Production process and device of environment-friendly peculiar-smell-free sound insulation coating material

A technology for sound insulation coatings and production devices, which is applied to mixers, dissolvers, mixers and other directions with rotary stirring devices, can solve problems such as poor dispersion effect, insufficient discharge and grinding, and unfavorable stirring processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

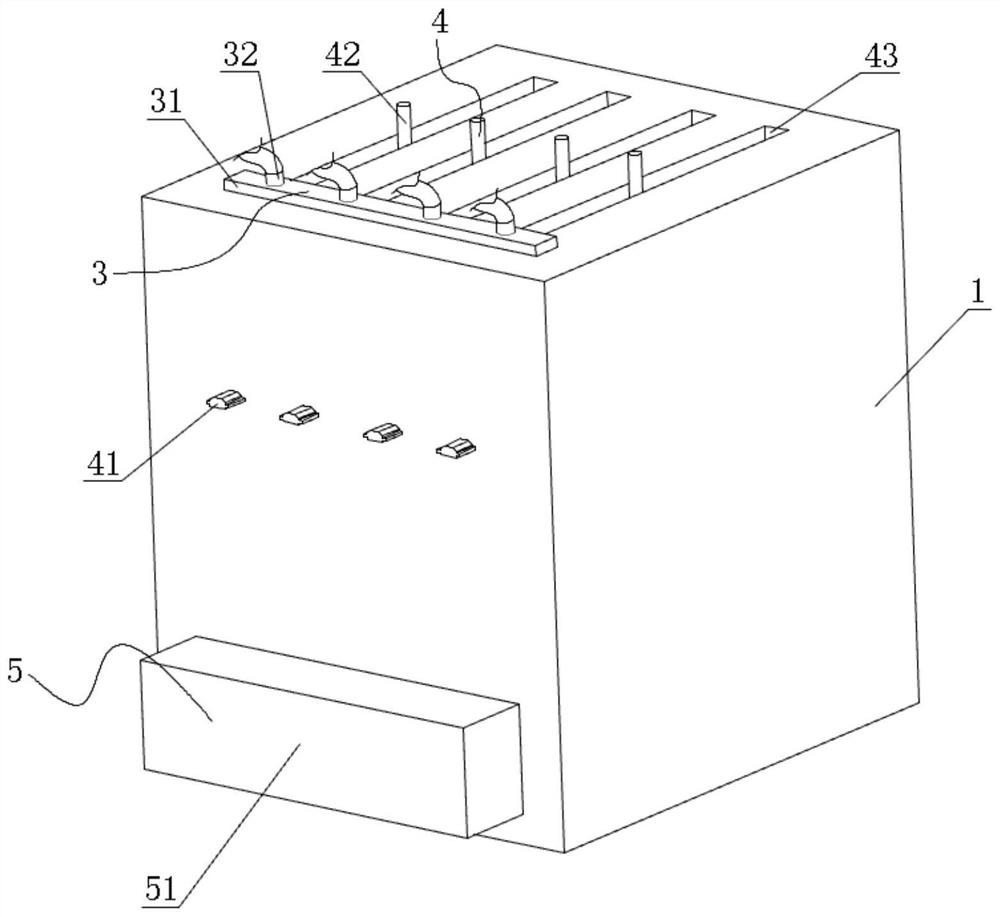

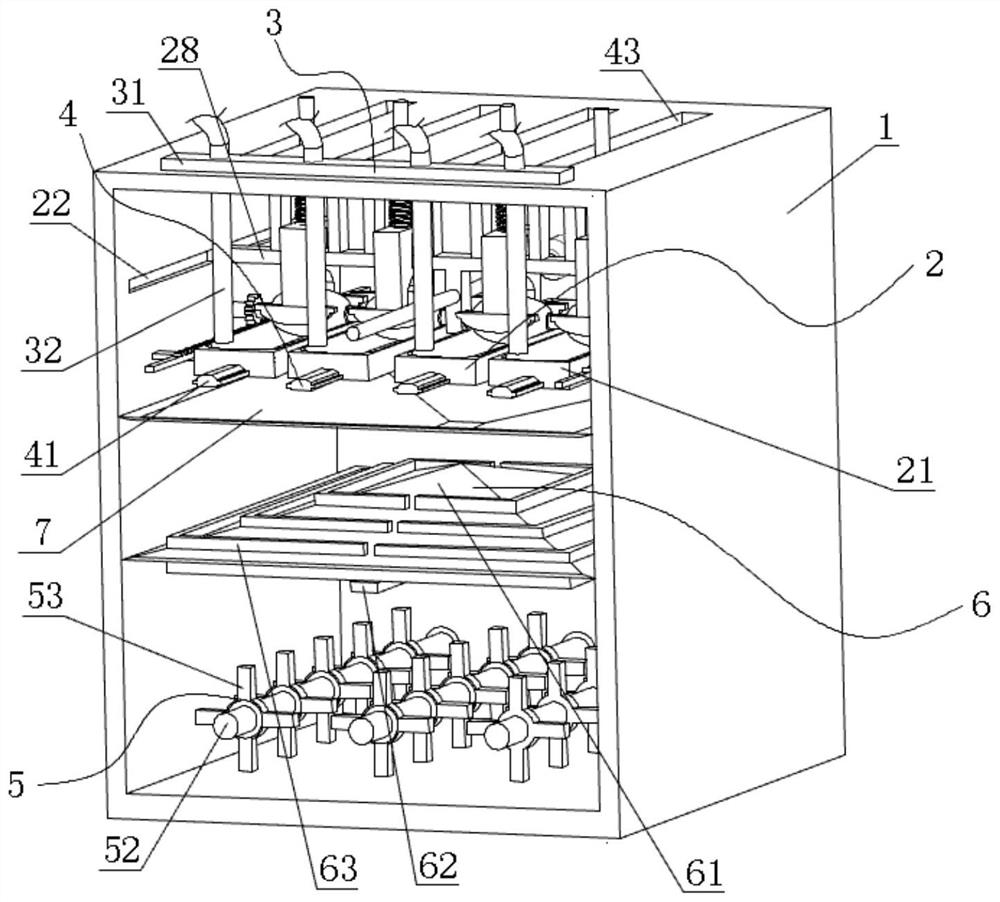

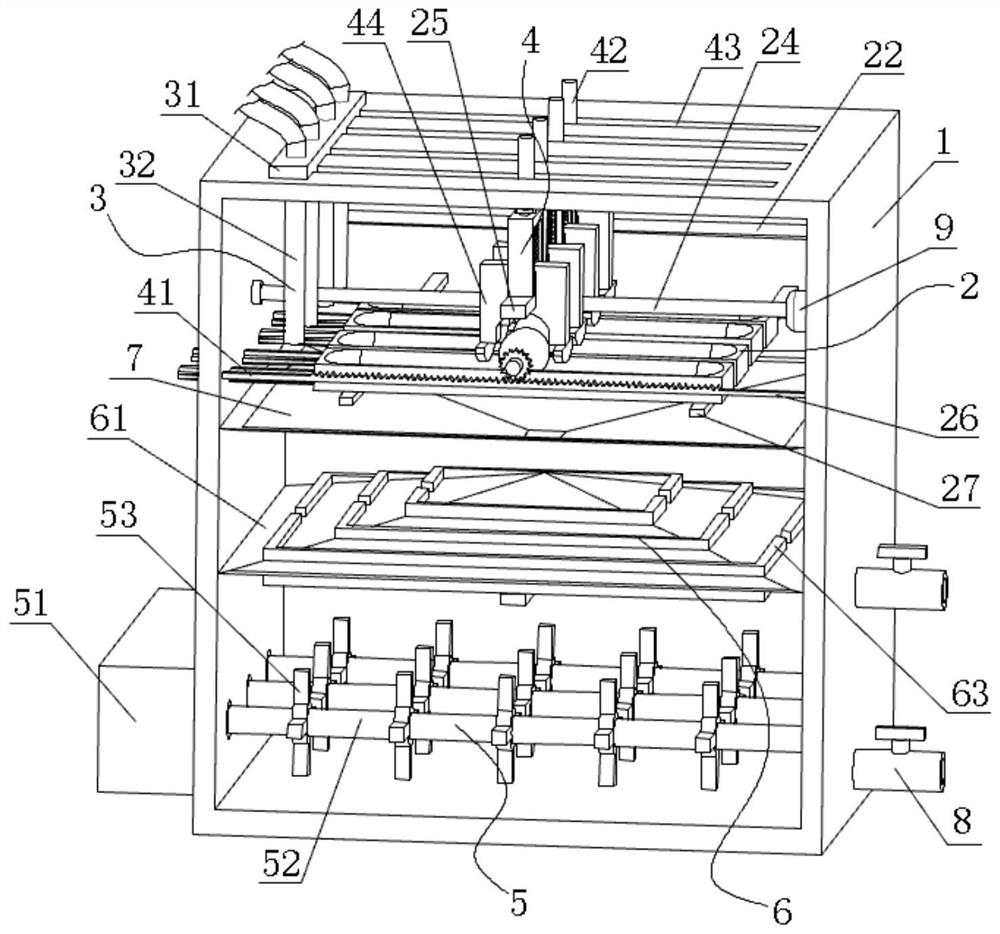

[0039] see Figure 1-11 , a production process of an environmentally friendly odorless soundproof coating, the production process of the environmentally friendly odorless soundproof coating is completed by a production device for an environmentally friendly odorless soundproof coating, the production device for the environmentally friendly odorless soundproof coating includes a cabinet 1, The middle part of the inner wall of the box body 1 is fixedly connected with a guide frame 7, and the right side wall of the box body 1 is fixedly connected with two connecting pipes 8, and the right end of the connecting pipe 8 runs through the box body 1 and extends to the right side of the box body 1. Valves are installed inside each connecting pipe 8, and the inside of the box body 1 is provided with a grinding mechanism 2, a feeding mechanism 3, an auxiliary feeding mechanism 4, a stirring mechanism 5 and a bulk material mechanism 6, and the stirring mechanism 5 is located at the bulk ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com