Patents

Literature

52results about How to "Evenly covered" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Foamed plastic mold

Owner:龙海市永隆泡沫包装有限公司

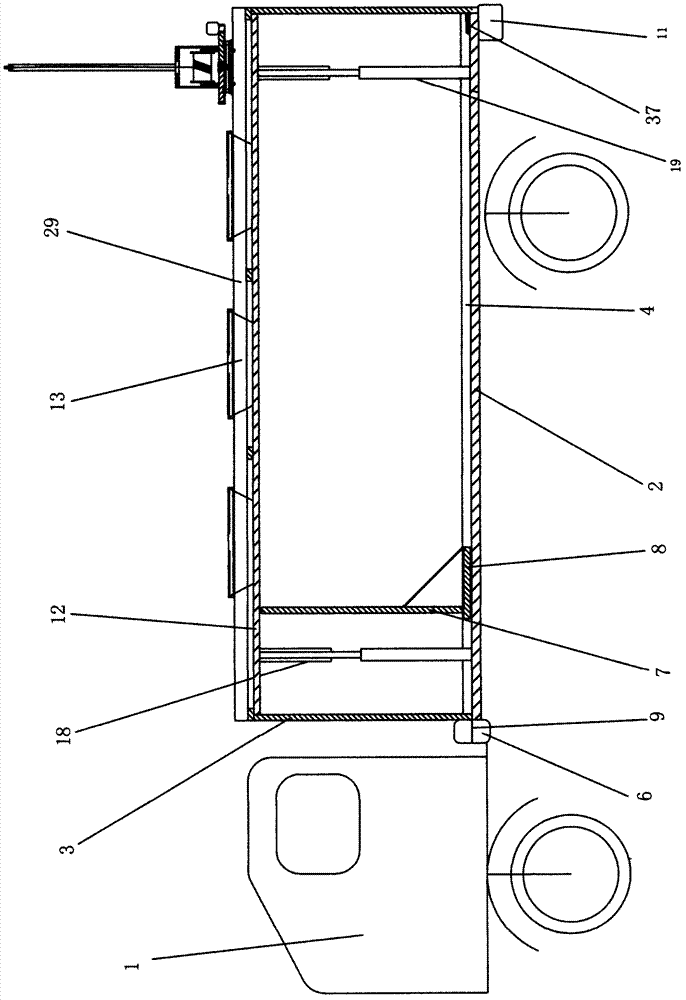

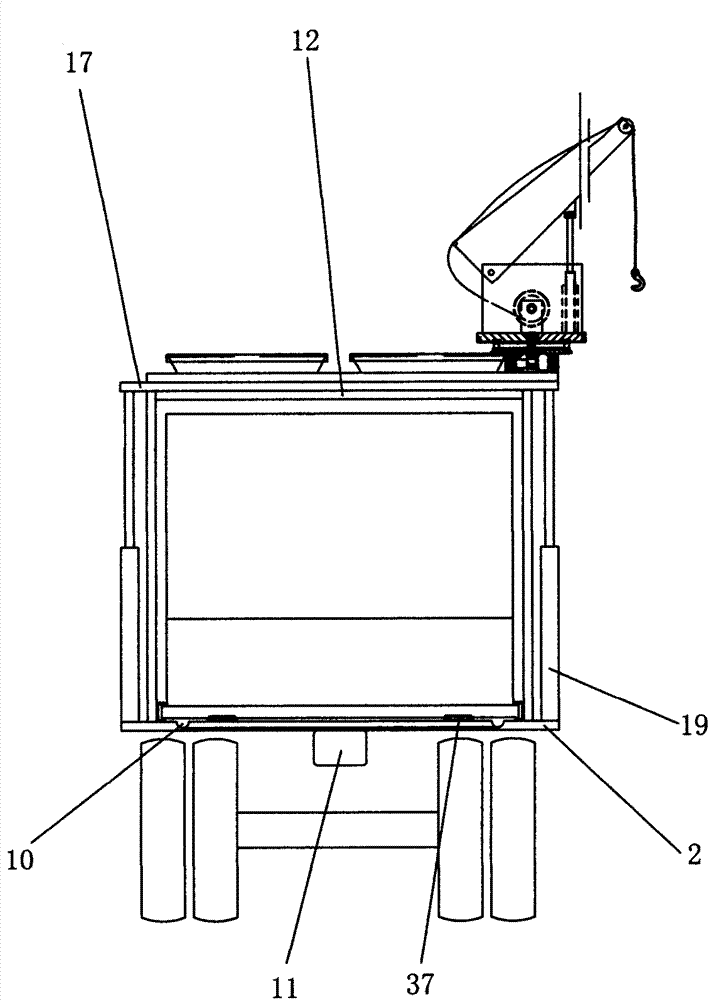

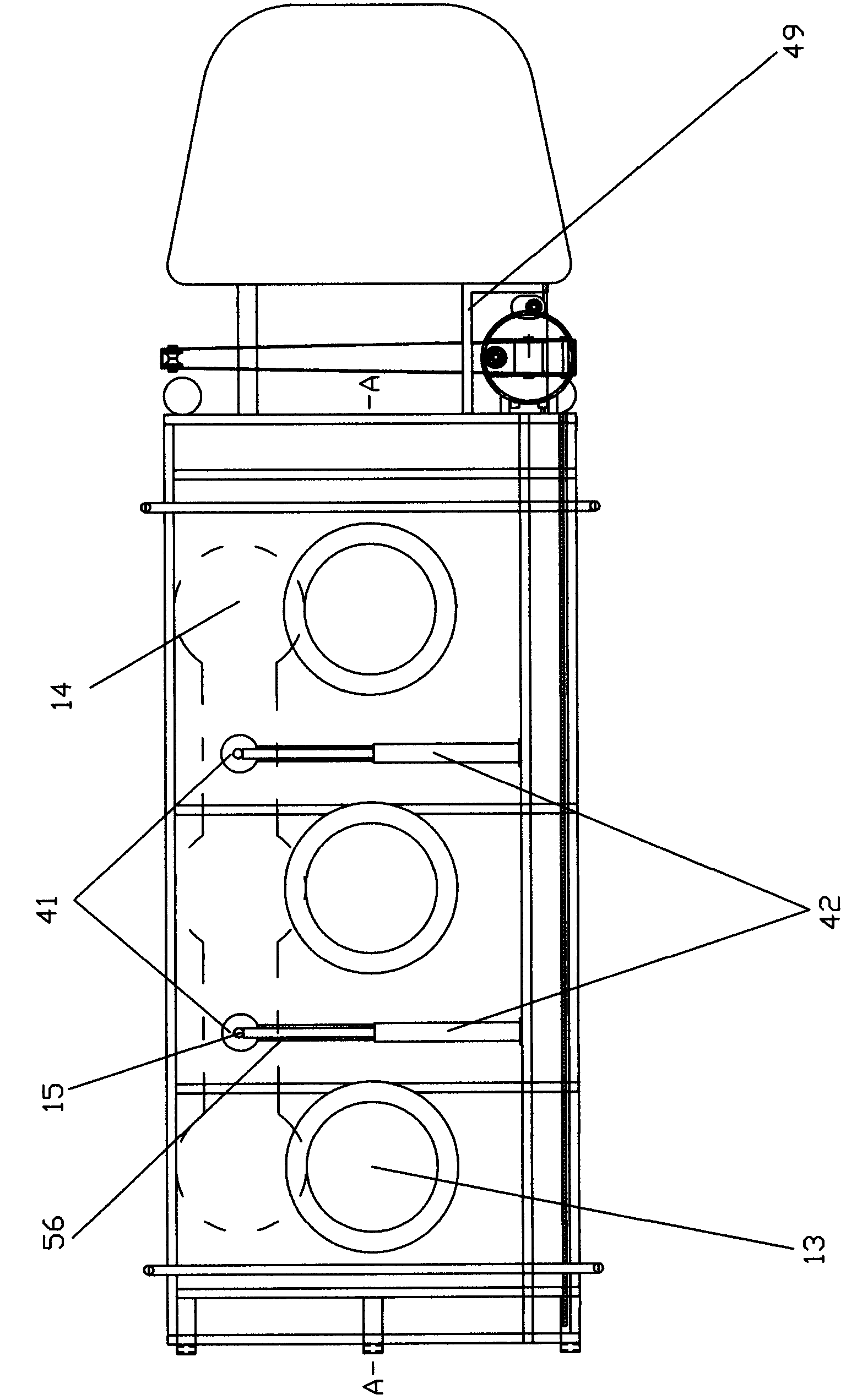

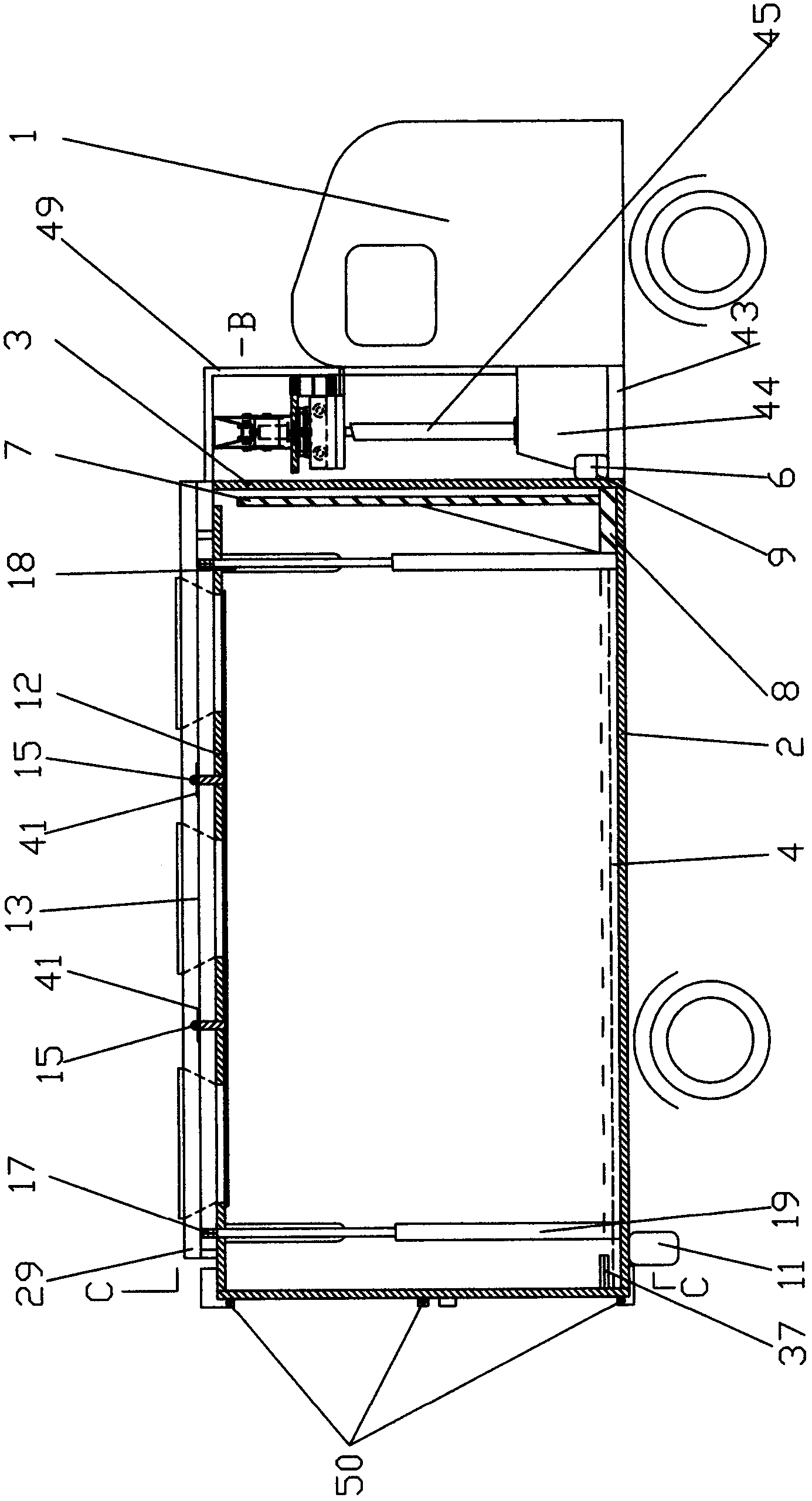

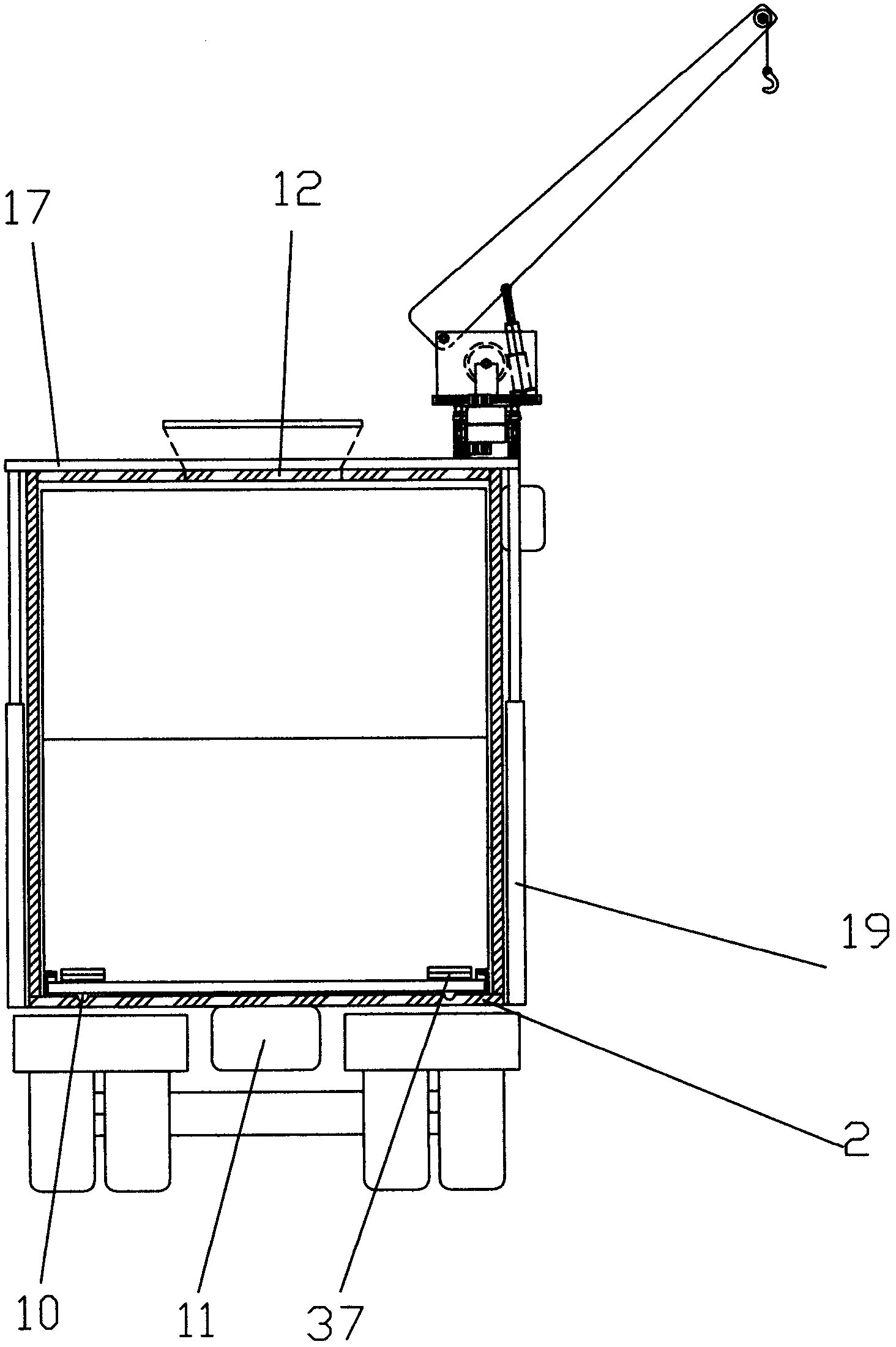

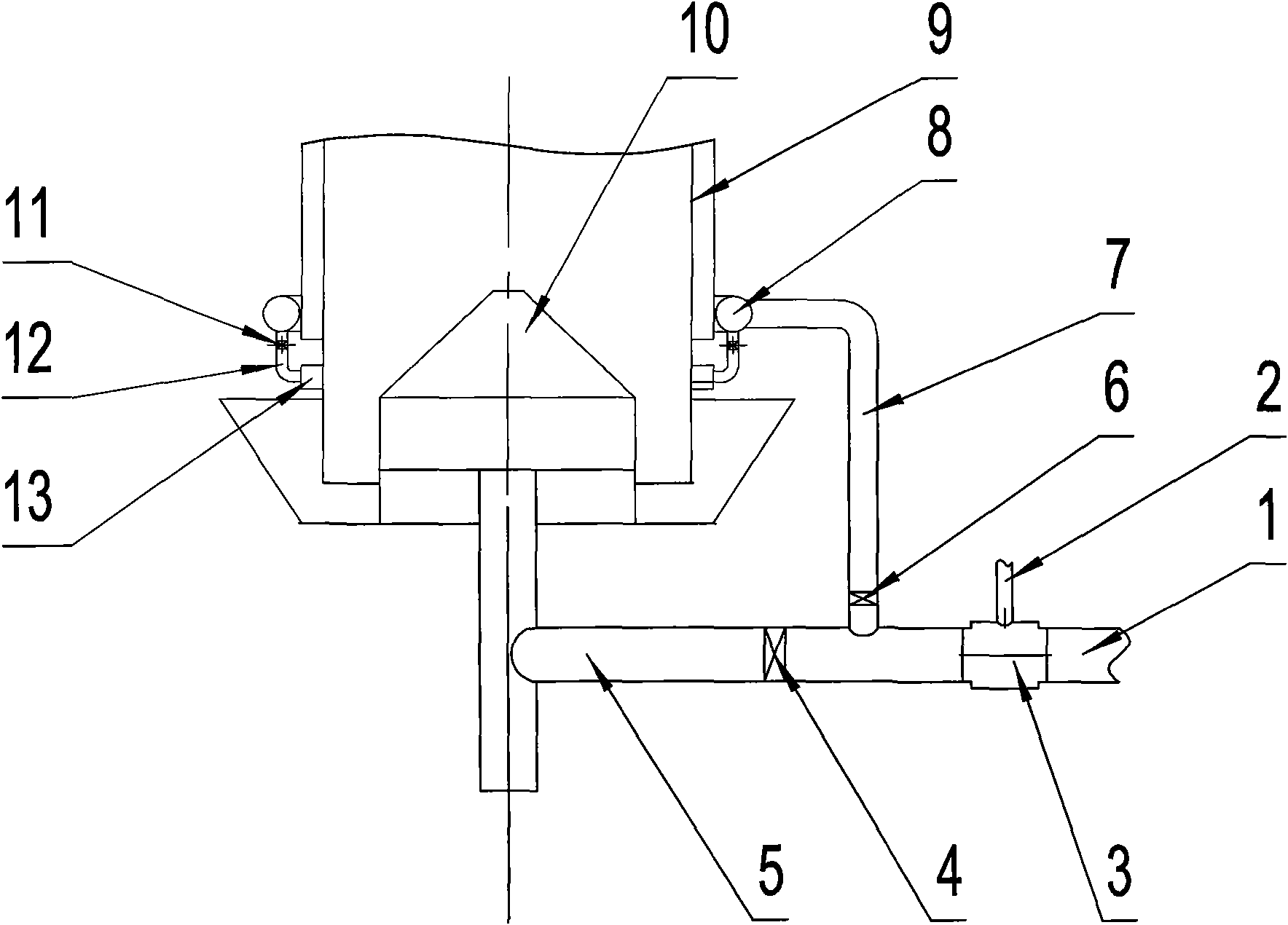

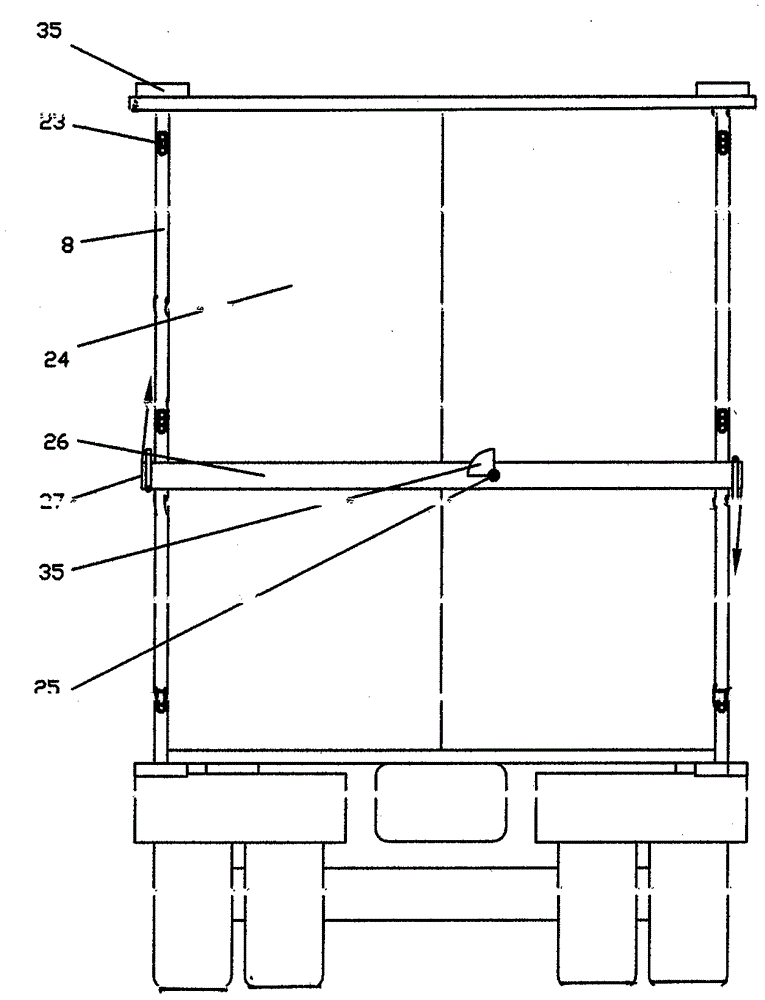

Transport vehicle for lifting, compacting, pulling and unloading waste

The invention discloses a transport vehicle for lifting, compacting, pulling and unloading waste, belongs to the field of city sanitation equipment manufacturing technologies, and particularly relates to an automobile for loading, unloading and transporting the waste. Due to the fact that currently, a garage transport vehicle in cities of China need to be used in cooperation with a waste transfer station, equipment is expensive, transporting efficiency is low, labor intensity is high, stay time of the waste is overlong, and secondary pollution is prone to being generated. A translational jib crane, unloading opening positioning bases, a top plate horizontal type compactor and an unloading mechanism installed on a carriage of the transport vehicle are adopted, so that defects existing in the prior art are effectively overcome, and the existing waste transport vehicle and the waste transfer station are replaced.

