesive can be used to glue wooden raw materials such as wood, bamboo, straw and the like and to prepare wooden composite materials such as particle boards, fiberboards, plywoods, reconstitutedwood / bamboo and the like, and has industrial application value.

Owner:BEIJING FORESTRY UNIVERSITY

Conveying belt edge glue adhesion system

ActiveCN110856994AMeet Bonding NeedsMeet the need for reuseRotary stirring mixersTransportation and packagingAdhesive glueElectric machinery

The invention discloses a conveying belt edge glue adhesion system, which comprises a supporting seat, wherein the middle end of the bottom of the supporting seat is fixedly connected with a glue storage box, a stirring motor is fixedly installed at the middle end of the left side of the glue storage box, the output shaft of the stirring motor is fixedly connected with a stirring shaft, stirring blades are fixedly connected to the outer surface of the stirring shaft, a pump machine is fixedly installed at the right end of the bottom of the inner cavity of the glue storage box, and the outlet of the pump machine is movably connected with a spray head through a pipeline. According to the invention, through the effects of the first supporting plate, the electric telescopic rod, the second supporting plate, the upper extrusion roller bracket and the upper extrusion roller, the adhesion requirements of people on conveying belts with different thicknesses can be met so as to provide great convenience in use by people; and through the effects of the scraping plate, the first reserved groove, the baffle, the filtering screen and the second reserved groove, the requirements on repeated utilization of a glue can be met so as to avoid the waste of the glue, save the production cost and meet the benefits of enterprises.

Owner:HENAN TIANGONG RUBBER TECHNOLOGY CO LTD

A kind of room temperature curing instantaneous high temperature resistant high flexibility epoxy adhesive and preparation method thereof

InactiveCN104927755BGood flexibilityHigh strengthNon-macromolecular adhesive additivesCouplingRoom temperature

The invention provides a normal-temperature solidification instant-high-temperature-resistant high-flexibility epoxy adhesive and a preparing method thereof and relates to an epoxy adhesive and a preparing method thereof. The epoxy adhesive and the preparing method thereof aim at solving the problems that existing normal-temperature solidification epoxy resin is poor in flexibility and cannot resist instant high temperatures. The normal-temperature solidification instant-high-temperature-resistant high-flexibility epoxy adhesive is prepared from, by weight, 50-100 parts of polyether modified epoxide resin, 60-120 parts of flexible curing agent, 10-30 parts of phenolic resin, 1-3 parts of accelerant, 1-3 parts of coupling agent. The preparing method comprises the steps that firstly, materials are weighed; secondly, the polyether modified epoxide resin and the phenolic resin are mixed and then ground through a three-roller grinding machine, then the flexible curing agent, the accelerant and the coupling agent are added and evenly mixed, and the normal-temperature solidification instant-high-temperature-resistant high-flexibility epoxy adhesive is obtained. The normal-temperature solidification instant-high-temperature-resistant high-flexibility epoxy adhesive can be obtained.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

