Flexible drive assembly

A transmission component and flexible technology, applied in the field of flexible transmission components, can solve problems such as leakage of lubricating oil, long stroke of lubricating oil filling, power loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further illustrate the features and purposes of the present invention, the following preferred embodiments are listed below and described with accompanying drawings.

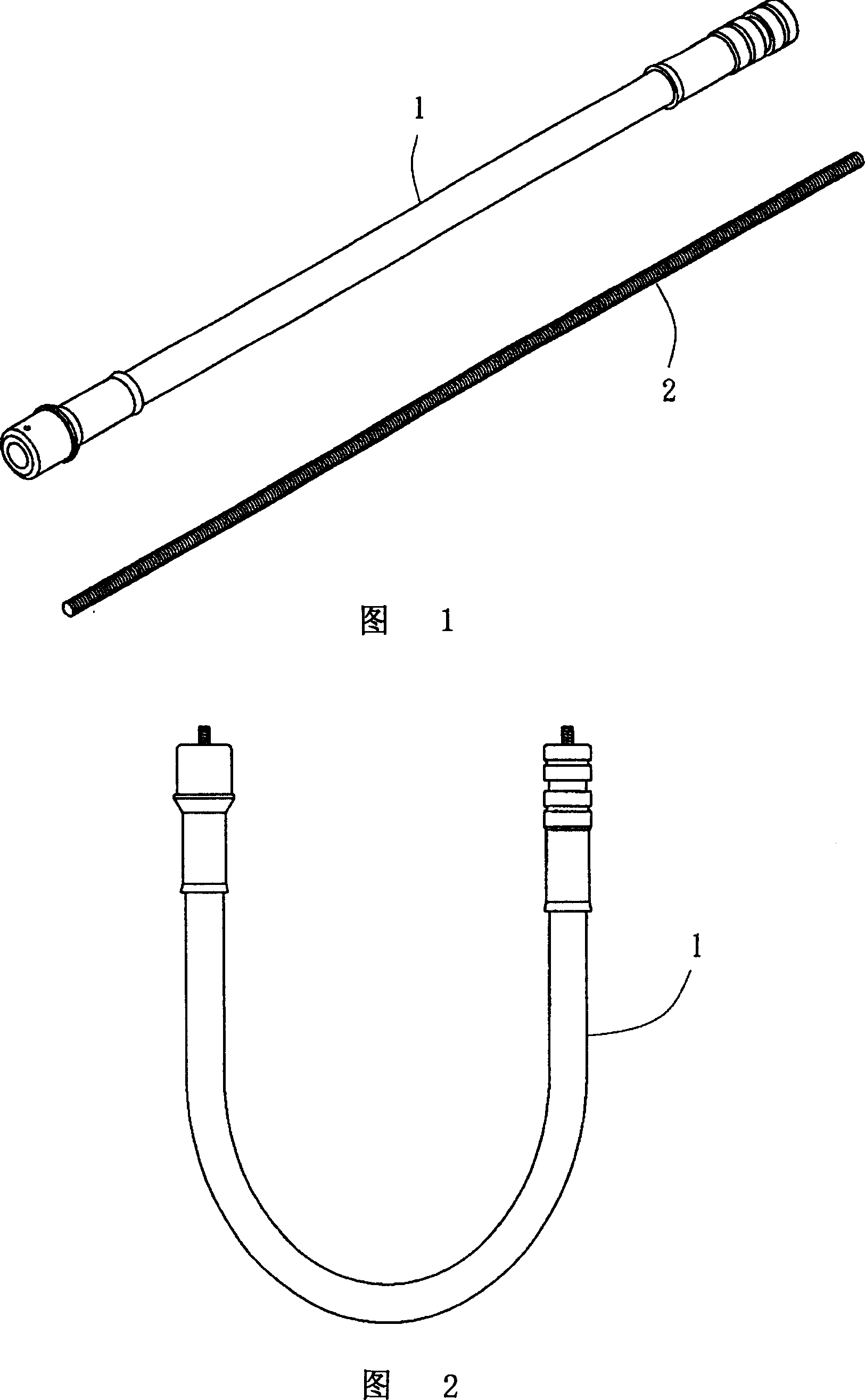

[0019] As shown in Figures 3 to 6, a flexible transmission assembly 100 provided by the first preferred embodiment of the present invention mainly includes a transmission hose 10 and a flexible transmission shaft 20 (as shown in Figure 3 shown), where:

