Trickling filter type biofilm reaction tower

A biofilm and reaction tower technology, applied in sustainable biological treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of back mixing, easy blockage of tubular components, gas-liquid mass transfer efficiency Low problems, to achieve the effect of high water distribution efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

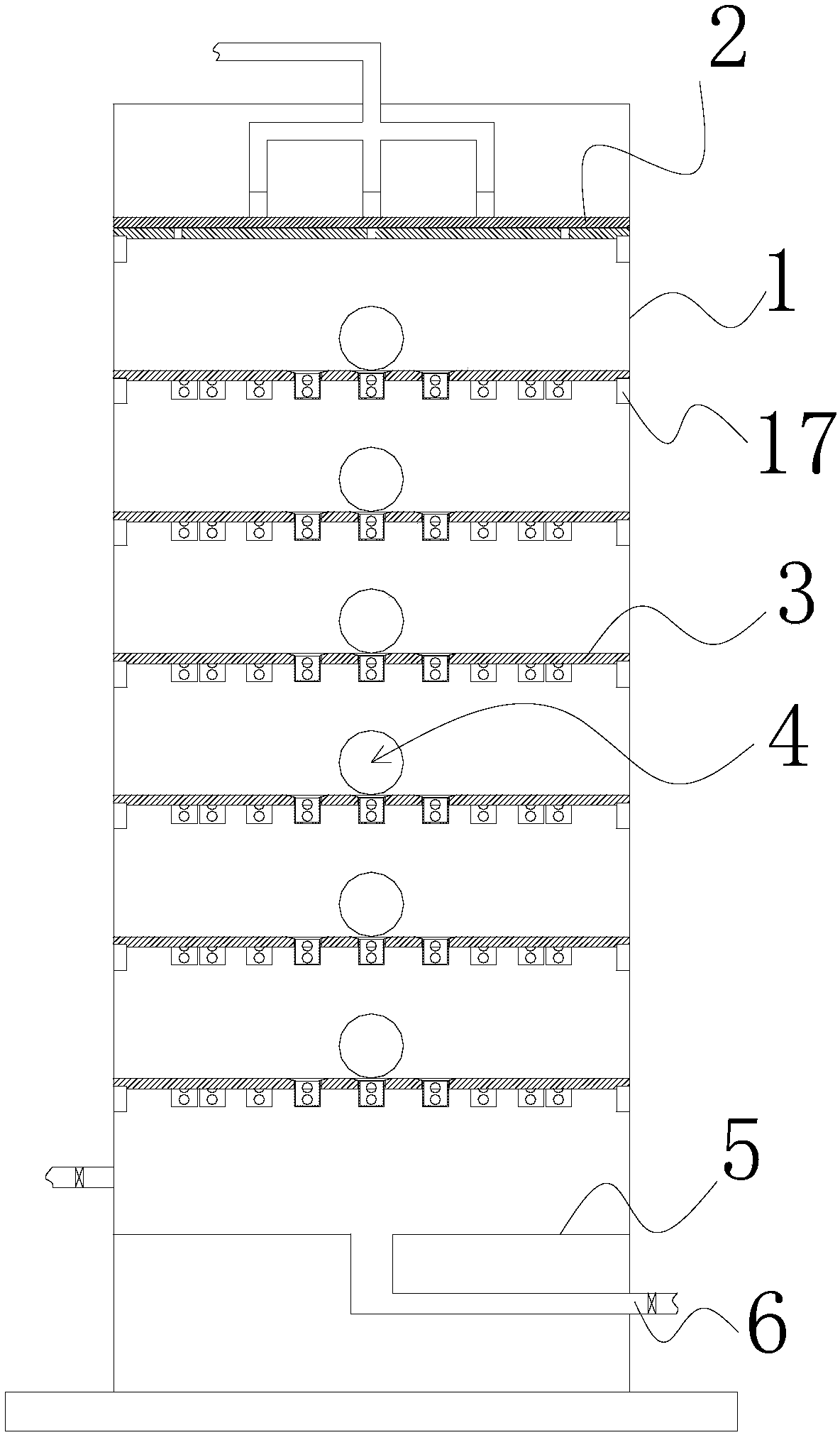

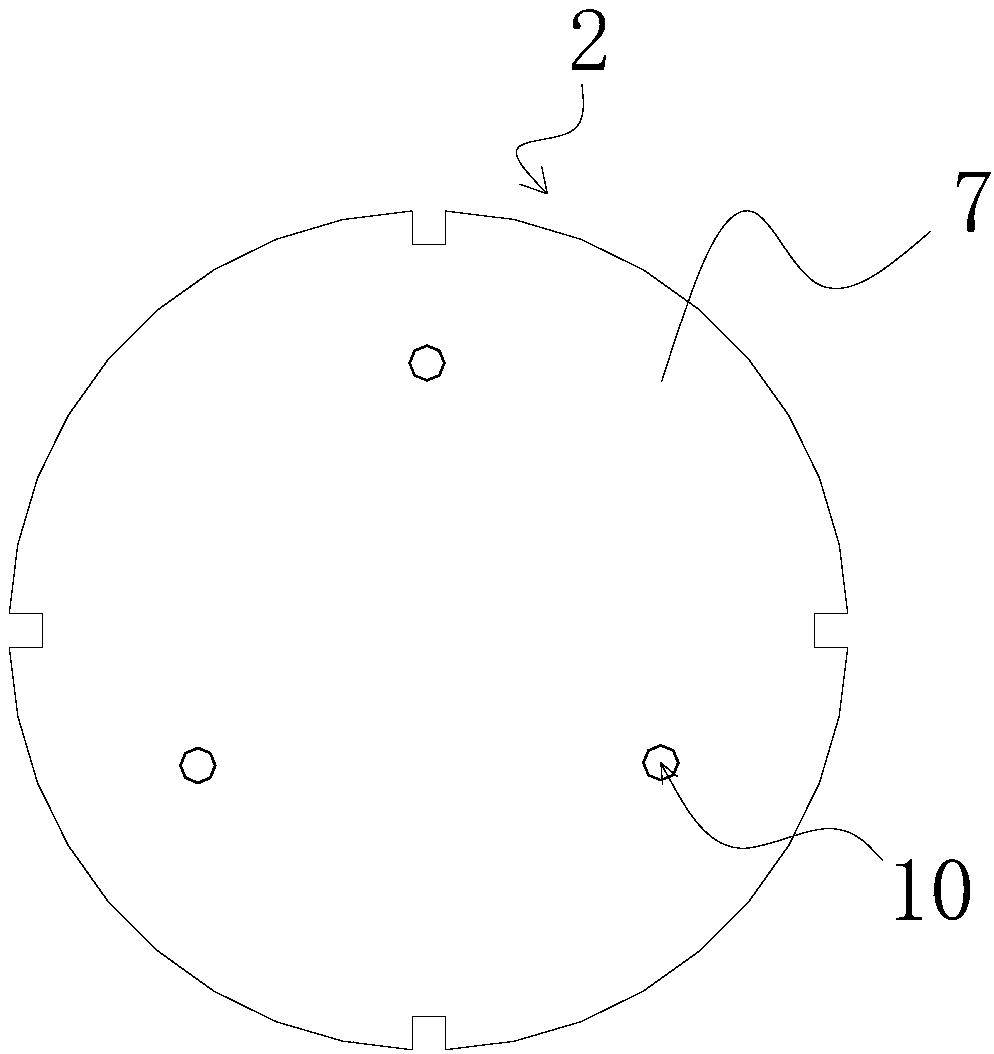

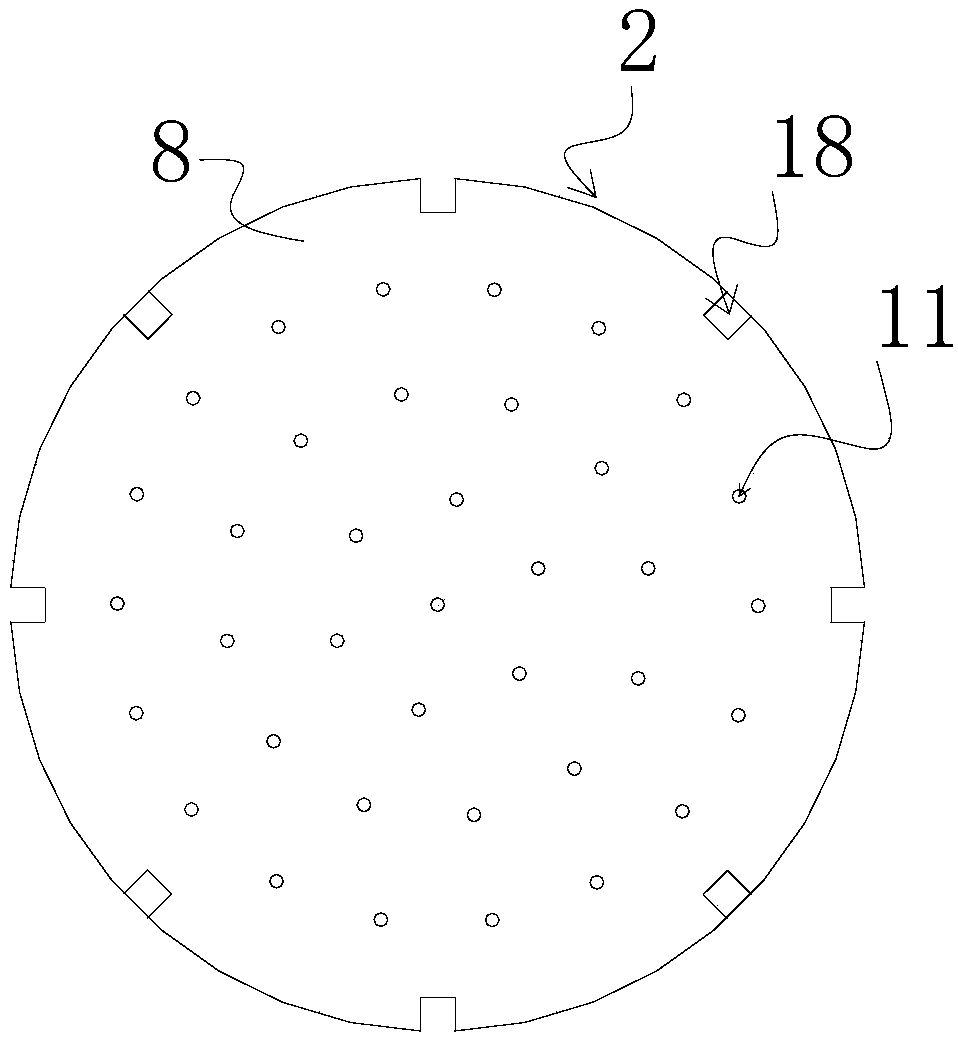

Embodiment 1

[0042] see Figure 1 to Figure 10 , is a specific embodiment of a trickling filter biofilm reaction tower. The trickling filter biofilm reaction tower includes a reaction tower body 1, a water distributor 2 and at least one trickling filter plate 3. In this embodiment, the number of trickling filter plates is six. The side wall of the reaction tower body 1 is provided with some air holes 4. In the present embodiment, the height of the reaction tower body is 500mm, and some air holes are divided into six layers, and the four air holes of each layer are evenly 360° circumference. The lower part of the inner cavity of the reaction tower body 1 is provided with a