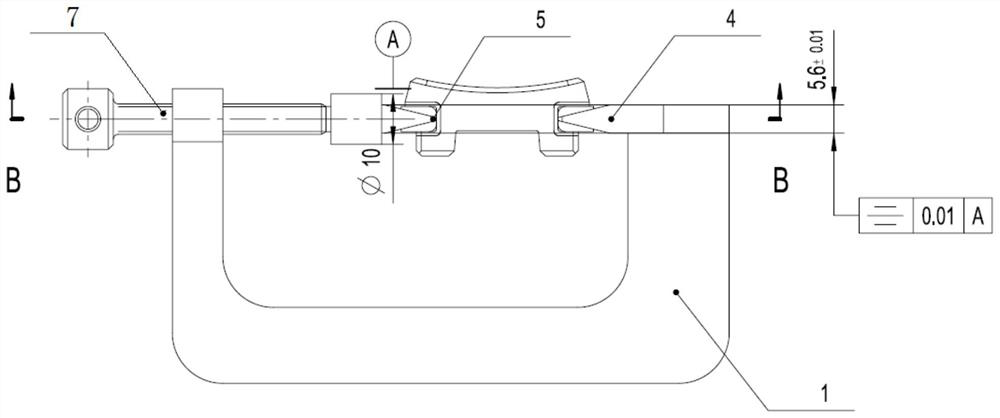

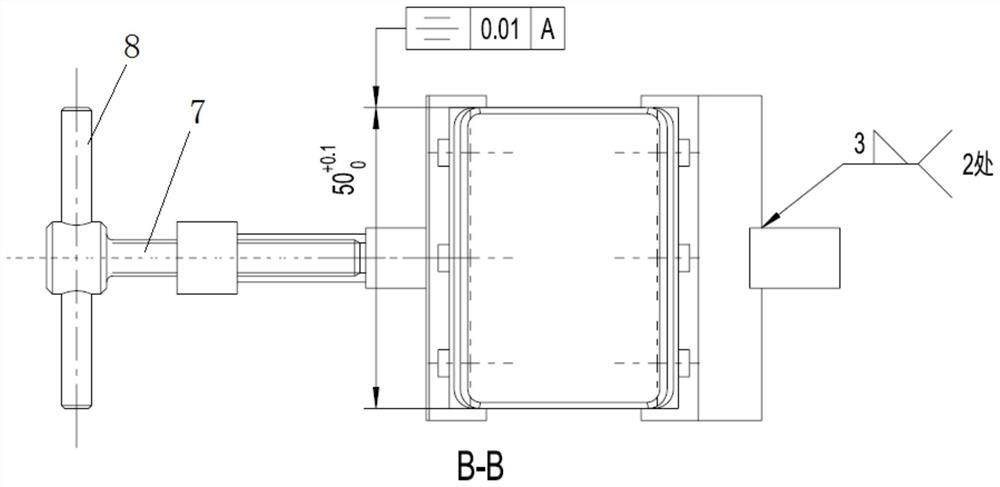

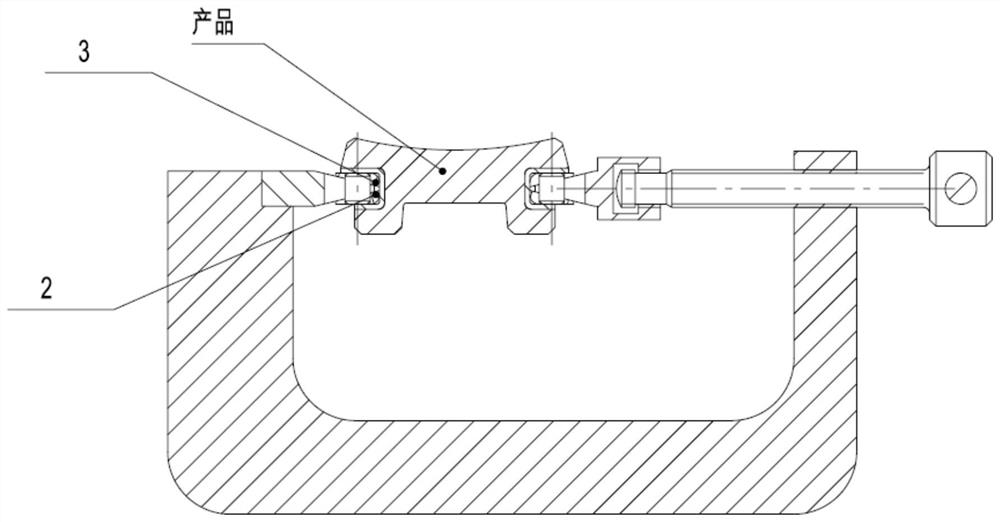

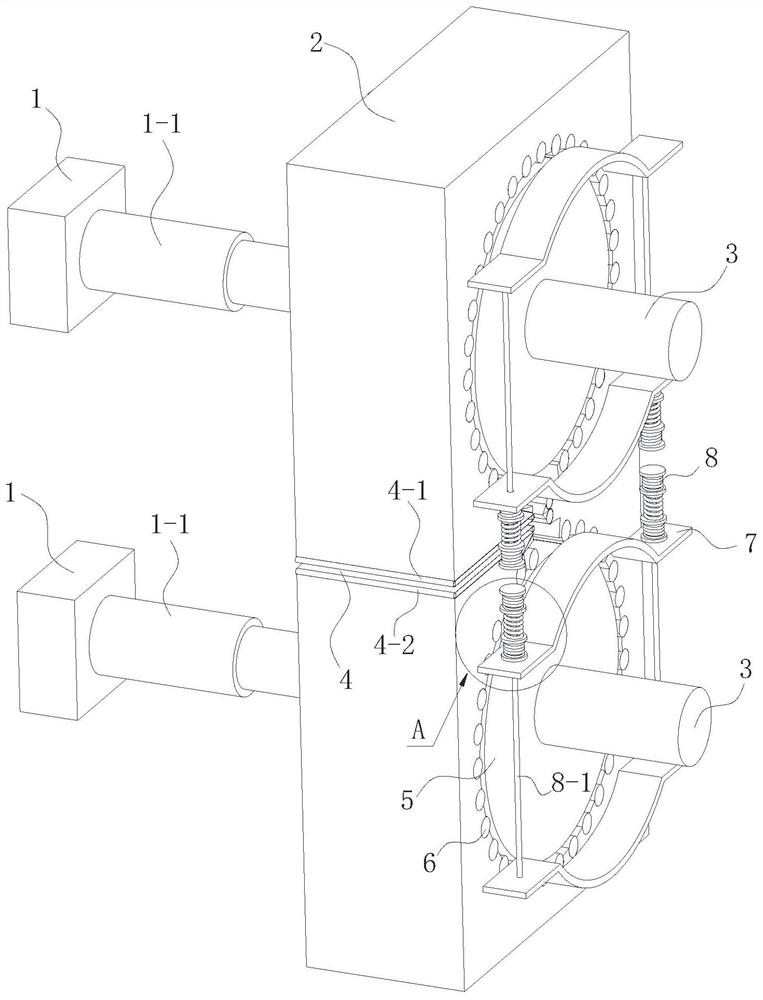

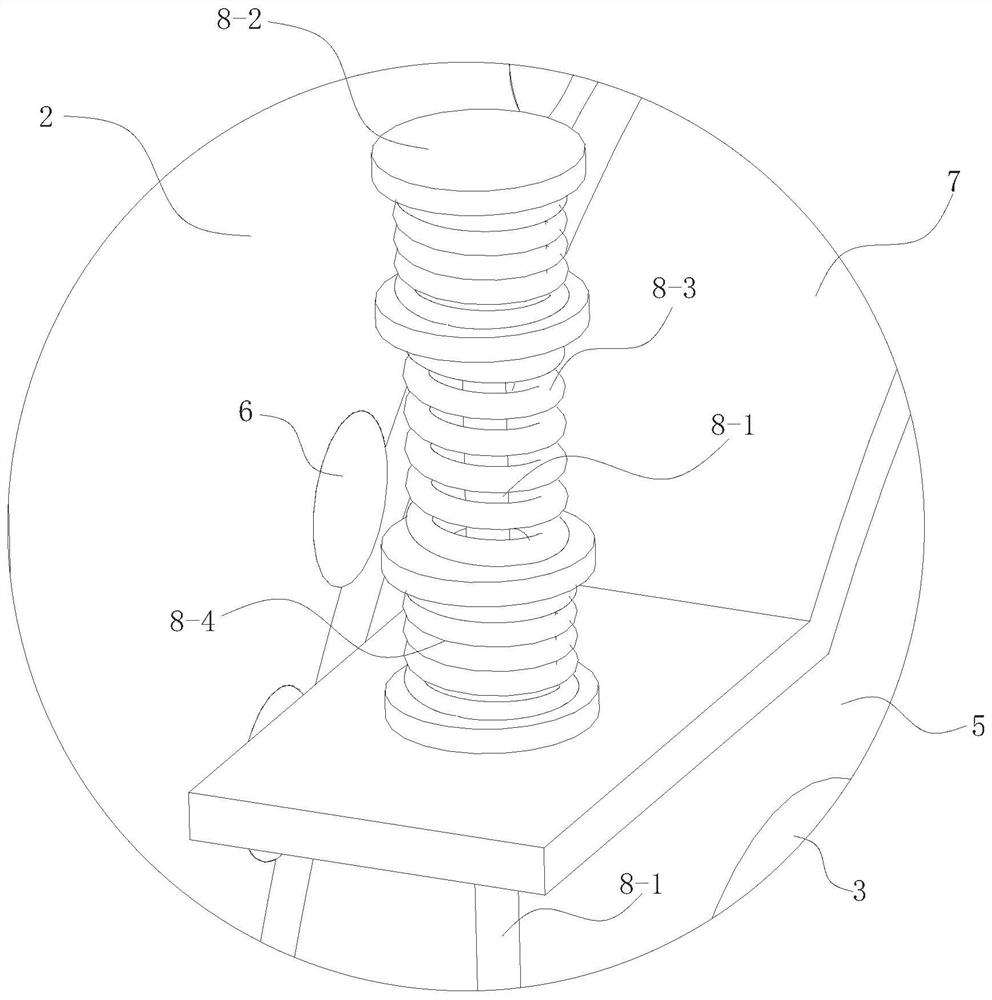

A slider bonding process equipment and bonding method

ActiveCN109469671BRealize bonding and fixing forming operationMeet bonding needsFastening meansBonding processScrew thread

The invention discloses sliding block bonding process equipment and a bonding method. The equipment comprises an arch clam, a first ejection block, a second ejection block, a third ejection block, a fourth ejection block, a positioning pin, a movable handle compression screw and a movable handle; a threaded hole is formed in one end of the arch clamp, and the movable handle compression screw is installed on the arch clamp through the threaded hole; a groove is formed in the other end of the arch clamp, the second ejection block is installed in the groove of the arch clamp and is welded and formed; threads and a mounting hole are formed in the movable handle compression screw, and the fourth ejection block is connected to the movable handle compression screw through the threads; the movablehandle penetrates through the mounting hole to be connected to the movable handle compression screw; the first ejection block and the second ejection block are located and connected through the positioning pin; and the third ejection block is welded to the other end of the arch clamp and is arranged in parallel with the fourth ejection block. According to the bonding process equipment and the bonding method, the equipment is located positioned through the arch clamp and the ejection blocks, and the movable handle compression screw is used for applying force and clamping, so that a product isbonded and fixedly formed with a product copper groove.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Green and environment-friendly packaging bag production equipment and production method thereof

InactiveCN112976687AMeet bonding needsImprove processing efficiencyBag making operationsPaper-makingPaper manufacturingElectric machinery

The invention discloses green and environment-friendly packaging bag production equipment and a production method thereof, and belongs to the technical field of packaging bag production. The green and environment-friendly packaging bag production equipment comprises a motor, a supporting mechanism, a glue spraying position and a folding and pressing mechanism, and is characterized by further comprising a paper feeding groove, a heating shaft, a first cutter and a second cutter. According to the equipment, the paper feeding groove serves as a symmetry plane, the upper structure and the lower structure are completely consistent, the lower structure of the equipment serves as an example, the paper feeding groove is formed in one side of the supporting mechanism, the first cutter is installed in the position, in front of the paper feeding groove, of the supporting mechanism, and the second cutter is located below the paper feeding groove and is in sliding connection with the supporting mechanism; the glue spraying position is fixedly installed between the second cutter and the paper feeding groove; and the heating shaft is rotatably installed in the supporting mechanism, and the motor and the folding and pressing mechanism are installed on the two sides of the heating shaft respectively. Through the structure, the standard paper manufacturing procedure in a traditional scheme is directly removed, the complexity of paper bag manufacturing is reduced, and then the paper bag machining efficiency is improved.

