A bedding cement device for building walls

A technology for cement installation and wall laying, which is applied in cement mixing installations, buildings, building structures, etc., can solve problems such as low paving efficiency and high labor intensity, and achieve the effects of preventing clumping, reducing labor intensity, and moving smoothly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

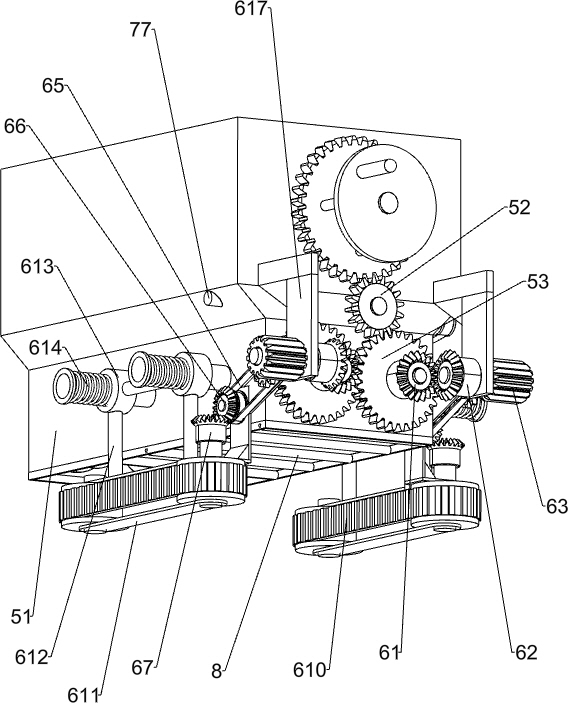

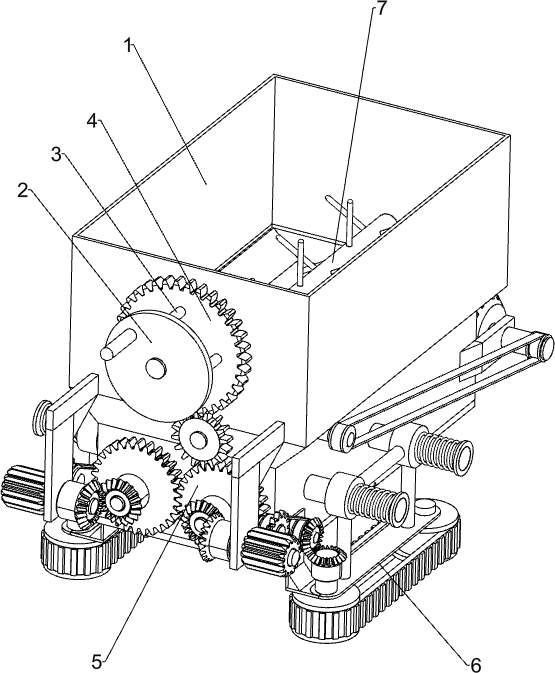

[0022] A bedding cement device for building walls, such as Figure 1-4 As shown, it includes a material storage box 1, a hand pan 2, a first connecting rod 3, a first gear 4, a spreading mechanism 5 and an auxiliary moving mechanism 6, and the front side of the material storage box 1 is rotatably connected with the first gear 4 , the front side of the first gear 4 is connected with a plurality of first connecting rods 3 evenly spaced along the circumferential direction, the front ends of the plurality of first connecting rods 3 are connected with a hand pan 2, and the material storage box 1 is equipped with a paving material Mechanism 5, the spreading mechanism 5 is connected with the transmission of the first gear 4, and the auxiliary moving mechanism 6 is installed on the spreading mechanism 5.

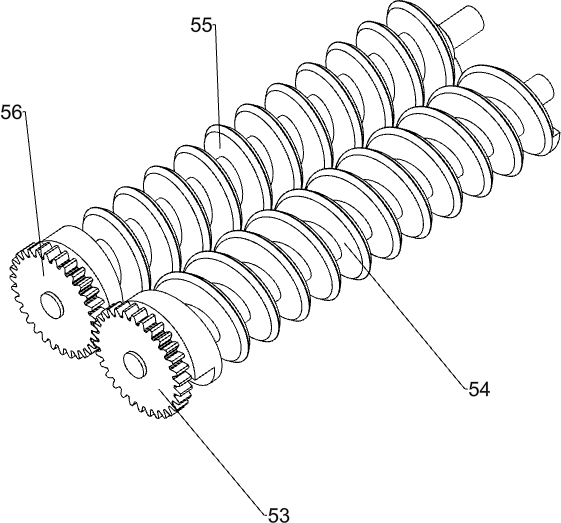

[0023] The spreading mechanism 5 includes a spreading box 51, a second gear 52, a third gear 53, a first screw shaft 54, a second screw shaft 55 and a fourth gear 56, and the front ...

Embodiment 2

[0027] On the basis of Example 1, such as Figure 1-3 Shown, also include stirring mechanism 7, and stirring mechanism 7 includes second transmission belt group 71, stirring bar 72, the 5th bevel gear 73, the 6th bevel gear 74, connecting shaft 75, the 3rd transmission belt group 76, dial The material rod 77 and the fixed plate 78 are connected with the stirring rod 72 in a rotating manner on the material storage box 1, and the second transmission belt group 71 is connected between the rear end of the stirring rod 72 and the rear end of the second screw shaft rod 55, and the first screw shaft The rear end of the rod 54 is connected with the fifth bevel gear 73, and the rear side of the right side of the spreading box 51 is connected with a fixed plate 78. The fixed plate 78 is connected with a connecting shaft 75 in a rotating manner, and the left end of the connecting shaft 75 is connected with a sixth cone. Gear 74, the 6th bevel gear 74 and the 5th bevel gear 73 meshes, on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com