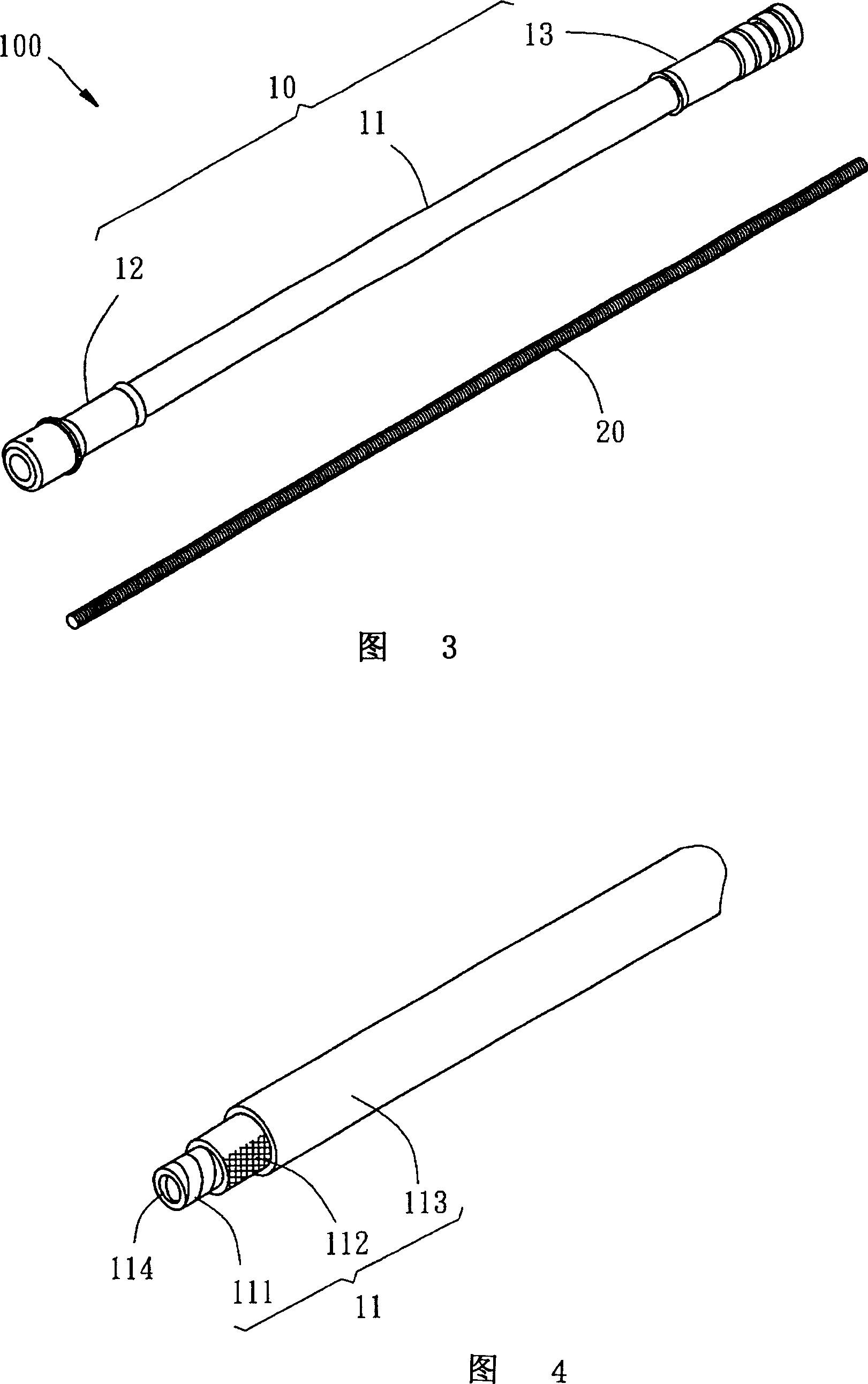

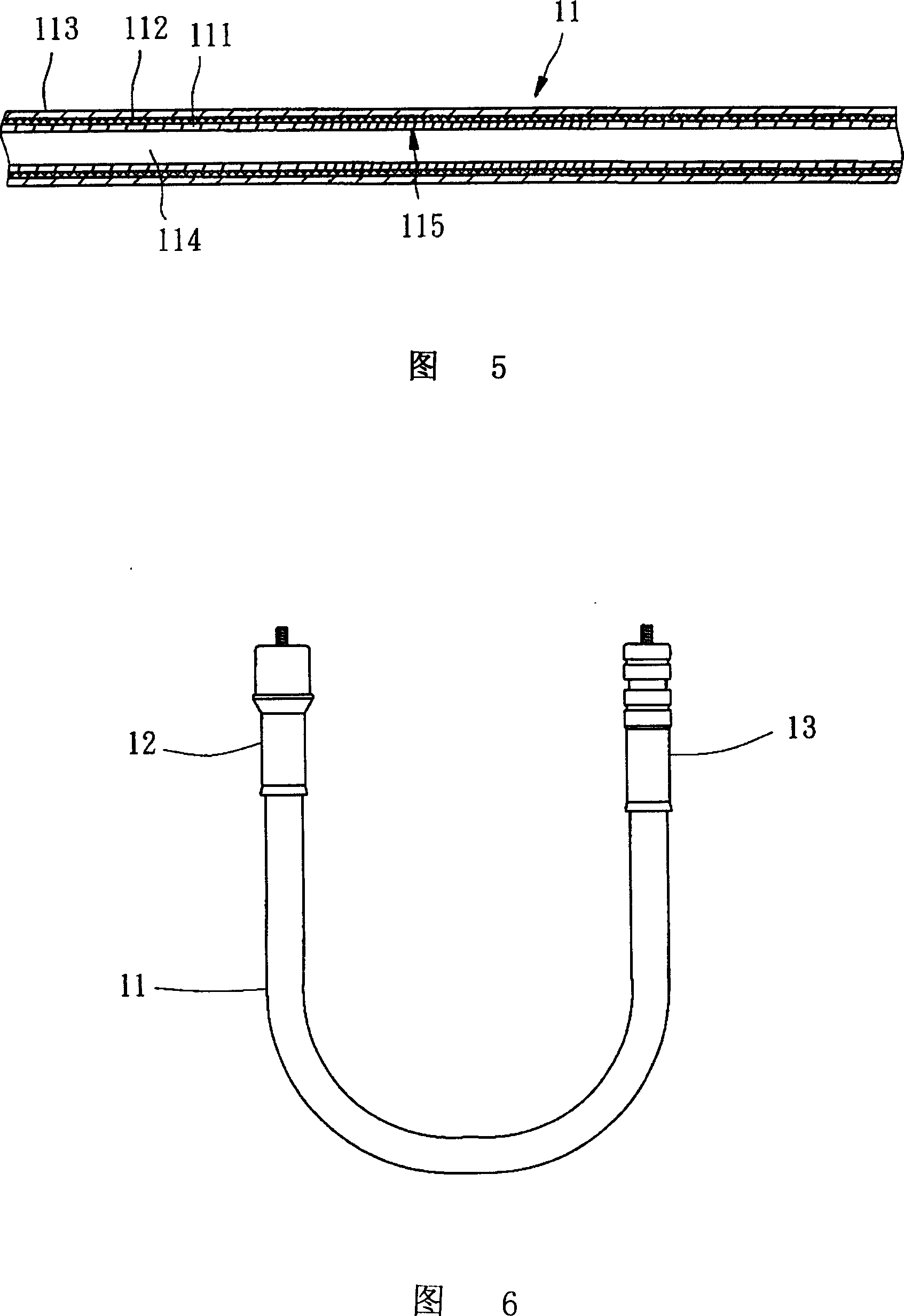

[0020] The transmission hose 10 has a hose body 11 , a first connecting piece 12 and a second connecting piece 13 . The hose body 11 is a tubular body with a metal hose layer 111, a metal mesh layer 112 and a cladding layer 113 (as shown in Figure 4), and the metal hose layer 111 is connected by a metal plate It is wound and has the characteristics of being flexible, so that an axial perforation 114 is formed inside, the metal mesh layer 112 is wrapped on the metal hose layer 112, and the covering layer 113 is made of rubber. Outside the met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com