Owner:苏州郎旭志远科技有限公司

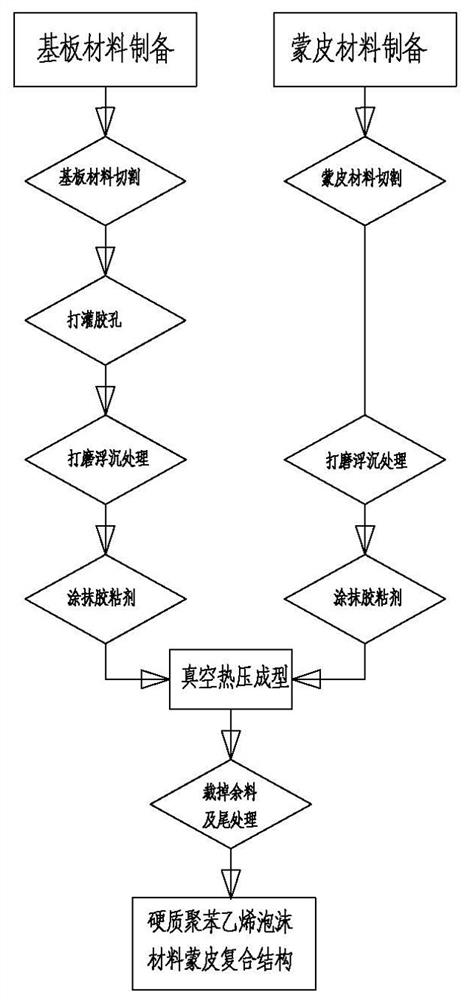

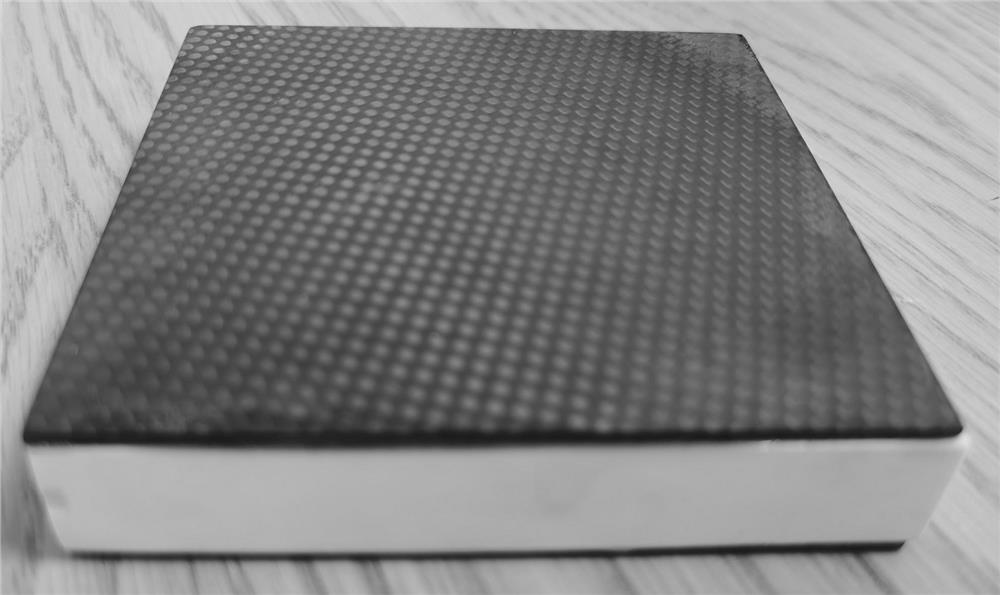

Forming method of rigid polystyrene foam material skin composite structure

PendingCN113427792AImprove mechanical propertiesEasy to control bond strengthGlass fiberCarbon fibers

The invention relates to a rigid foam composite structure, in particular to a forming method of a rigid polystyrene foam material skin composite structure. The method comprises the following steps of 1, selecting a rigid polystyrene foam material as a substrate material, and selecting a metal plate or a carbon fiber plate or a carbon cloth laminated plate or an aramid fiber plate or an aramid fiber cloth laminated plate or a phenolic aldehyde laminated plate or a glass fiber reinforced plastic reinforced plate as a skin material; and 2, punching on the substrate material to form a glue filling hole. According to the method, a glue filling hole structure designed according to the bonding requirement is punched in advance in the rigid polystyrene foam material substrate material, and a glue hole position is reasonably arranged; the skin material is attached to the outer portion of the substrate material, a proper adhesive is selected, and composite structure foam is formed after heating and curing; and according to the method, the process is easy to control, the composite structure foam material is excellent in mechanical property, the bonding strength is easy to control, the structure bearing capacity and the wide application range are achieved, and meanwhile the application requirements of special environments are met.