Owner:白景魁

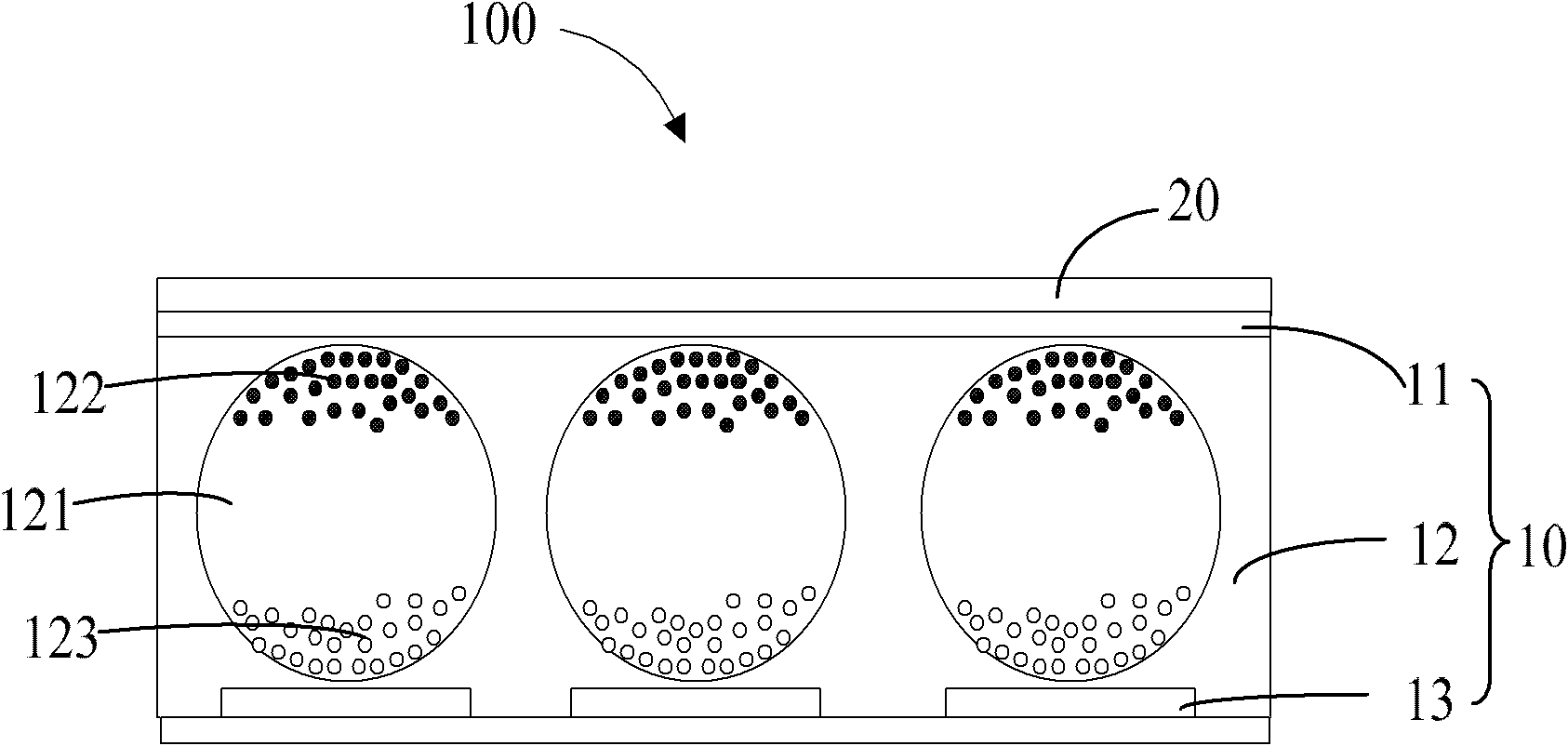

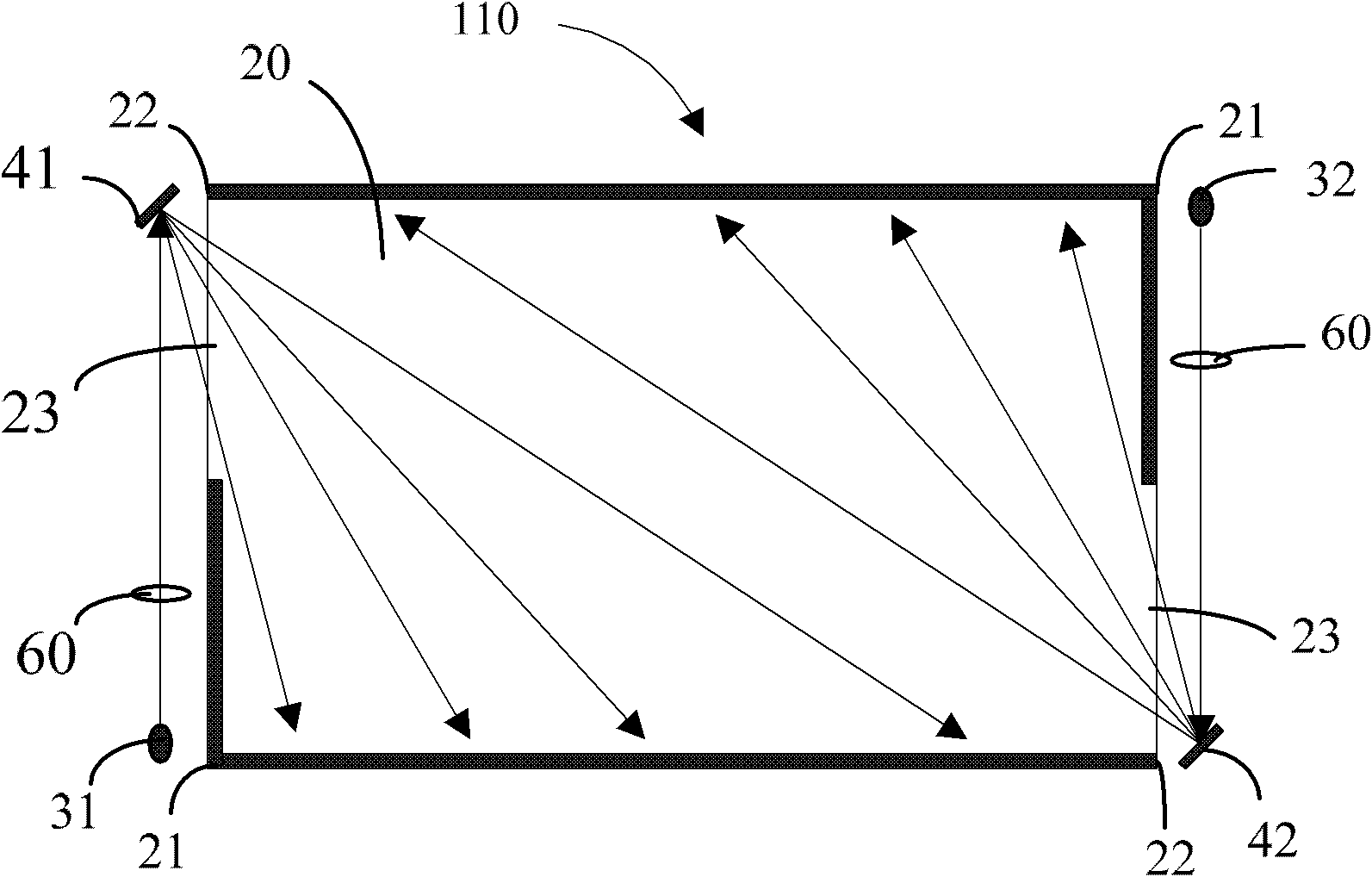

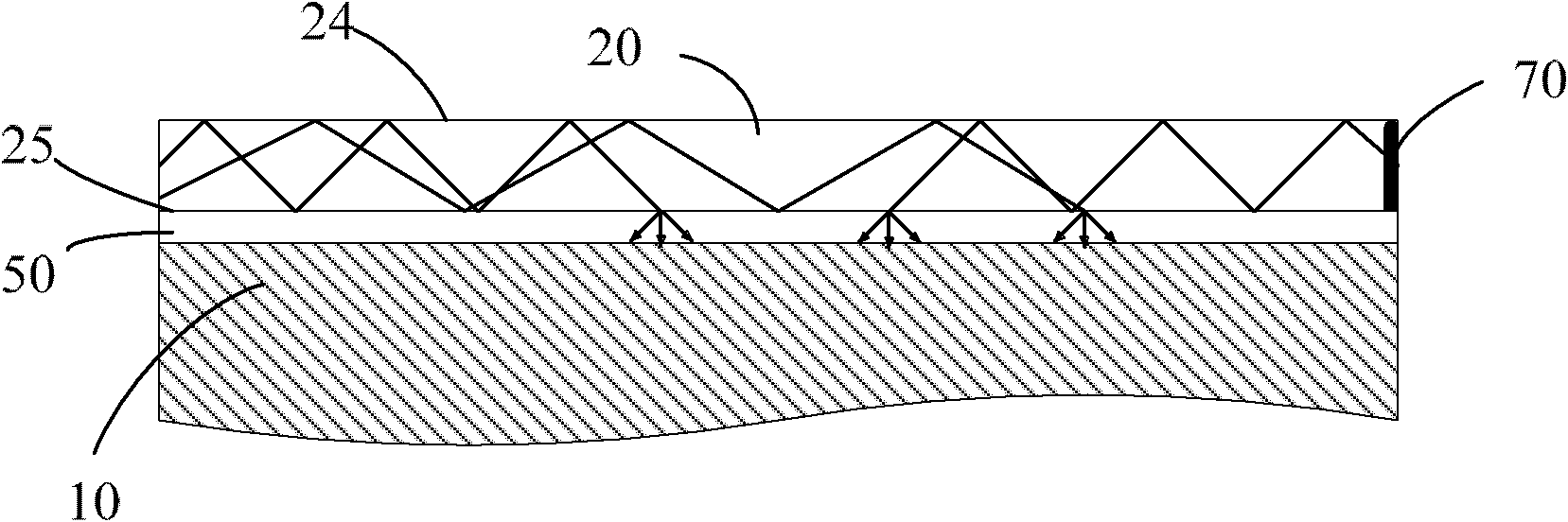

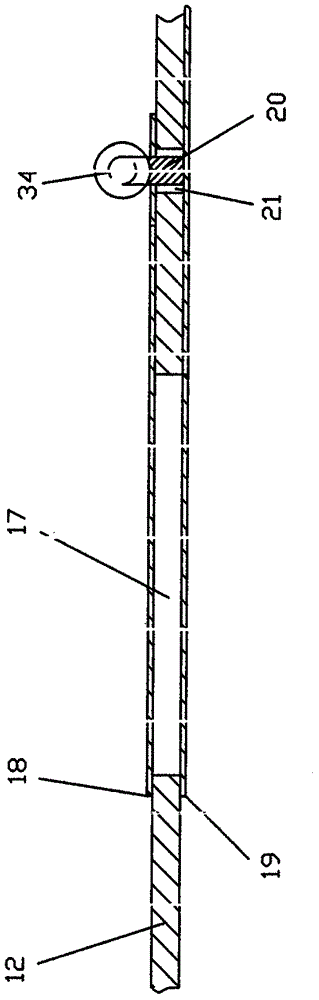

Front lighting device and reflective display device using same

InactiveCN102279498AReduce usageFull of lightLighting device detailsNon-linear opticsForward propagationLight guide

A reflective display device with a front lighting device, comprising a display layer and a light guide plate arranged on the display layer. At least one light source is arranged on the side of the light guide plate, at least one scanning mirror is arranged on the side of the light guide plate, and a diffusion plate is also arranged between the light guide plate and the display layer. The light guide plate includes a first surface away from the display layer and a second surface close to the display layer. The light emitted by the light source is reflected by the scanning mirror and then enters the inside of the light guide plate. Repeated reflection between the first surface and the second surface of the light plate propagates forward, refracts through the second surface, enters the diffuser plate and diffuses to the display layer to provide front light illumination. The invention also provides a front lighting device.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

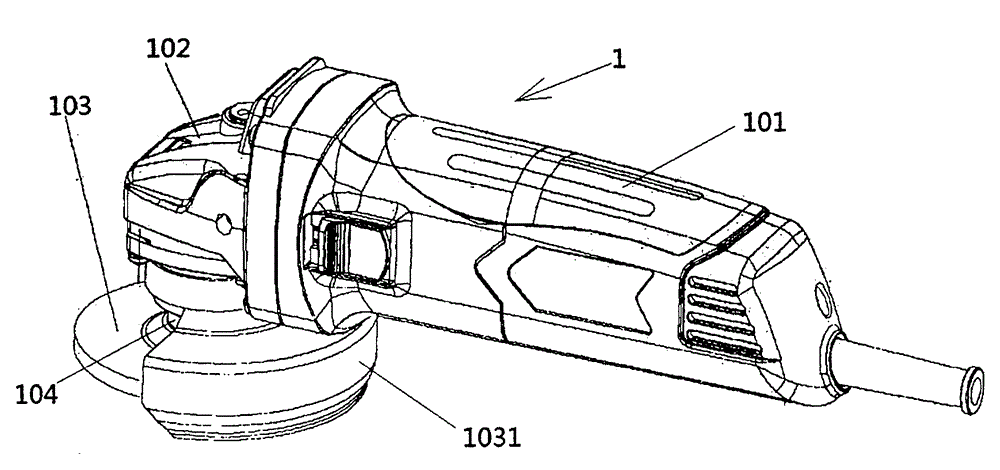

Angle grinder

InactiveCN105033825AEvenly coveredAvoid flyingPortable grinding machinesGrinding/polishing safety devicesAngle grinderWater flow

The invention provides an angle grinder. The angle grinder comprises an angle grinder body, wherein the angle grinder body comprises a holding part, a deceleration gear part and an abrasive disc; a driving motor is arranged in the holding part; in addition, the holding part is provided with a main shaft connected to the deceleration gear part; after the deceleration gear part decelerates the rotating output of the driving motor, the decelerated rotating output is transmitted to the main shaft; the abrasive disc is arranged at the end part of the main shaft; the periphery of the abrasive disc is wrapped through an abrasive-disc cover; a water pipe is arranged in the angle grinder body; the water pipe is inverted in the angle grinder body from the tail end of the holding part, and enters the main shaft; the outlet of the water pipe is positioned at the center of the abrasive disc. According to the angle grinder disclosed by the invention, water flows to the abrasive disc through the water pipe, and water is uniform on the abrasive disc and the surface of a ground object; the working manner of an angle grinder is changed from dry and coarse grinding into water-supply coarse grinding, so that the dust is effectively prevented from flying and scattering, and the harm of dust to operators is reduced; in addition, the abrasive-disc cover wraps the abrasive disc, so that the dust is effectively prevented from flying and scattering, and water is effectively prevented from splashing.

