Concrete prefabrication member bottler

A technology of concrete prefabricated parts and pouring machines, which is applied in the direction of manufacturing tools, ceramic forming machines, reinforced molding, etc. It can solve the problems of affecting the roundness of the mold, affecting the roundness of the pipe pile, and large physical exertion, so as to enhance the precision of the mold and prolong the life of the mold. The effect of improving the service life and labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

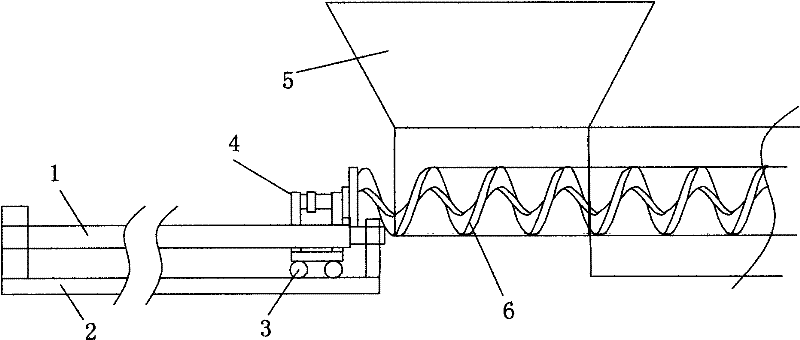

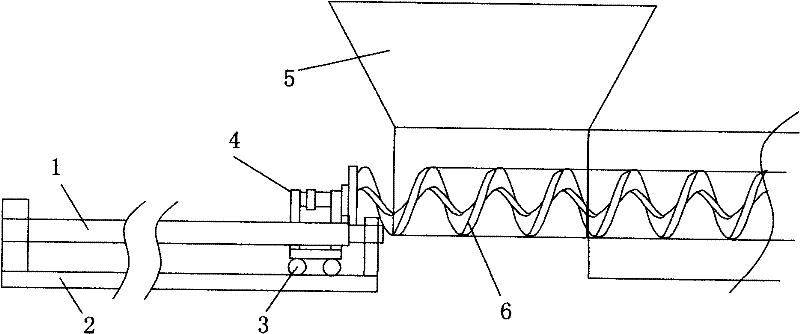

[0018] Next, the concrete prefabricated pouring machine of the present invention will be described in detail with reference to the accompanying drawings.

[0019] Prefabricated concrete pouring machine, its structure includes a hopper 5 and a propelling pouring mechanism under the hopper; the propelling pouring mechanism consists of a spiral blade 6 placed in the pouring pipeline and a drive connected to the rear end of the spiral blade to drive the spiral blade to move back and forth Organization 4 constitutes. The driving mechanism connecting the helical blades is placed on the traveling trolley 3 below, and the traveling trolley moves back and forth on the guide rail 2 . An idler roller 1 is arranged on the guide rail, and the traveling trolley drives the driving mechanism and the helical blade to move back and forth on the guide rail along the guide rail which is stable on the idler roller.

[0020] The working principle of the present invention is to put the steel cage i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com