Owner:CHINA ACADEMY OF ENG PHYSICS FUNCTION MATERIAL RES INST

A kind of polyurethane adhesive and preparation method thereof

ActiveCN106221650BGood flexibilityImprove cohesive strengthPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention discloses polyurethane, a composition with same and a method for preparing the polyurethane. The polyurethane is a random copolymer with repeat units shown as a formula I and a formula II. An R<1> in the formulas selectively represents C<2>-C<5> diol, an R<2> selectively represents R<3>CH<2>-CHR<3>-CH<2>R<3>, and the R<3> represents OCO (CH<2>) <7>CH=CHCH<2>CHOH (CH<2>) <5> CH<3>; an n<1> is selectively 1 or 2, an n<2> is selectively an integer ranging from 0 to 3, and the mass percentages of the repeat units, which are shown in the formula I, in the polyurethane range from 4% to 12%; the mass percentages of the repeat units, which are shown in the formula II, in the polyurethane range from 2% to 10%. The polyurethane, the composition and the method have the advantages that the polyurethane is doubly modified by the aid of polyester polyol modified by castor oil and bisphenol A type epoxy resin in polyurethane preparation procedures, accordingly, the cohesion strength, the water resistance and the heat resistance of adhesive can be obviously improved, and base material surface adhesive force of the adhesive can be obviously increased.

Owner:中科华宇(福建)科技发展有限公司

Preparation method of acrylamide-containing polymer emulsion

The invention relates to a preparation method of acrylamide-containing polymer emulsion. The preparation method comprises the steps of adding toluene, ethyl acetate and chlorinated polypropylene to a reaction kettle, stirring the materials, and controlling the temperature to be 60-80 DEG C; adding methyl methacrylate, an acrylic monomer and an acrylamide monomer; after heating to 85-95 DEG C, adding a vinyl acetate solution of benzoyl peroxide, and carrying out polymerization for 3-5 hours; carrying out reduced pressure distillation at 50-60 DEG C to remove 50-80% of solvents, then adding a neutralizing agent until the PH value of the system is 6.5-8.5, and carrying out salt forming reaction for 0.5-1 hour; gradually adding deionized water at 50-60 DEG C under high speed stirring, finally adding polyvinylpyrrolidone and stirring the materials, thus obtaining the acrylamide-containing polymer emulsion. The acrylamide-containing polymer emulsion prepared by the method has obvious bonding acceleration effects on EVA (ethylene-vinyl acetate copolymer) materials, and can meet the bonding requirements of hard EVA materials.

Owner:杭州象信科技有限公司

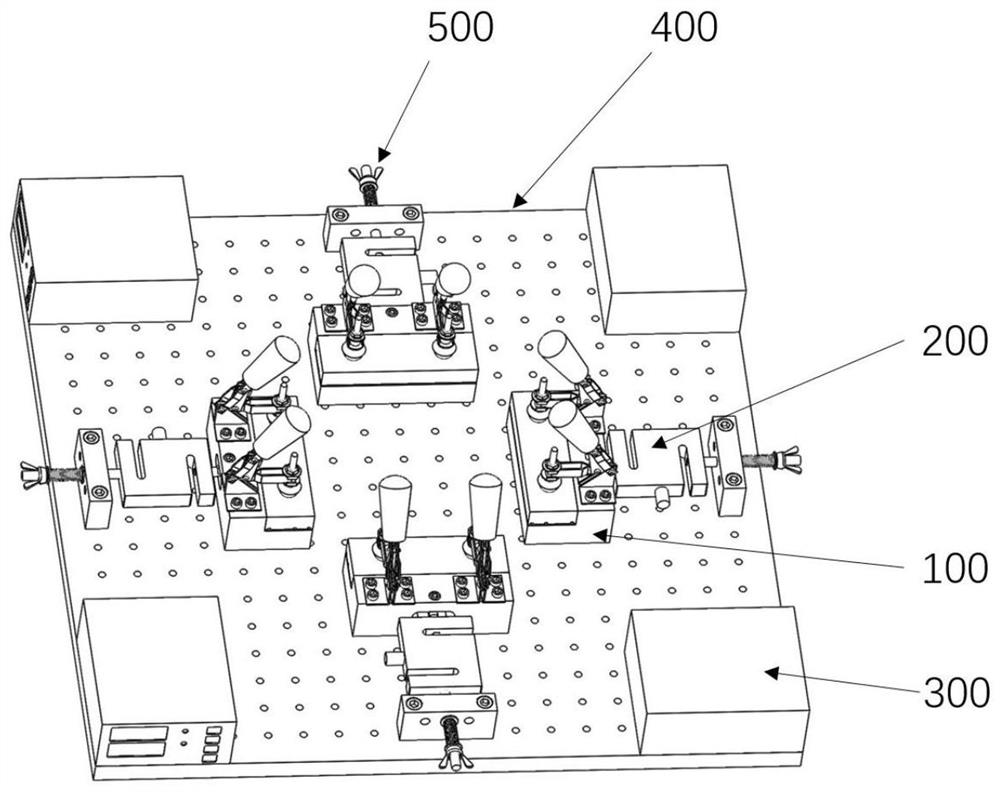

Tension-controllable film drawing device

ActiveCN111307349ATension real-time detectionEasy to adjustApparatus for force/torque/work measurementThin membraneForce sensor