Owner:朱卫

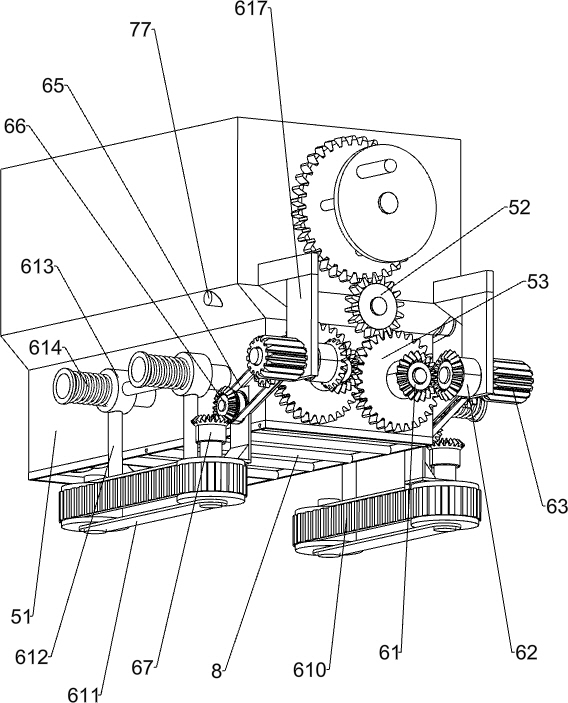

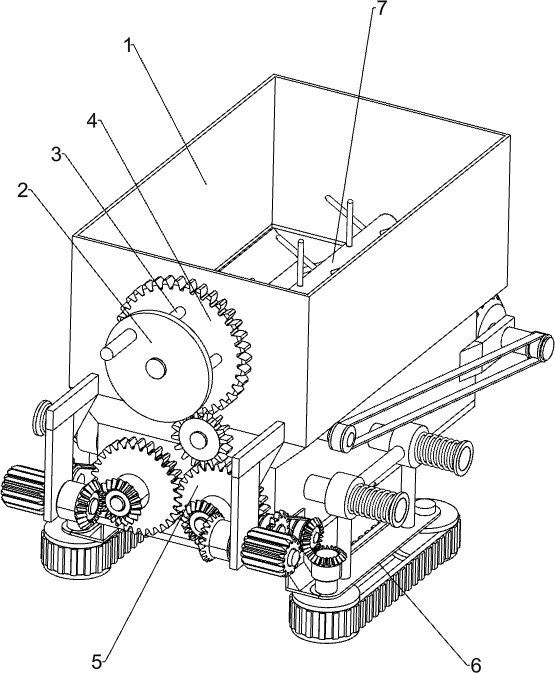

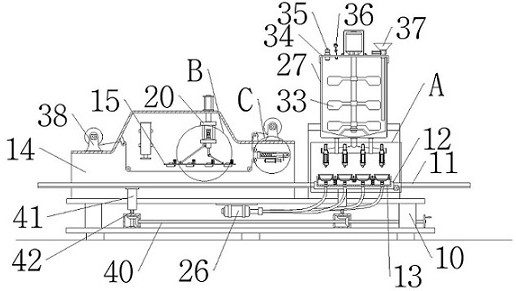

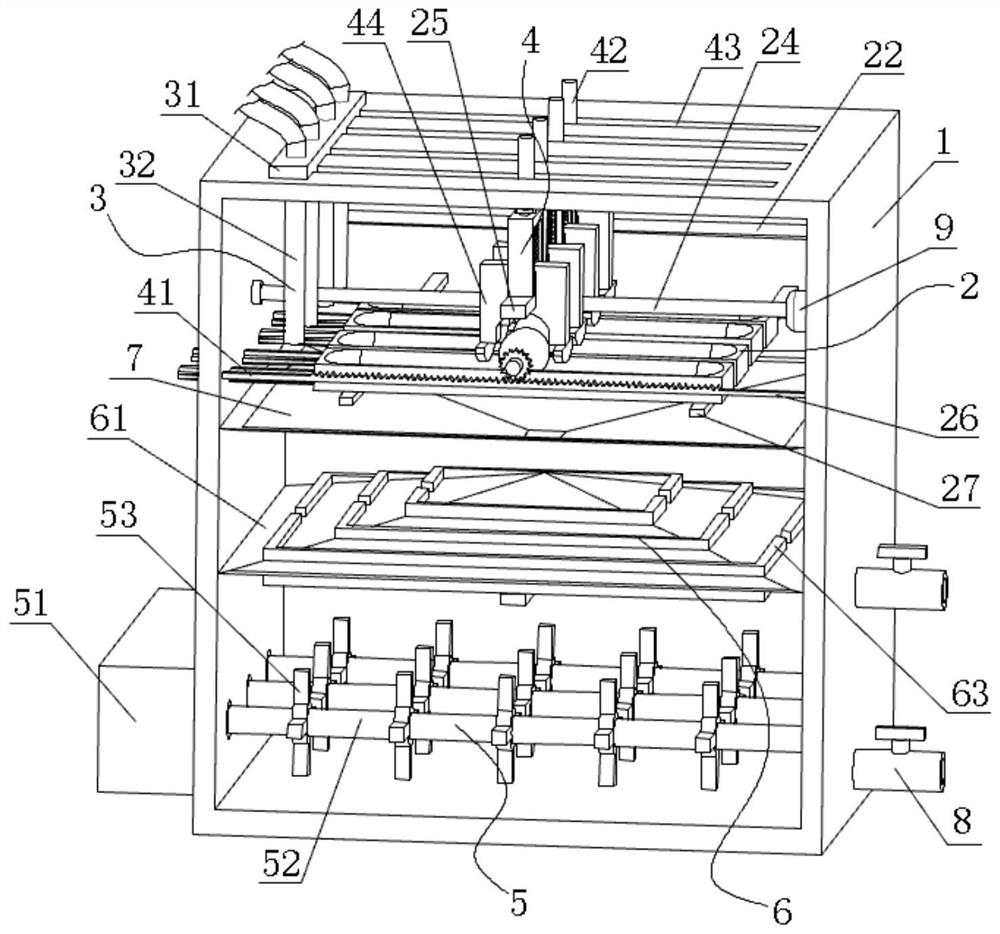

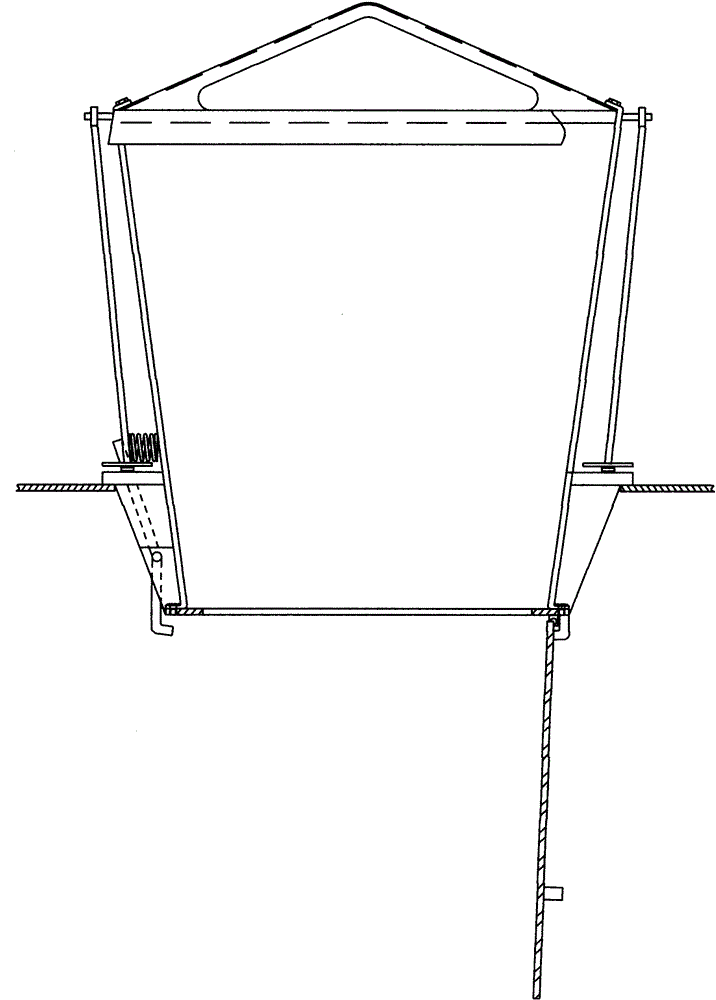

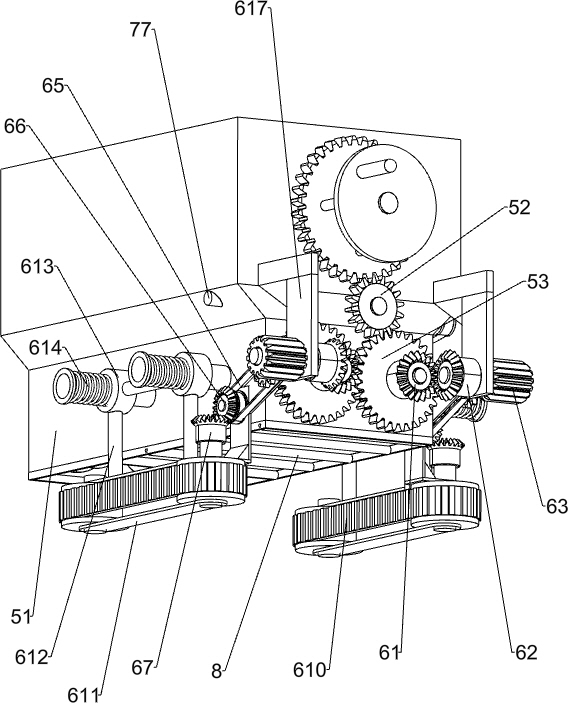

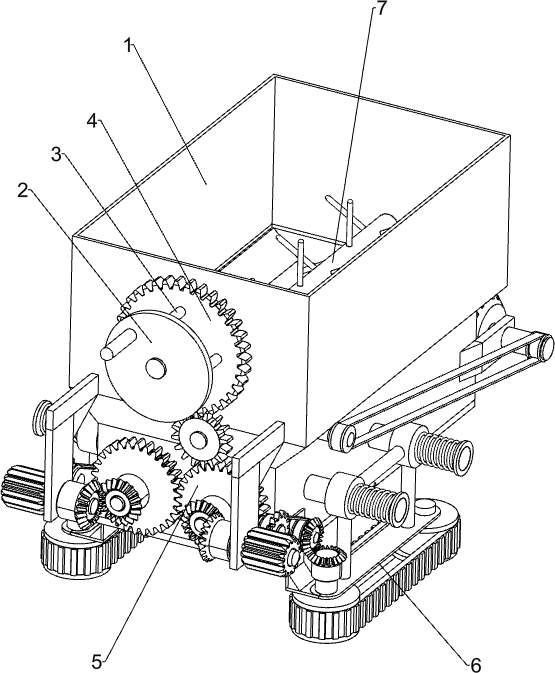

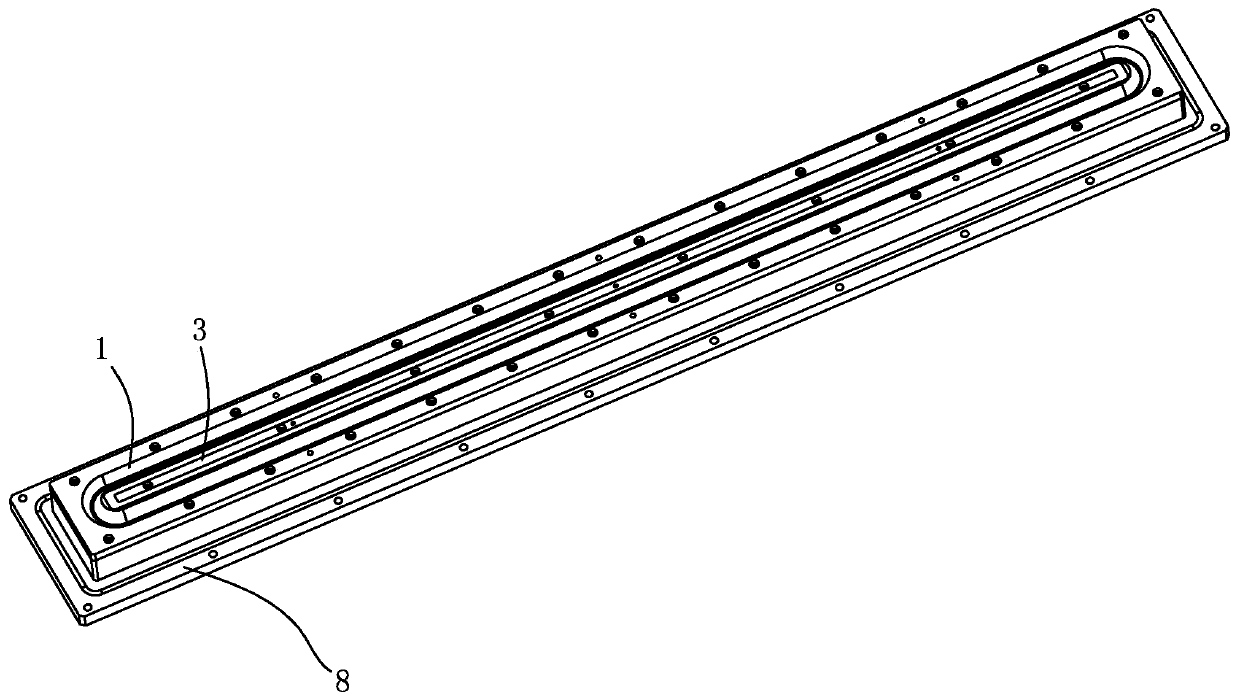

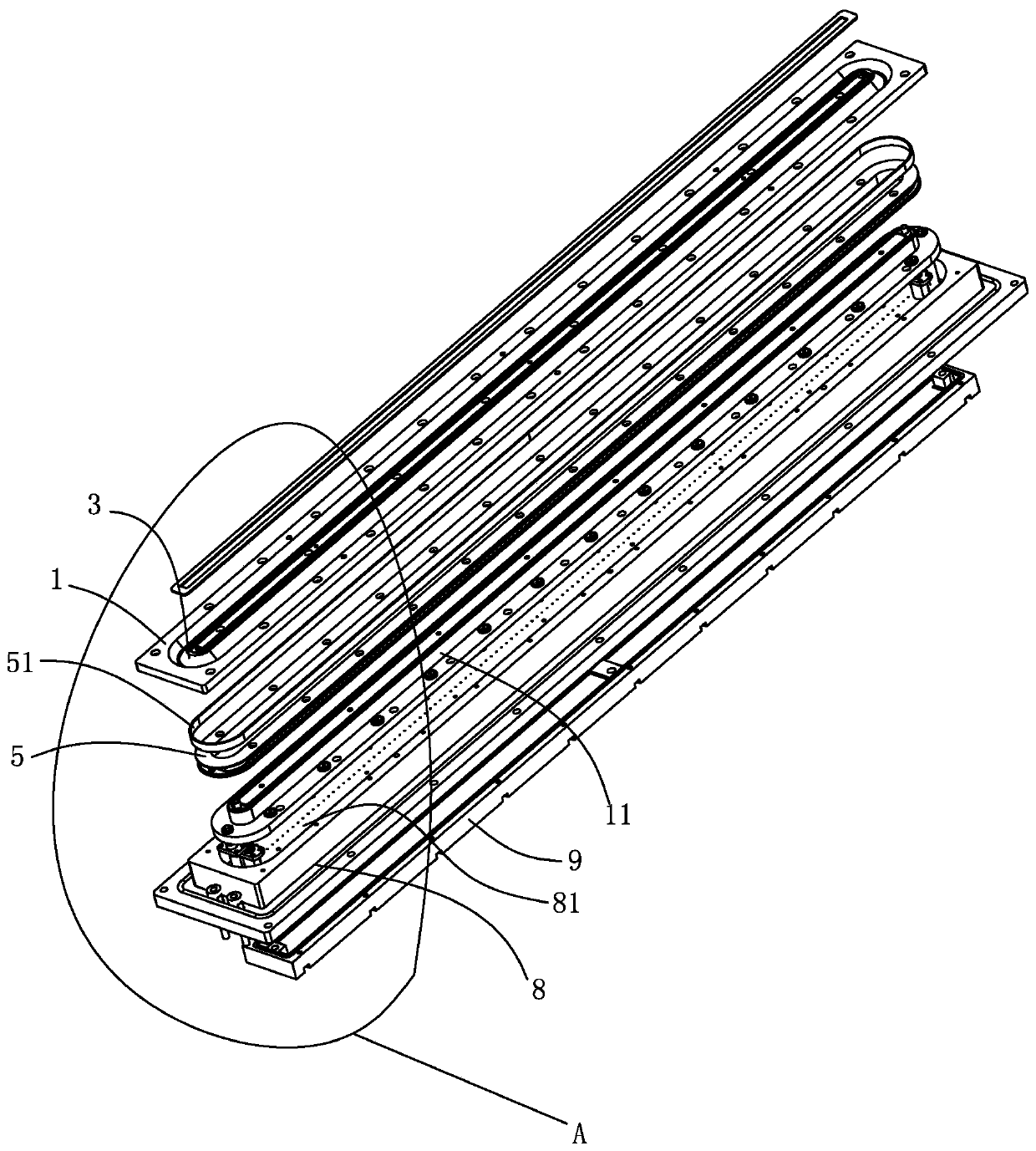

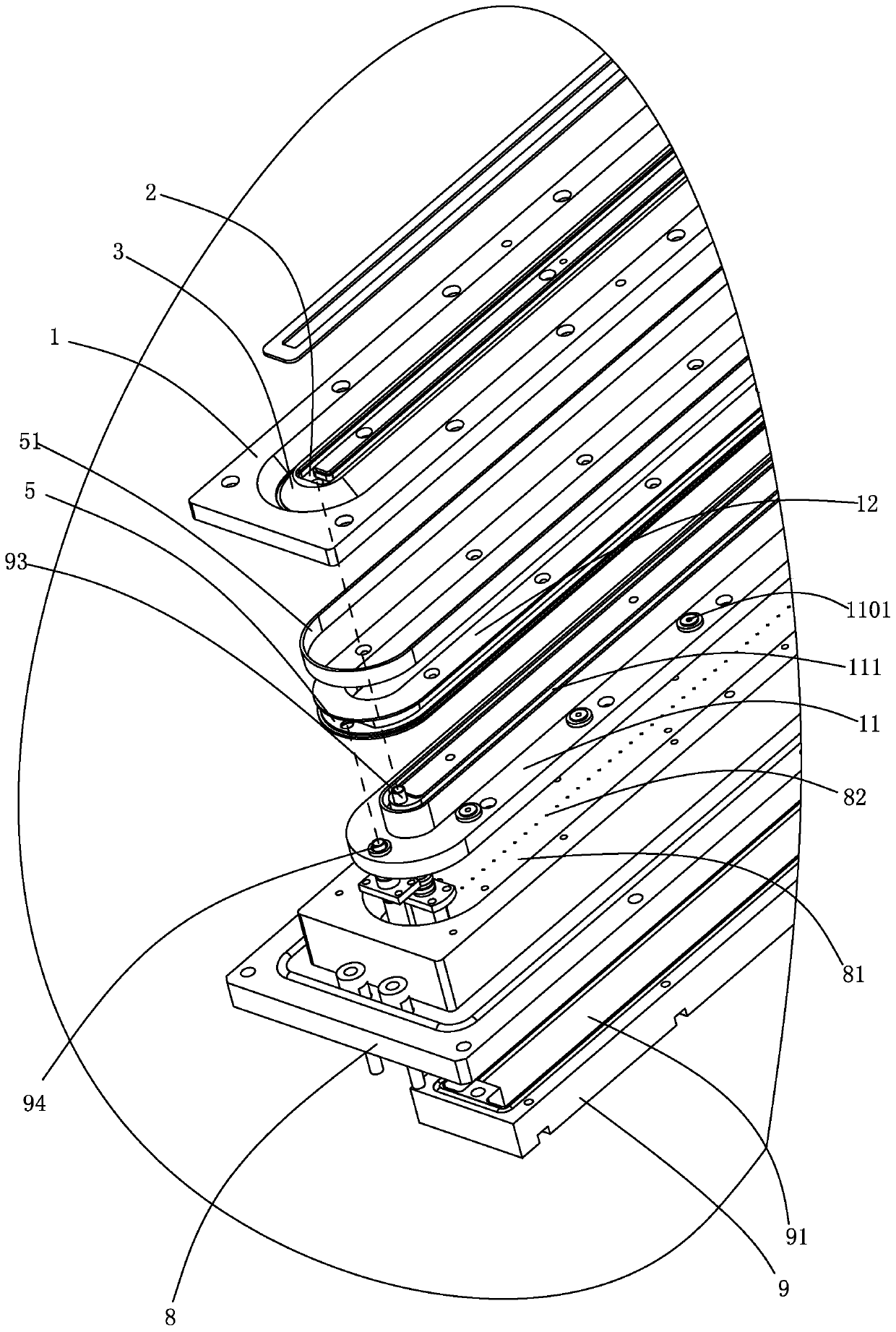

Cement laying device applied for architecture wall building

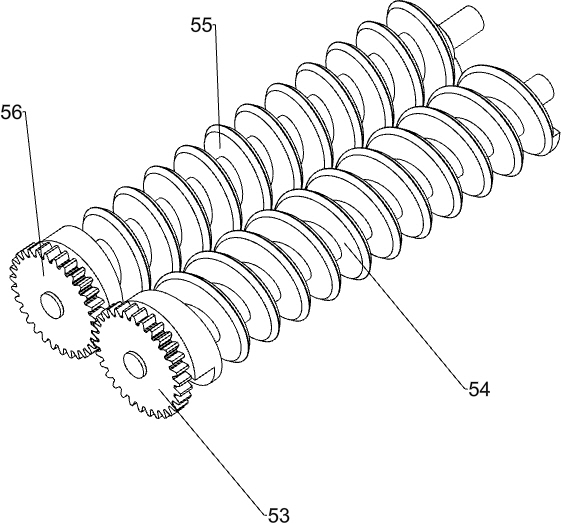

ActiveCN111809898AEvenly coveredReduce labor intensityBuilding material handlingCement mixing apparatusBrickGear wheel

The invention relates to a cement laying device, in particular to a cement laying device applied for architecture wall building. The device aims at solving the technical problem of how to provide a cement laying device applied for architecture wall building, and the cement laying device applied for architecture wall building can reduce the labor intensity of a construction worker and improve the efficiency of laying cement slurry. To solve the above technical problem, the cement laying device applied for architecture wall building is provided, and comprises a material storage tank, a first connecting rod, a hand-driven plate, and a material laying mechanism. One side of the material storage tank is connected with a first gear in a rotating mode. The first gear is connected with the first connecting rod. The first connecting rod is connected with the hand-driven plate. The material laying mechanism is mounted on the material storage tank, and is connected with the first gear in a transmission way. The first gear of the device can drive the material laying mechanism to work by rotating anticlockwise. The working material laying mechanism is capable of placing cement slurry over bricks and also capable of driving an auxiliary moving mechanism to work.

Owner:天长市振业建设工程有限公司

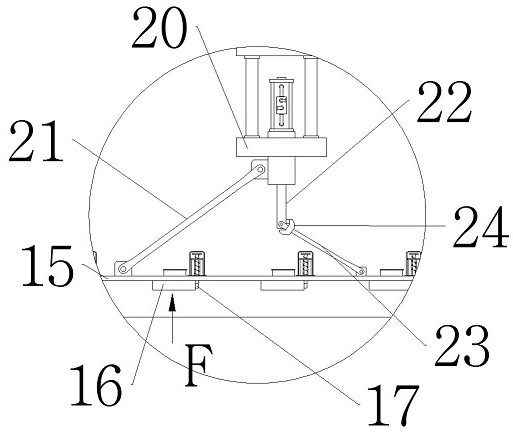

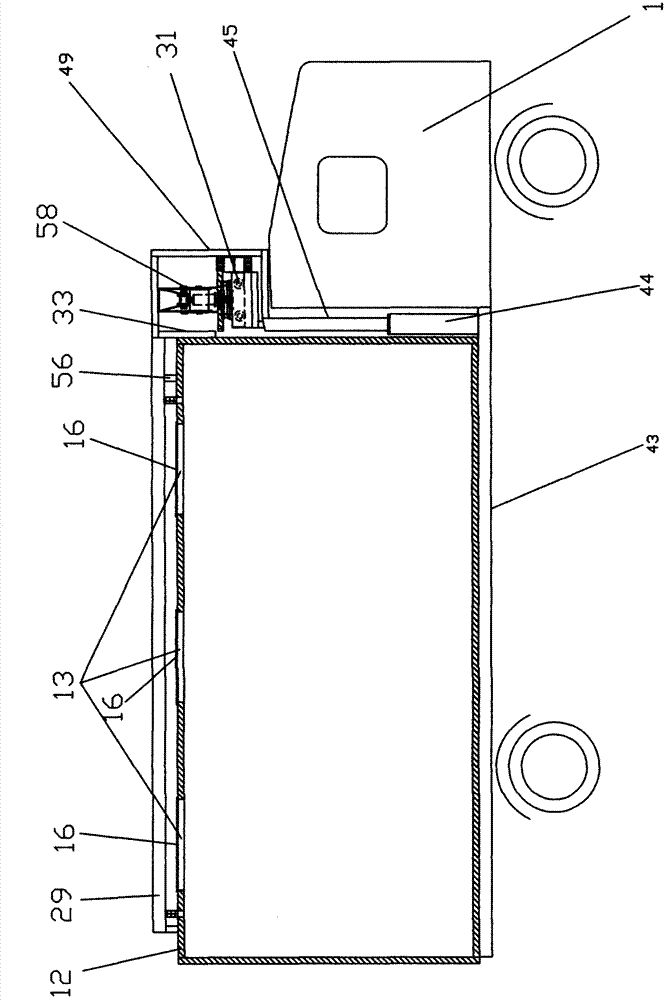

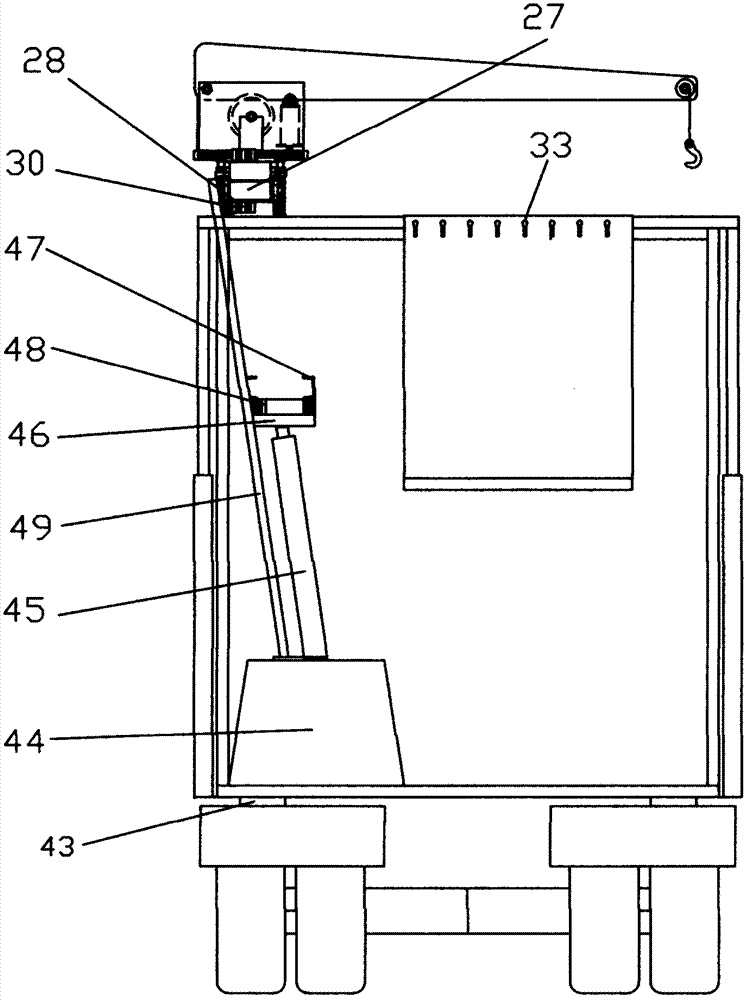

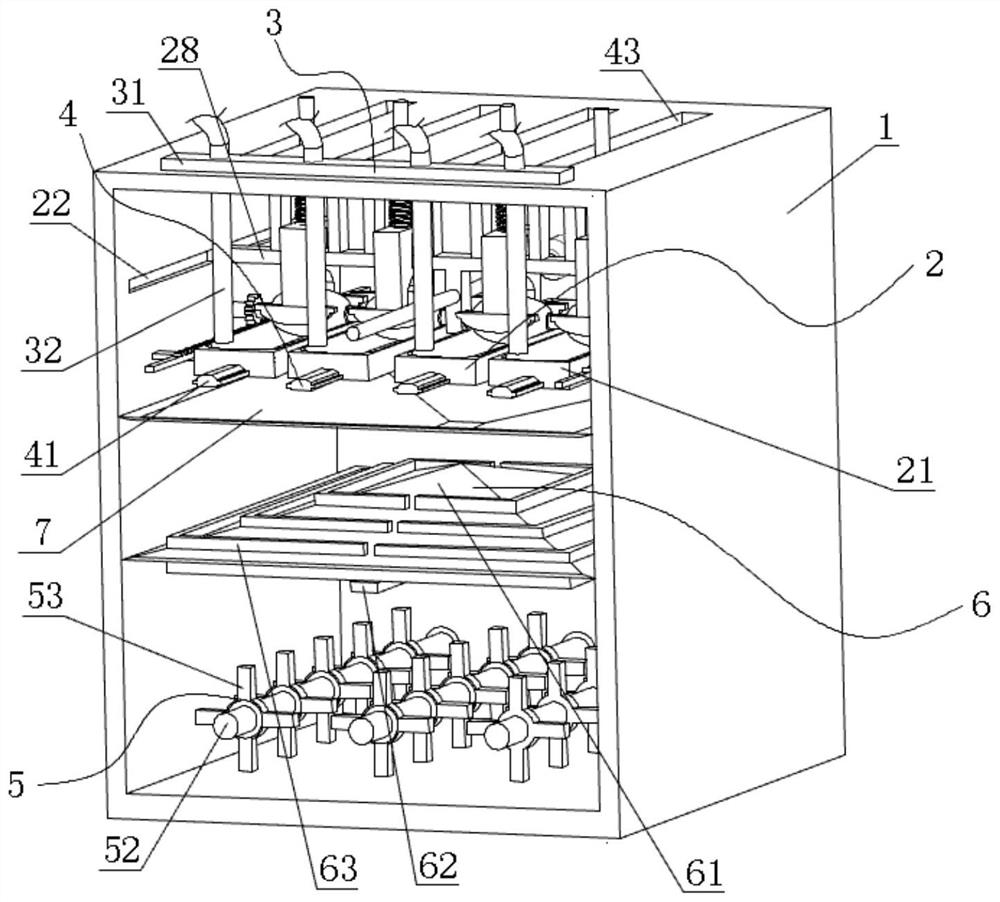

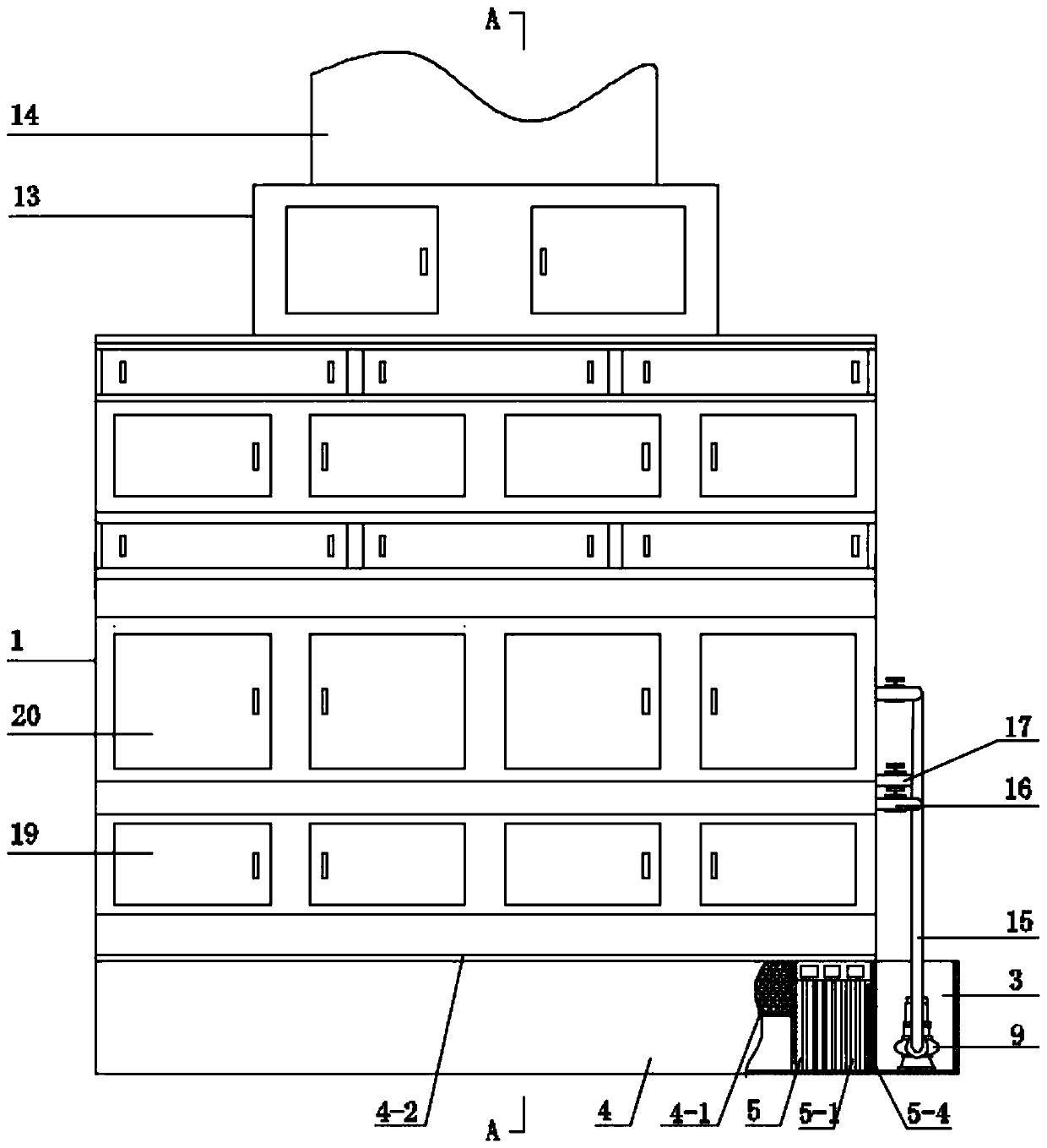

Transport vehicle for hoisting, compacting and unloading rubbish

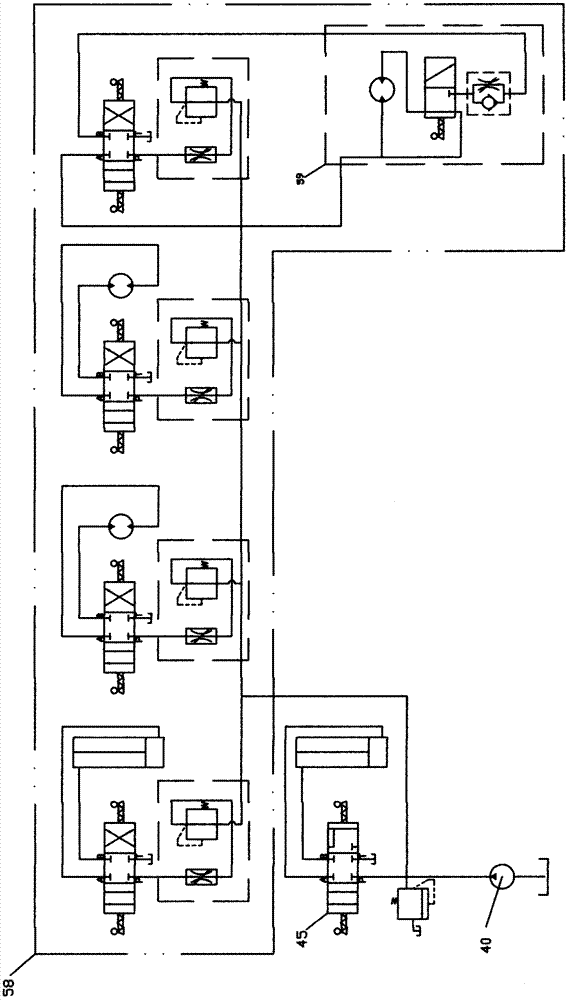

InactiveCN103708151AIncrease volumeEvenly coveredRefuse transferringStorage devicesEnvironmental hygieneTransport engineering

The invention provides a transport vehicle for hoisting, compacting and unloading rubbish, belongs to the technical field of urban environmental hygiene equipment manufacturing, and particularly relates to a vehicle for loading and unloading the rubbish. At present, rubbish transport vehicles in cities in China need to be matched with a rubbish transfer station for use, the equipment price is high, transport efficiency is low, labor intensity is large, rubbish storage time is long, and secondary pollution is produced easily. According to the transport vehicle, a compartment of the transport vehicle is provided with a jib crane, an unloading opening locating base, a top board horizontal compacting device, an unloading mechanism and a rear door switch mechanism, wherein the jib crane can move horizontally and is provided with a machine base lifting mechanism. The transport vehicle effectively overcomes the defect that the transport efficiency is low in the prior art, and therefore replaces a current rubbish transport vehicle and the rubbish transfer station.

