Water distributor of trickling biofilm reactor

A biofilm reactor and water distributor technology, applied in biological water/sewage treatment, biological treatment devices, sustainable biological treatment, etc., can solve the problem of poor water distribution effect, uneven water distribution, small water distribution range, etc. problems, to prevent impact, ensure dripping efficiency, reduce operating costs and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

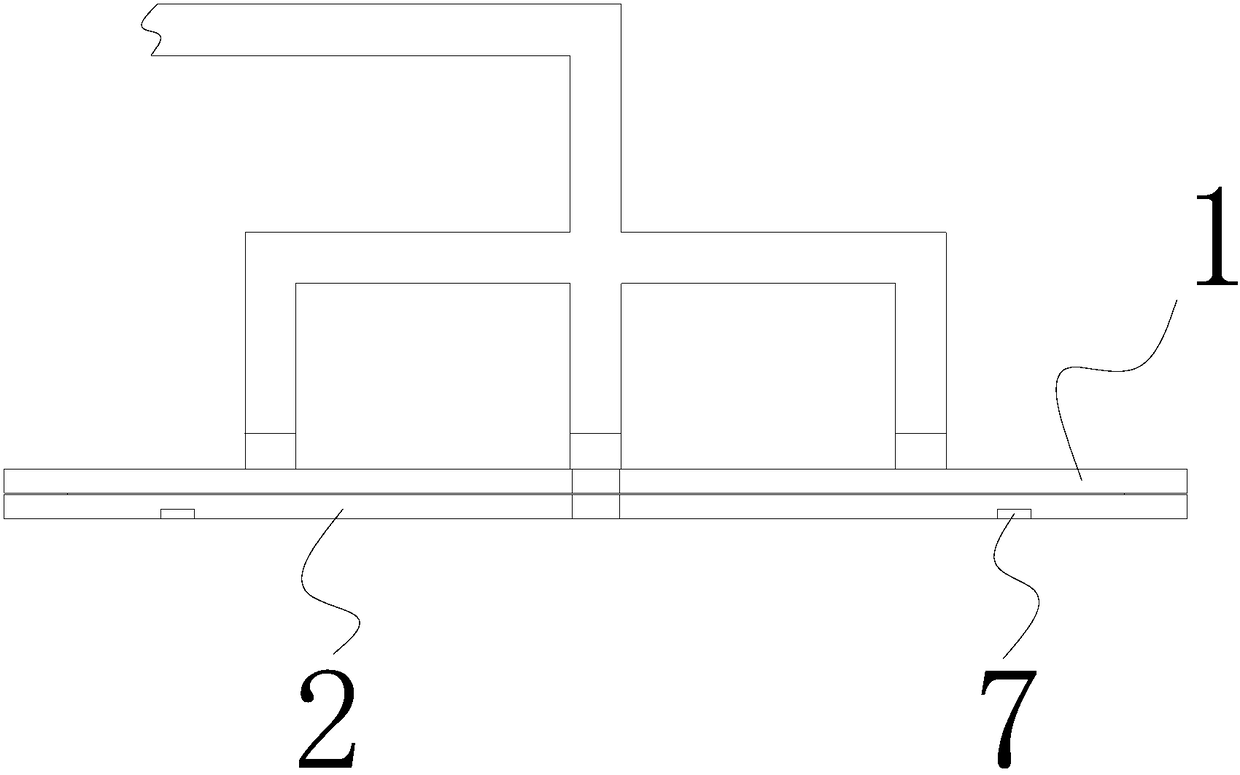

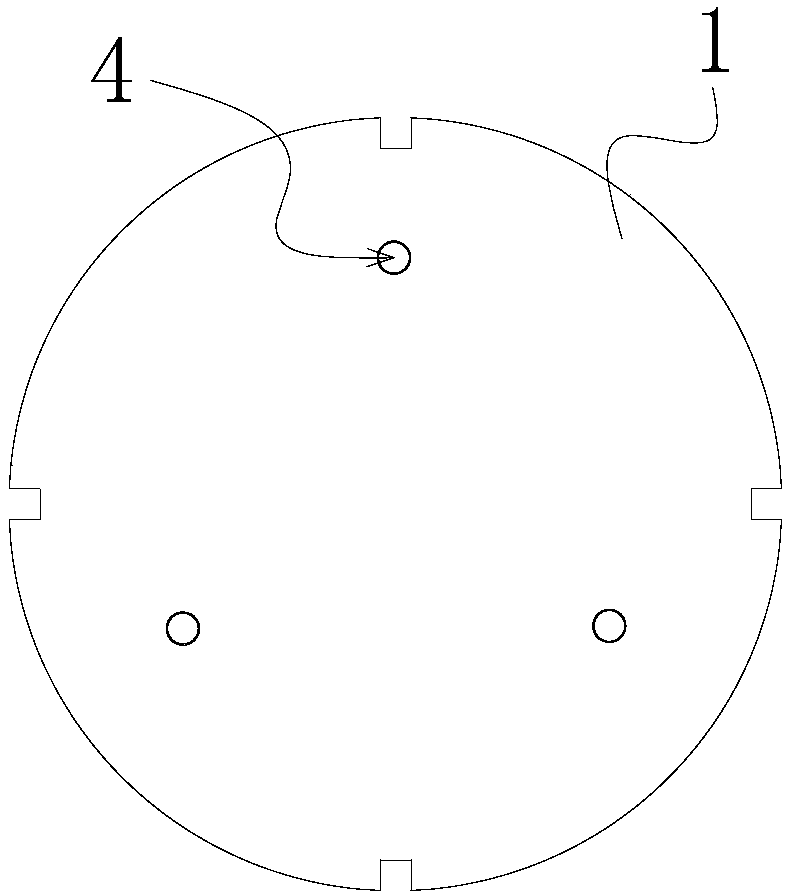

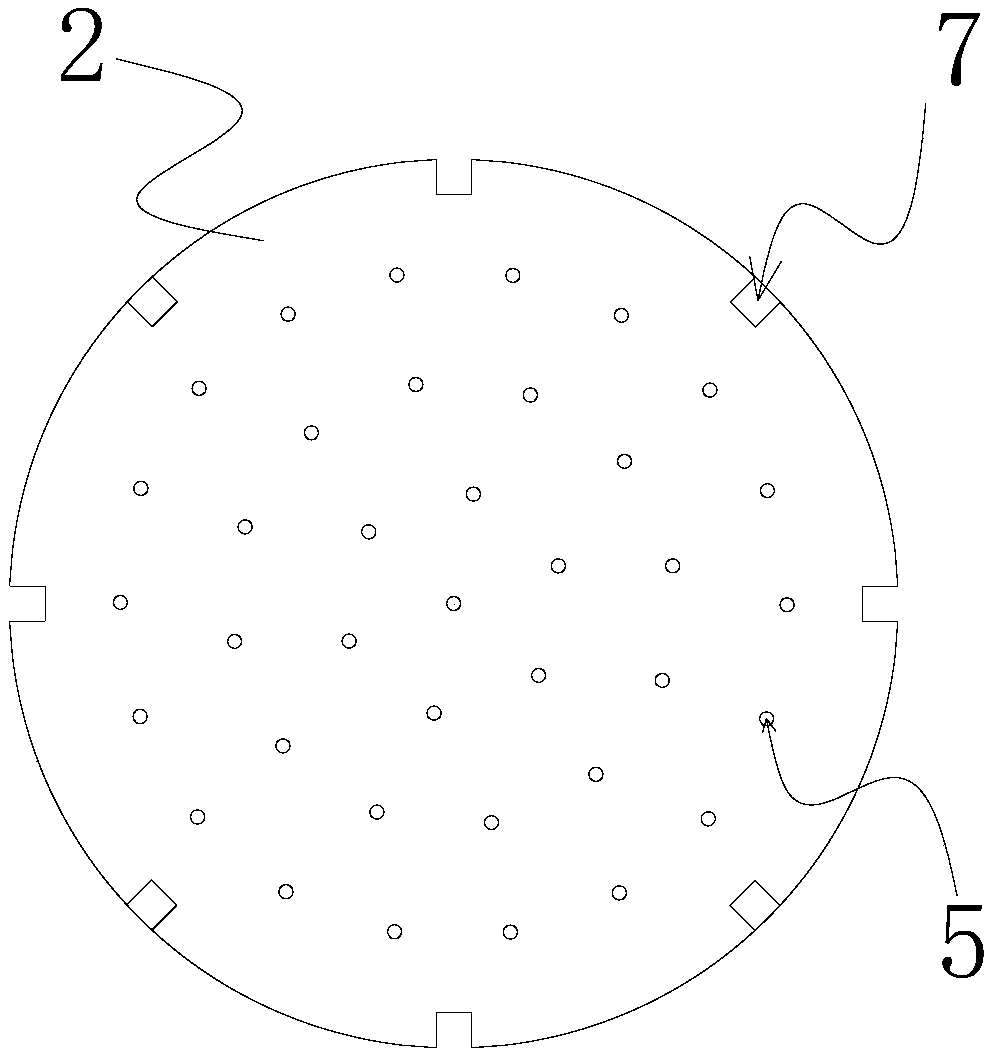

[0030] see Figure 1 to Figure 5 , is a specific example of a water distributor for a trickling filter biofilm reactor. The water distributor of the drip filter biofilm reactor includes an upper water inlet plate 1 and a lower drip leak plate 2, the upper water inlet plate 1 and the lower drip leak plate 2 are fixedly connected, and between the upper water inlet plate 1 and the lower drip leak plate 2 There is a gap space, and the periphery of the gap space is sealed to form a water distribution interlayer 3. The space height of the water distribution interlayer 3 is 0.2-0.8mm. In this embodiment, the upper water