The invention relates to a tension-controllable film drawing device which is characterized by comprising a film drawing module, a tension sensor and a telescopic module, and the film drawing module isused for clamping and fixing a film; the telescopic module comprises a screw rod, a nut and a fixing block, the screw rod penetrates through the fixing block and can move forwards and backwards in the axial direction relative to the fixing block, the screw rod is fixedly connected with the tension sensor in one side of the fixing block, and the screw rod is in threaded connection with the nut inthe other side of the fixing block; and the tension sensor is connected with the film drawing module. Tension control over the thin film can be conveniently achieved, multiple sets of film drawing combinations can be further applied in different directions of the thin film, and the tension of the thin film is uniform.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

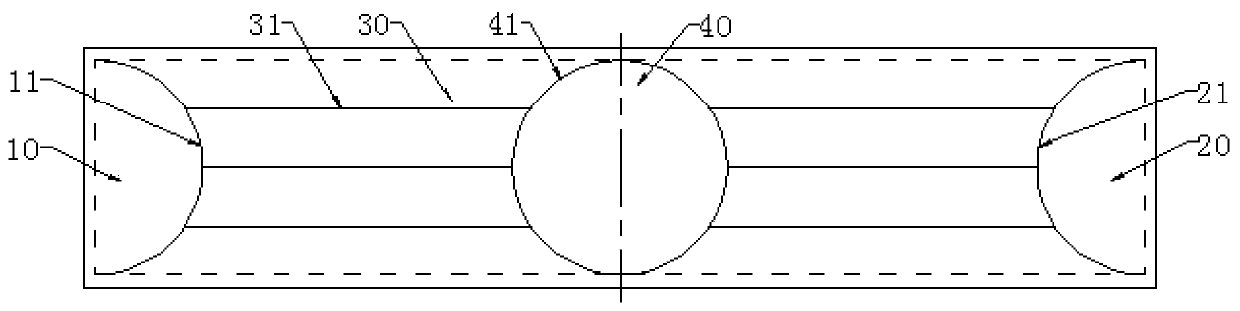

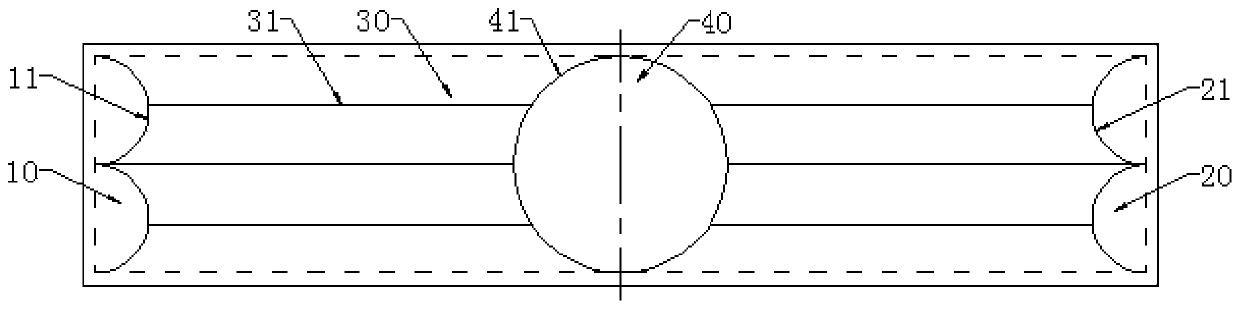

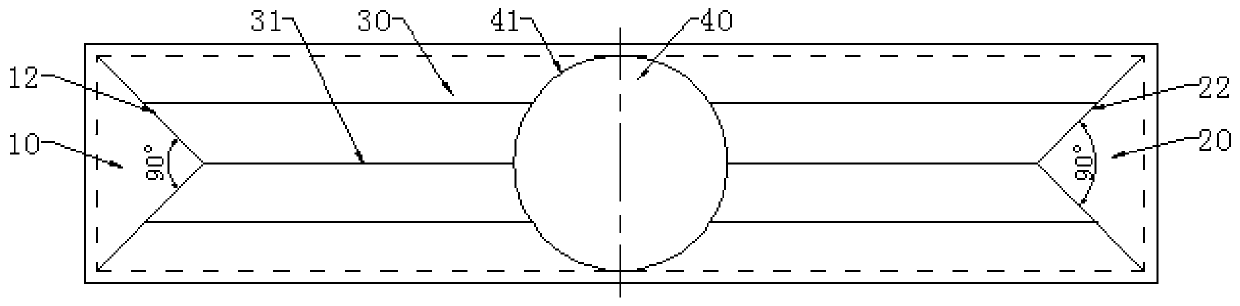

Automatic rod sticking and dispensing route and dispensing method

PendingCN110935604AMeet bonding needsHigh strengthSpecial surfacesCoatingsEngineeringUltimate tensile strength