Owner:溧阳凯元新材料科技有限公司

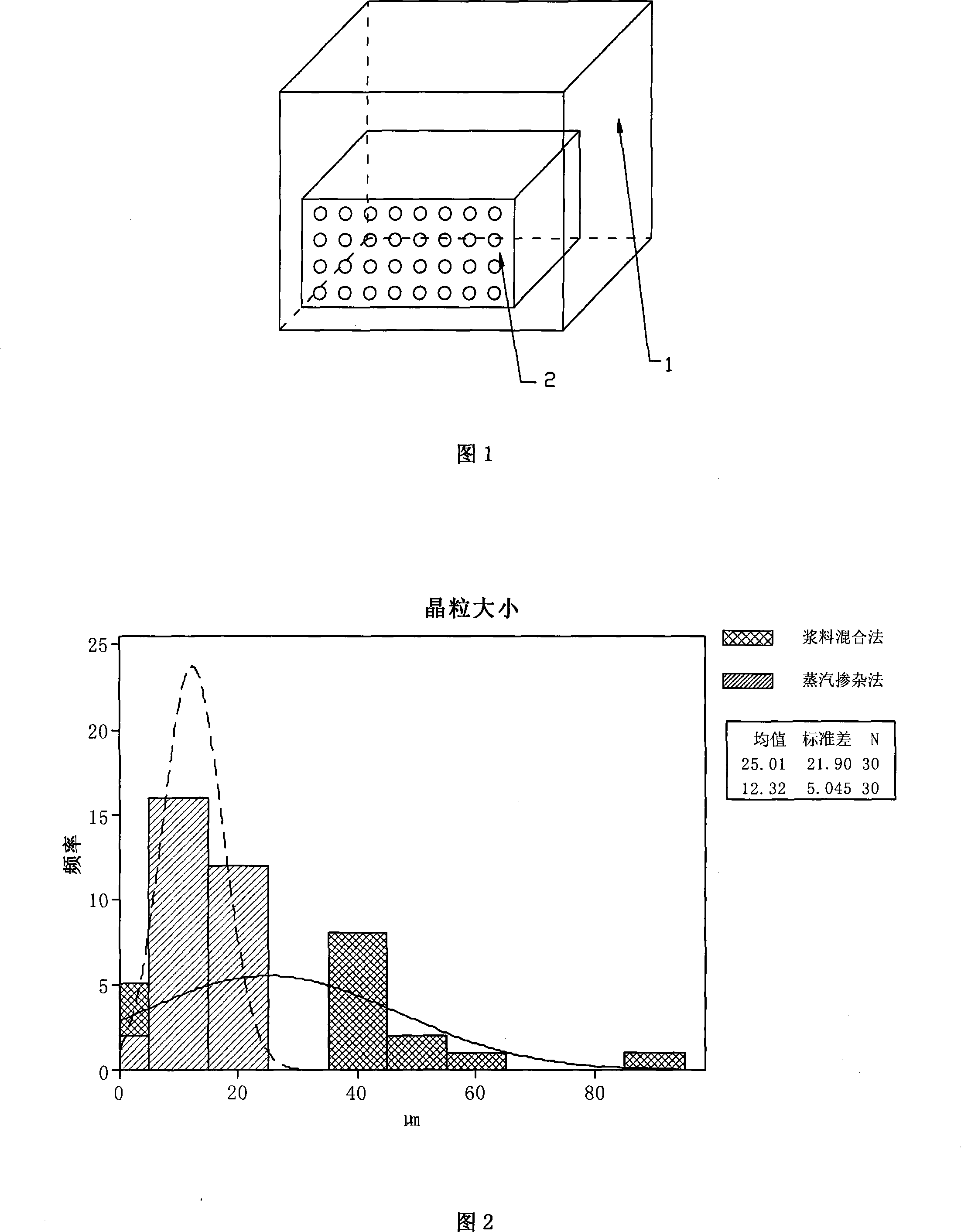

Method for doping polycrystalline alumina ceramics

The invention discloses a method of doping in polycrystal alumina ceramics, including the following steps: the alumina product is formed first and is initially burnt under the temperature of 900 DEG C to 1,250 DEG C for one or two hours; then the burnt alumina product is put together with the impurity but the two do not contact directly, and then are heated to 800 -1,500 DEG C for two hours to five hours, thereby ensuring that impurity is heated and changed into steam which is evenly distributed on an alumina product; last, the alumina product with the impurity is heated for a third time to 1,700 to 2,000 DEG C for 10 hours to 12 hours. The invention adopting steam doping can keep the distribution of impurities more even, in particular suitable for the doping of impurity in small quantity. The invention has the advantages of mechanical production, fast speed and large yield, etc. in comparison with prior slurry blending doping patterns.

Owner:SHANGHAI YAMING LIGHTING

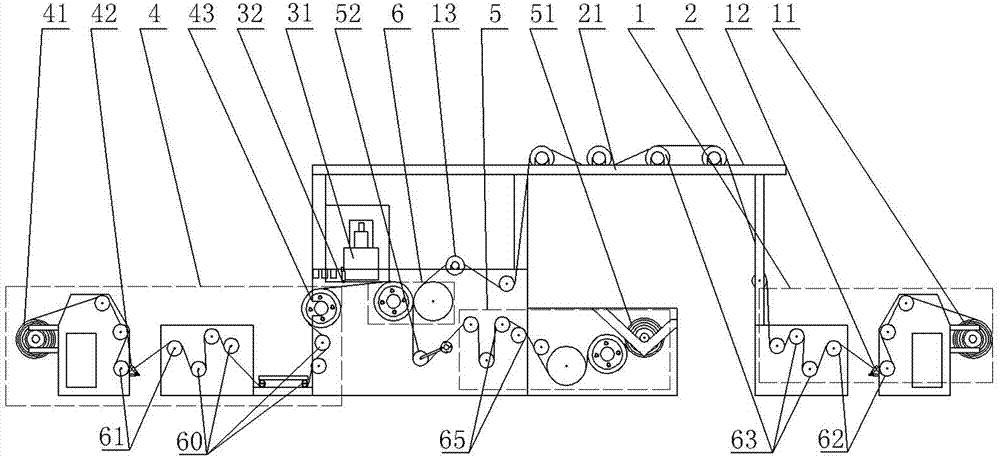

Automatic production system for glue spraying type gas-permeable membrane composite cloth

The invention relates to an automatic production system for glue spraying type gas-permeable membrane composite cloth. The automatic production system comprises a frame body, wherein a gas-permeable membrane conveyer is arranged at the left side of the frame body, a non-woven cloth conveyer is arranged at the right side of the frame body, composite paired rollers are arranged on the frame body, a material receiving device is arranged at the right sides of the composite paired rollers, and a wide-range glue spraying nozzle covering a gas-permeable membrane is arranged between the gas-permeable membrane conveyer and the composite paired rollers; and the material receiving device comprises a material receiving roll, and a plurality of traction rollers are arranged between the material receiving roll and the composite paired rollers. The automatic production system has the characteristics that the covering is uniform, the compositing is firm, the product percent of pass is high and the like. According to the automatic production system, the glue melting, glue spraying, compositing and rolling can be automatically realized due to the integrated structural design; and as the glue spraying is carried out by the fixed glue spraying nozzle, the fixed glue spraying nozzle and the gas-permeable membrane conveyer are organically integrated, the large-area and wide-coverage glue spraying can be carried out on a gas-permeable membrane, and glue spraying face is changed from a point into a surface, so that the glue joint area and the viscosity of hot melting glue are substantially improved, furthermore, the coverage of the hot melting glue is uniform, and the glue dosage is little.

Owner:HUBEI HONGYUE NEW MATERIAL

Small box-packed sauce filling device

ActiveCN112693649AEvenly coveredClamp firmlyWrapper twisting/gatheringLiquid materialEngineeringMaterials science

The invention discloses a small box-packed sauce filling device, and belongs to the field of filling and packaging. The small box-packed sauce filling device comprises a supporting seat and a rail, wherein a storage device for storing sauce is arranged on the supporting seat; an adjusting device for adjusting the rail is arranged between the supporting seat and the rail; a sliding seat is slidably arranged on the rail; a rotating seat is rotatably arranged on the sliding seat; and a clamping device for placing a sauce packaging box is arranged on the rotating seat. By the negative pressure effect of a suction pump, the packaging box can be stably fixed on a placing plate; and during packaging, a fixed heat-sealing plate and a movable heat-sealing plate package a packaging film twice, a pressing plate rotates along with the rotating seat, thus, the sauce flows to the packaged side of the fixed heat-sealing plate, by vibration of a vibrator and extrusion of an extrusion head to the packaging box, air in the packaging box is extruded out, then the packaging box is completely packaged through the movable heat-sealing plate, and the air in the packaging box can be greatly reduced.

Owner:湖南佳元禄食品有限公司

Car for transporting rubbish

The invention discloses a car for transporting rubbish, and belongs to the technical field of manufacture and use of environmental sanitation devices. The car for transporting the rubbish overcomes the defects that due to the fact that a rubbish transporting car currently used needs to be used in combination with a rubbish transfer station, equipment cost is high, transport efficiency is low, labor environment is severe, labor intensity is high, rubbish sojourn time is long, secondary pollution is easy to generate and the like. The car for transporting the rubbish is formed by installing a hydraulic spiral arm lifting crane which can walk, and rise and fall on a dump truck, is used cooperatively with a collision dumping type rubbish can, completes operation of hoisting, transportation, dumping and the like of the rubbish, and thereby replaces various rubbish transporting cars and rubbish transfer stations, which are currently used, and furthermore can obviously reduce the use quantity of sanitation workers and improve work conditions.

Owner:白景魁

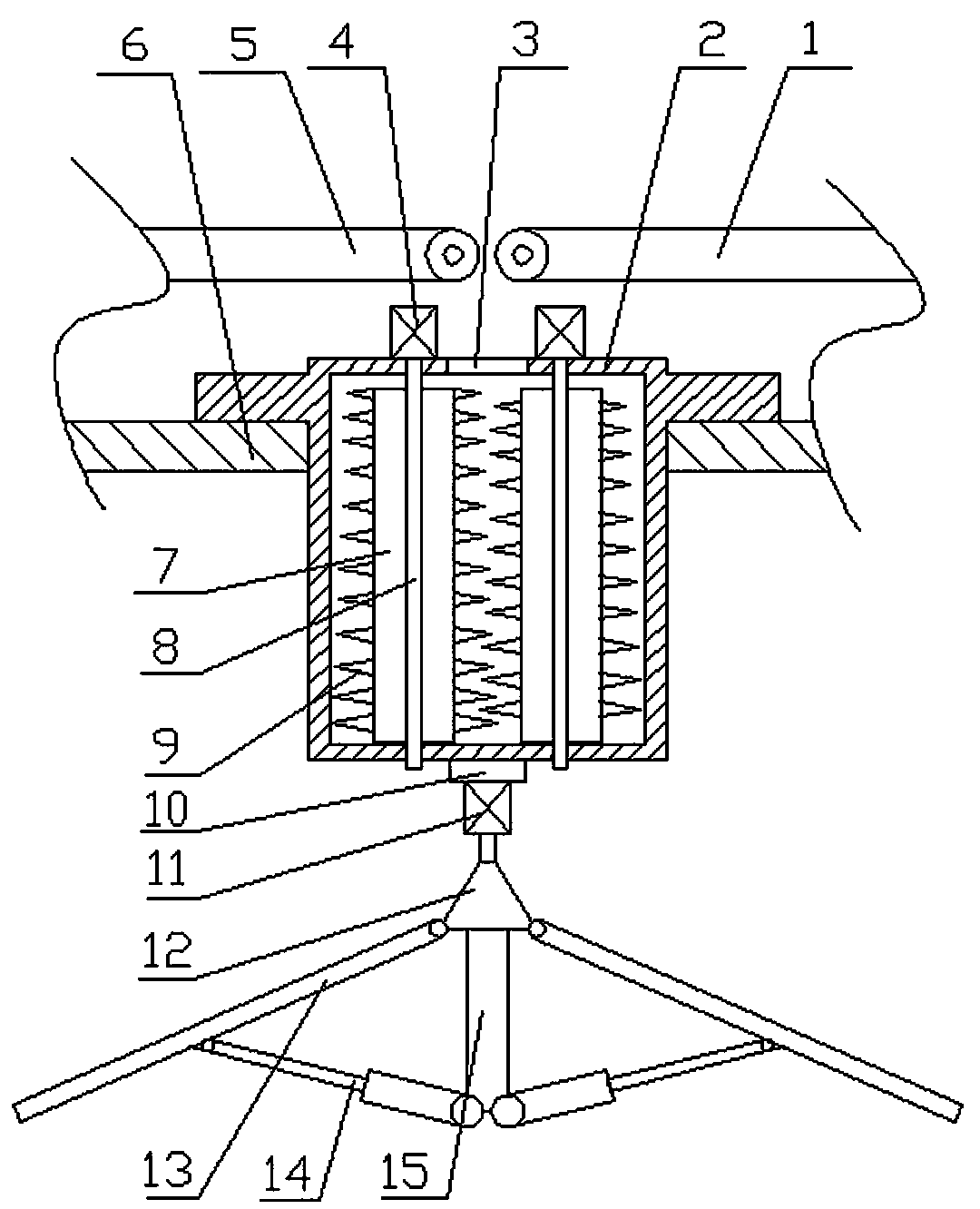

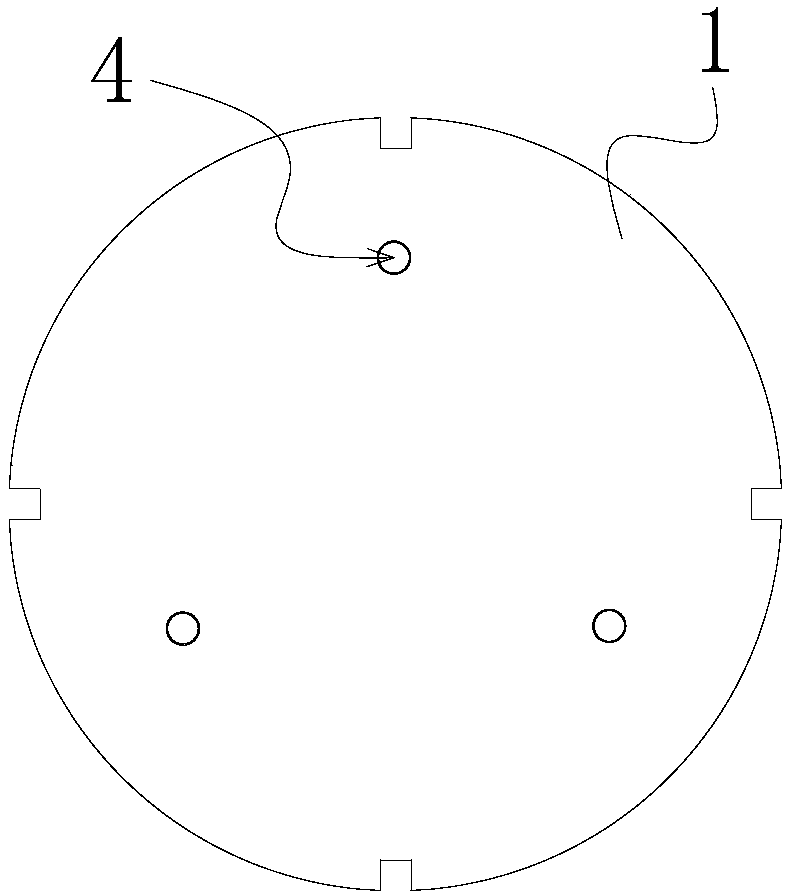

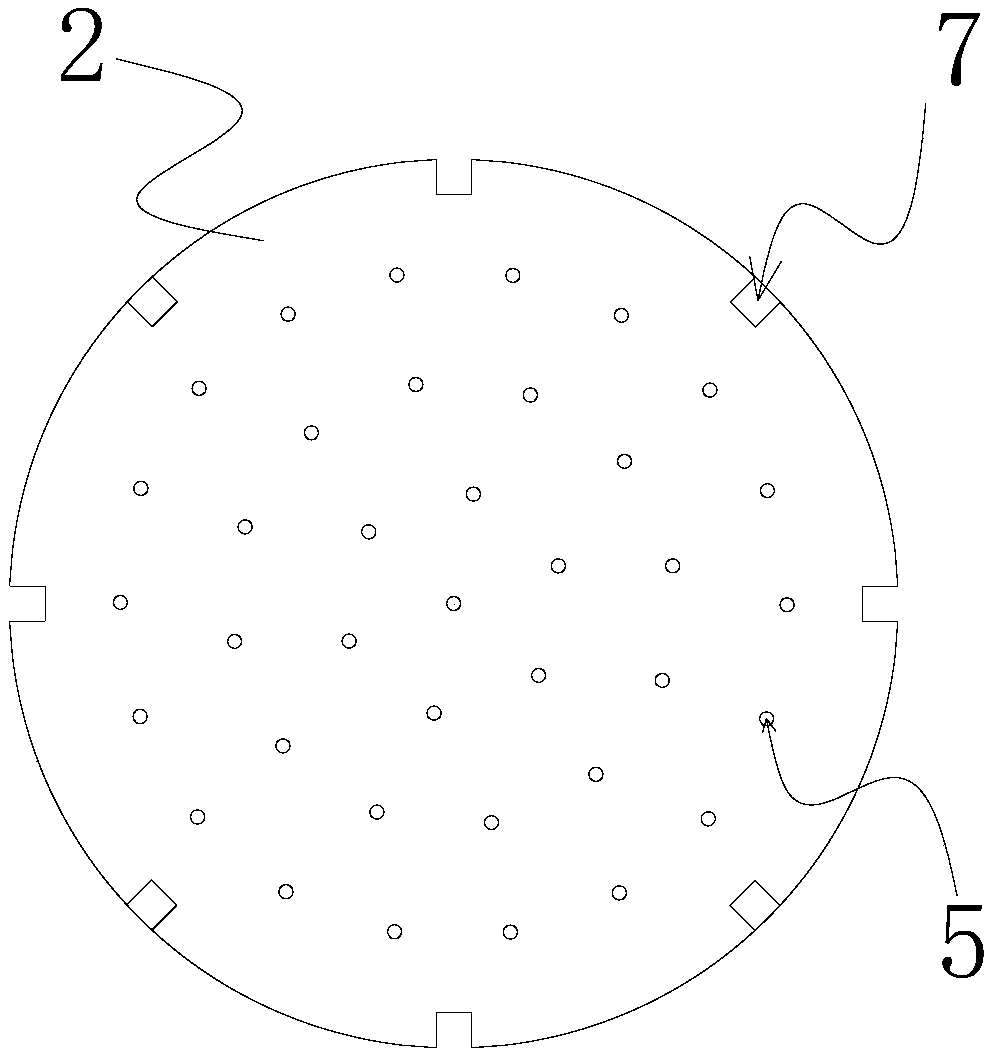

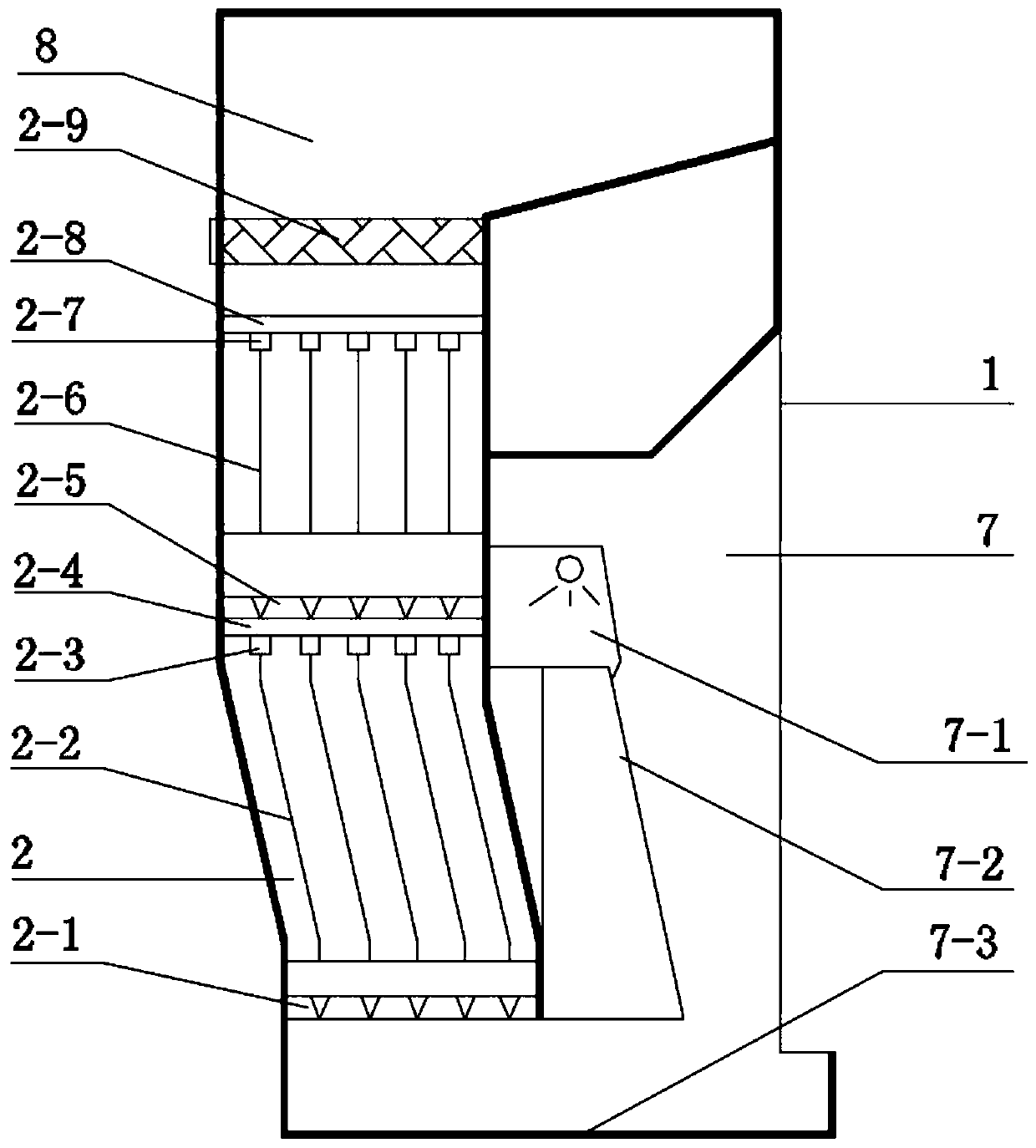

Two-way gas distribution device for large gas generator

InactiveCN101597521AReduce utilizationEvenly coveredCombined combustion mitigationCombustible gas productionProcess engineeringHearth

A two-way gas distribution device for large gas generator belongs to the field of gas generator device. The gas distribution device is especially applicable to a large-diameter hearth with the diameter Phi of 3.4m, 3.6m and 3.8m. The gas distribution device comprises a central gasification agent branch pipe (5) and a gas stove body (9) and is characterized in that a periphery gasification ring pipe (8) is arranged between the central gasification branch pipe (5) and the gas stove body (9), the periphery gasification ring pipe (8) surrounds outside the gas stove body (9) and is connected with the central gasification agent branch pipe (5) by a periphery gasification branch pipe (7) and a periphery branch gasification agent regulating valve (6), and the periphery gasification ring pipe (8) is provided with a plurality of gasification agent distribution regulating devices communicated with the gas stove body (9). The invention has the advantages that the gas distribution device can cause the gasification agent to be evenly distributed in the whole hearth space; the gasification agent distribution amount in the hearth can be easily adjusted; and the stove can be simply and fast adjusted when the stove is in deviation.

