Foam model bonding machine for lost foam casting

A technology of lost foam casting and foam model, applied in casting and molding equipment and other directions, can solve the problems of low efficiency and poor precision, and achieve the effect of high bonding precision, high speed and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

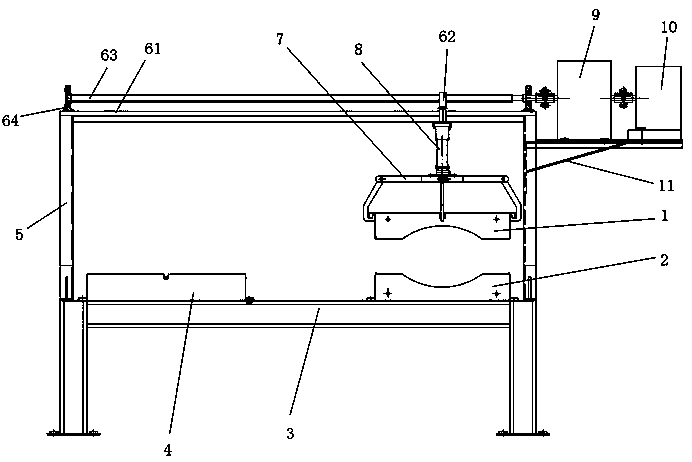

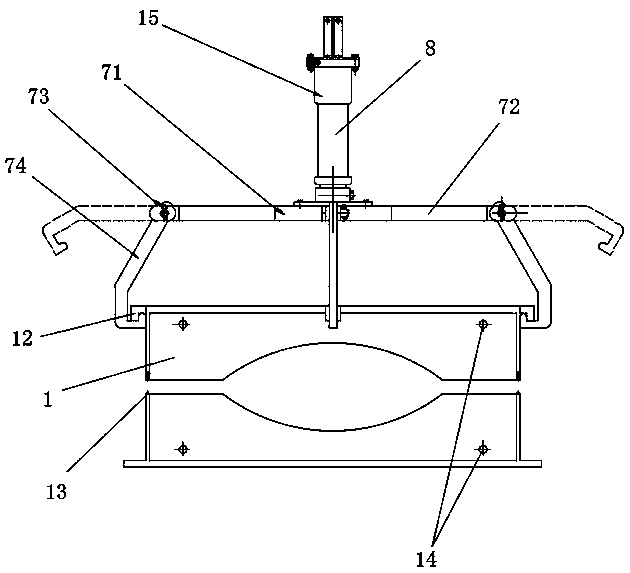

[0026] Such as Figure 1-2 As shown in , a foam model bonding machine for lost foam casting includes an upper mold box 1 and a lower mold box 2, the lower mold box 2 is fixed on a workbench 3, and a glue brush pool 4 is fixed on the workbench 3, and the working The table 3 is connected with the model box transmission mechanism through the bracket 5, and the upper model box 1 is clamped by the box clamp 7 and then hung on the model box transmission mechanism. Move between glue pools above 4.

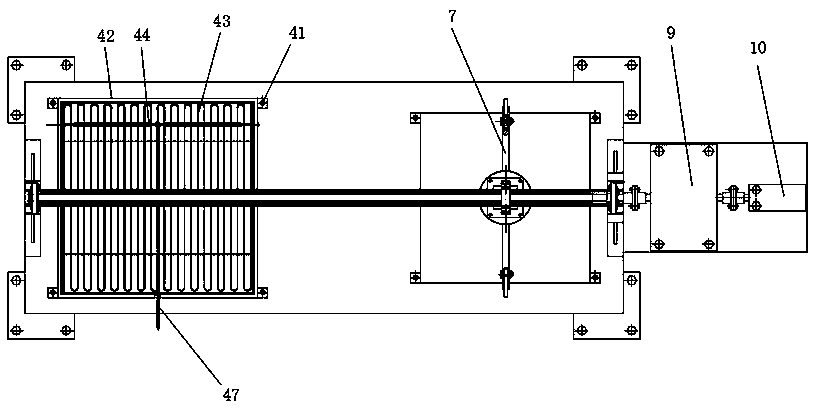

[0027] The model box transmission mechanism includes a slide table 61 and a slide block 62, the top of the slide block 62 is sleeved on the lead screw 63 and cooperates with the lead screw 63, and the bottom of the slide block 62 fits in the groove of the slide table 61, as Figure 4 As shown in , the slider 62 can perform linear reciprocating motion along the groove of the slide table, the slide table 61 is supported by the bracket 5, the two ends of the screw 63 are connected to the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com