The invention provides an automatic rod sticking and dispensing route. The dispensing route comprises a first dispensing area, a second dispensing area and a third dispensing area, wherein the first dispensing area and the second dispensing area are respectively arranged at two ends of a material seat, the third dispensing area is arranged between the first dispensing area and the second dispensing area, and the third dispensing area is respectively connected with the first dispensing area and the second dispensing area. The invention further provides an automatic rod sticking and dispensing method. The dispensing route is advantaged in that bonding requirements of surfaces of various monocrystalline silicon rods are met, the dispensing track route is optimized to the maximum extent, the adhesive solution can be evenly distributed on a bonding surface of the silicon rod, the dispensing effect is good, dispensing efficiency is high, consistency is good, no bubble is generated in the dispensing process, continuity is good, the bonding effect good in stability, even in adhesive solution and good in strength can be obtained after the silicon rod is placed, and the activation rate of rod bonding equipment is increased.

Owner:天津市环智新能源技术有限公司

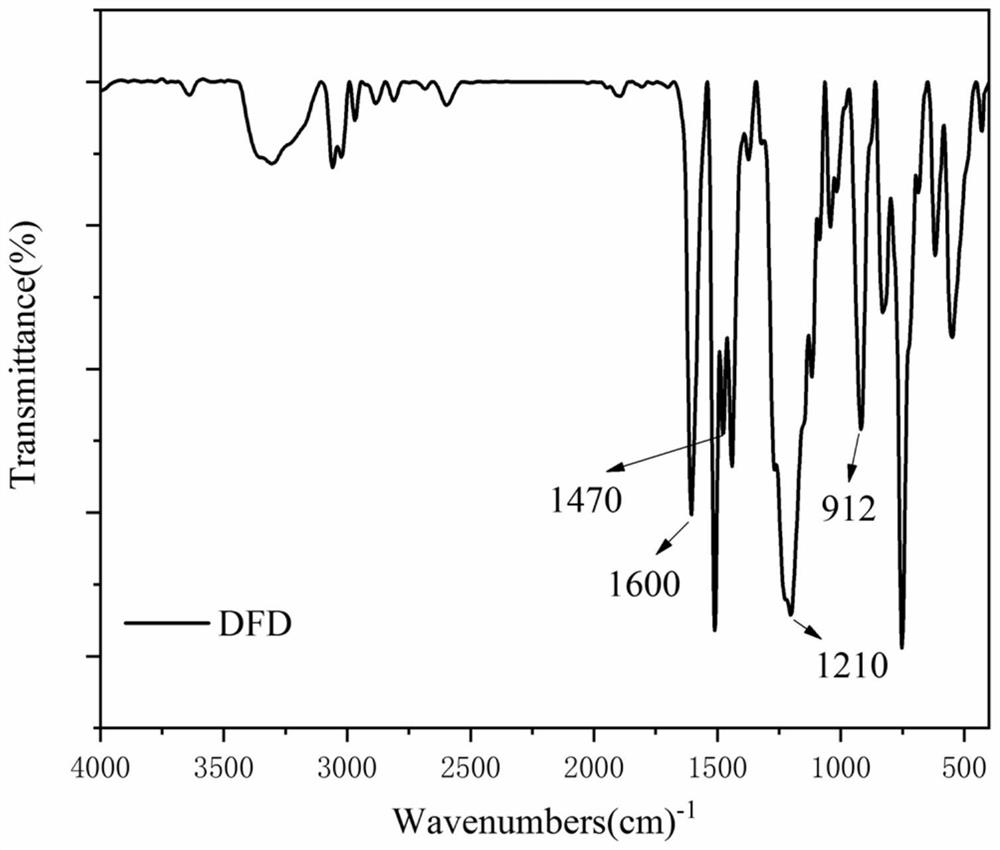

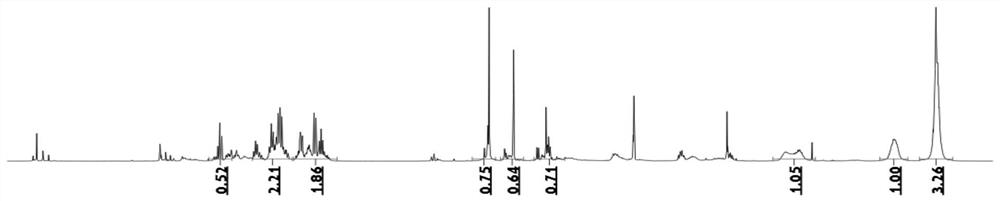

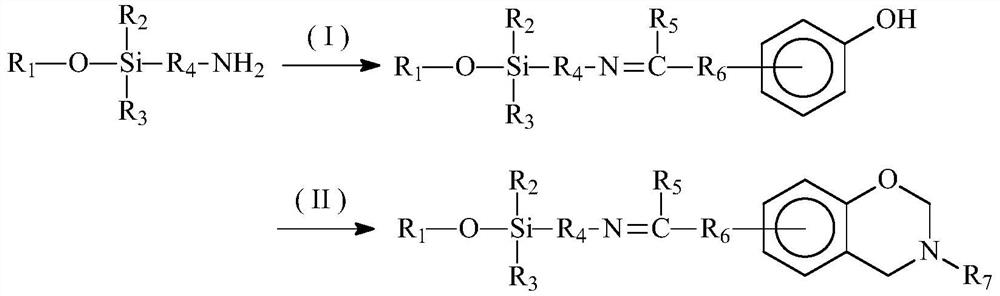

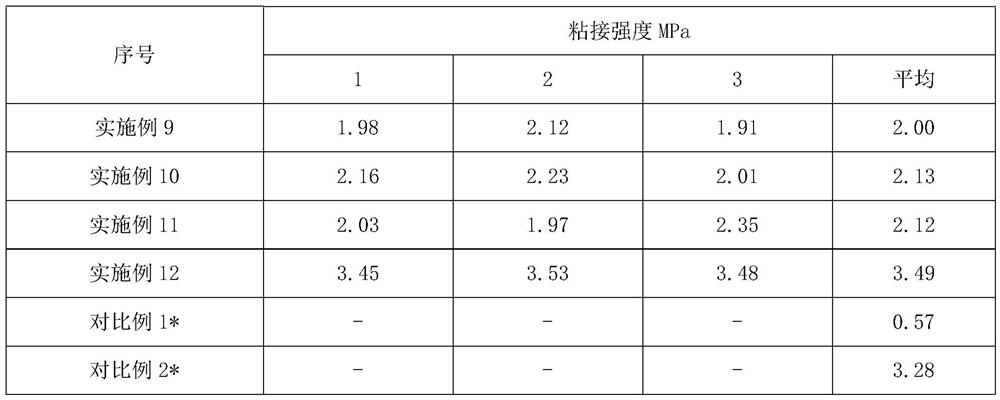

Adhesive prepared based on amino-containing siloxane and its preparation and use method

ActiveCN109054734BAvoid destructionHigh bonding strengthNon-macromolecular adhesive additivesPolymer scienceAminosilochrome

The invention provides an adhesive prepared based on amino siloxane, and a preparation and application method thereof. The amino siloxane is subjected to two-step reaction to prepare benzoxazine group-containing siloxane. The method has simple and controllable synthesis conditions and high synthesis efficiency; the benzoxazine group-containing siloxane synthesized by the method can be directly used as the adhesive, and has high bonding strength; the benzoxazine group-containing siloxane synthesized by the method can be also used as a base formula, and serves as the adhesive after other fillersare added so as to meet the different needs of various special occasions.

Owner:SHANDONG UNIV

A conveyor belt edge glue bonding system

ActiveCN110856994BMeet bonding needsMeet the need for reuseRotary stirring mixersTransportation and packagingElectric machineAdhesive glue