Owner:山东义丰环保机械股份有限公司

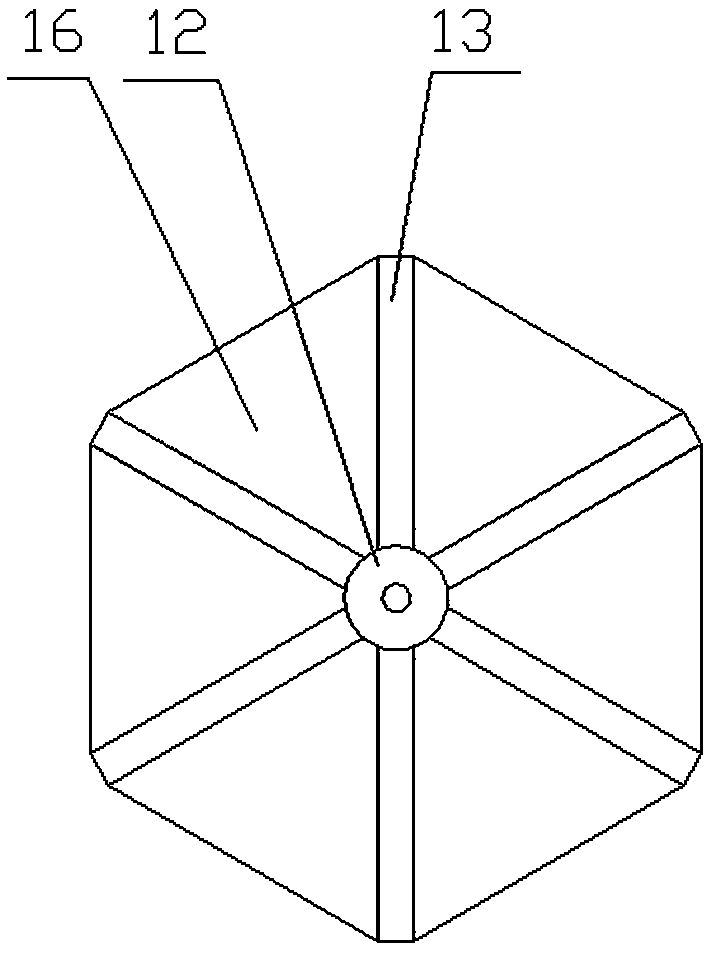

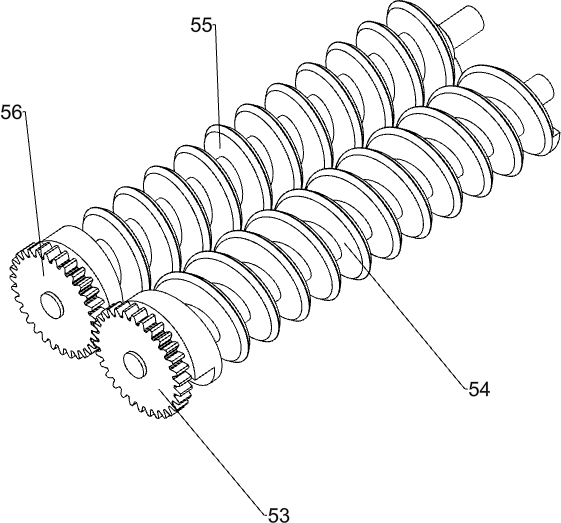

Bulk material distributing device used for lime kiln

ActiveCN108249787AImprove production efficiencyEasy and reliable adjustmentLime productionPush and pullCoal

The invention relates to the field of calcium hydroxide production equipment, and particularly relates to a bulk material distributing device for a lime kiln. The bulk material distributing device comprises a crushing barrel fixed in an opening at the top wall of a lime kiln along a vertical direction; a second motor distributed along the vertical direction is arranged at the center position of the lower end of the crushing barrel, a bulk material cone is coaxially arranged on the output shaft of the second motor, the small end of the bulk material cone is fixedly connected with the output endof the second motor, a plurality of framework plates are hinged at the large end of the bulk material cone at intervals along the peripheral direction, a flexible connecting plate with elasticity isarranged between any two adjacent framework plates, a support pillar is coaxially arranged at the large end of the bulk material cone, and electric push rods which are equal in quantity with that of the framework plates and used for pushing and pulling all the framework plates to expand or retract are arranged on the support pillar at intervals. According to the invention, limestone and coal can be uniformly distributed in the lime kiln to improve the combustion efficiency, and thus being convenient for controlling calcination quality and avoiding the phenomena of under-calcination or over-calcination.

Owner:洛阳钙丰工贸有限公司

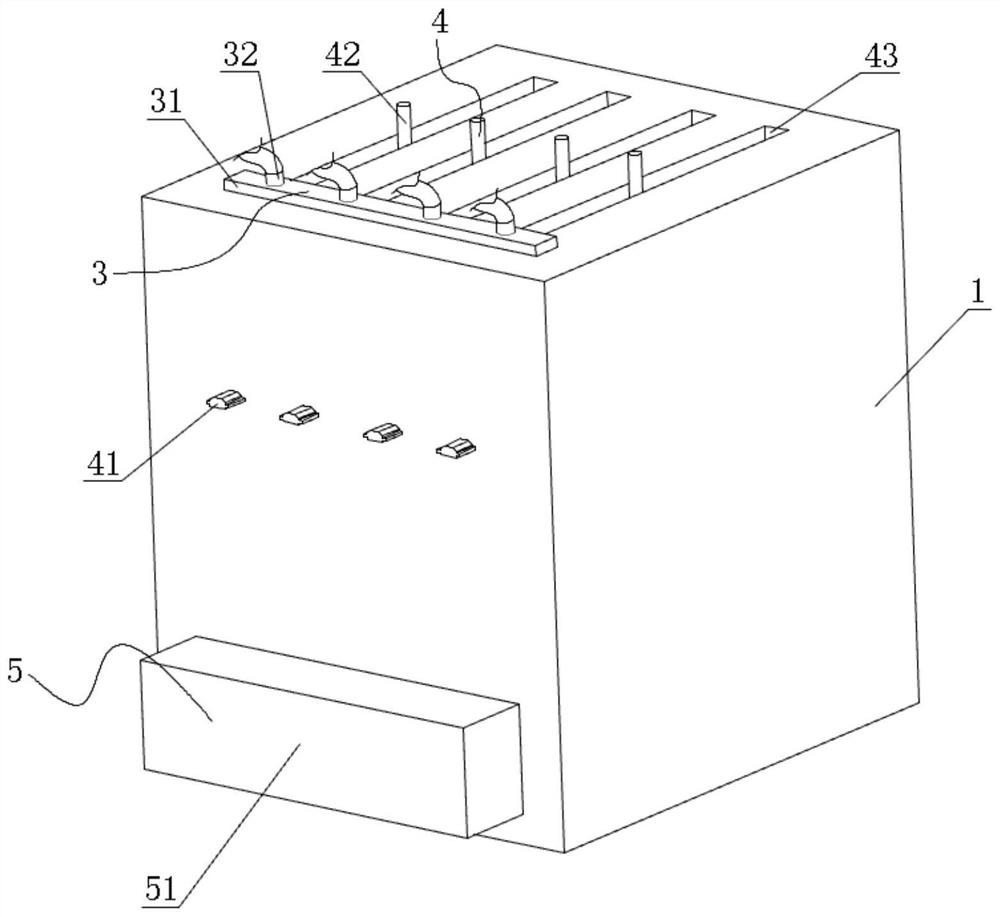

Production process and device of environment-friendly peculiar-smell-free sound insulation coating material

ActiveCN113368755AEasy to GrindImprove grinding effectRotary stirring mixersMixer accessoriesReciprocating motionElectric machinery

The invention relates to the technical field of coating material production, and discloses a production process of an environment-friendly peculiar-smell-free sound insulation coating material. The production process of the environment-friendly peculiar-smell-free sound insulation coating material is completed by adopting a production device of the environment-friendly peculiar-smell-free sound insulation coating material, wherein the production device comprises a box body, and the middle portion of the inner wall of the box body is fixedly connected with a guide frame. According to the production process of the environment-friendly peculiar-smell-free sound insulation coating material, the bottom of a sliding piece can slide in a first through groove by arranging the sliding piece and a discharging pipe, so that the discharging pipe can be manually driven to move above grinding frames, materials can be uniformly spread into the grinding frames only by communicating the discharging pipe with an external feeding device, and grinding is convenient; and different materials can be placed through the four arranged grinding frames, and through the arranged first motor, under the effect of a threaded rod, a T-shaped plate reciprocates under limiting of a sliding groove.

Owner:福建宏盛建设集团有限公司 +5

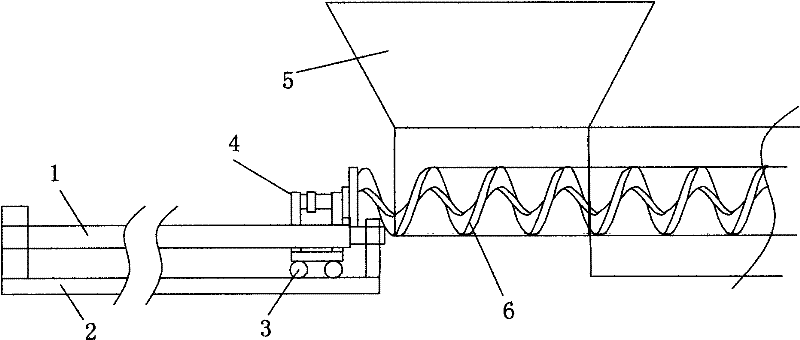

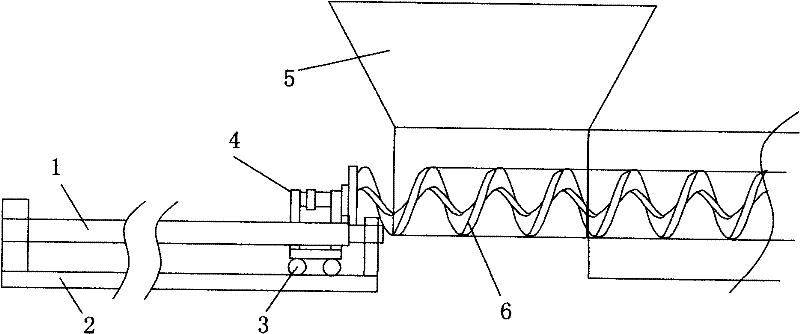

Concrete prefabrication member bottler

The invention discloses a concrete prefabrication member bottler. The concrete prefabrication member bottler structurally comprises a hopper and a boosting and pouring mechanism below the hopper, wherein the boosting and pouring mechanism comprises a spiral vane arranged in a pouring pipeline and a driving mechanism connected to the rear end of the spiral vane for driving the spiral vane to move back and forth. The concrete prefabrication member bottler has the work principle that a die is closed after a reinforcement cage is put in an empty die, then, the screw conveyor part of a feeding mechanism is put into the die, and the material is directly conveyed into the die by being conveyed by the spiral conveyor. Because of mechanical conveying, the labor efficiency is improved, and the difficulty caused to worker operation because materials are dry and thin is avoided. Meanwhile, because a die compounding operation is carried out under the empty die state, user conditions for all relevant equipment is relatively better, the service life of the equipment is prolonged, the die precision is enhanced, and the product quality is improved.

