Method for doping polycrystalline alumina ceramics

A polycrystalline alumina and alumina technology, which is applied in the field of ceramic manufacturing, can solve the problems of difficulty in mixing, affecting lamp life, light efficiency, and the effect cannot meet the predetermined requirements, and achieves uniform distribution, high speed and large output. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

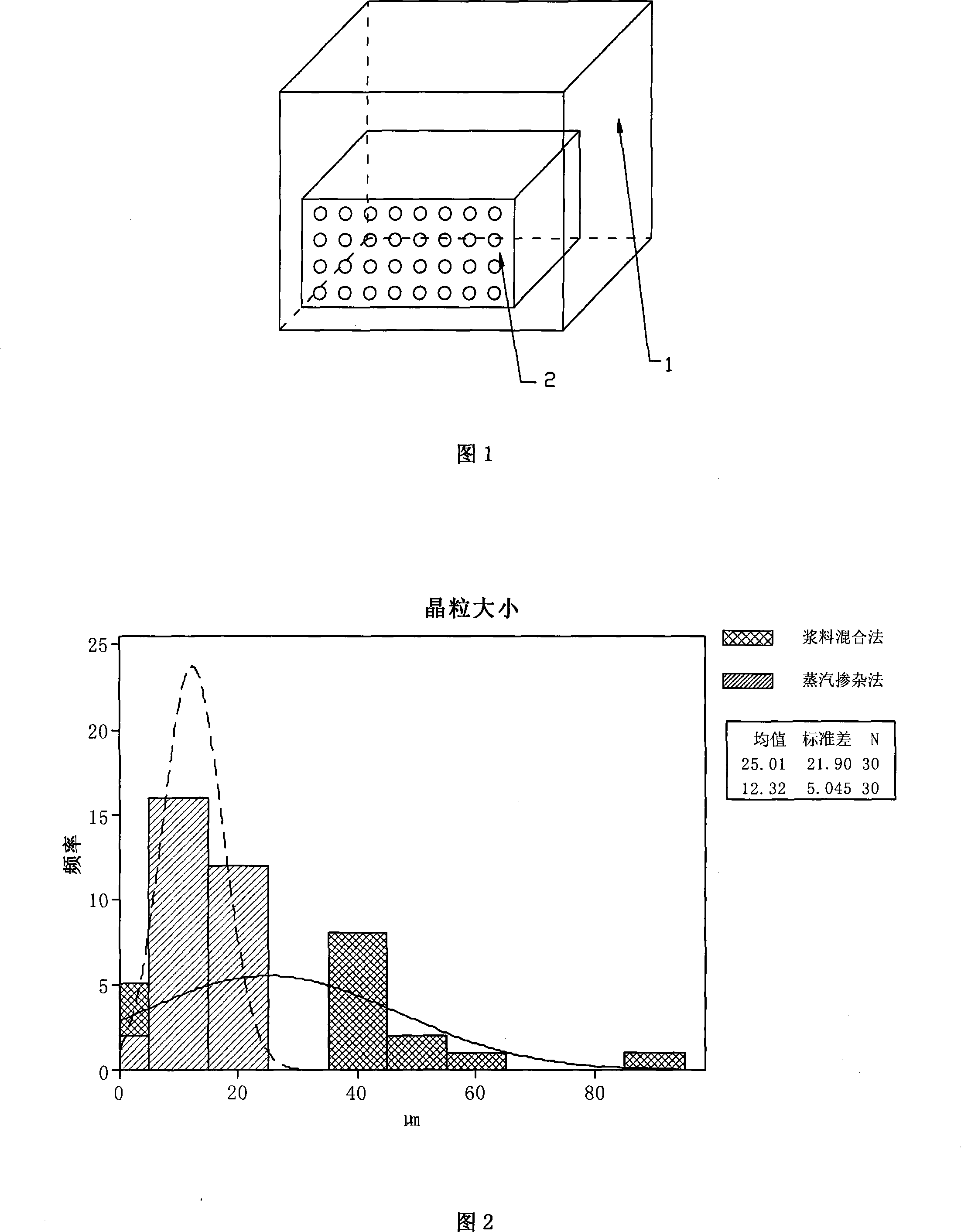

[0013] The doping method of the present invention is that the alumina product is formed first and then initially fired to increase the mechanical strength. The initial firing temperature is 900°C-1250°C for 1-2 hours; Put it in a perforated container 2 shown in Figure 1, and then place it in a semi-closed container 1, the semi-closed container 1 is filled with impurities that need to be added, and spread around the perforated container 2, At this time, the impurities and the product are separated by the container 2 with holes, and then they are sent together to a high-temperature furnace for heating at a temperature of 800°C to 1500°C for 2 to 5 hours. During this process, the impurities are heated and become The steam passes through the small holes and spreads evenly on the product; then the alumina product with impurities is heated for the third time, at this time, the temperature is 1700°C-2000°C, and the time is 10-12 hours, and the impurities are completely fused into it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com