The invention discloses a conveyor belt edge glue bonding system, comprising a support seat, a glue storage box is fixedly connected to the middle end of the bottom of the support seat, and a stirring motor is fixedly installed at the middle end of the left side of the glue storage box. The output shaft of the stirring motor is fixedly connected with the stirring shaft, and the outer surface of the stirring shaft is fixedly connected with the stirring blade, the right end of the bottom of the inner cavity of the glue storage box is fixedly installed with a pump, and the outlet of the pump is flexibly connected with a nozzle. Through the functions of the first support plate, the electric telescopic rod, the second support plate, the upper squeeze roller bracket and the upper squeeze roller, the present invention can meet people's bonding requirements for conveyor belts of different thicknesses, and bring great benefits to people's use. Great convenience, at the same time, through the functions of the scraper, the first reserved slot, the baffle, the filter and the second reserved slot, it can meet the need for repeated use of glue, thereby avoiding the waste of glue and saving production costs. in the interests of the enterprise itself.

Owner:HENAN TIANGONG RUBBER TECHNOLOGY CO LTD

A foam model bonding machine for lost foam casting

ActiveCN109434018BMeet bonding needsSimple designFoundry moulding apparatusMechanical engineeringLost-foam casting

The invention provides a foam model bonding machine for lost foam casting. The foam model bonding machine comprises an upper model box and a lower model box, the lower model box is fixed to a worktable, a glue brushing pool is fixed to the worktable, a model box conveying mechanism is connected to the worktable through a bracket, the upper model box is clamped through a box-type fixture and then suspended on the model box conveying mechanism, and the upper model box is driven by themodel box conveying mechanism to move between the upper part of the lower model box and the upper part of thegluebrushing pool. Compared with the prior art, the foam model adhesive machine for lost foam casting has the beneficial effects that overall design is simple, integration of glue brushing, assembling and shaping of a foam model is realized, and the foam model adhesive machine has the advantages of high assembly and bonding accuracy and high speed, the bonding requirements of foam models with different shapes can be met, and the problems of low efficiency, poor quality stability, and uneven glue application in the process of glue brushing as well as the problem ofbonding precision of the upper and lower foam models are solved.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com