Owner:沈阳市振兴建材实业有限公司

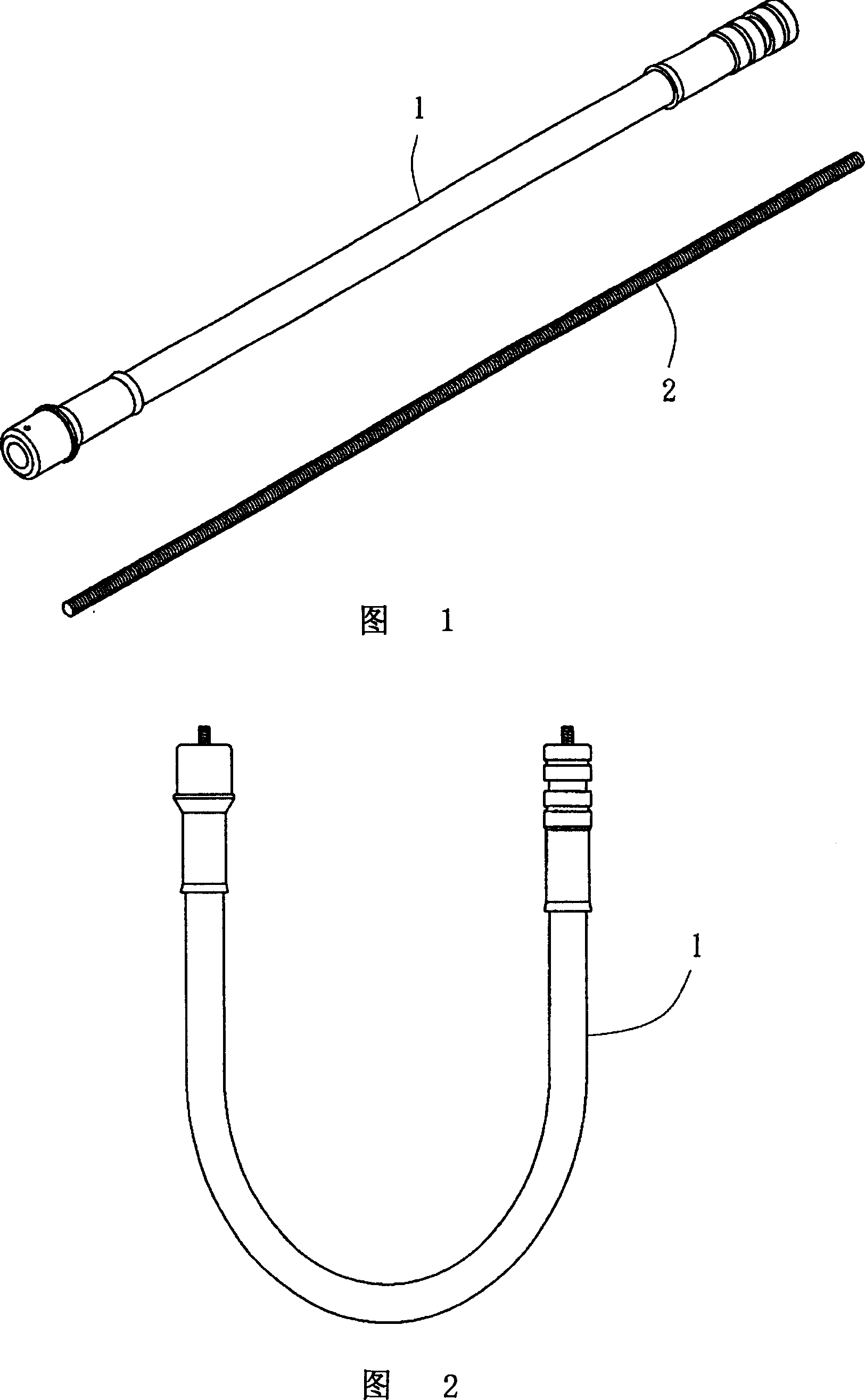

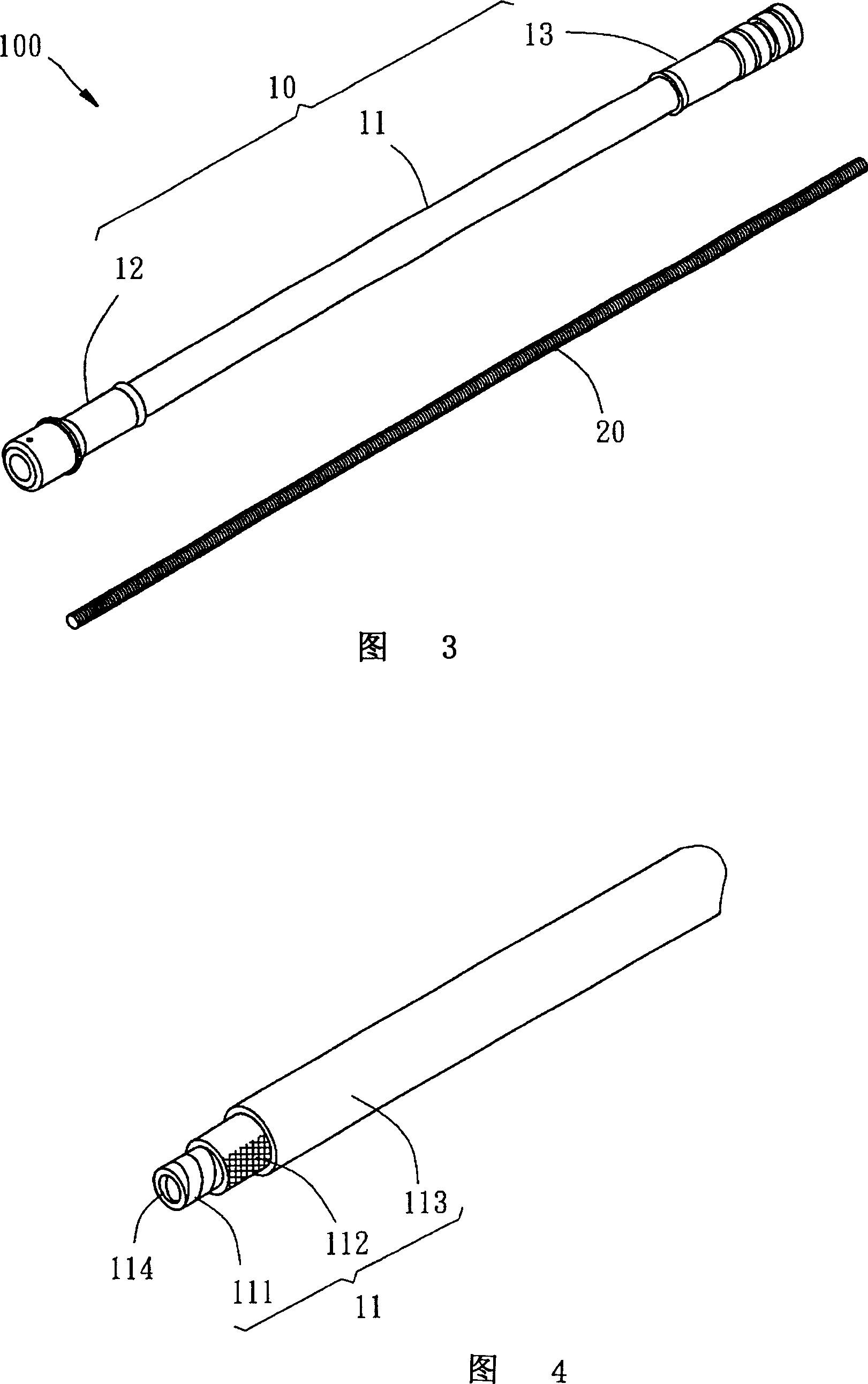

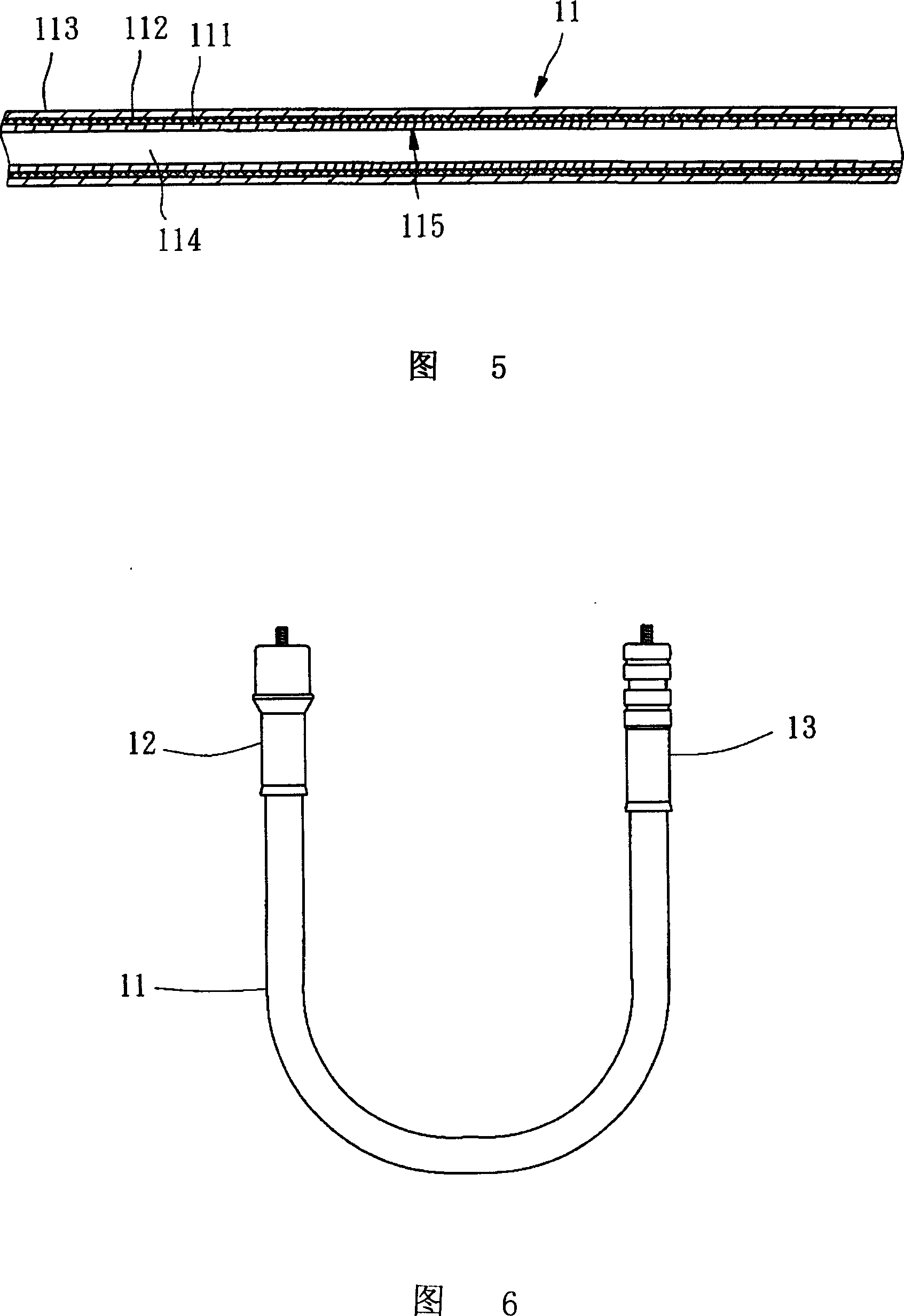

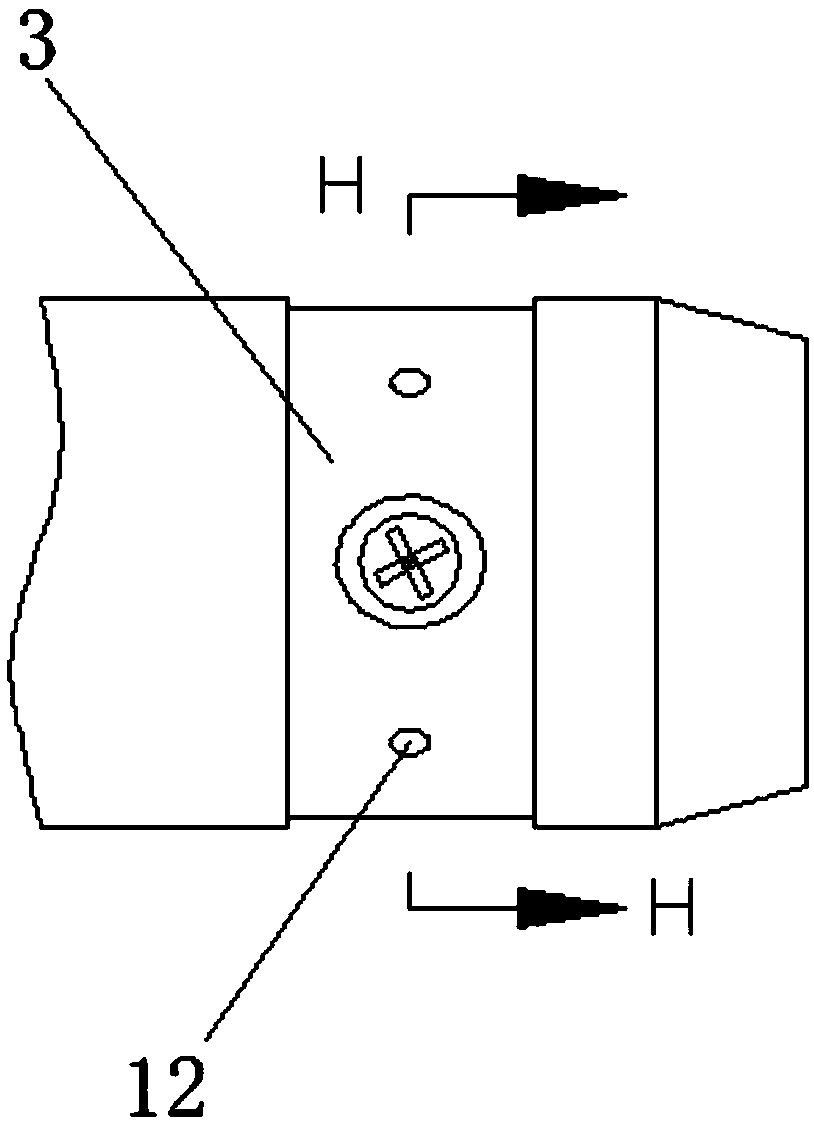

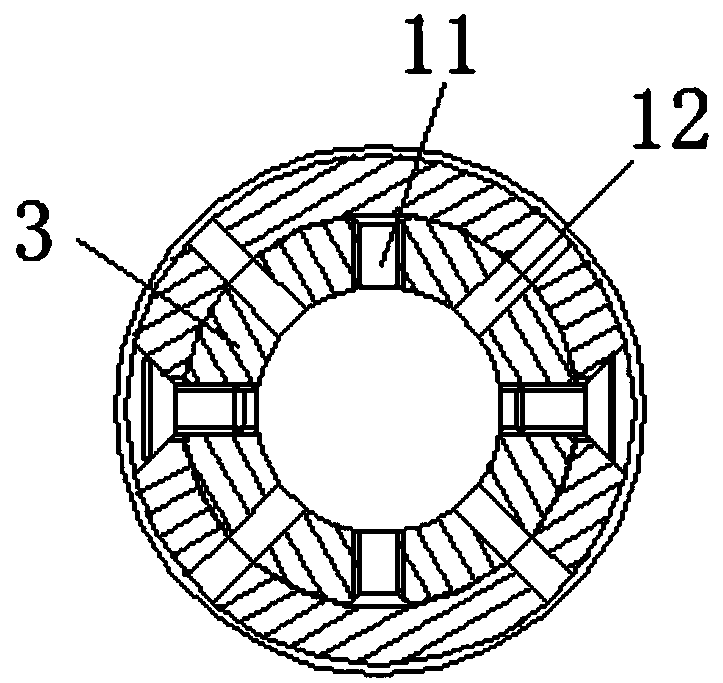

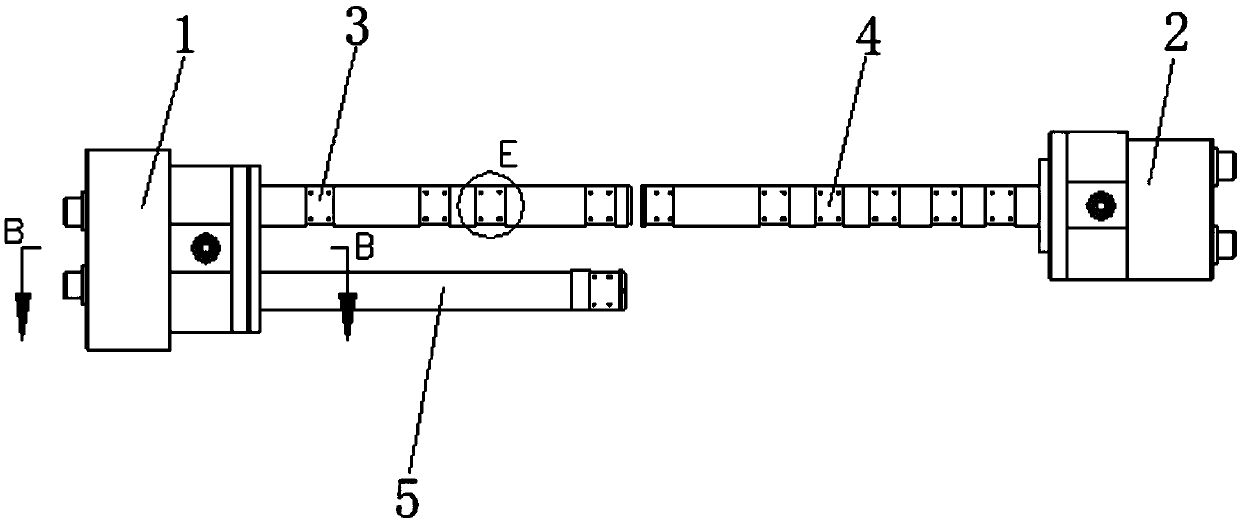

Flexible drive assembly

InactiveCN101070875AEvenly coveredAvoid large curvatureShaft for rotary movementDrive shaftEngineering

Owner:黄昱翔

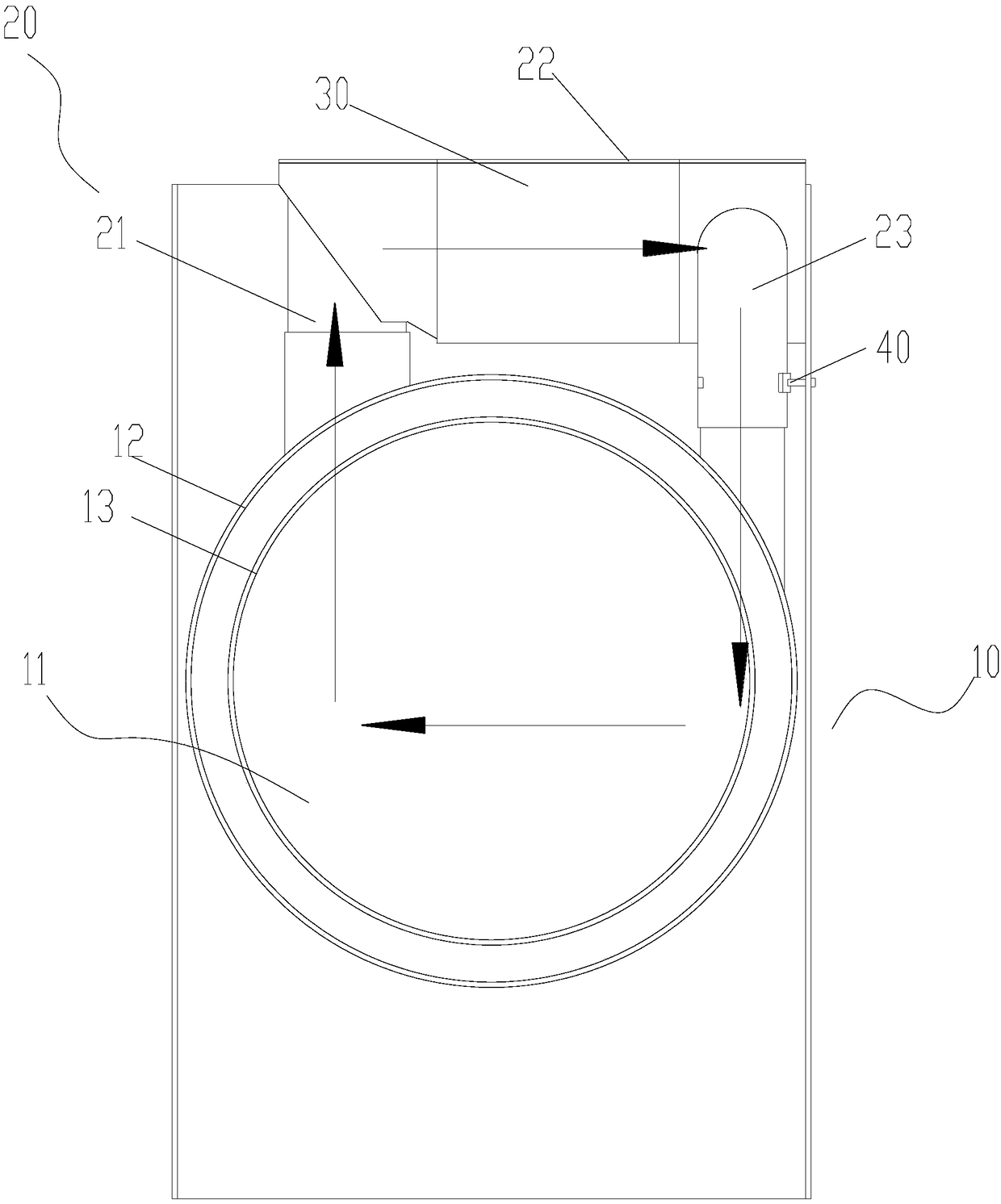

Cleaning device and washing machine with cleaning device

PendingCN109505099AImprove practicalityImprove reliabilityOther washing machinesTextiles and paperEngineeringFull scale

The invention provides a cleaning device and a washing machine with the cleaning device. The cleaning device comprises a shell, a heat pump system and a fragrance-increasing part, wherein the shell isprovided with a working chamber, and the working chamber is used for cleaning a to-be-cleaned object; the first end of a pipeline structure is communicated with an air outlet of the working chamber,and the second end of the pipeline structure is communicated with an air inlet of the working chamber; the heat pump system is arranged in the pipeline structure; the fragrance-increasing part is arranged in the pipeline structure and used for containing a solid fragrance-increasing object, when the heat pump system dries the to-be-cleaned object, a hot gas flow in the pipeline structure volatilizes the solid fragrance-increasing object to increase the fragrance of the to-be-cleaned object. Since the solid fragrance-increasing object is vaporized after being volatilized, the vaporized fragrance-increasing object can reach any position in the cleaning device, thereby achieving full-scale and non-dead-angle fragrance-increasing operation of the to-be-cleaned object in the cleaning device, sothat the fragrance of the solid fragrance-increasing object can be evenly spread on the to-be-cleaned object. The practicability and reliability of the cleaning device are effectively improved.

Owner:GREE ELECTRIC APPLIANCES INC

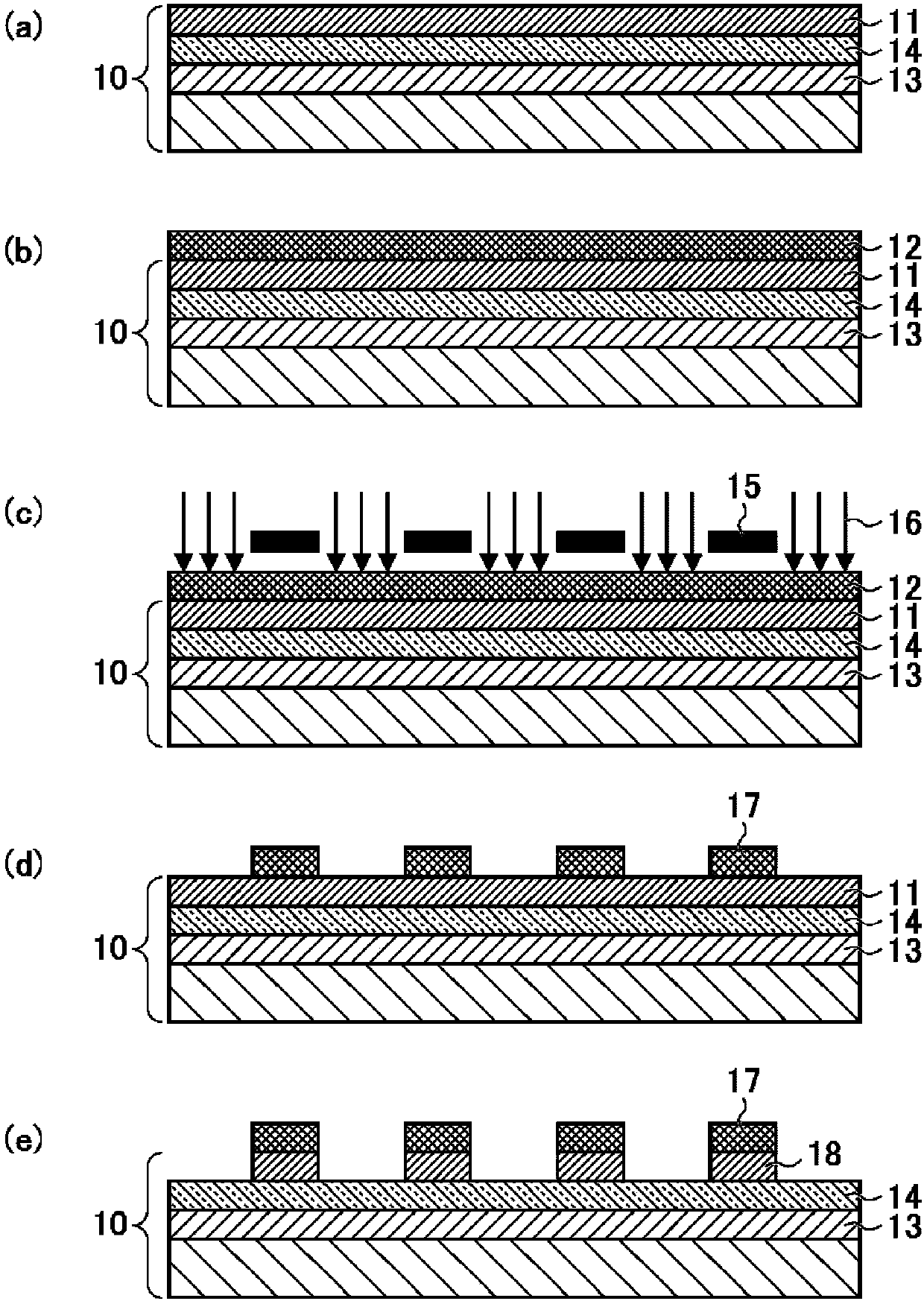

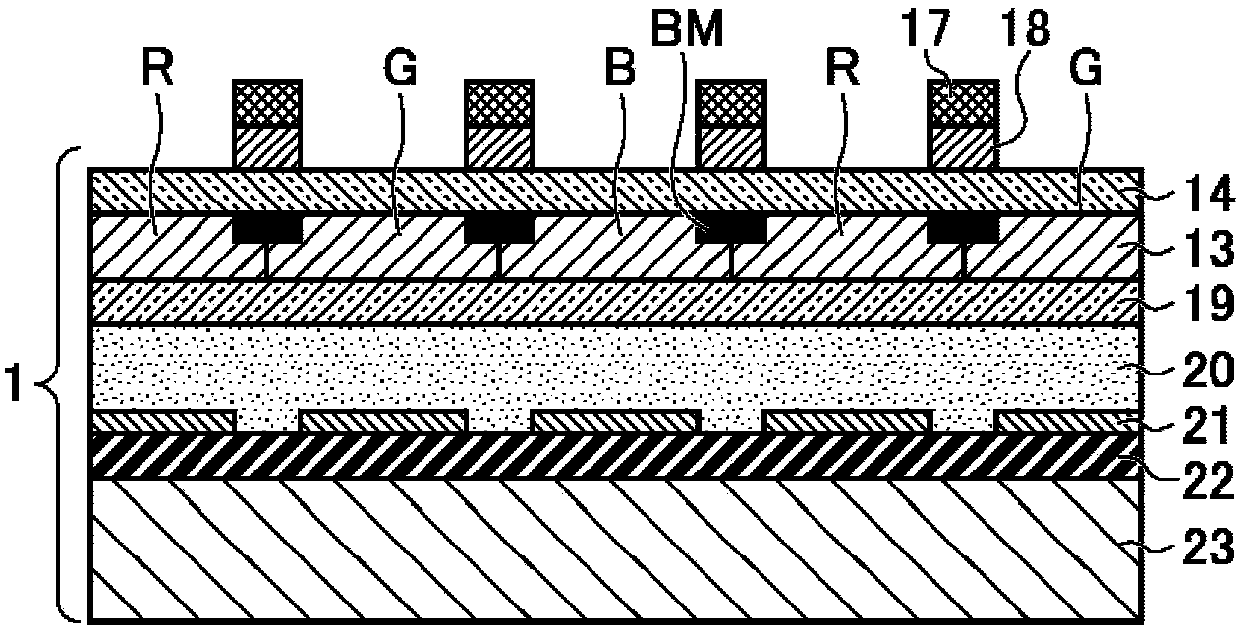

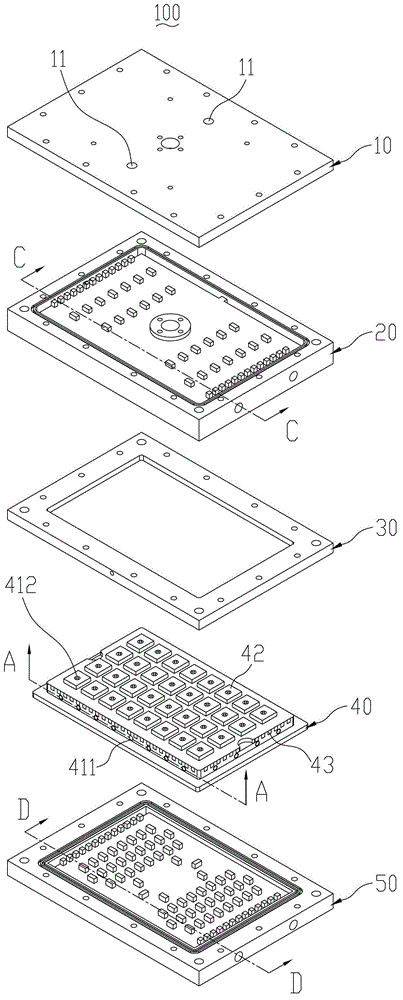

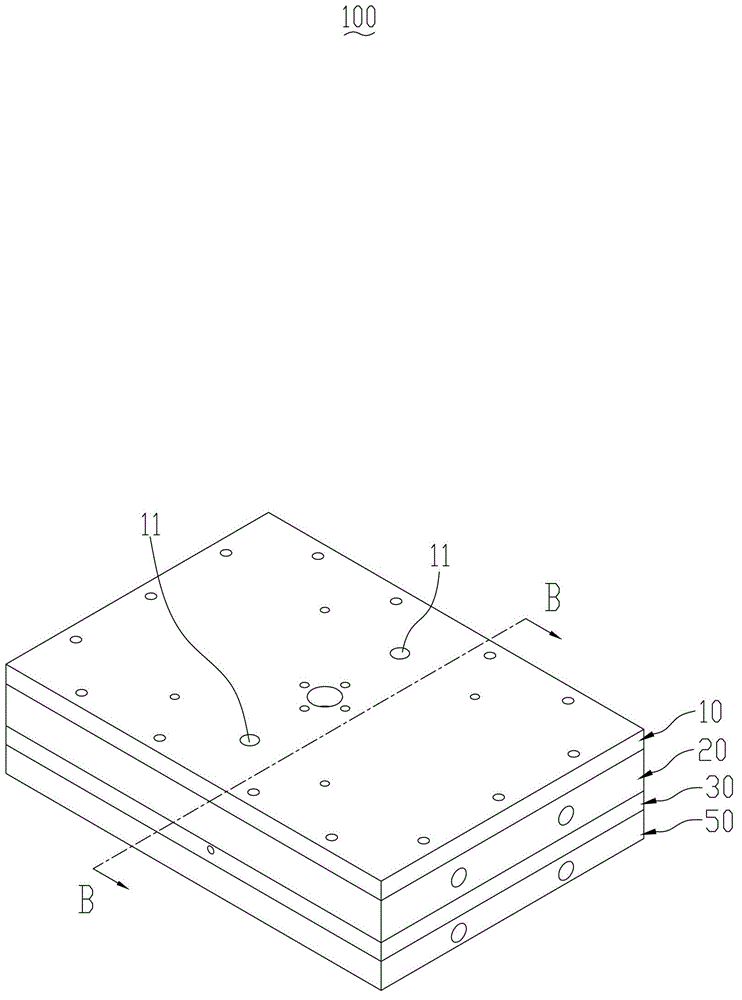

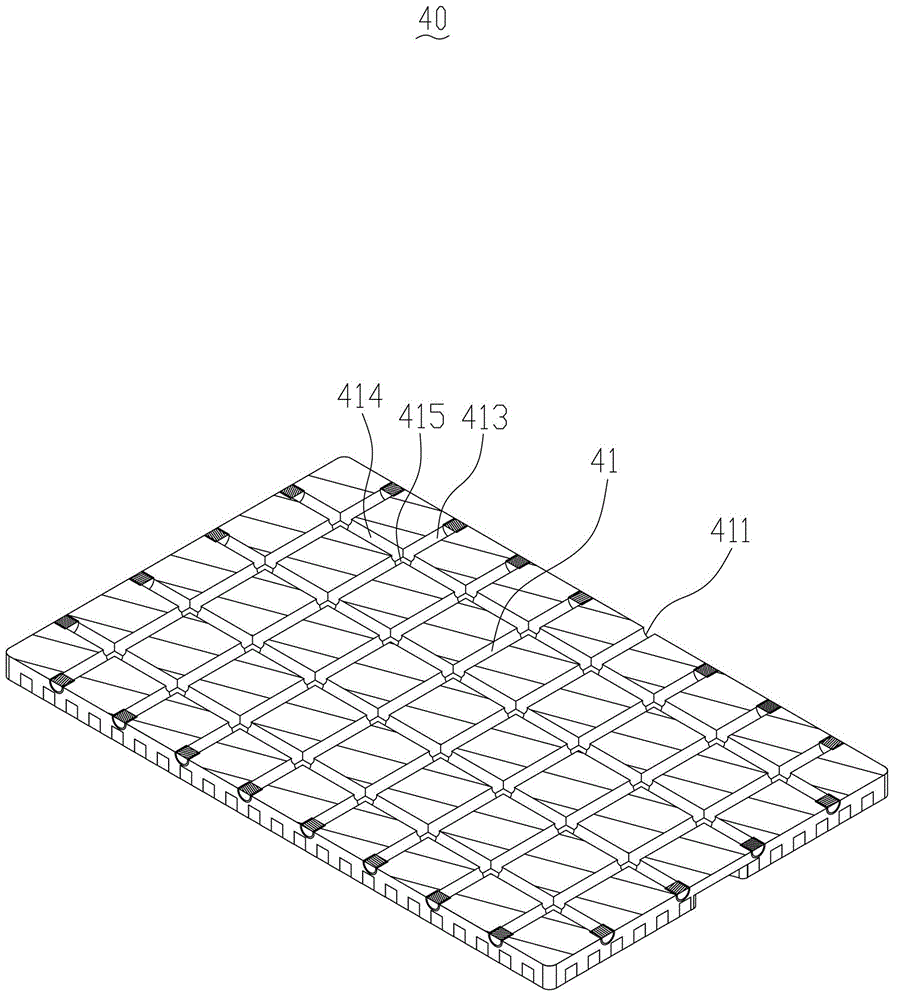

A method for manufacturing a substrate

ActiveCN107703658ACovered easilyCoating of patterned metal layer is easyPhotomechanical exposure apparatusMicrolithography exposure apparatusDispersityEngineering

The invention provides a method for manufacturing a substrate. The substrate comprises a filter sheet formed on a main surface, a patterned metal layer formed directly on the filter sheet or formed across a transparent layer, and a covering resin layer (reflectivity control mechanism) covering the patterned metal layer. According to the method, it is easy to cover the patterned metal layer uniformly by using the covering resin layer on the substrate with the filter shell and it is not easy to cover parts without metal layers formed with the covering resin layer. When the substrate with the filter sheet formed on a main surface, the patterned metal layer formed directly on the filter sheet or formed across a transparent layer, and the covering resin layer covering the patterned metal layeris manufactured, a positive photosensitive resin composition containing a matrix resin component (A) with a dispersity (weight-average molecular weight / number-average molecular weight) being greater than 1 and lower than 20 to form the covering resin layer.

Owner:TOKYO OHKA KOGYO CO LTD

Waterborne biomass negative oxygen ion paint

InactiveCN110256906AImprove performanceFacilitated releaseAntifouling/underwater paintsCellulose coatingsDecompositionOxygen ions

The invention discloses waterborne biomass negative oxygen ion paint. A formula of the waterborne biomass negative oxygen ion paint comprises the following raw materials by weight: 45-60 parts of a pure natural plant extract, 25-40 parts of a mineral extract, 25-40 parts of filler, 15-30 parts of a surfactant, 5-10 parts of a tackifier, 1-3 parts of an antifreeze agent, 1-3 parts of a dispersion agent, 0.8-1.2 parts of a film-forming agent, 0.4-0.8 part of a defoaming agent and 0.2-0.8 part of a mildew preventive. According to the waterborne biomass negative oxygen ion paint, an extracted pure natural plant, the rare mineral extract and the like are used as the raw materials, thus the comprehensive performance of the biomass paint is good, a wall is air-permeable, negative oxygen ions escape in an infrared radiation mode, and active time of solid molecules is long so that the negative oxygen ions can be released for a long time. The waterborne biomass negative oxygen ion paint is high in wear resistance capability, scratch-resistant, high-temperature-resistant, acid and alkali resistant, high in stability and long in service life, has functions of removal of harmful gas VOCs (volatile organic compounds), formaldehyde decomposition, air purification, health care and the like, does not contain formaldehyde, and is suitable for large-scale popularization.