filtrate collecting plate 5 connected to the confluence outlet 6 through a pipeline, and the confluence outlet is provided with a valve to control the opening and closing. In order to facilitate cleaning of the filtrate collecting plate in the reaction tower body, in the reaction tower A cleaning nozzle is reserved on t...

Embodiment 2

[0045] Relationship between space height of water distribution interlayer and drop rate

[0046] Using water distributors with different space heights in the water distribution interlayer, the number of water inlet holes in the water distribution interlayer is three, the aperture is 6mm, the number of drip outlet holes is 37, the aperture is 2mm, and the diameter of the water distributor is 200mm ( With embodiment one). Connect the four-way pipe to the three water inlet holes of the water distribution interlayer, inject water into the water distribution interlayer through the peristaltic pump, control the water inlet flow to 280ml / min, turn on the peristaltic pump, and start to observe and record the water outlet of the water distributor after running for 2 minutes. Record the droplet rate of water distributors with different thicknesses of water distribution interlayer as Figure 11 shown. The results show that the water distribution interlayer has three water inlet holes w...

Embodiment 3

[0048] The relationship between drop rate and flow rate of water distributor

[0049] Using the water distributor of Example 1, the four-way pipe is connected to the water inlet holes of the three water distribution interlayers, and the peristaltic pump is used to inject water into the water distribution interlayer to control the inflow flow. After the peristaltic pump is turned on, the water entering the water distributor will be Under the action of the surface tension of the liquid, the entire water distribution interlayer is slowly diffused. After the water distribution interlayer is full, the liquid begins to drip under the action of gravity. After running for 2 minutes, the stopwatch and counter are used to record the dripping of the water distribution device after the water distribution is stable. , increasing the influent flow in turn, and drawing the data as follows Figure 12 shown. The results show that the water distribution interlayer has three water inlet holes w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com