Automatic rod sticking and dispensing route and dispensing method

A dispensing and sticking technology, which is applied to coatings, devices for coating liquid on surfaces, special surfaces, etc., can solve problems such as unreasonable dispensing track design, unstable bonding quality, and high production costs, and achieve Optimize the dispensing track route, high dispensing efficiency and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

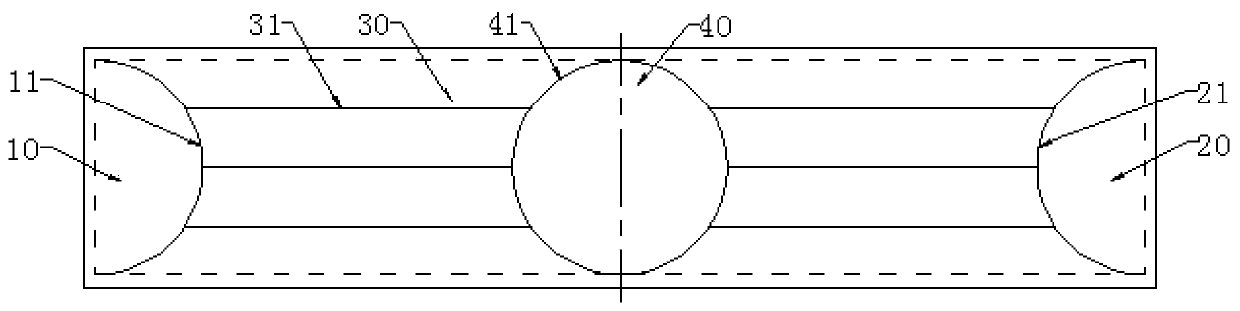

[0059] Such as figure 1 As shown, the shape of the dispensing route of the first dispensing area 10 is a semicircular curve 11, and the dispensing needle starts from the upper end point on the left side of the material seat 50, that is, the first dispensing area 10 is close to the upper end of the material seat 50. At the end point, rotate the dispensing clockwise until the lower end point ends, and then lift the dispensing needle.

[0060] After finishing the dispensing route of the first glue dispensing area 10, begin to dispensing glue to the dispensing straight line 31 of the third glue dispensing area 30 on the left side, and then to the lower section straight line 31 in the third glue dispensing area 30 on the left side , Middle section straight line 31 and upper section straight line 31 carry out glue dispensing. Specifically, the dispensing needle first moves to the intersection of the straight line 31 on the side of the lower section and the curve 11, and moves along...

Embodiment 2

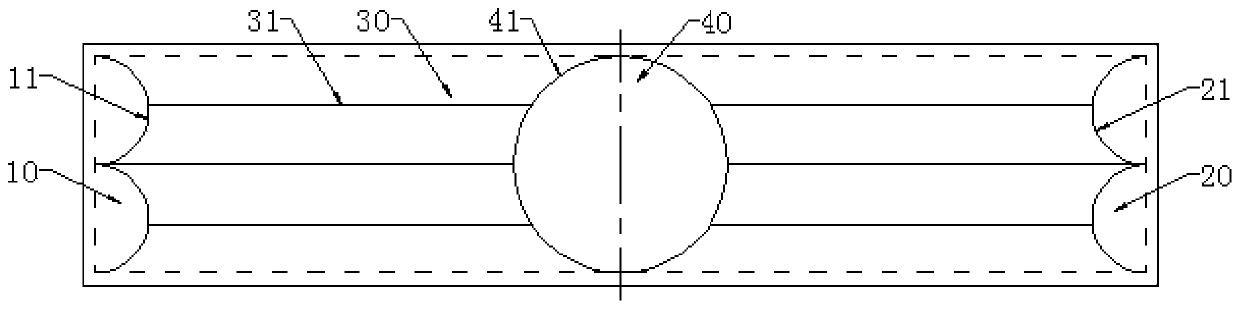

[0065] Such as Figure 5 As shown, the difference from Embodiment 1 is only the difference in the shape of the dispensing route in the third dispensing area 30, the dispensing method of the first dispensing area 10, the second dispensing area 20 and the fourth dispensing area 40 are the same and are omitted here. The third glue dispensing area 30 includes two horizontally parallel straight lines 31 correspondingly arranged on the left and right sides, and symmetrically arranged on both sides of the central axis of the material holder 50 in the width direction.

[0066] After finishing the dispensing route of the first glue dispensing area 10, begin to dispensing glue to the dispensing straight line 31 of the third glue dispensing area 30 on the left side, and then to the lower section straight line 31 in the third glue dispensing area 30 on the left side Carry out dispensing with upper section straight line 31. Specifically, the dispensing needle first moves to the intersect...

Embodiment 3

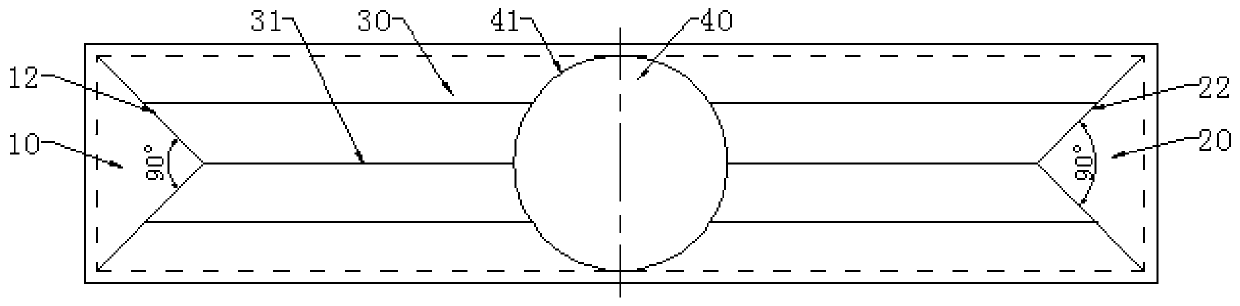

[0069] Such as Figure 4 As shown, the difference from Embodiment 1 is only the difference in the shape of the dispensing route in the third dispensing area 30, the dispensing method of the first dispensing area 10, the second dispensing area 20 and the fourth dispensing area 40 are the same and are omitted here. The third dispensing area 30 includes a horizontal straight line 31 and is located at the central axis of the material holder 50 in the width direction.

[0070] Start dispensing in the third dispensing area 30 on the left, lift the dispensing needle and move to the apex position on the right side of the curve 11, that is, the intersection with the middle axis in the width direction of the material seat 50, and move along a horizontal line from the left Dispensing until the end point on the right side, that is, ending at the apex of the curve 41 on the left side of the fourth dispensing area 40, and then lift the dispensing needle.

[0071] Then the third dispensing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com