Owner:中山市君泽科技有限公司

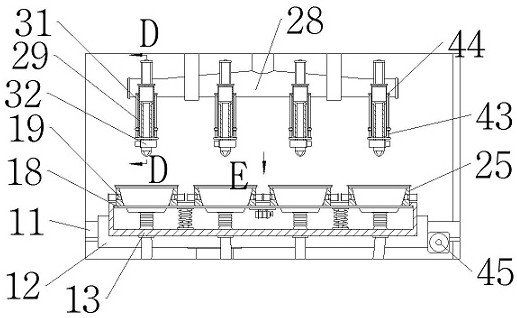

Electrolytic deburring device of air cylinder body

ActiveCN109570667ACompact structureEasy to useElectrical-based auxillary apparatusElectrolysisEngineering

The invention discloses an electrolytic deburring device of air cylinder body. The electrolytic deburring device of air cylinder body comprises an electrode left connector, an electrode right connector, a main oil channel left electrode, a main oil channel right electrode and an auxiliary oil channel electrode, wherein the electrode left connector comprises a panel and a connecting sleeve, the main oil channel left electrode and the auxiliary oil channel electrode are integrally installed on one side of the panel through the connecting sleeve, a first infusion hole is formed in the panel, andthe two third infusion holes communicating the first infusion hole with second infusion holes formed in the main oil channel left electrode and the auxiliary oil channel electrode correspondingly is further formed in one side of the panel; and threaded holes and liquid spraying holes are both formed in the main oil channel left electrode, the main oil channel right electrode and the auxiliary oilchannel electrode, the threaded holes and the liquid spraying holes are arranged at intervals along the axial direction of the corresponding electrodes. According to the electrolytic deburring deviceof the air cylinder body, the strength of an electrode rod can be effectively improved, the service life of the electrode rod can be prolonged, so that the electrolyte is more sufficiently and uniformly distributed around the burrs, and the effect of electrolytic deburring is improved.

Owner:GUANGXI YUCHAI MASCH CO LTD

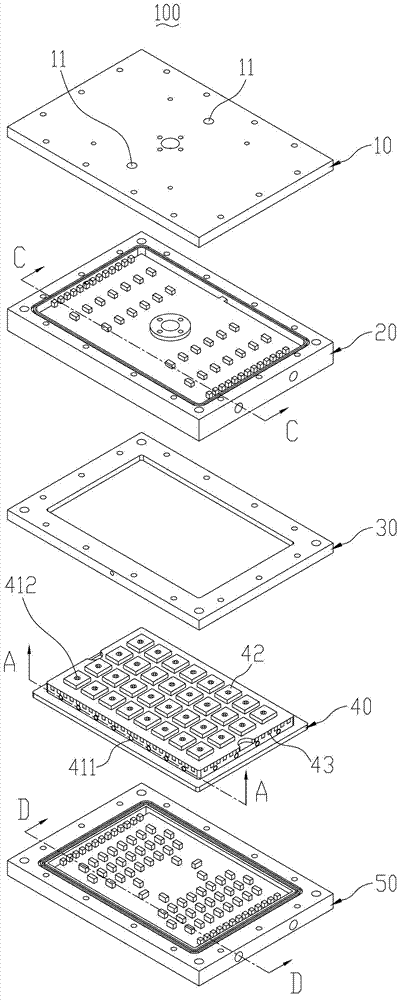

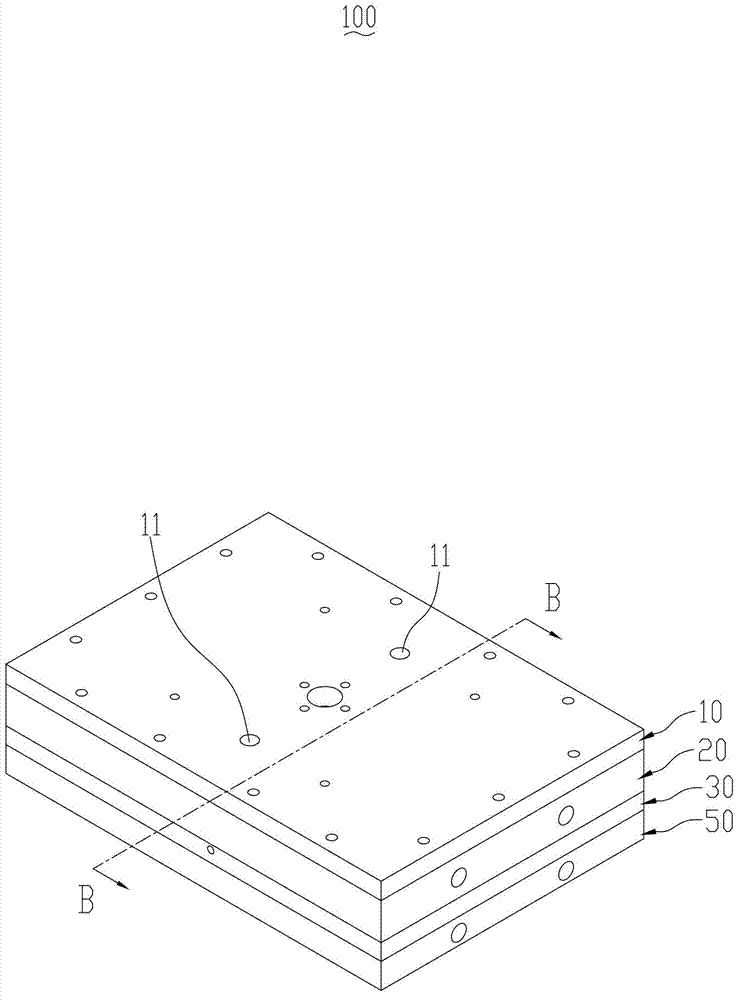

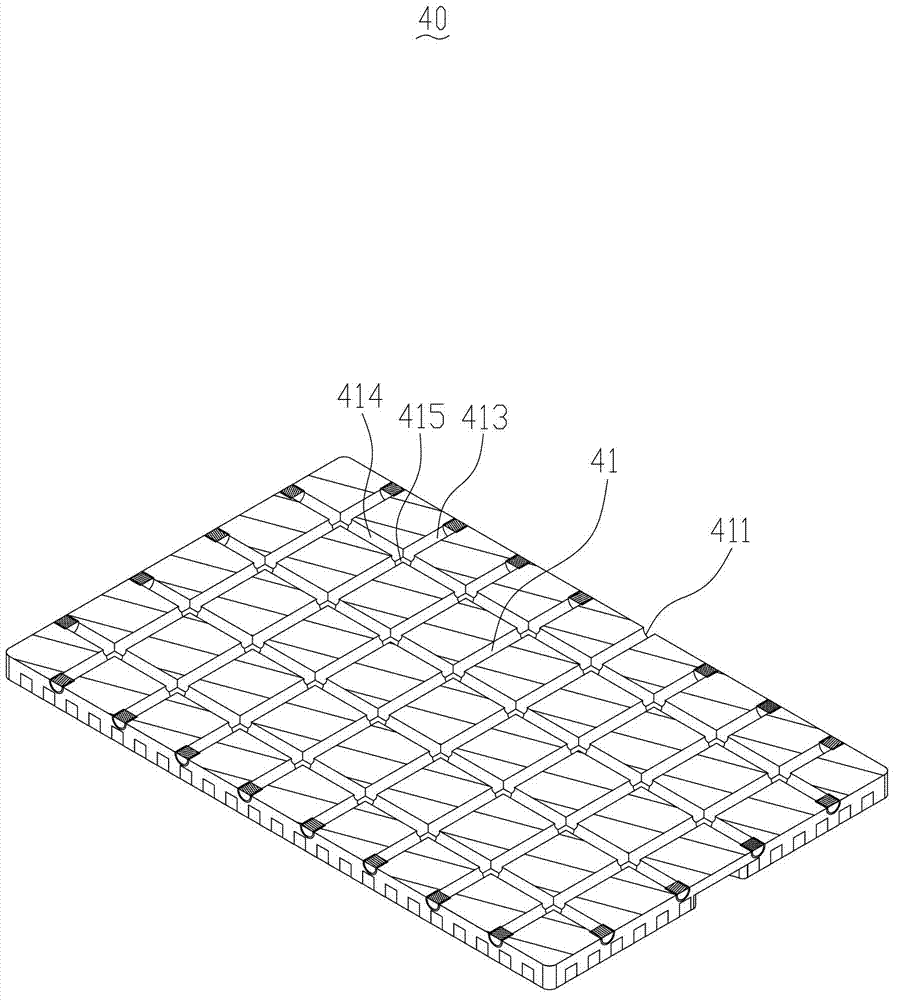

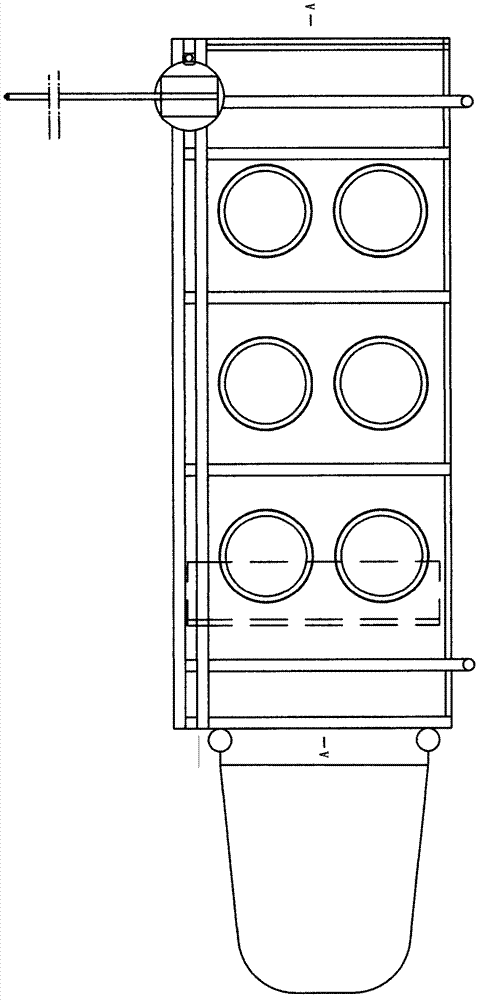

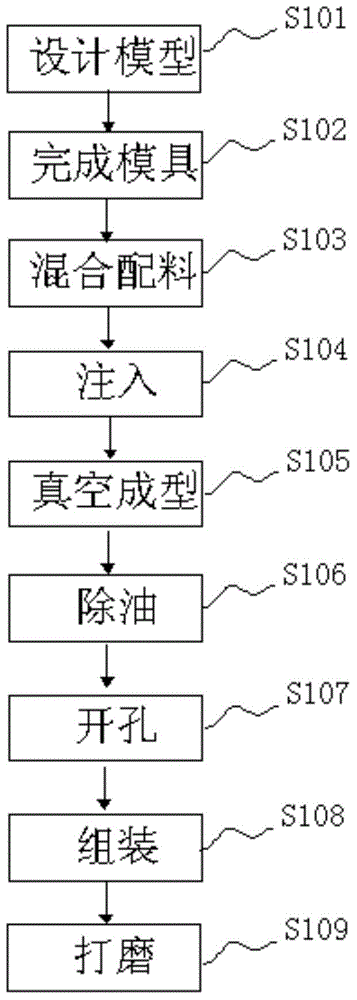

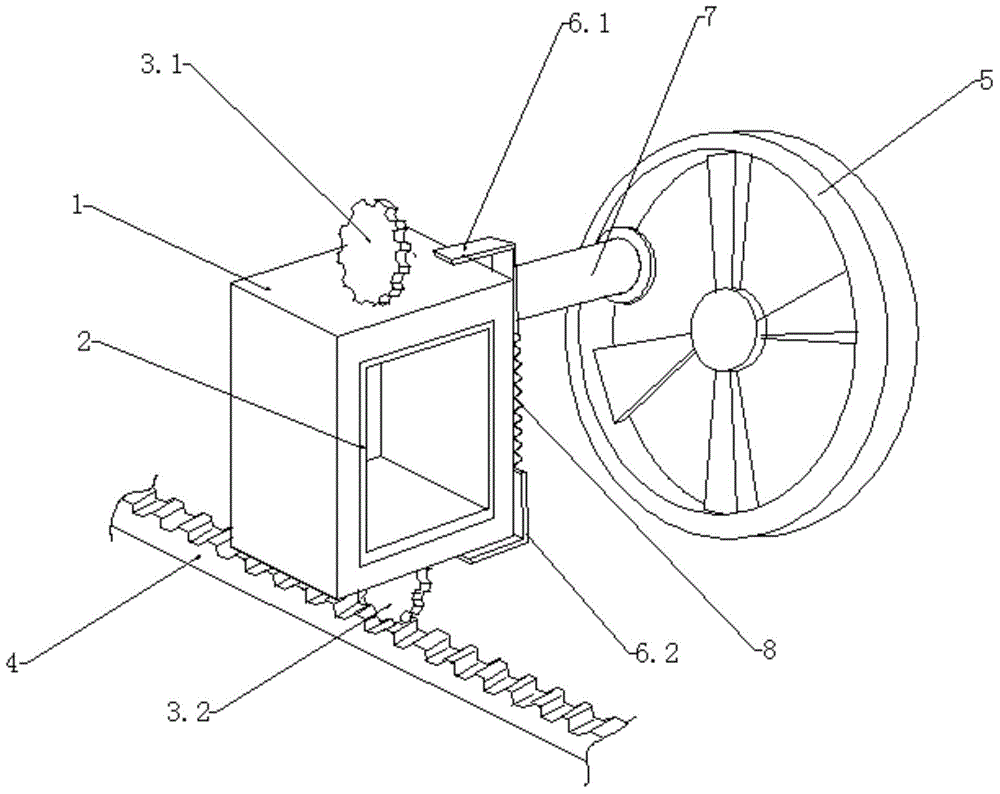

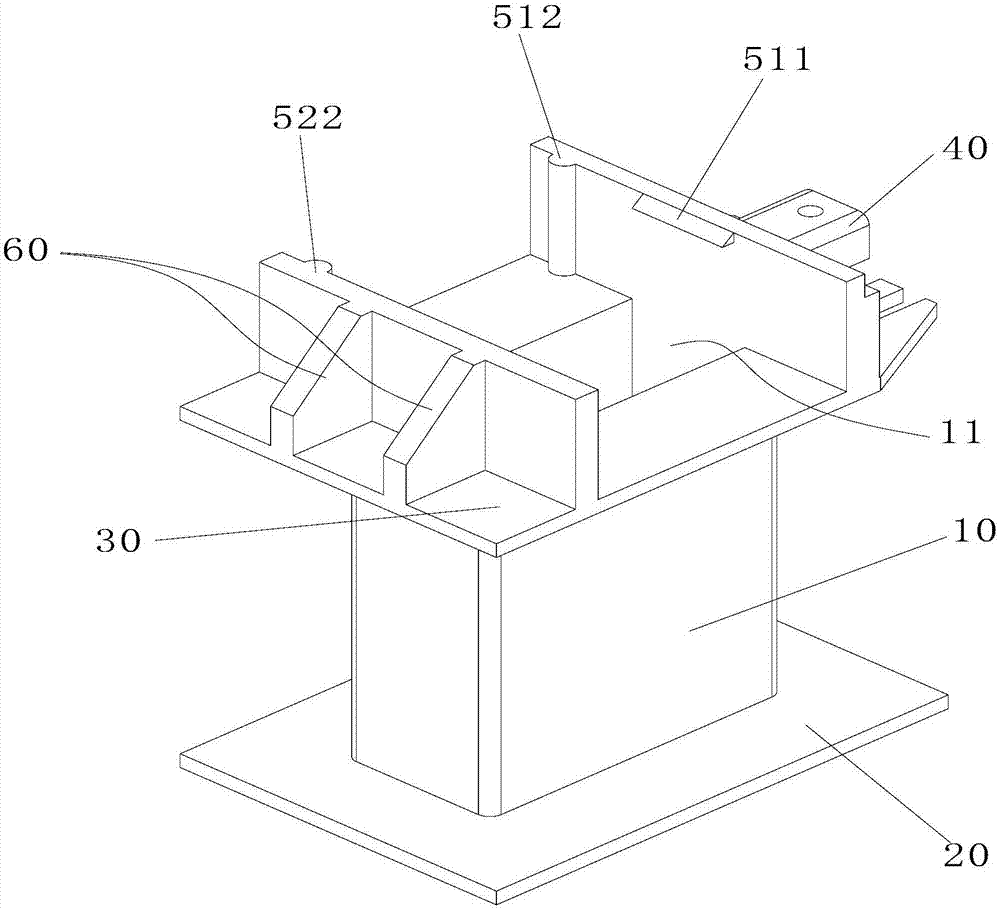

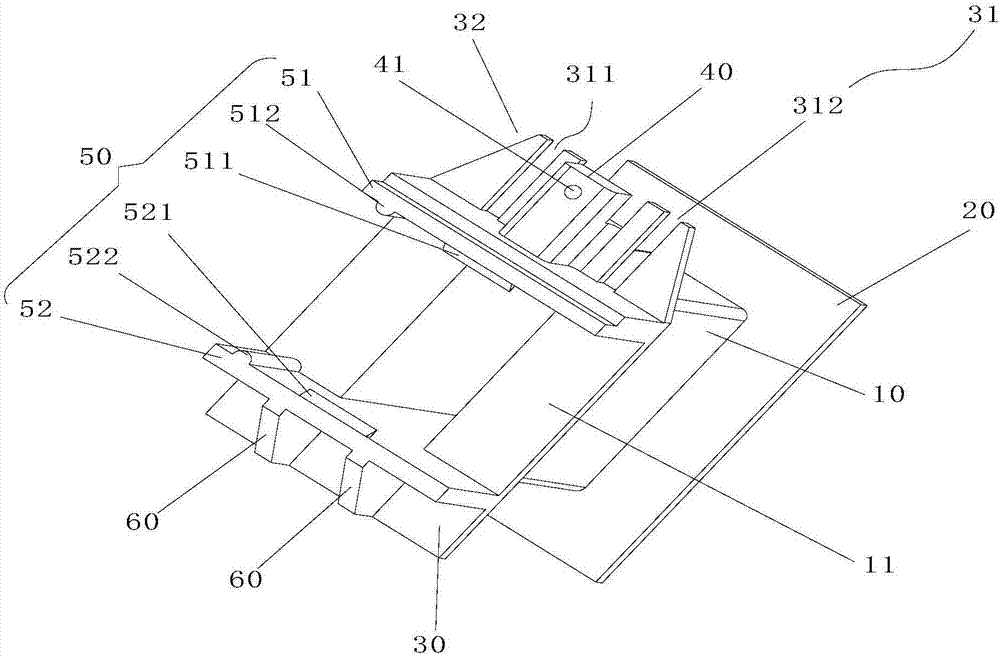

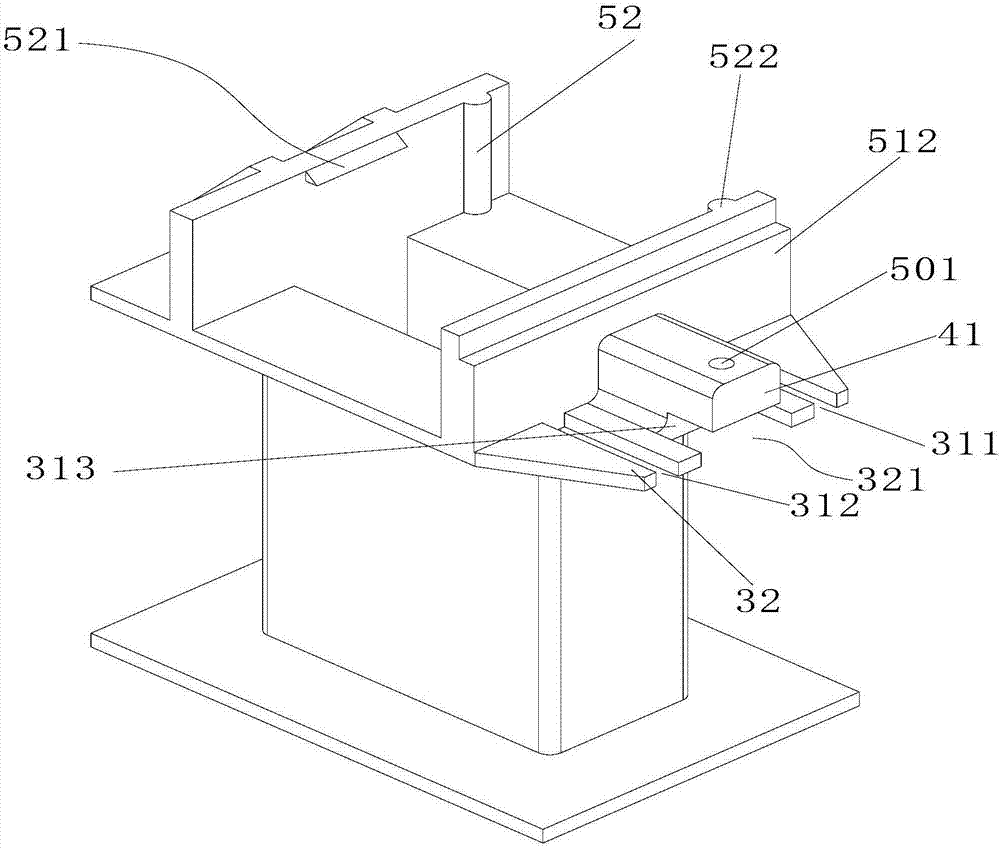

Manufacturing method of composite type high polymer material sound box body and mould equipment

ActiveCN104943187AGood sealingPrevent one-way forceFrequency/directions obtaining arrangementsHollow articlesComposite materialVacuum forming

The invention provides a manufacturing method of a composite type high polymer material sound box body, and further provides mould equipment. The manufacturing method comprises the steps of designing a model, completing a mould, mixing materials, injecting, performing vacuum forming, removing oil, opening holes, assembling, etc. The mould equipment comprises a sliding device and a turnover device. According to the manufacturing method, the steps of mixing the materials, injecting and assembling are performed in a vacuum environment, so that the interior of the resin sound box can be effectively prevented from producing gas; in the manufacturing method of a resin sound box, the same vacuum degree is adopted in the steps of injecting and assembling, so that the texture and the density of the whole sound box are kept the same, and the sealability between a back board and the box body is good. According to the mould equipment, with the adoption of the sliding device with a gear rack, the closing and locating accuracy of the mould is realized; the turnover device can turn over the mould vertically, so that unidirectional stress of the interior of a mould cavity is avoided; the cavity is further prevented from deforming; and the materials can be filled in the whole mould cavity quickly and uniformly.

Owner:陈建新

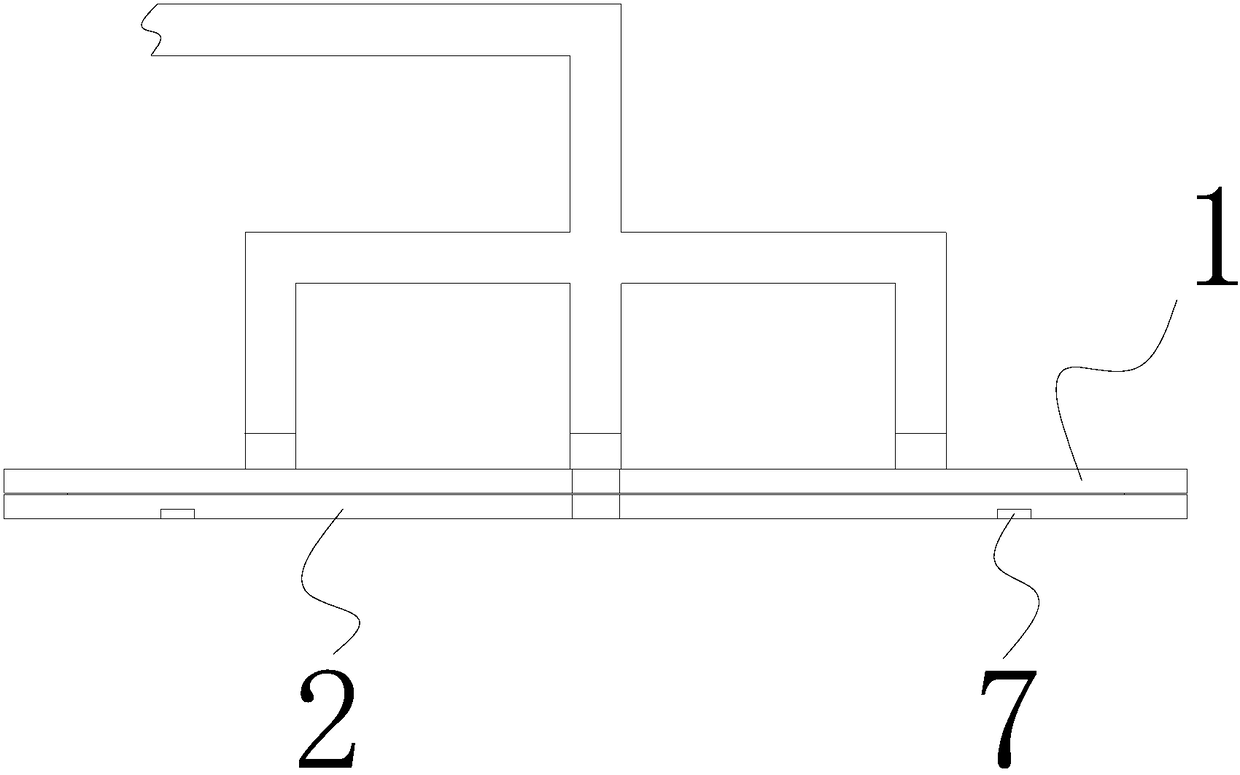

Motor winding framework and motor with same

The invention provides a motor winding framework and a motor with the same. The motor winding framework comprises a framework body, a first limitation part and a second limitation part, wherein the first limitation part is connected with one end of the framework body, the second limitation part is connected with a second end of the framework body, a winding region is formed between the first limitation part and the second limitation part, and a surface, arranged in a winding region, of the first limitation part is parallel to a surface, arranged in the winding region, of the second limitationpart. The shape of the winding region encircled by the first limitation part and the second limitation part is a regular winding region, so that wires can be uniformly laid in the winding region, thecondition that the wires cannot be uniformly laid in the winding region to cause waste of the winding region due to irregular shape of the winding region in the prior art is prevented, the utilizationratio of a winding groove formed in the winding region is improved, so that the material utilization ratio of the motor winding framework with the motor is effectively improved.