inlet plate and the lower drip drain plate are of the same size. Circular plates with a diameter of 200mm respectively, a sealing ring 6 is provided between the upper water inlet plate 1 and the lower dripping drain plate 2, the thickness of the sealing ring 6 is 0.3mm, and the inner space of the sealing ring 6 forms a water distribution interlayer, wherein , the upp...

Embodiment 2

[0033] Relationship between space height of water distribution interlayer and drop rate

[0034] Water distributors with different space heights of the water distribution interlayer are used. The number of water inlet holes in the water distribution interlayer is 6mm, the number of drip outlet holes is 37, the diameter of the holes is 2mm, and the diameter of the water distributor is 200mm. Connect the four-way pipe to the three water inlet holes of the water distribution interlayer, inject water into the water distribution interlayer through the peristaltic pump, control the water inlet flow rate to 280ml / min, turn on the peristaltic pump, and start to observe and record the water outlet of the water distributor after running for 2 minutes. Record the droplet rate of water distributors with different thicknesses of water distribution interlayer as Figure 6 shown. The results show that the water distribution interlayer has three water inlet holes with a diameter of 6 mm, the n...

Embodiment 3

[0036] The relationship between drop rate and flow rate of water distributor

[0037] Using the water distributor of Example 1, the four-way pipe is connected to the water inlet holes of the three water distribution interlayers, and the peristaltic pump is used to inject water into the water distribution interlayer to control the inflow flow. After the peristaltic pump is turned on, the water entering the water distributor will be Under the action of the surface tension of the liquid, the entire water distribution interlayer is slowly diffused. After the water distribution interlayer is full, the liquid begins to drip under the action of gravity. After running for 2 minutes, the stopwatch and counter are used to record the dripping of the water distribution device after the water distribution is stable. , increasing the influent flow in turn, and drawing the data as follows Figure 7 shown. The results show that the water distribution interlayer has three water inlet holes wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com