Owner:ZHUHAI KAIBANG MOTOR MFR +1

foam plastic mold

Owner:龙海市永隆泡沫包装有限公司

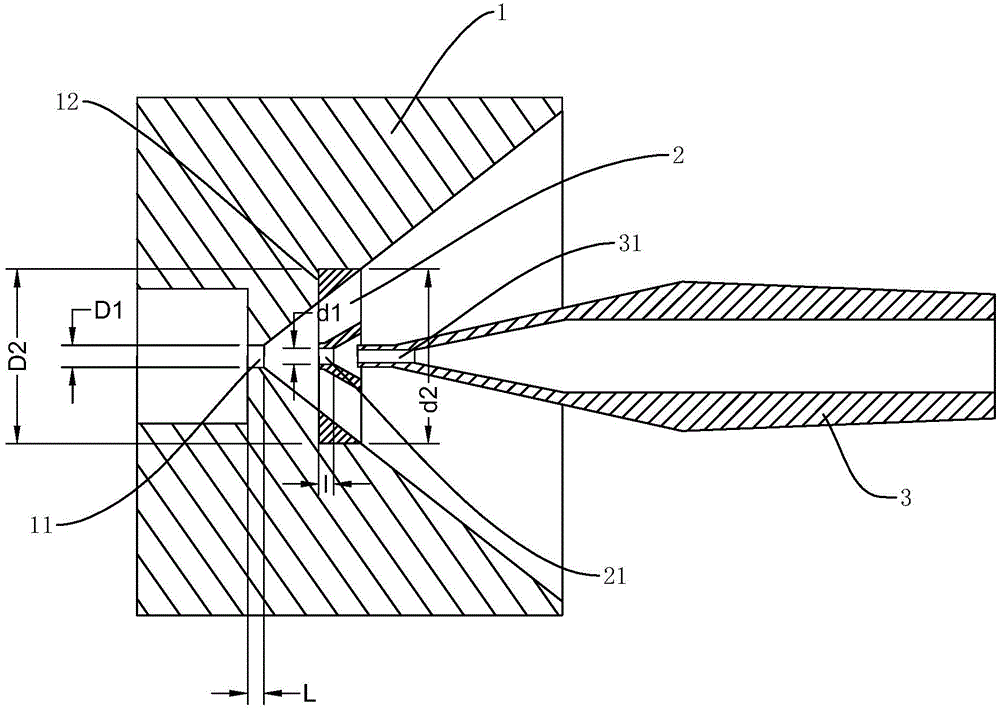

Alignment-free Headphone cable extrusion mold system and manufacturing method of headphone cable extrusion mold system

The invention discloses an alignment-free headphone cable extrusion mold system and a manufacturing method of the headphone cable extrusion mold system. The mold system comprises a mouth mold, a guide cone and a mold core arranged between the mouth mold and the guide cone; during manufacture, the mouth mold and the mold core are clamped once, processed once and integrally assembled, and the coaxiality of a mold hole and a mold core hole is greatly guaranteed, so that a cable core can be accurately positioned in the center of the mold hole through the mold core hole, the alignment work of a conventional mold is avoided, a cable core jacket is uniform, a produced product quality is stable, the consistency is good, the boot time is shortened, the productivity and the success rate of one-time boot are increased, the cost can be effectively saved, the mold core can be replaced according to different cable cores, cables and wear conditions, and use and maintenance are very convenient.

Owner:ZHONGSHAN TIANJIAN ELECTROACOUSTIC

A set of equipment for collecting and transporting garbage

ActiveCN104309971BReduce volumeIncrease in sizeRefuse vehiclesManufacturing technologyWaste collection

The invention discloses garbage collecting and conveying equipment, belongs to the technical field of environmental sanitation production and expands and improves the conventional garbage collecting, hoisting, compressing and conveying methods and equipment. The conventional environmental sanitation can only collect and convey household garbage through waster transfer stations and fails to solve small-scale construction garbage, made during house decoration and reconstruction and the like, and large-piece garbage including abandoned large old furniture which are required to be conveyed by owners themselves. According to the arrangement, the conventional garbage collecting and conveying process is simplified, the waste transfer stations are omitted, fewer sanitation workers are required, and household garbage, construction garbage and large-piece garbage are collected and conveyed in the rapid manner.

Owner:江苏乐尔环境科技股份有限公司

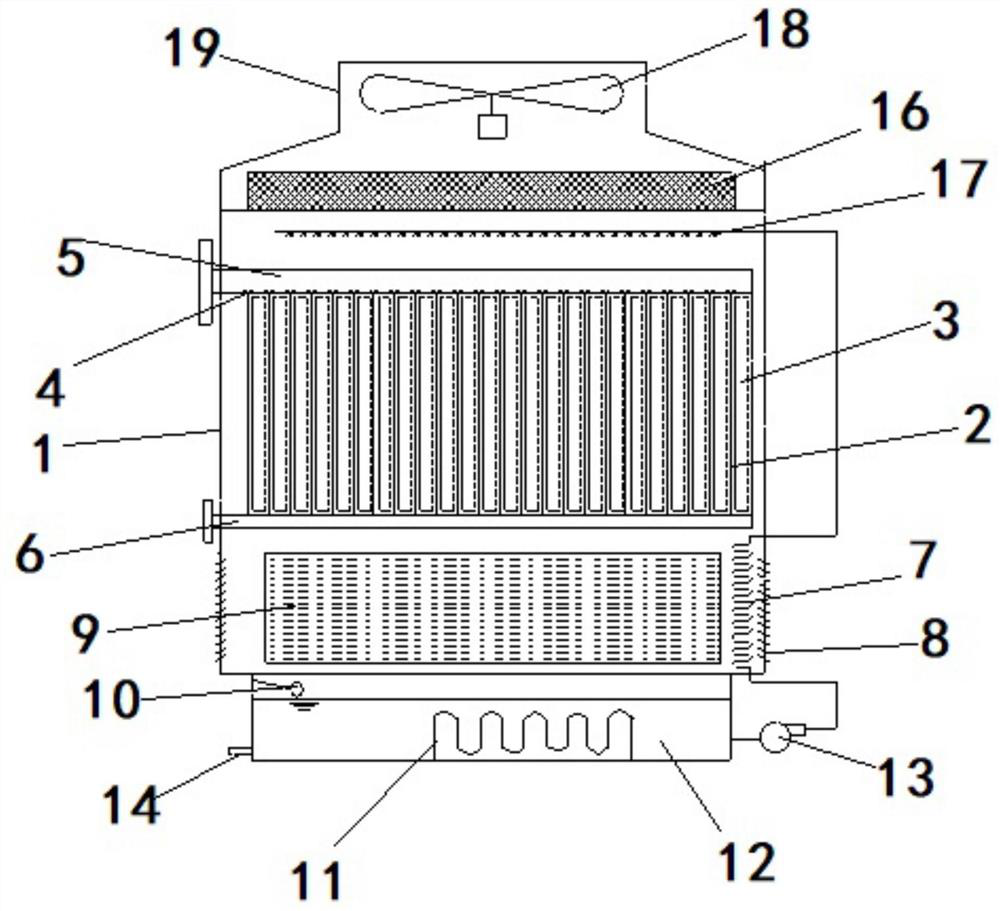

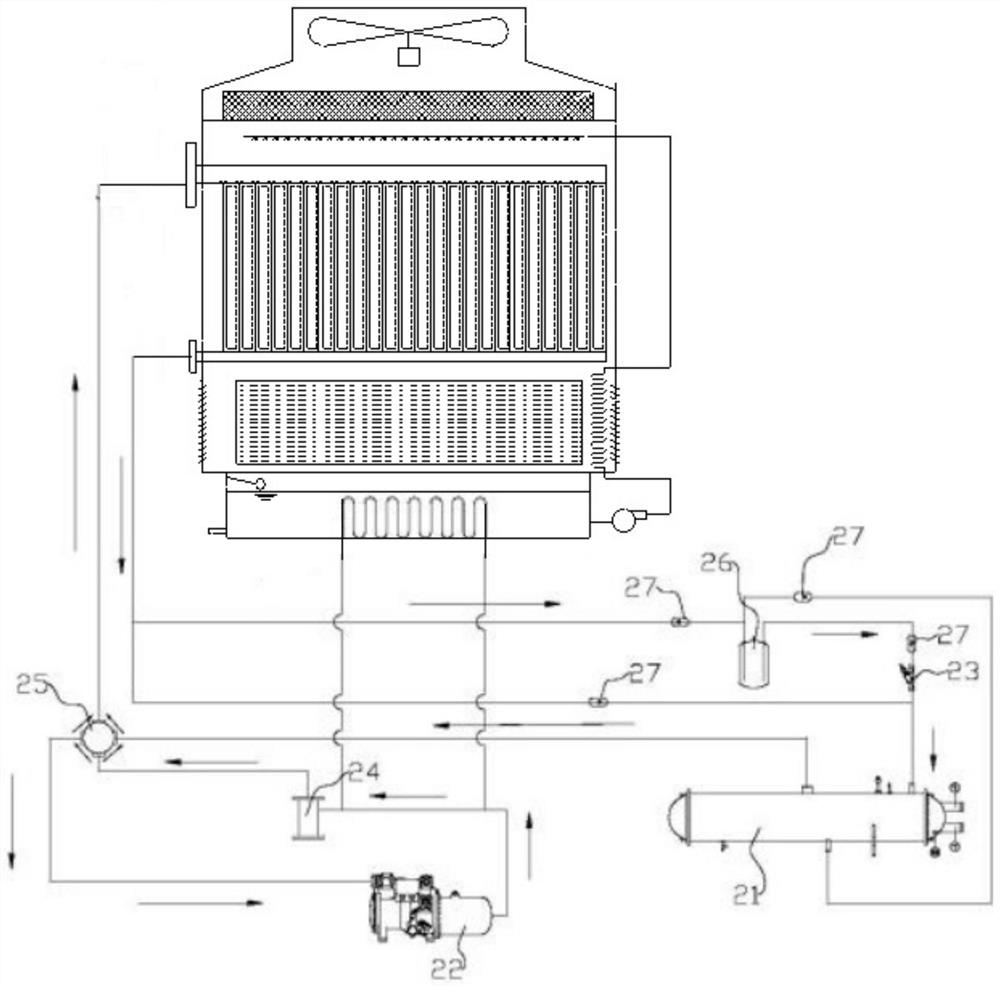

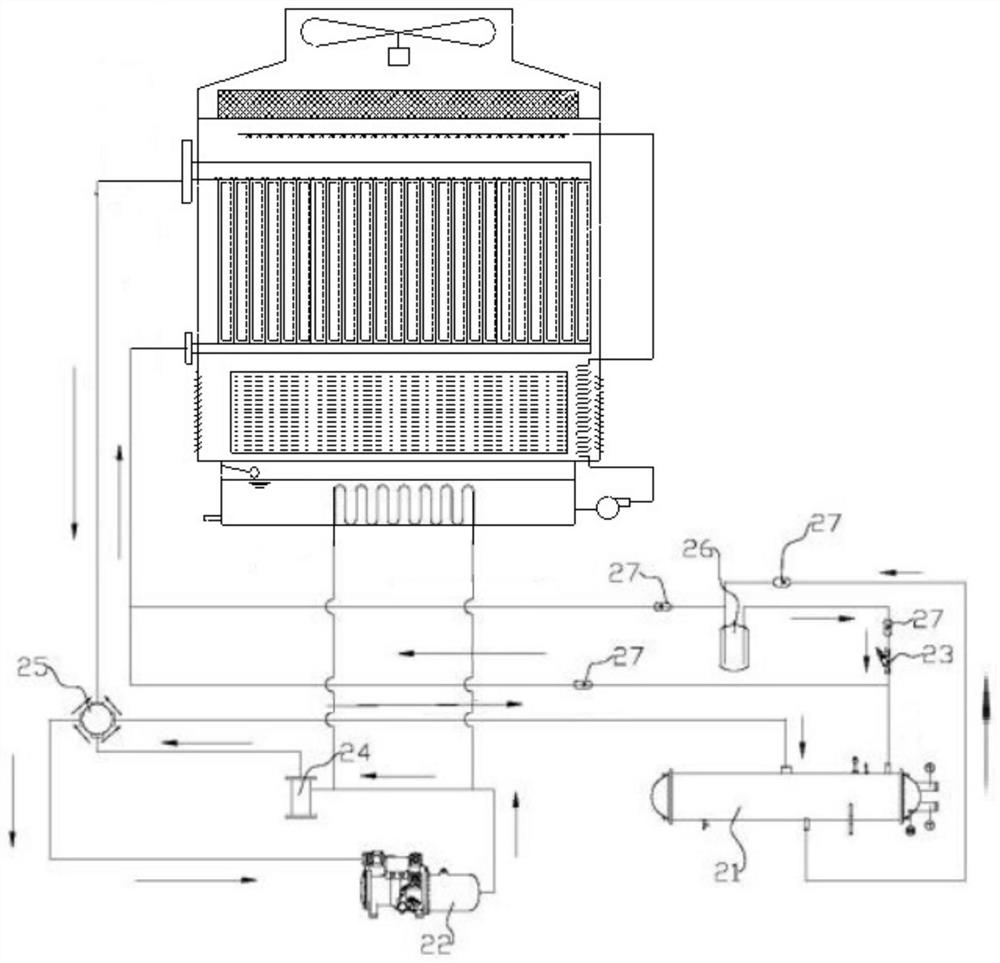

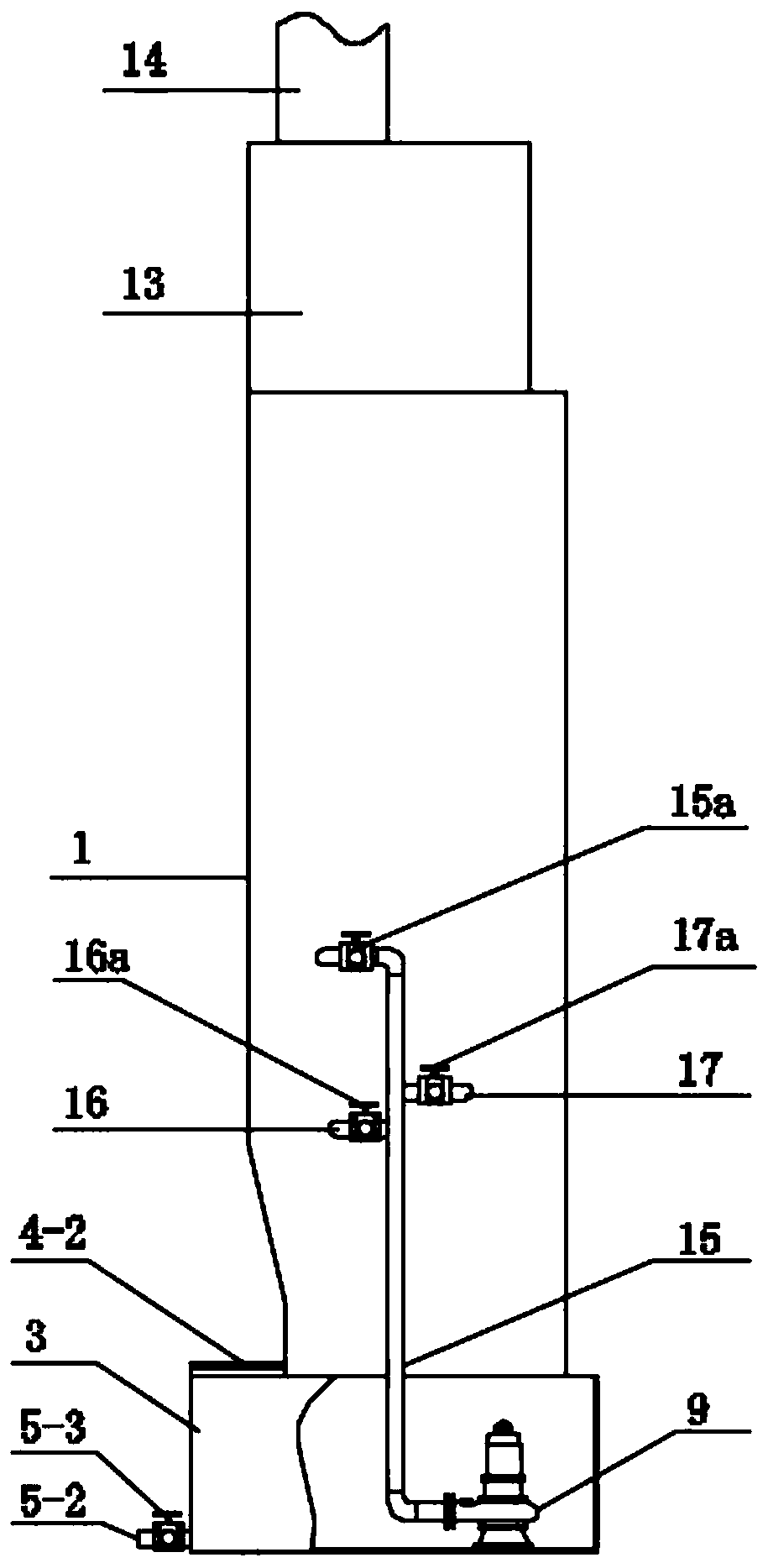

Energy tower and heat pump system thereof

PendingCN111678356AIncrease disturbanceReduce chargeHeat storage plantsFluid circulation arrangementLiquid storage tankRefrigerant

The invention relates to the field of heat exchange equipment, in particular to an energy tower and a heat pump system thereof. A heat exchange assembly for sealed conveying of a refrigerant is arranged in a tower body, and a phase change medium is used as a liquid spraying system; the spraying system comprises a spraying machine of which the spraying direction faces a heat exchange pipe, arrangedon the heat exchange assembly, and a liquid storage tank which is arranged below the heat exchange assembly and used for bearing a phase change medium; the heat exchange assembly comprises an air collecting pipe, a liquid collecting pipe and a plurality of heat exchange plates which are arranged between the air collecting pipe and the liquid collecting pipe and are arrayed and arrayed in an equalspacing manner; the liquid storage tank communicates with the spraying machine through a pipeline; one or more precooling heat exchangers located in the tower body are arranged on the pipeline; and the phase change medium sprayed from the spraying machine and the refrigerant in the heat exchange plates are in heat exchange in the manner of a part evaporation or condensing manner, and the heat exchange effect is increased.

Owner:EXTEK ENERGY EQUIP ZHEJIANG

A kind of filling material and its construction method for the expansion joints of the concrete face of the rockfill dam

ActiveCN107043545BIncrease elasticityImprove adhesionMarine site engineeringBuilding insulationsKeroseneArchitectural engineering

The invention relates to the technical field of hydraulic construction and particularly relates to a packing material for an expansion joint of a concrete facing rockfill dam and a construction method of the packing material. The packing material is prepared from the following components in parts by weight: 100 parts of petroleum asphalt, 50-60 parts of kerosene, 70-80 parts of asbestos mud and 45-50 parts of rubber powder. The packing material has the advantages of being available in materials and wide in application range, has good elasticity, cohesiveness and plasticity, and is capable of uniformly bestrewing the whole concrete surface; and the material has good adhesive force and can meet the construction quality requirements of a vertical construction joint.

Owner:ZHEJIANG PROVINCIAL NO 1 WATER CONSERVANCY & ELECTRIC POWER CONSTR GRP HLDG

Water distributor of trickling biofilm reactor

ActiveCN108609724AMeet the water distribution requirements for efficient sewage treatmentAvoid shockTreatment using aerobic processesBiological treatment apparatusBiofilmEngineering

The invention relates to a water distributor of a trickling biofilm reactor. The water distributor comprises an upper water inlet plate and a lower trickling plate, wherein the upper water inlet plateand the lower trickling plate are fixedly connected, and a clearance space is left between the upper water inlet plate and the lower trickling plate, and the periphery of the clearance space is sealed to form a water distribution interlayer, and space height of the water distribution interlayer is 0.2- 0.8 mm; water distribution interlayer water inlet holes are formed in the upper water inlet plate, a plurality of trickling water outlet holes of the water distribution interlayer are formed in the lower trickling plate, and the total cross-sectional area of the plurality of trickling water outlet holes is larger than the cross-sectional area of the water distribution interlayer water inlet holes. The water distributor is simple in structure, convenient to use and low in operation and maintenance cost, and can realize 100% trickling water distribution on the basis of liquid surface tension principle, and the water distribution requirement of efficient sewage treatment of a trickling device is met.

Owner:重庆理享生态修复研究院有限公司

A bedding cement device for building walls

ActiveCN111809898BEvenly coveredReduce labor intensityBuilding material handlingCement mixing apparatusBrickGear drive

The invention relates to a bedding cement device, in particular to a bedding cement device for building walls. The technical problem to be solved by the present invention is how to provide a bedding cement device for building walls that can reduce the labor intensity of builders and improve the efficiency of bedding cement slurry. In order to solve the above-mentioned technical problems, the present invention provides such a bedding cement device for building walls, comprising: a material storage box, one side of which is rotatably connected to a first gear; a first connecting rod, on which a first gear is connected A connecting rod; a hand-operated plate, the hand-operated plate is connected to the first connecting rod; a material-spreading mechanism, the material-spreading mechanism is installed on the material storage box, and the material-spreading mechanism is connected with the first gear through transmission. The counterclockwise rotation of the first gear of the device can drive the material spreading mechanism to work, the material spreading mechanism can cover the cement slurry on the bricks, and the material spreading mechanism can also drive the auxiliary moving mechanism to work.

Owner:天长市振业建设工程有限公司

Novel durable anode layer ion source

PendingCN110867366AEvenly dispersedEvenly coveredElectric discharge tubesCooling/ventilation/heating modificationsEngineeringMechanical engineering

The invention belongs to the technical field of ion source auxiliary coating, and particularly relates to a novel durable anode layer ion source. According to the novel durable anode layer ion source,a mounting cavity is formed in a base, and an outer cathode and an inner cathode are arranged on the upper end face of the base; gaps are reserved between the outer cathode and an anode and between the inner cathode and the anode; a gas homogenizing seat is also arranged in the mounting cavity; a plurality of air guide holes which are formed at equal intervals and are communicated with the gaps are formed in the gas homogenizing seat; the structure of the gas homogenizing seat is added, so that process gas is enabled to pass through the air guide holes in the gas homogenizing seat before entering into a working space, the air guide holes arranged at equal intervals are adopted for uniform dispersion of the process gas, so that the process gas enters the gap between the cathode and the anode more uniformly, the process gas is uniformly distributed, the plasma concentration is balanced and stable when an ion source works, and the coating quality is more stable.

Owner:GUANGDONG SHENGBOER PHOTOELECTRIC TECH CO LTD

An energy-saving and environment-friendly bio-glue curtain cabinet and its waste gas waste treatment method

ActiveCN108176174BEvenly coveredSmooth and fullCombination devicesGas treatmentExhaust fumesDust control

The invention discloses an energy-saving and environment-protection type biological glue water curtain cabinet and a waste gas and waste residue treatment method thereof. The energy-saving and environment-protection type biological glue water curtain cabinet is characterized in that a biological glue waste gas residue-blocking dust-removing chamber is arranged in a cabinet, a two-stage wind inletflow guide plate, a two-stage glue distribution diversion device, a two-stage biological glue waste gas residue-blocking wind distribution plate, a two-stage glue distribution diversion device, a two-stage glue guide groove and a residual glue collection device are arranged in the biological glue waste gas residue-blocking dust-removing chamber, each stage of the glue guide groove is connected toeach stage of the glue distribution diversion device, and each stage of the glue distribution diversion device is correspondingly connected to each stage of the biological glue waste gas residue-blocking wind distribution plate. The treatment method comprises: purifying large-particle waste residue, purifying fine-particle waste residue, carrying out photolysis sterilization and discharge on wastegas, purifying and recycling a biological glue, and other steps. According to the present invention, the energy-saving and environment-protection type biological glue water curtain cabinet has advantages of zero discharge, zero pollution and significant purification effect, and uses the biological glue to replace the clear water so as to perform circulation purification treatment.

Owner:武汉斯特蓝科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com